A method for preparing a large number of uniform non-spherical janus particles

A non-spherical and uniform technology, applied in the field of colloid chemistry, can solve the problems of rough surface of particles, serious particle agglomeration phenomenon, etc., and achieve the effect of wide application range, mild conditions and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

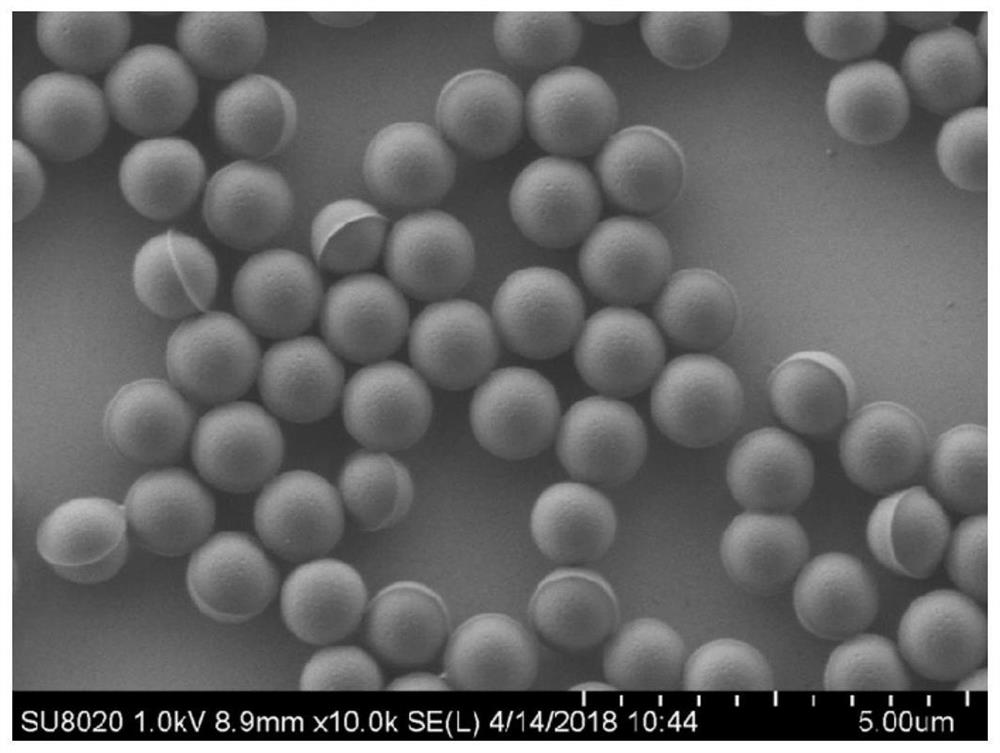

[0016] Add polystyrene microspheres with a particle size of 1.2 μm into a mixture of 2 mL of ethanol and 8 mL of deionized water, ultrasonically disperse for 10 min, and mix evenly, and then slowly add the resulting dispersion into a container filled with 80 mL of deionized water. In a 100mL beaker, it quickly forms a single layer of large-area close-packed polystyrene microspheres at the gas-liquid interface. Then place the beaker inside a 1000mL beaker, pour 20mL of dichloromethane into the 1000mL beaker, seal it and let it stand for 5min, the volatilized dichloromethane gas will engrave the part of the polystyrene microsphere exposed above the water surface. eclipse, get as figure 1 Non-spherical polystyrene particles are shown.

