An indexable thread machining insert

A thread processing and blade technology, which is applied in the field of indexable thread blades, can solve the problems that the blade is difficult to process cast iron materials, it is difficult to curl and break, and the strength of the cutting edge is reduced, so as to facilitate heat dissipation, reliable processing, and reduce contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

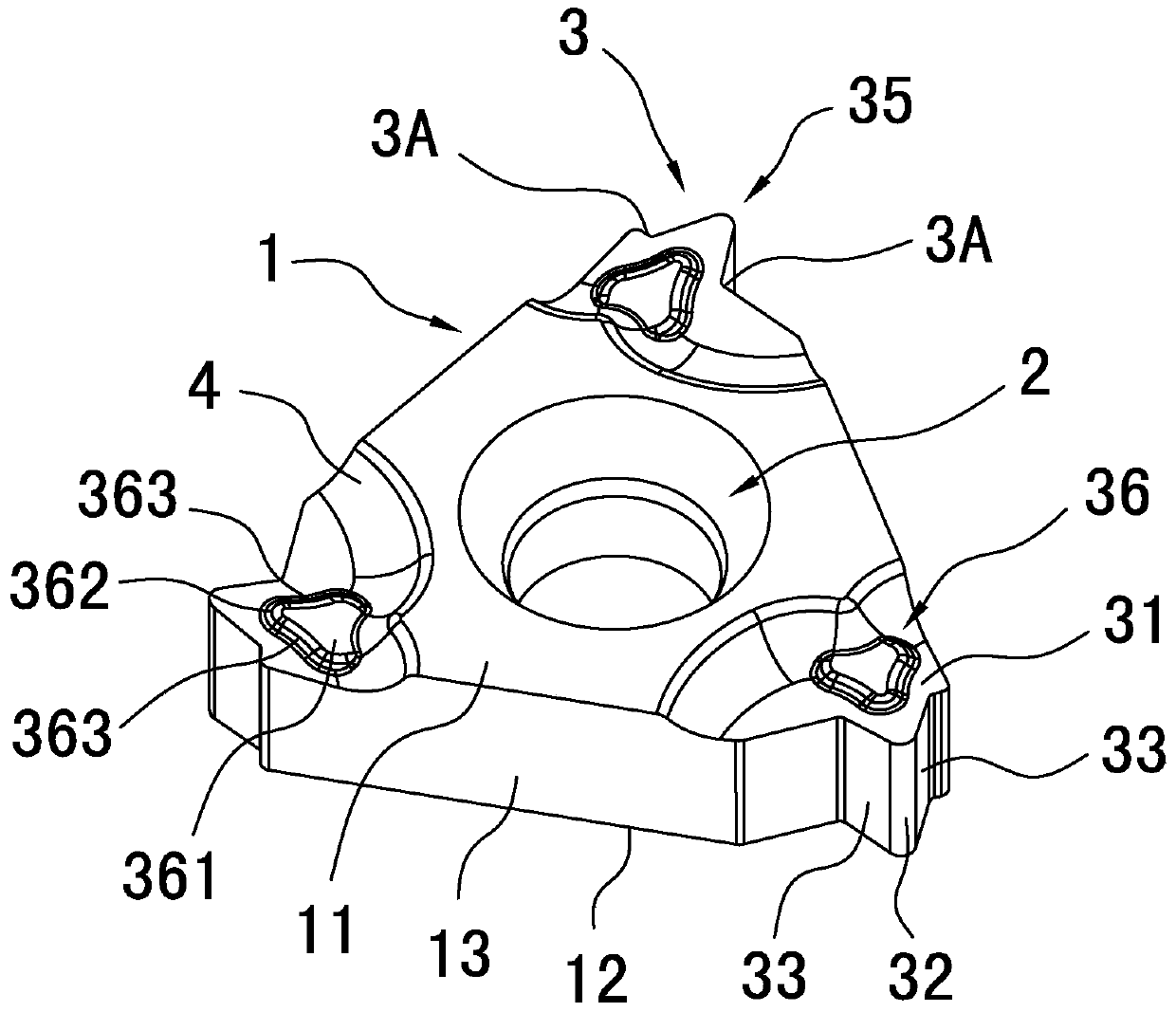

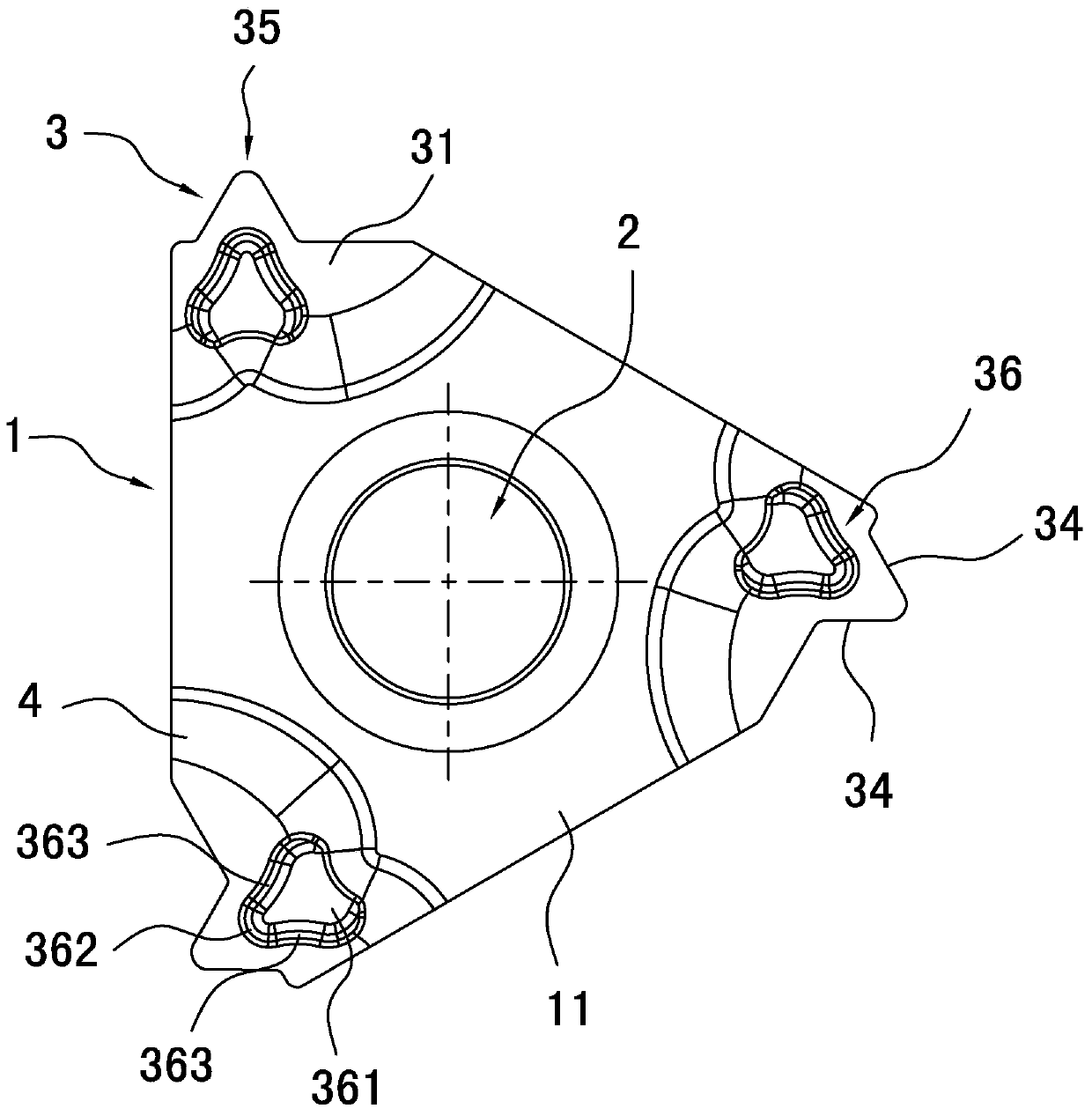

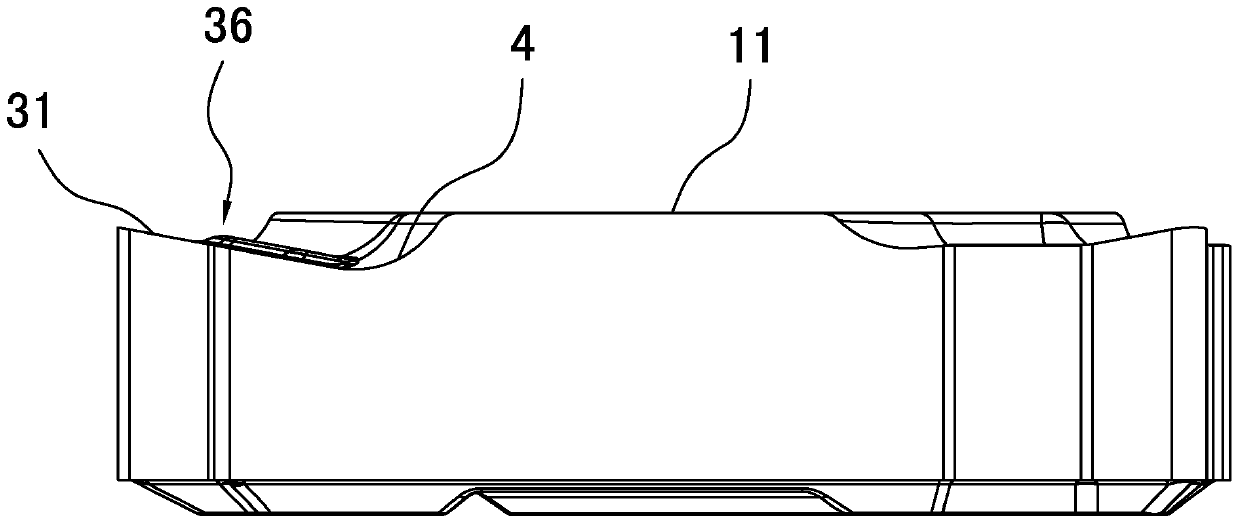

[0029] like Figure 1 to Figure 5 As shown, an indexable threading insert of the present invention, the insert body 1 is surrounded by an upper surface 11, a lower surface 12 and a side surface 13, and is in the shape of an approximately equilateral triangle. There is a center hole 2 of the insert that runs through the insert body 1 along the thickness direction of the insert. The insert body 1 is also provided with a cutting edge portion 3. There are three cutting edge portions 3. The cutting edge portion 3 consists of a rake face 31, a corner round The arc surface 32, the two edge surfaces 33 and the lower surface 12 are enclosed, and the two edge surfaces 33 intersect with the rake surface 31 to form two side cutting edges 34, which are connected to the rear ends of the two side cutting edges by trimming. Edge 3A, the angle between the two side cutting edges 34 is the cutting edge angle 35, the rake face 31 gradually sinks from the edge arc surface 32 to the direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com