A kind of etching method of c-plane sapphire

A technology of sapphire and hydrofluoric acid, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problem of reducing grain boundary defects aimlessly, etc., and achieve good etching effect, good quality, and good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

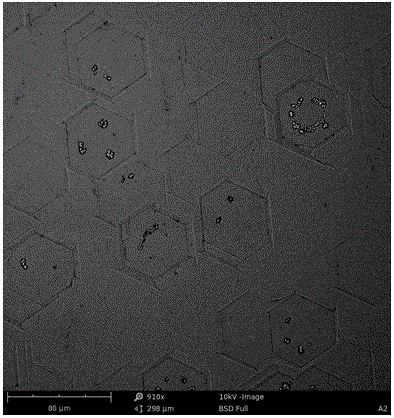

Image

Examples

Embodiment 1

[0019] A kind of etching method of a face sapphire, specifically comprises the steps:

[0020] (1) Calculated by volume ratio, the ratio of hydrofluoric acid aqueous solution with a concentration of 40% by mass: water is 1:200, pour 0.2ml of aqueous solution of hydrofluoric acid with a concentration of 40% by mass and 40ml of water into a beaker After mixing, the temperature of the resulting mixture is controlled at 25°C. Put the clean c-plane sapphire slices into it, ultrasonicate at 40Khz for 20min, then take out the c-plane sapphire slices, and wash them with alcohol in turn. Ultrasonic cleaning, and finally drying to obtain the c-plane sapphire treated with hydrofluoric acid;

[0021] (2) Calculated by volume ratio, the ratio of concentrated sulfuric acid to concentrated phosphoric acid is 3:1. After mixing 30ml of concentrated sulfuric acid and 10ml of concentrated phosphoric acid, the resulting mixed acid is heated to a temperature of 160°C, and then the Put the c-face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com