Patents

Literature

41results about How to "To achieve the corrective effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

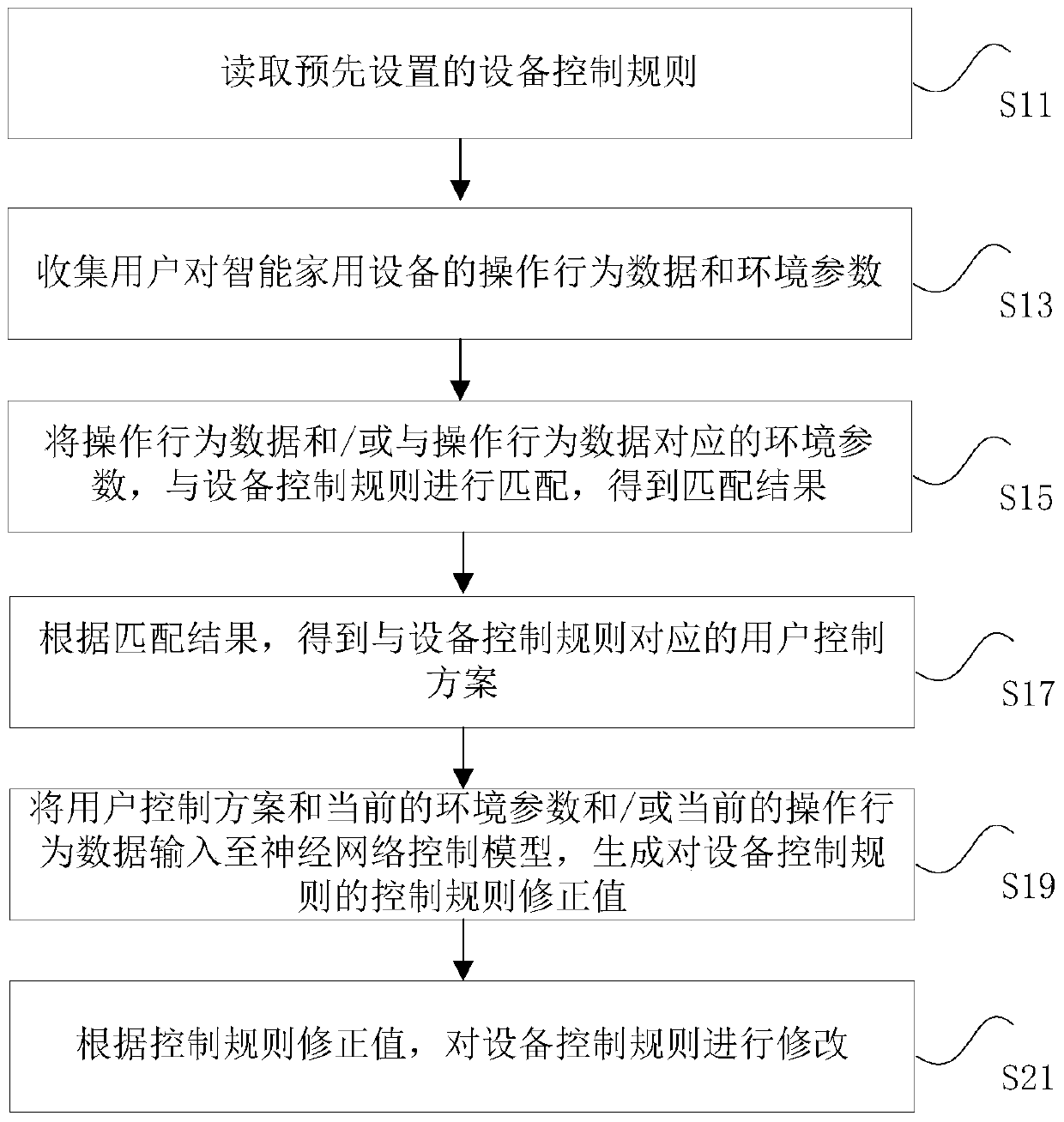

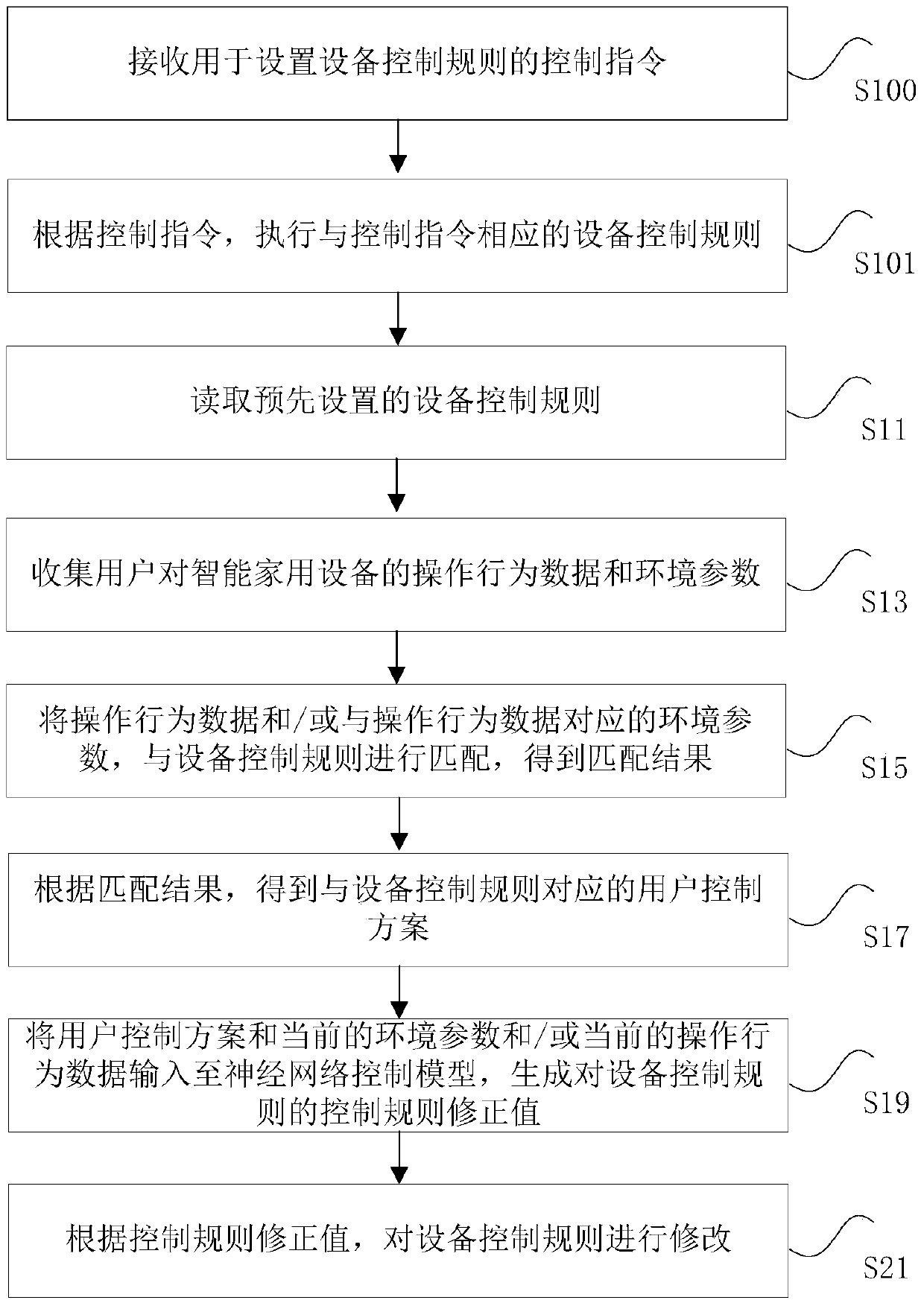

