Airplane test liquid level measurement and control system

A control system and test liquid technology, applied in liquid level control, control/regulation system, aircraft component testing, etc., can solve problems such as the inability to realize low-temperature brine evacuation and filling functions, and achieve a smooth and applicable test process Wide range, effect of slowing down the flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

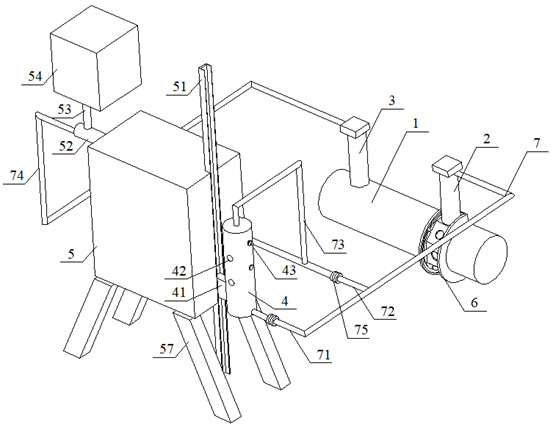

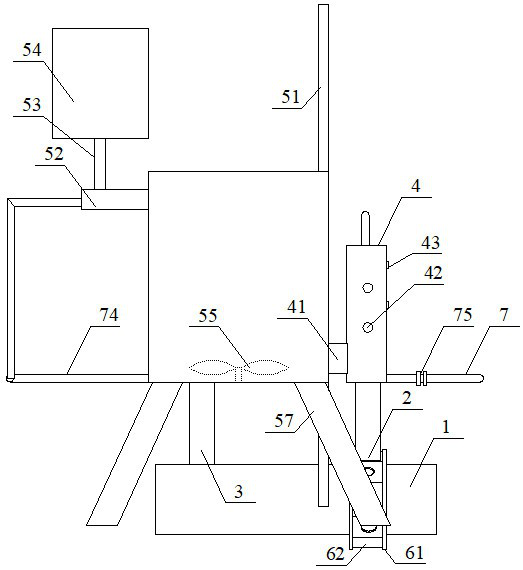

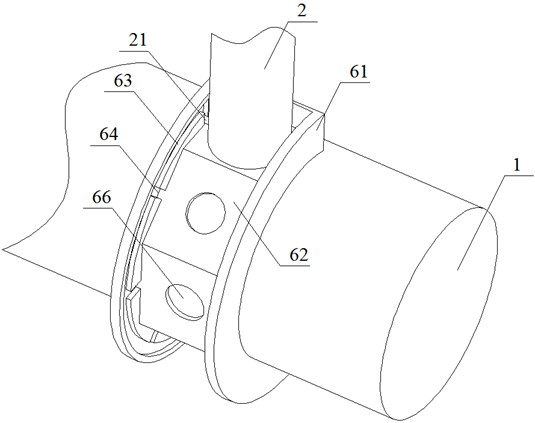

[0032] like figure 1 As shown, the aircraft test liquid level measurement and control system includes a liquid outlet pipe 2 and a liquid return pipe 3 installed on the pipeline 1 to be tested, a sight liquid barrel 4 communicated with the liquid outlet pipe 2, and a liquid sight barrel 4 connected to each other. The connected effusion bag 5, the effusion bag 5 communicates with the liquid return pipe 3, the liquid outlet pipe 2 is connected to the pipeline 1 to be tested through a group of adjustment mechanisms 6 for adjusting its angle and position, and the end of the liquid outlet pipe 2 is provided with There is a set of hoses 7, the ends of the hoses 7 are bifurcated into a first hose 71 and a second hose 72, the first hose 71 is connected to the bottom of the sight barrel 4, and the second hose 72 is connected to the bottom of the effusion pack 5 Connection, the first flexible pipe 71 and the second flexible pipe 72 are provided with a valve 75, and the top of the liquid...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that there are 6 sets of fixing blocks 62 .

Embodiment 3

[0039] The difference between this embodiment and Embodiment 1 is that there are 7 sets of fixing blocks 62 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com