Electric packer, electric packer control method and electric packer utilization method

A packer, electric technology, used in sealing/packing, earth-moving drilling, wellbore/well components, etc., can solve problems such as increased operating costs, fracture failure, deformation of motor and mechanical structure, etc., and it is easy to ensure control accuracy. , The effect of low torque and power supply pressure, and enhanced stability of the circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

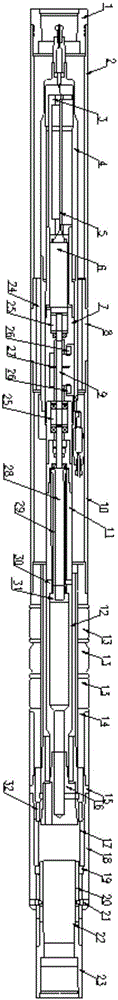

[0053] Such as figure 1 An electric packer according to an embodiment of the present invention is shown, including a casing, a control mechanism, an actuator, a limit mechanism, a setting mechanism, and a lifting and unsealing mechanism.

[0054] The shell is composed of a lower joint 1 , a lower shell 2 , a mounting base 8 and an upper shell 10 .

[0055] Control mechanism is located in the shell, and control mechanism is made up of circuit board support 3, circuit board waterproof cover 4 and circuit board 5, and circuit board support 3 is installed in the circuit board waterproof cover 4, and circuit board 5 is installed on the circuit board support 3.

[0056] The actuator is arranged in the casing, and is an actuator motor 6 connected to the circuit board 5 .

[0057] The limit mechanism is located in the shell, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com