Enhanced geopolymer and preparation method thereof

A geopolymer and enhanced technology, applied in cement production, etc., can solve the problems of complicated processing technology and increased cost, and achieve the effects of enhanced mechanical properties, fast molding speed, and good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

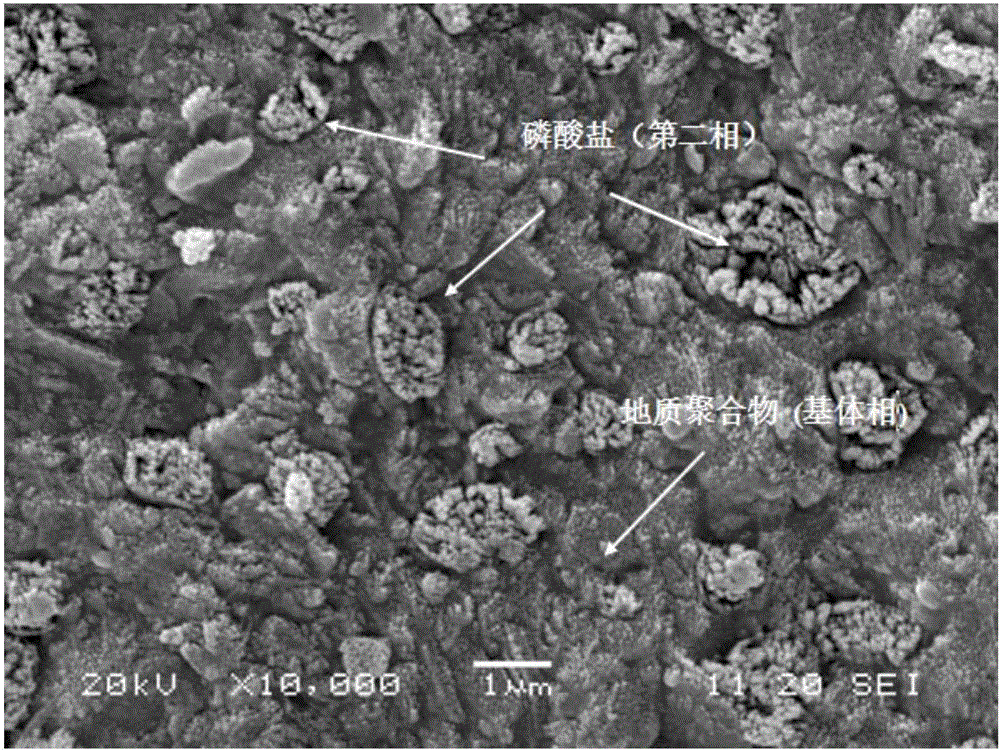

Image

Examples

Embodiment 1

[0029] A reinforced geopolymer, the raw materials of which include by weight parts: 0.1 part of sodium tripolyphosphate, 10 parts of 2000 mesh metakaolin, 10 parts of liquid-2 water glass (modulus 3.1-3.4), 5 parts of sodium hydroxide 5 parts, water 5 parts.

[0030] The preparation method of above-mentioned reinforced geopolymer specifically comprises the steps:

[0031] (1) In parts by weight, prepare 0.1 parts of sodium tripolyphosphate, 10 parts of 2000 mesh metakaolin, 10 parts of liquid-2 water glass (modulus 3.1-3.4), 5 parts of sodium hydroxide, and 5 parts of water;

[0032] (2) Mix the water glass prepared in step (1) with sodium hydroxide, stir and ultrasonically, then leave it for 24 hours to obtain an alkali activator;

[0033] (3) Mix the sodium tripolyphosphate and metakaolin prepared in step (1) evenly, add the alkali activator obtained in step (2) to grind and mix, and add the water prepared in step (1) and mix evenly to obtain uniform slurry;

[0034] (4) ...

Embodiment 2

[0039] A kind of reinforced geopolymer, its raw material comprises by weight: 2 parts of sodium dihydrogen phosphate, 80 parts of 8000 mesh metakaolin, 80 parts of 8000 mesh fly ash, liquid-4 water glass (modulus 2.2-2.5 ) 80 parts, potassium hydroxide 30 parts, 8000 mesh silicon dioxide 50 parts, water 30 parts.

[0040] The preparation method of above-mentioned reinforced geopolymer specifically comprises the steps:

[0041] (1) In parts by weight, prepare 2 parts of sodium dihydrogen phosphate, 80 parts of 8000 mesh metakaolin, 80 parts of 8000 mesh fly ash, 80 parts of liquid-4 water glass (modulus 2.2-2.5), hydrogen 30 parts of potassium, 50 parts of 8000 mesh silica, 30 parts of water;

[0042] (2) mixing the water glass prepared in step (1) with potassium hydroxide, ultrasonicating after stirring, and then standing for 24 hours to obtain the alkali activator;

[0043] (3) Mix sodium dihydrogen phosphate prepared in step (1) with metakaolin, fly ash and silicon dioxide...

Embodiment 3

[0048] A reinforced geopolymer, the raw materials of which include, in parts by weight, 0.4 parts of aluminum tripolyphosphate, 41 parts of 250 mesh metakaolin, 43 parts of liquid-1 water glass (modulus 3.5-3.7), and 6 parts of sodium carbonate , 1 part of 250 mesh silicon dioxide, 9 parts of water.

[0049] The preparation method of above-mentioned reinforced geopolymer specifically comprises the steps:

[0050] (1) In parts by weight, prepare 0.4 parts of aluminum tripolyphosphate, 41 parts of 250-mesh metakaolin, 43 parts of liquid-1 water glass (modulus 3.5-3.7), 6 parts of sodium carbonate, and 250-mesh silica 1 part, 9 parts of water;

[0051] (2) Mix the water glass prepared in step (1) with sodium carbonate, ultrasonically stir after stirring, and then let stand for 24 hours to obtain the alkali activator;

[0052] (3) Mix the aluminum tripolyphosphate prepared in step (1) with metakaolin and silicon dioxide evenly, add the alkali activator obtained in step (2) to gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com