Processing method of ogs capacitive touch screen cover glass

A capacitive touch screen, cover glass technology, applied in the direction of electrical digital data processing, data processing input/output process, instruments, etc., can solve the problems of low product yield, high production cost, glass breakage, etc., to improve production Efficiency, improved quality, and improved dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

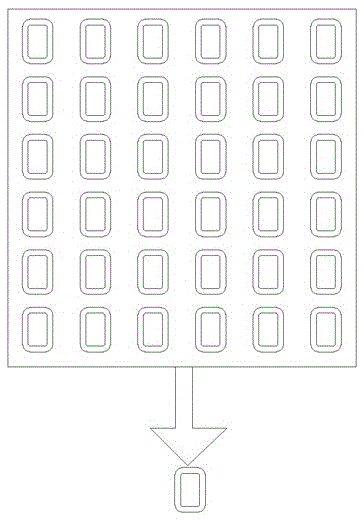

Image

Examples

Embodiment 1

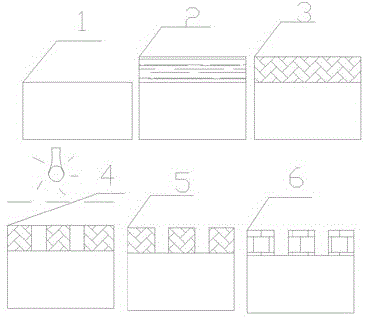

[0029] Step 1: Print an acid-resistant protective layer with a thickness of 20 mm on one of the front and back sides of a large OGS tempered glass plate with a thickness of 0.3 cm, and then sequentially bake and dry the acid-resistant protective layer. Drying is done in an infrared oven. The drying time is 25 minutes and the temperature is 130°C. After baking and drying, exposure, development, and film hardening are performed to form a follow-up on one side of the large OGS tempered glass plate. Etching patterns required when etching small pieces of OGS strengthened glass plates; using the same process steps on the other side of the large piece of OGS strengthened glass plates to form etching patterns required for subsequent etching of small pieces of OGS strengthened glass plates on the other side;

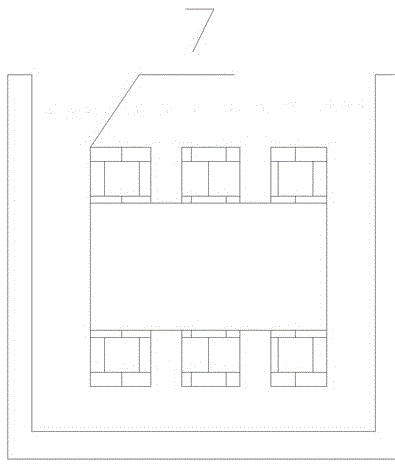

[0030] The second step: the large piece of OGS strengthened glass plate treated in the first step is immersed in an etching solution at a temperature of 21° C. for etching treatme...

Embodiment 2

[0032] Same as Example 1, the difference is that the thickness of the large OGS strengthened glass plate in the first step is 0.4-0.5 cm; the etching width formed by etching in the second step is 0.6-0.7 cm.

Embodiment 3

[0034] Same as Example 1, the difference is that in the first step, an acid-resistant protective layer with a thickness of 25 mm is screen-printed on one of the front and back sides of the large OGS tempered glass plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com