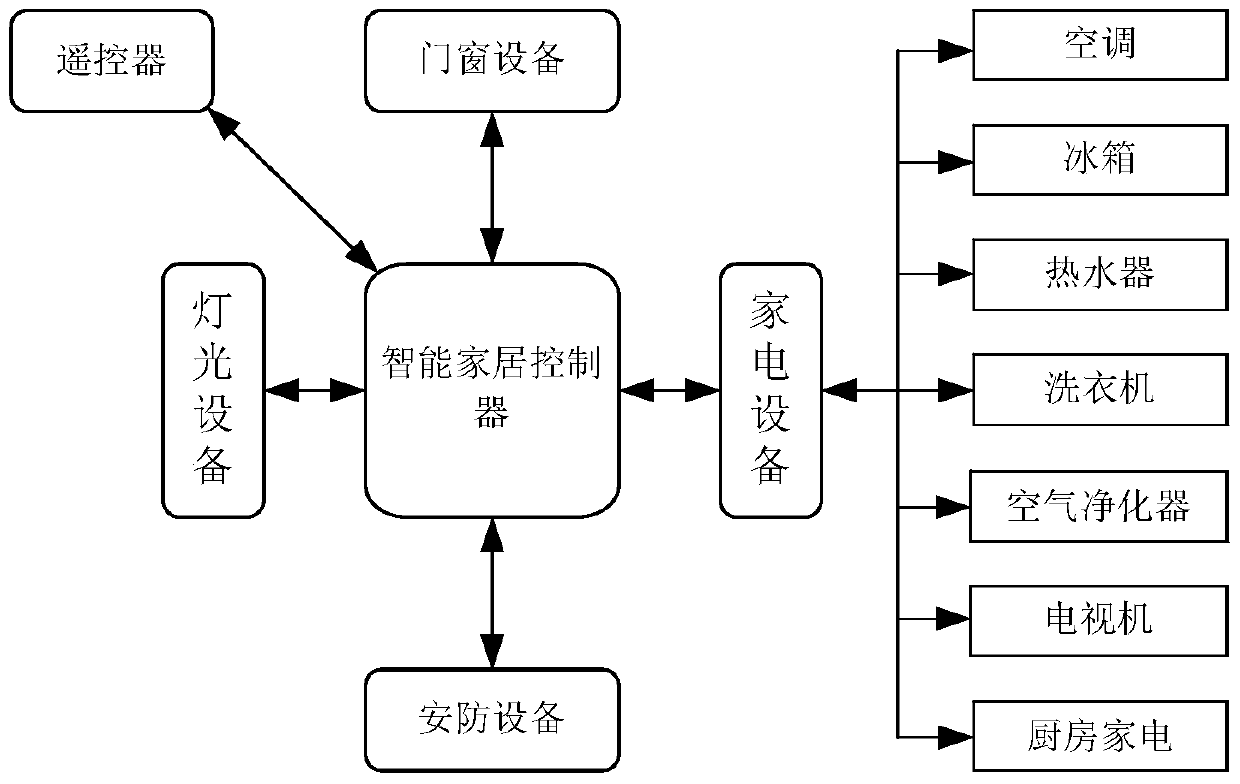

Control method and device of intelligent household appliances

ActiveCN104597761ATo achieve the corrective effectComputer controlProgramme total factory controlEmbedded systemUser control

