Flexible circuit board etching liquid concentration control device

A flexible circuit board and control device technology, applied in circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of inability to directly measure the concentration of oxidants, lack of pertinence and accuracy, and affecting the etching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

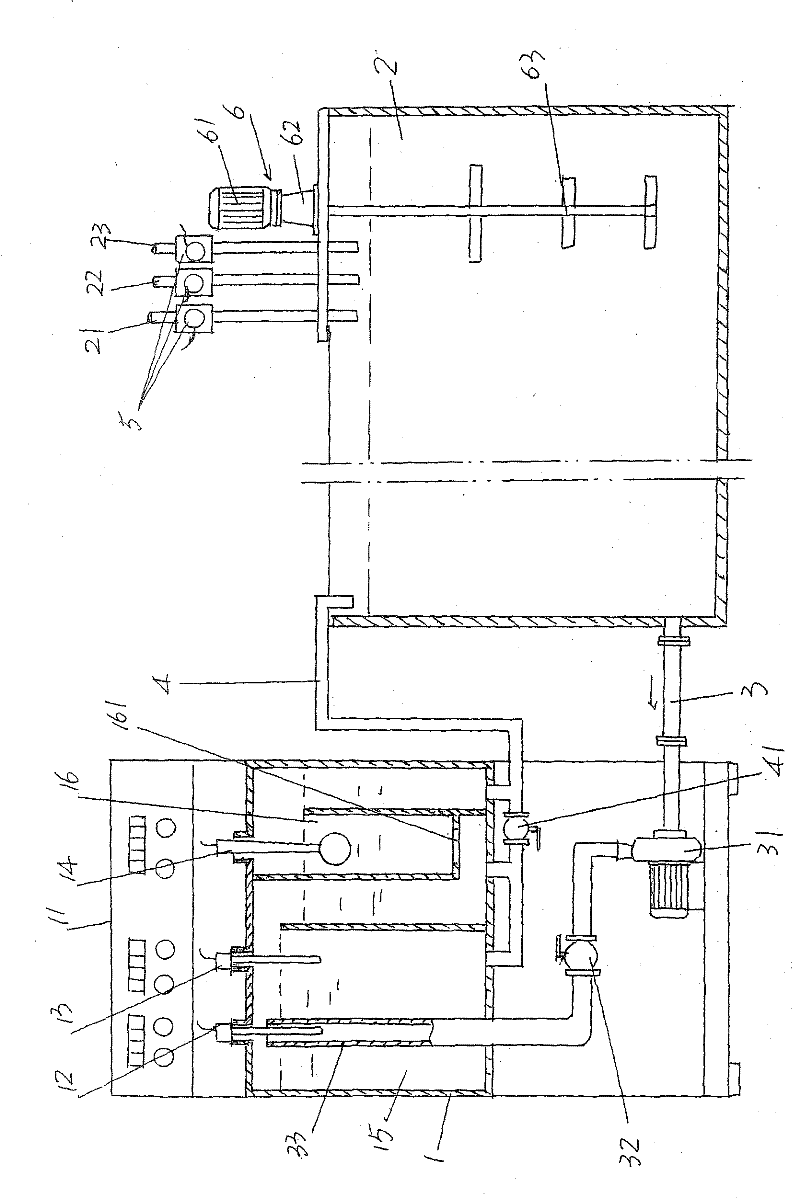

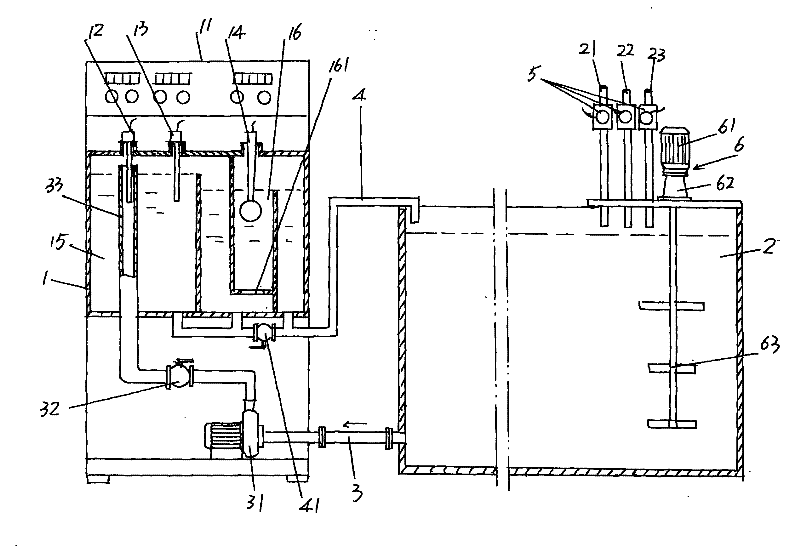

[0019] Please see figure 1 The test box 1 equipped with controller 11, oxidant probe 12, hydrochloric acid probe 13 and hydrometer 14 can be purchased from the market, for example, the name of oxidant regeneration added by China Changzhou Great Electronic Equipment Co., Ltd., Changzhou City, Jiangsu Province is selected for use. controller. The aforementioned oxidant probe 12 , hydrochloric acid probe 13 and hydrometer 14 are all electrically connected to the controller 11 by lines. A hydrometer test barrel 16 is separated in the chamber cavity 15 of the test box 1, and the hydrometer 14 is corresponding to the barrel chamber of the hydrometer test barrel 16, and a liquid introduction hole 161 is provided at the bottom of the hydrometer test barrel 16, and the liquid introduction The hole 161 communicates with the tank cavity 15 .

[0020] One end of a liquid inlet pipe 3, namely the right end shown in the figure, is connected to the lower part of the etching pool 2 and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com