Laminated metal and metal oxide etching liquid composition and use method thereof

A technology for laminating metals and etching solutions, which is applied in the direction of surface etching compositions, chemical instruments and methods, etc., can solve problems such as difficulties in the development of chemical solutions, large differences in chemical and electrochemical properties of metal wires, etc., and achieve improved etching Loss of shape and line width, low cost of waste liquid treatment, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

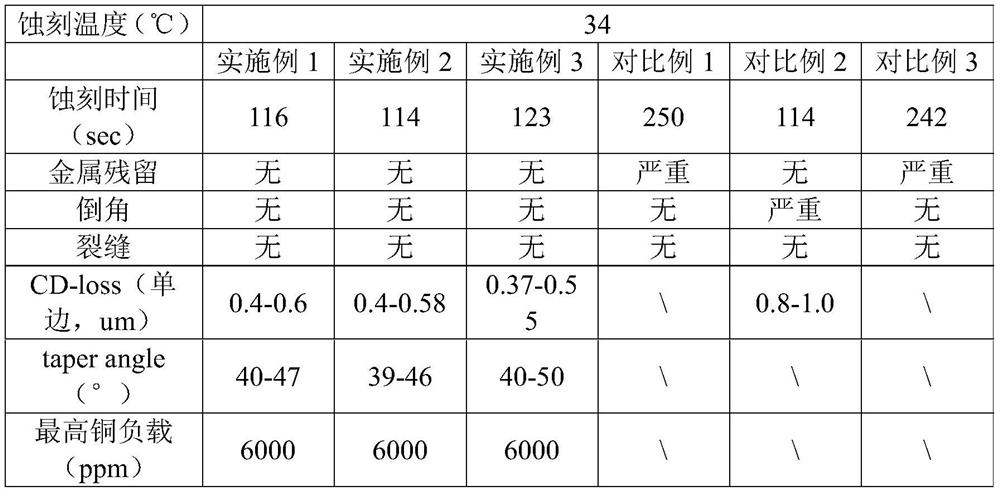

Embodiment 1

[0061] A laminated metal and metal oxide etchant composition, raw materials include: by mass percentage, hydrogen peroxide 8%, inorganic acid 1.56%, fluoride ion source 0.05%, complexing agent 4.36%, alkali compound 3.64% , metal corrosion inhibitor 0.28%, and solvent supplement the balance.

[0062] The inorganic acid is nitric acid.

[0063] The fluoride ion source is HF.

[0064] The complexing agent is a polyhydric alcohol complexing agent. The polyhydric alcohol complexing agent includes ethylene glycol and triethylene glycol. The mass ratio of ethylene glycol and triethylene glycol is 0.49%:3.87%.

[0065] The base compound is an organic base. The organic base is triethanolamine.

[0066] The metal corrosion inhibitor is selected from amino nitrogen azole compounds. The aminoazole compound 5-aminotetrazole.

[0067] The solvent is deionized water.

Embodiment 2

[0069] A kind of laminated metal and metal oxide etchant composition, raw material comprises: by mass percentage, hydrogen peroxide 8%, inorganic acid 1.98%, fluoride ion source 0.03%, complexing agent 4.1%, alkali compound 3.63% , metal corrosion inhibitor 0.28%, and solvent supplement the balance.

[0070] The inorganic acid is nitric acid.

[0071] The fluoride ion source is HF.

[0072] The complexing agent is a polyhydric alcohol complexing agent. The polyhydric alcohol complexing agent is ethylene glycol and triethylene glycol. The mass ratio of ethylene glycol and triethylene glycol is 0.68%:3.42%.

[0073] The base compound is an organic base. The organic base is triethanolamine.

[0074] The metal corrosion inhibitor is selected from amino nitrogen azole compounds. The amino nitrogen azole compound is 5-amino tetrazole.

[0075] The solvent is deionized water.

Embodiment 3

[0077] A kind of laminated metal and metal oxide etchant composition, raw material comprises: by mass percentage, hydrogen peroxide 8%, inorganic acid 2.18%, fluoride ion source 0.14%, complexing agent 4.18%, alkali compound 3.97% , metal corrosion inhibitor 0.28%, and solvent supplement the balance.

[0078] The inorganic acid is sulfuric acid.

[0079] The fluoride ion source is a fluoride salt. The fluoride salt is ammonium bifluoride.

[0080] The complexing agent is a polyhydric alcohol complexing agent. The polyhydric alcohol complexing agent includes ethylene glycol and triethylene glycol. The mass ratio of ethylene glycol and triethylene glycol is 1.24%:2.94%.

[0081] The base compound is an organic base. The organic base is isopropanolamine.

[0082] The metal corrosion inhibitor is selected from amino nitrogen azole compounds. The amino nitrogen azole compound is 5-amino tetrazole.

[0083] The solvent is deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com