Gradient method preprocessing technique for depositing CVD diamond film on hard metal surface

A technology of surface deposition and diamond film, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem of uneven deposition and unevenness of Co removal at edges and sharp corners, affecting the cutting performance of tools, etc. problem, to achieve the effect of good bonding performance, good quality and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with embodiment.

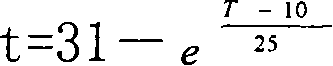

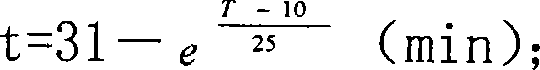

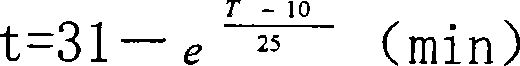

[0018] A gradient method pretreatment process for depositing CVD diamond film on the surface of cemented carbide. The process is: (1) polishing → (2) cleaning → (3) etching WC → (4) cleaning → (5) first engraving Etching Co → (6) Cleaning → (7) Drying → (8) Coating → (9) Second etching of Co → (10) Cleaning → (11) Sol → (12) Planting; Polish the turning tool on the tool grinder (step 1), then clean the polished turning tool with an ultrasonic cleaner at room temperature (step 2) for one to three times, the cleaning solution is deionized water (distilled water is also available), each time 5min. Put the cleaned turning tool into a plastic container, pour the etching WC solution prepared by potassium ferricyanide, potassium hydroxide and water according to 1:1:10 (the same formula as the prior art can also be used) In the plastic container, the liquid level exceeds the turning tool b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com