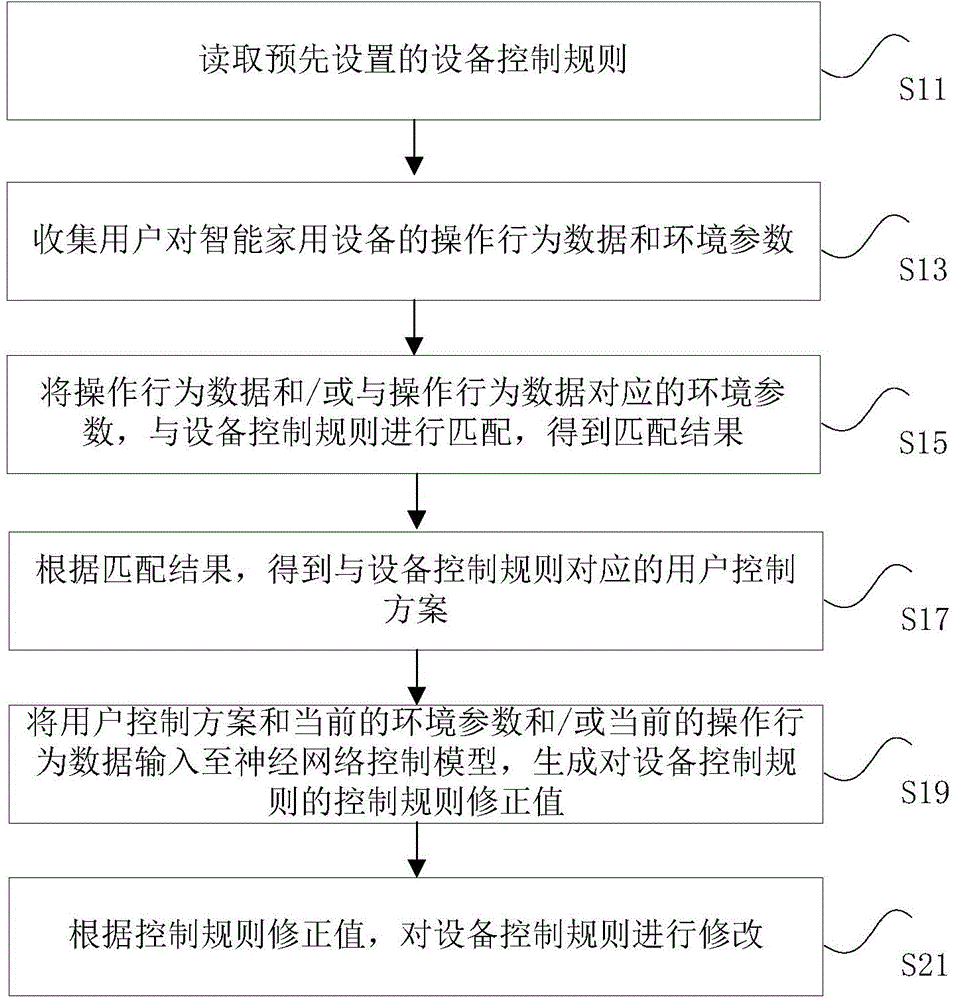

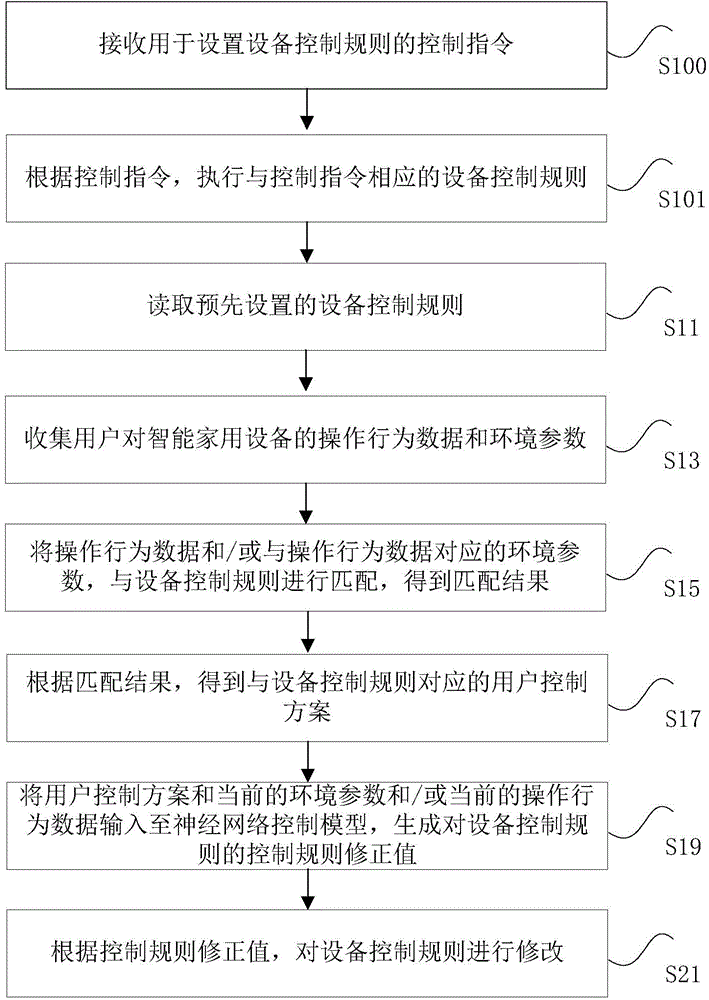

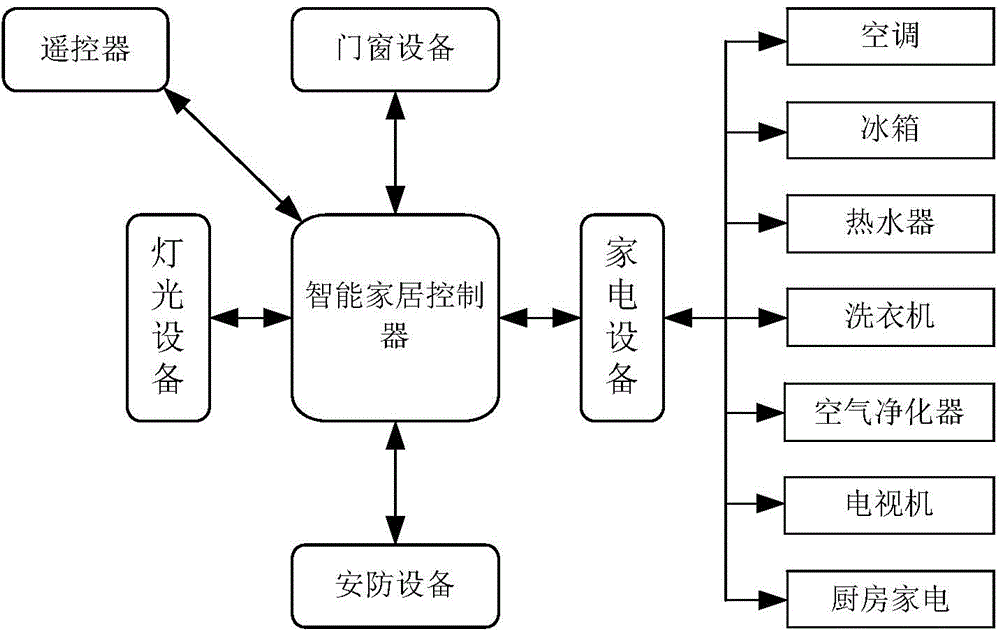

The invention discloses a control method and a control device of intelligent household appliances. The control method of the intelligent household appliances includes: reading a preset appliance control rule; collecting operation behavior data and environment parameters of a user for the intelligent household appliances; matching the operation behavior data and / or the environment parameters corresponding to the operation behavior data with the appliance control rule so as to obtain a matching result; obtaining a user control scheme corresponding to the appliance control rule according to the matching result; inputting the user control scheme, and the current environment parameters and / or the current operation behavior data into a neural network control model, and generating a control rule modification value for the appliance control rule; modifying the appliance control rule according to the control rule modification value. The control method and the control device of the intelligent household appliances solve the problem that an intelligent household system can not be controlled according to actual needs of the user due to the fact that an existing control rule of all the intelligent household appliances in the intelligent household system can not be modified in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

