Etching process for semiconductors

A semiconductor and etching technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as rough surfaces and low etching rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

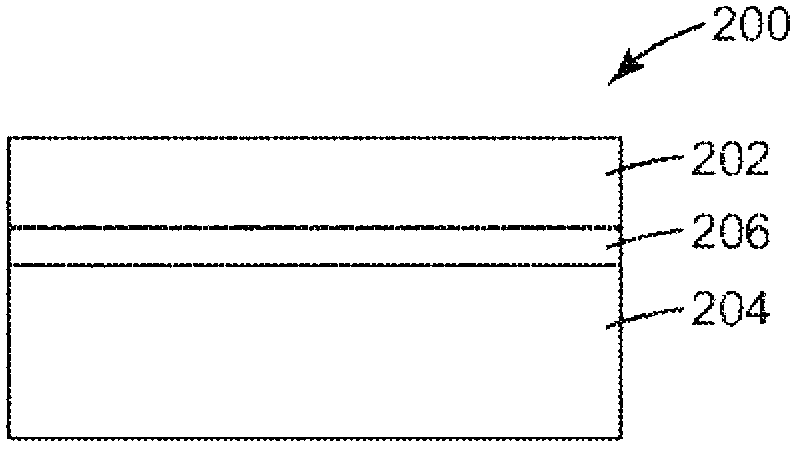

[0034] A II-VI semiconductor color conversion layer structure based on a CdMgZnSe alloy was grown by molecular beam epitaxy on an InP substrate. The color conversion layer structure is schematically shown in figure 2 , and the layer thicknesses and compositions are shown in Table I below. figure 2 It is a schematic diagram of the color conversion layer 200 , which includes a top window 202 , a light absorbing layer 204 , and a graded composition layer 206 whose composition gradually changes from the composition of the top window 202 to the composition of the light absorbing layer 204 . Embedded in the light-absorbing layer (not shown) are quantum wells that trap carriers produced when pump light is absorbed in the light-absorbing layer and re-emit longer wavelength light. Details of color converting structures can be found, for example, in US Patent No. 7,402,831 (Miller et al.).

[0035] Table I

[0036] Composition of the color conversion layer structure

[0037] ...

example 1

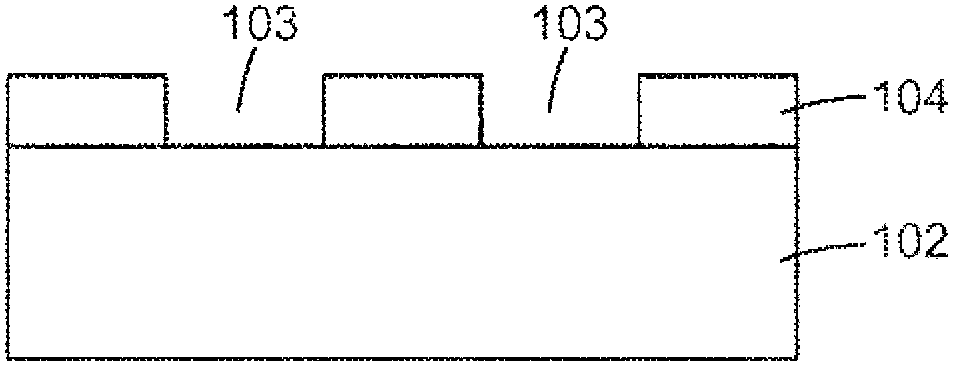

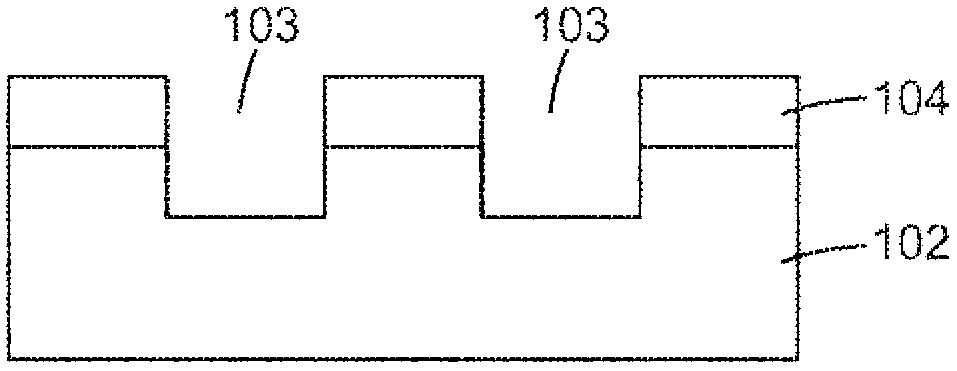

[0041] Example 1 - Ar etching of II-VI semiconductor with photoresist mask

[0042] A sample of the II-VI semiconductor color converter described above was coated with a photoresist mask with a stripe pattern using NR9-1000P negative photoresist (from Futerrex, Franklin, NJ). The dimensions of the stripe patterns are 2 μm and 100 μm. Small split samples of II-VI semiconductors with photoresist masks on them were placed on Si carrier wafers, loaded into the RIE chamber, and heated using 5-50 sccm Ar, 20-200 watts Rf power, 700-2000 Watts Inductively Coupled Plasma Power (ICP) Plasma etching was performed at a pressure of 4-30 mTorr and an etching time of 5 x 60 second intervals. Pixel stripes as small as 2 μm in width continued to exhibit strong photoluminescence several months after treatment. With the same conditions as in Comparative Example 1, with the 2 The same sample etched showed rapid degradation of photoluminescence after one day. image 3 A photomicrograph of a...

example 2

[0043] The Ar etching of 3 micron channel in the example 2-II-VI group semiconductor material

[0044]The patterned photoresist on the II-VI semiconductor color converter structure as described above in Table 1 was obtained by photolithography with NR9-3000PY negative photoresist (available from Futurrex, Franklin, NJ) and etched using the procedure of Example 1. Figure 4a is a scanning electron micrograph of the resulting structure and shows a pattern of 3 μm wide channels with ~6 μm bumps in between. Figure 4b Darkfield optical micrograph showing photoluminescence of semiconductor bumps. A series of emission "pixels" were observed in which the semiconductor color converter had been left untouched (protected by photoresist during etching).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com