Remote control based network-distribution conduction device for live working

A technology of remote control and live work, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as uneven operating force, heavy operating pressure of operators, and unstable operating direction, so as to avoid inconvenience and unsafe problems, avoid operating Reliability issues, the effect of simplifying operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Best practice:

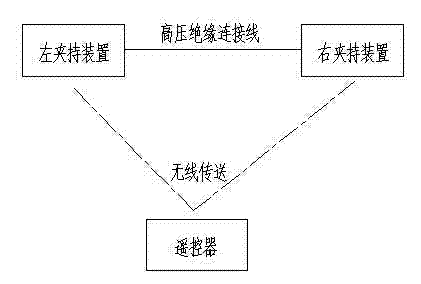

[0047] Refer to attached figure 1 , the drainage device for live work in distribution network based on remote control, including a pair of clamping devices (left clamping device and right clamping device), high-voltage insulated connecting wire and remote control, the two ends of the high-voltage insulated connecting wire are respectively connected to the left clamping device device and right clamping device. The remote control is respectively connected to the remote control of the left and right clamping devices, see the following scheme for details.

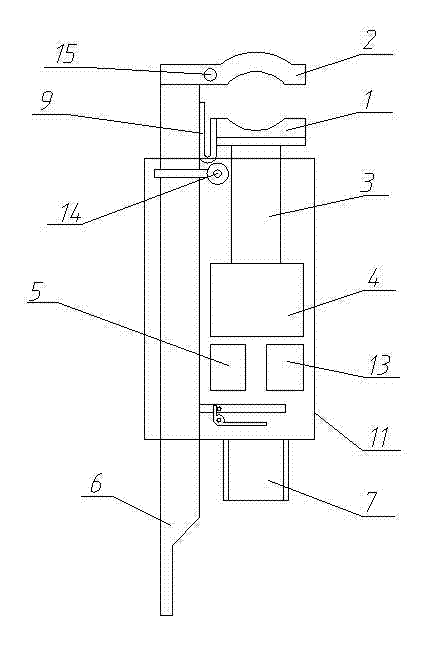

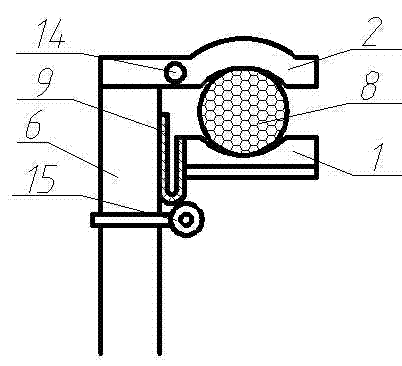

[0048] Refer to attached figure 2 , The structure of the left and right clamping devices is the same, specifically as follows, the clamping device includes an outer shell 11, a jaw part, a clamping mechanism 3, a reduction motor 4, a main control board 5, a drainage connection device 6 and an operation rod connection part 7. The drainage connection device is a rod-shaped structure, which passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com