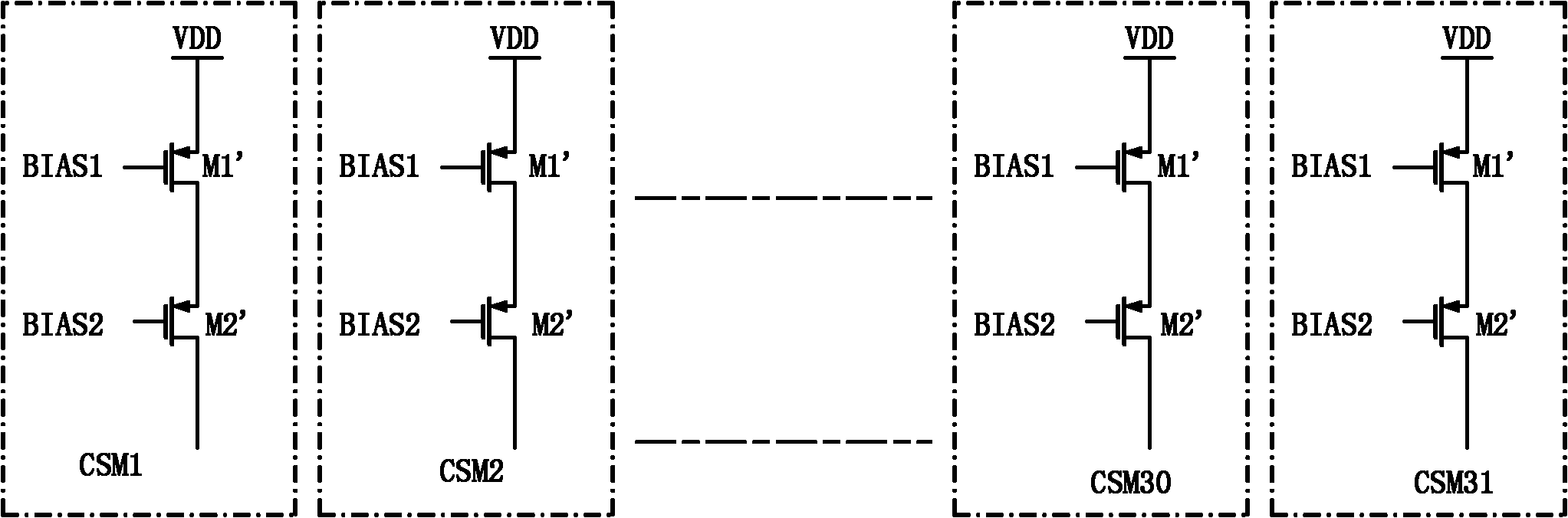

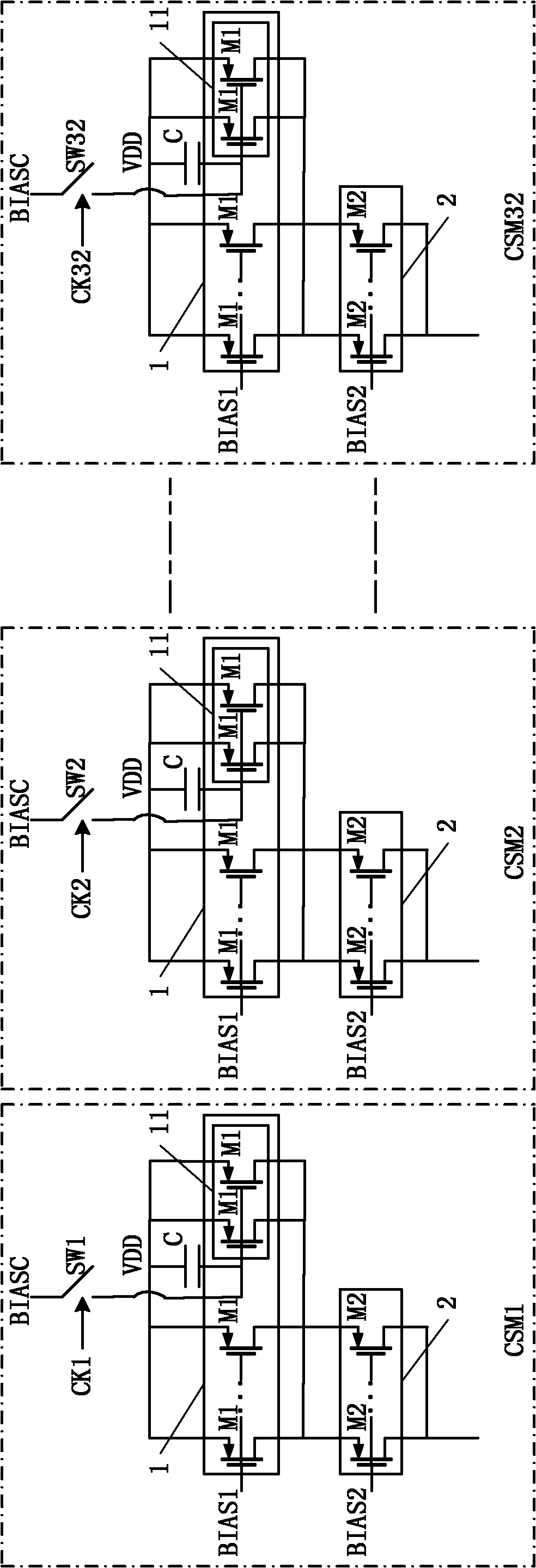

Dynamic correction circuit for current source of current-steering digital-to-analog convertor

ActiveCN102013892AImprove output characteristicsImprove performanceAnalogue/digital conversion calibration/testingCapacitanceDigital analog converter

The invention relates to a dynamic correction circuit for the current source of a current-steering digital-to-analog convertor. The current source comprises multiple groups of current source modules, each current source module comprises a first MOS (metal oxide semiconductor) tube unit and a second MOS tube unit which are connected in series; the first MOS tube unit comprises a plurality of first MOS tubes connected in parallel, and the source electrodes and drain electrodes of the first MOS tubes are respectively connected to form the source electrode and drain electrode of the first MOS tube unit; the source electrode of the first MOS tube unit is connected with an external power supply; and the correction circuit is composed of a feedback control module as well as a correction MOS tube subunit, a capacitor and a switch which are arranged in each group of current source modules. The dynamic correction circuit is used for dynamically correcting the current source to stabilize the current source basically so as to obtain a digital-to-analog convertor with better properties.

