High-selectivity etching solution for aluminum nitride and silicon

A high-selectivity, etchant technology, applied in the field of electronic chemicals, can solve the problems of low etching rate, residual substrate silicon, and long process time, and achieve the effect of improving the etching selectivity ratio, protecting the substrate silicon, and reducing the etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

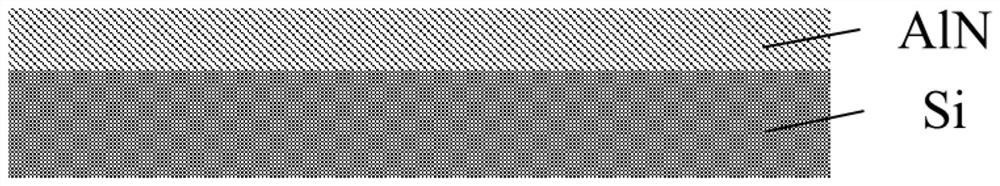

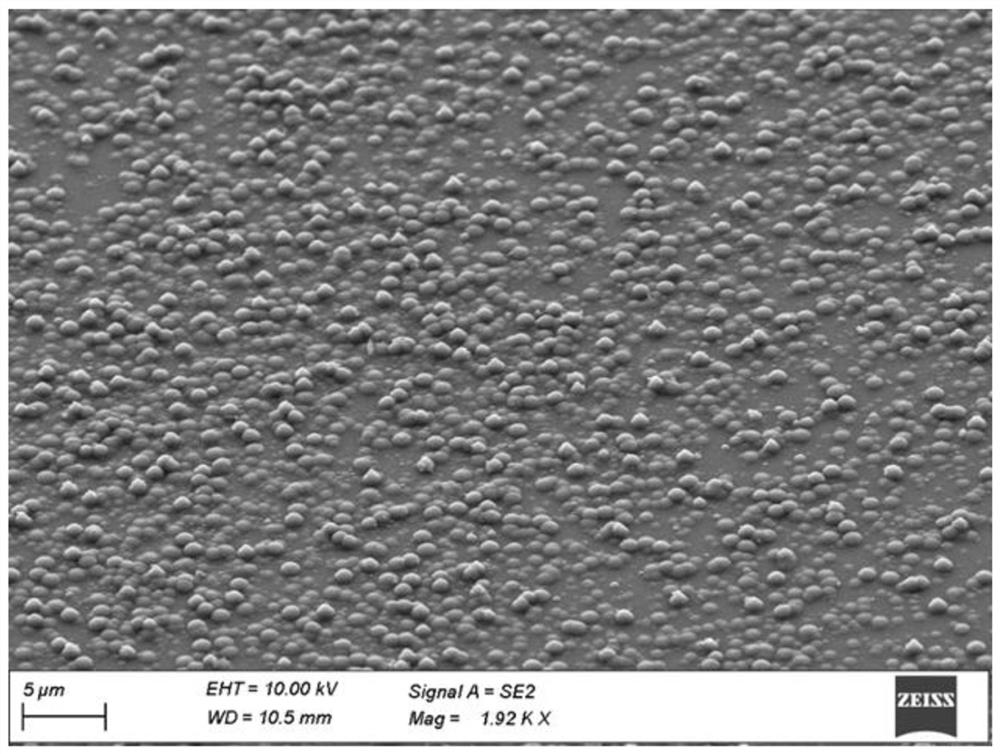

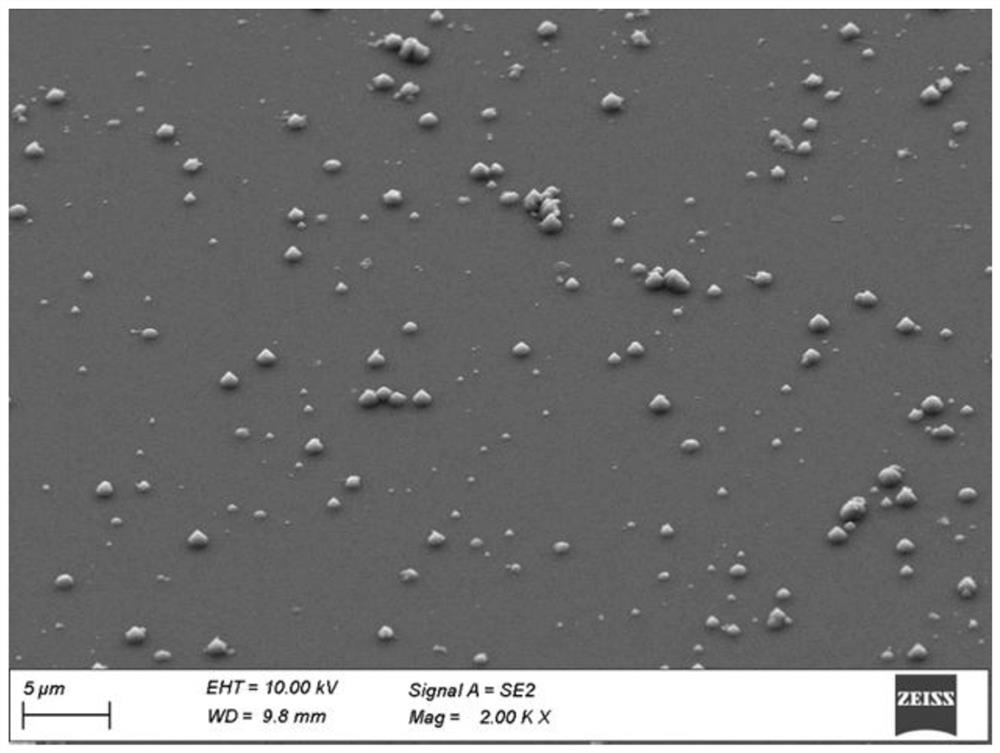

Image

Examples

Embodiment 1-15 and comparative example 1-3

[0024] The content of each component according to the conceived examples and comparative examples of the present invention is listed in Table 1, and the balance is water.

[0025] Table 1

[0026]

[0027]

[0028]

[0029] A highly selective etchant for aluminum nitride and silicon was prepared and used in the following manner:

[0030] 1. According to the type and quantity of raw materials in the above table, take raw materials for later use;

[0031] 2. Add water, fluoride, silicate and organochlorosilane in turn to the lye;

[0032] 3. Stir the above mixed solution evenly and ultrasonically disperse it to make a highly selective etching solution for aluminum nitride and silicon;

[0033] 4. Cut the AlN and Si wafers into small pieces of 1*1cm, wash them with water and dry them with nitrogen, and then use an ellipsometer to measure the initial thickness of the two wafers;

[0034] 5. Heat the highly selective etching solution prepared in step 3 to 45°C in a wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com