Embodiment 2

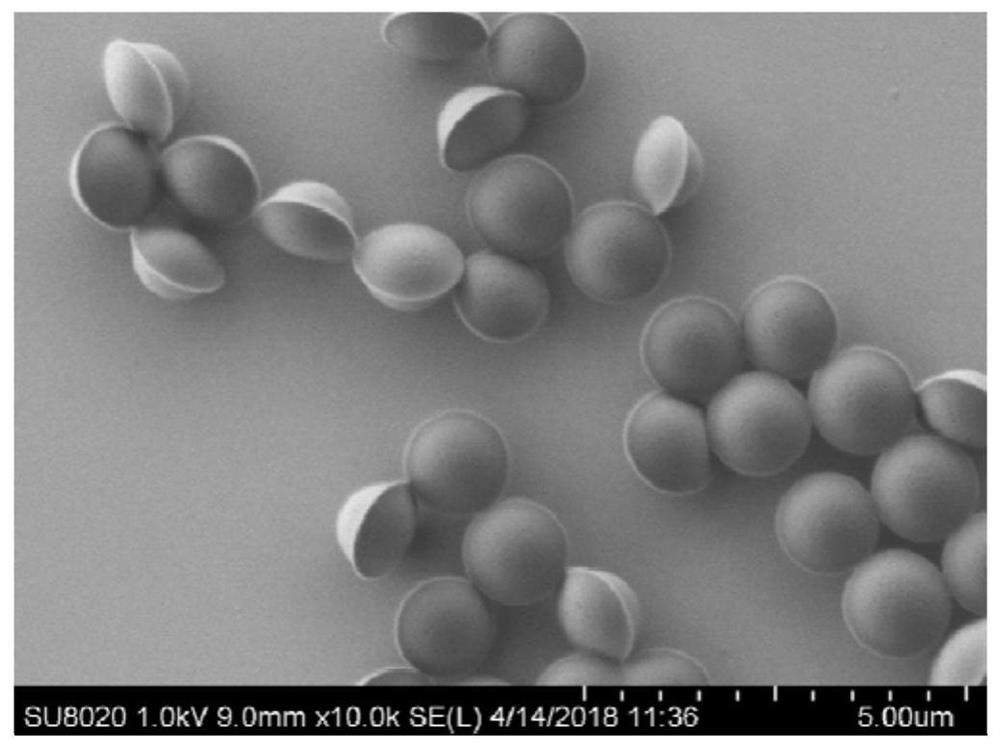

[0018] In the present embodiment, the sealing time of resting is 45min, and other steps are identical with embodiment 1, obtain figure 2 Non-spherical polystyrene particles are shown.

Embodiment 3

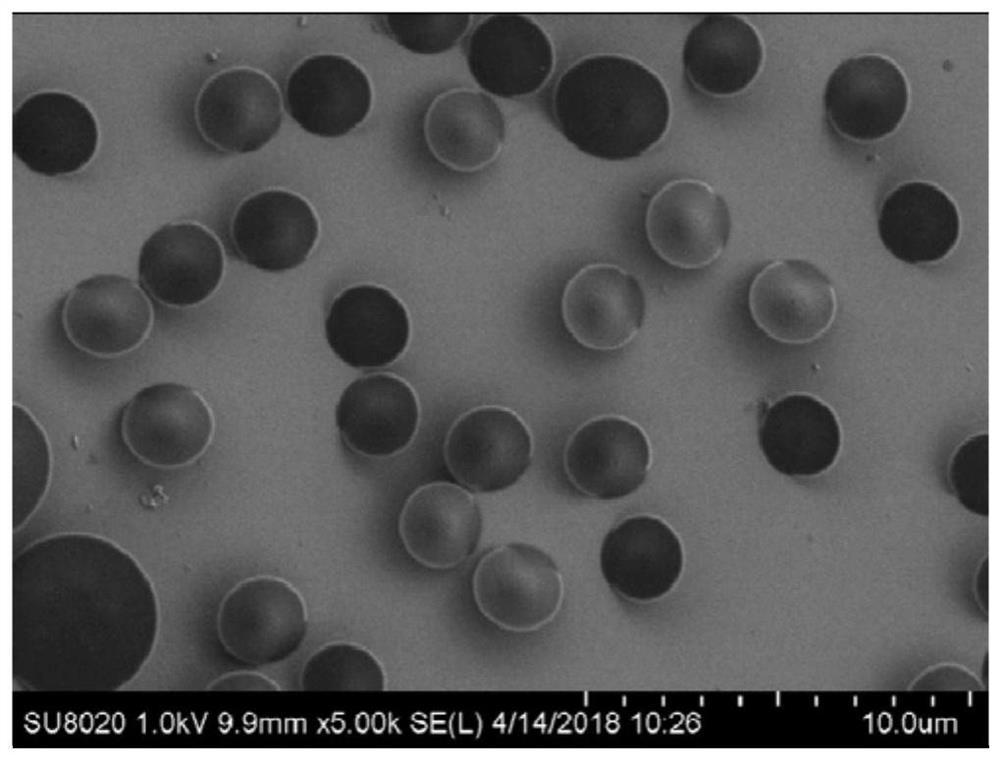

[0020] In the present embodiment, the sealing time of resting is 95min, and other steps are identical with embodiment 1, obtain image 3 Non-spherical polystyrene particles are shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com