Owner:SHANGHAI BEILING

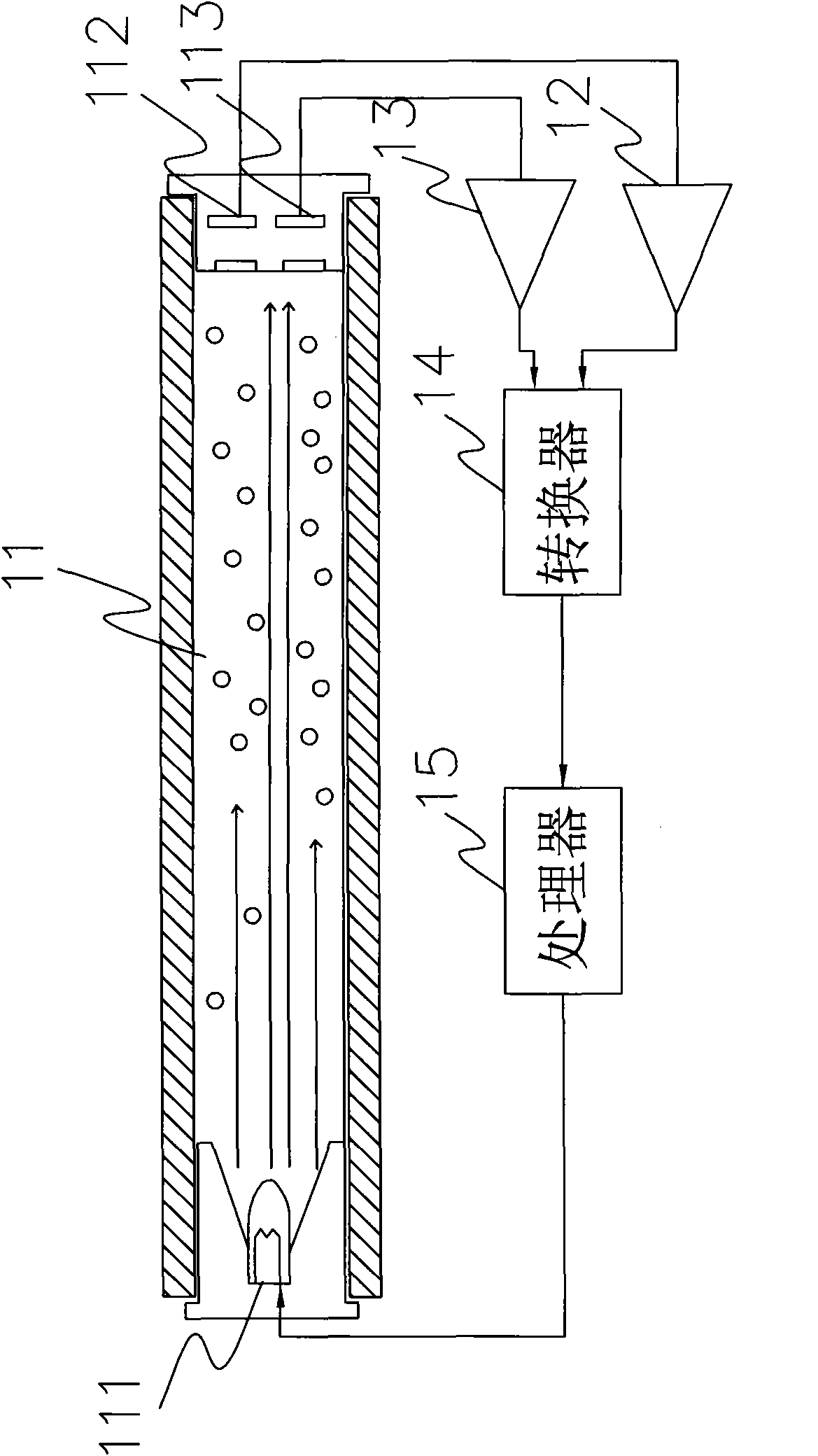

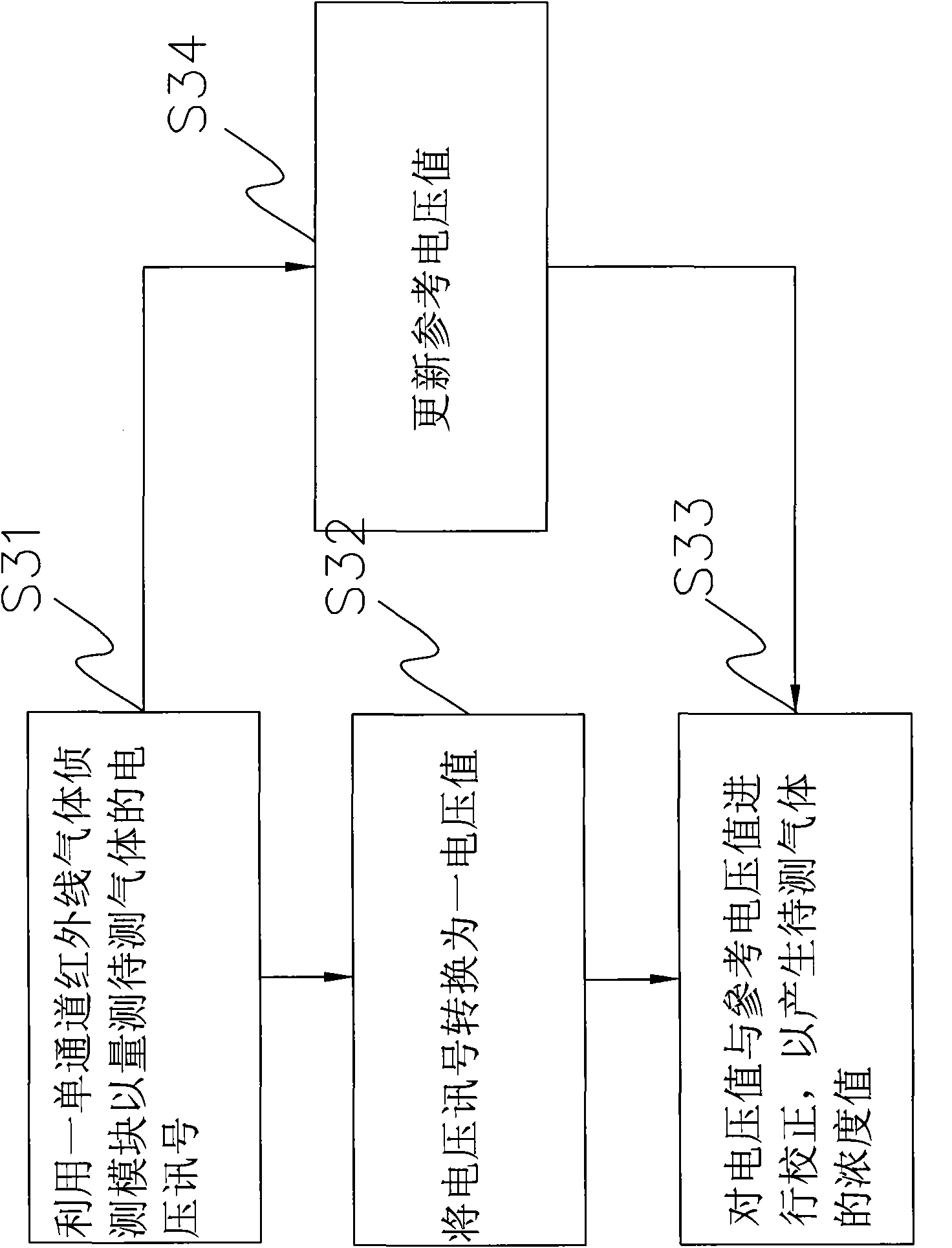

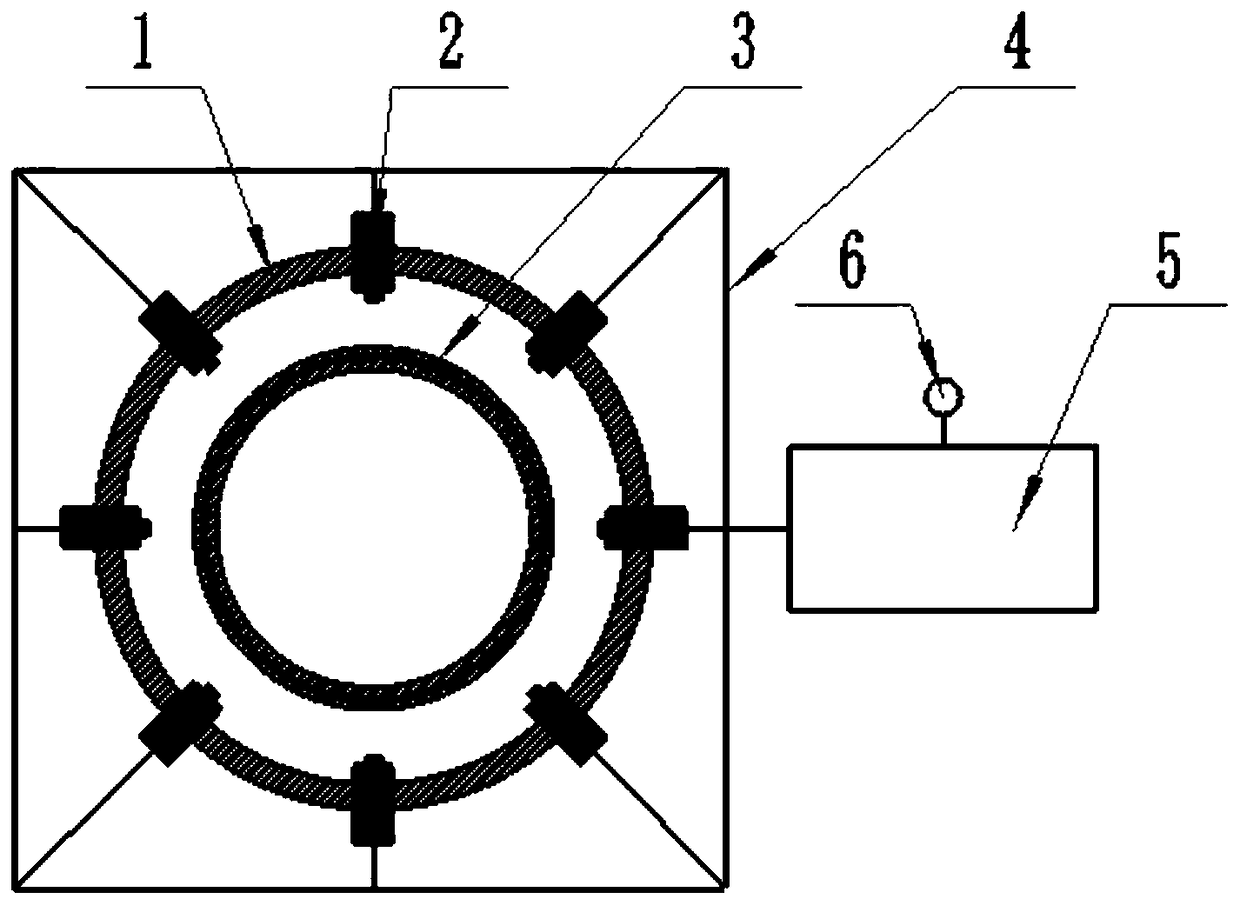

Gas concentration measuring device and method thereof

InactiveCN101915747AImprove accuracyTo achieve the corrective effectColor/spectral properties measurementsProduct gasVoltage reference

The invention discloses a gas concentration measuring device and a method thereof, which is applied to measuring the concentration of carbon dioxide; a single-channel infrared gas detecting module is used for detecting a voltage signal of gas to be measured; the voltage signal can be converted into voltage value by a digital to analog convertor; and a processing module is used for correcting the voltage value and reference voltage value for generating the concentration valve of the gas to be measured. If the reference voltage value is initial reference voltage value, the carbon dioxide concentration value in atmospheric environment can be taken as reference data, and the processing module is used for correcting voltage excursion of the gas to be measured. Therefore, the measurement accuracy is improved.

Owner:RADIANT INNOVATION INC

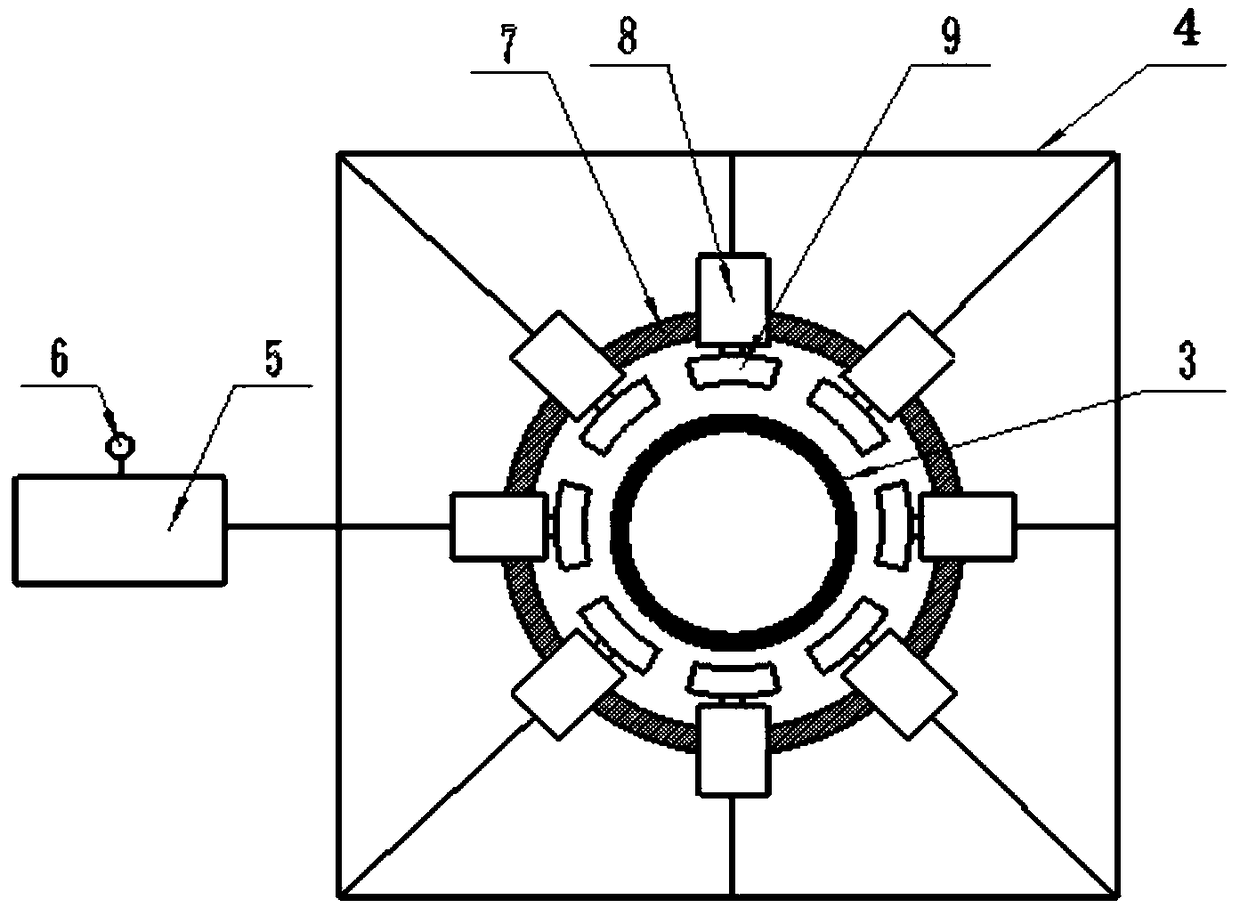

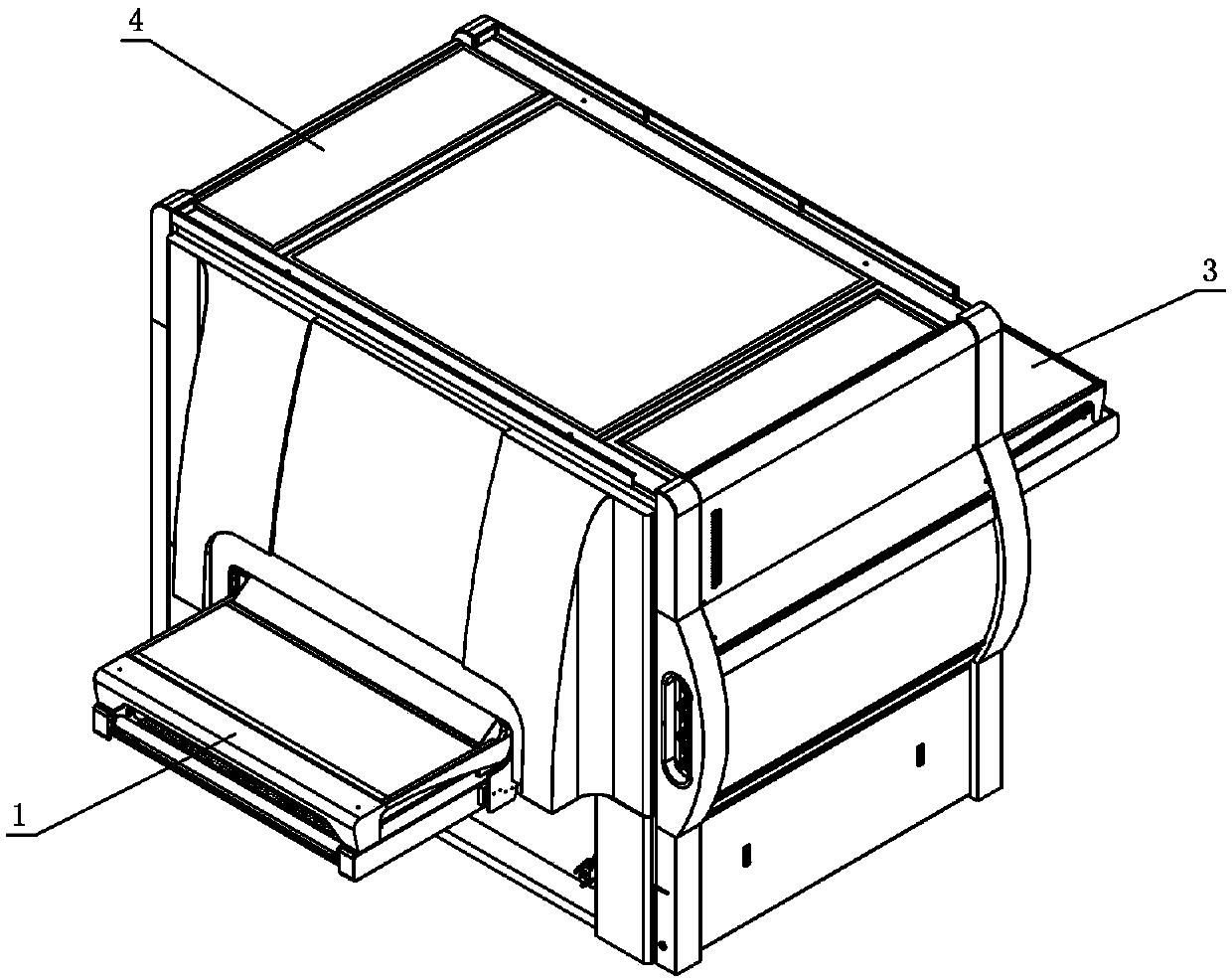

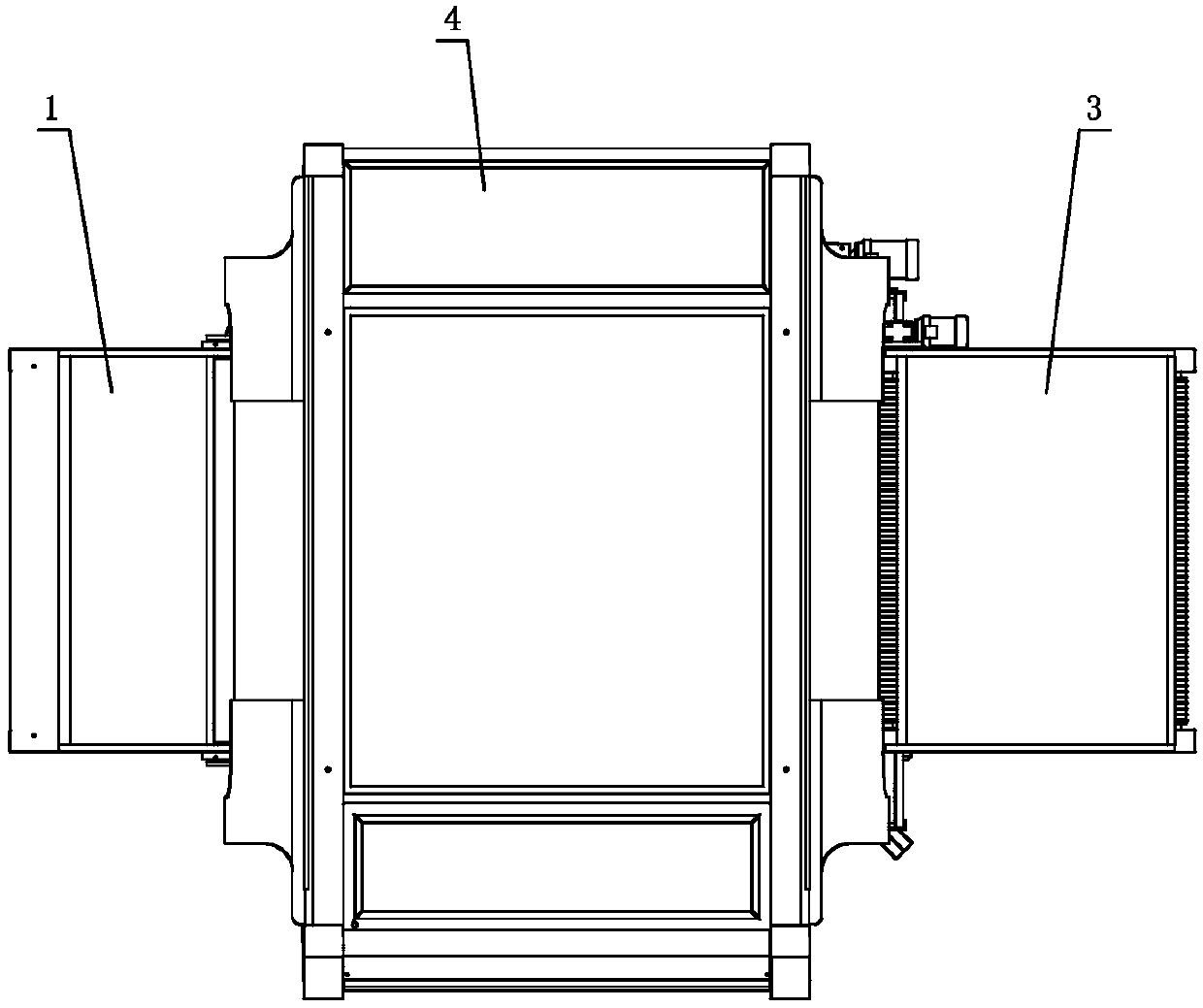

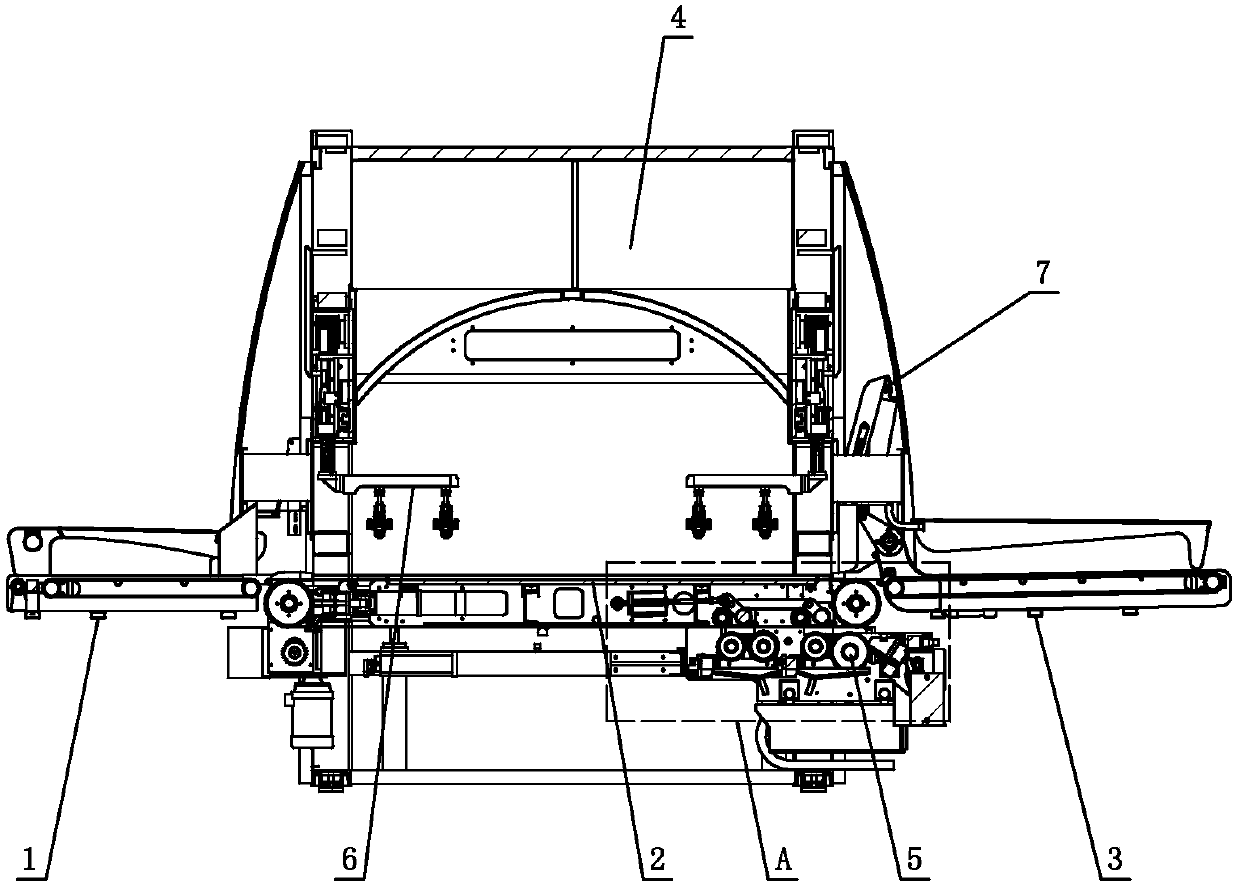

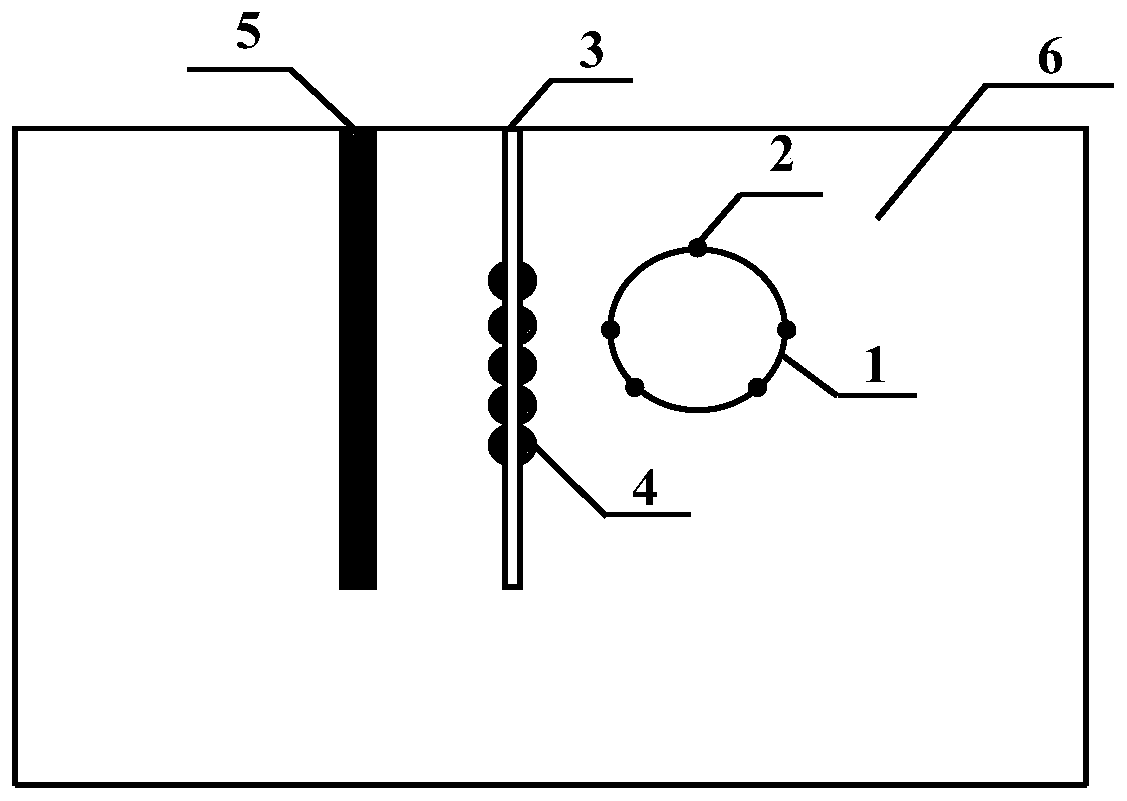

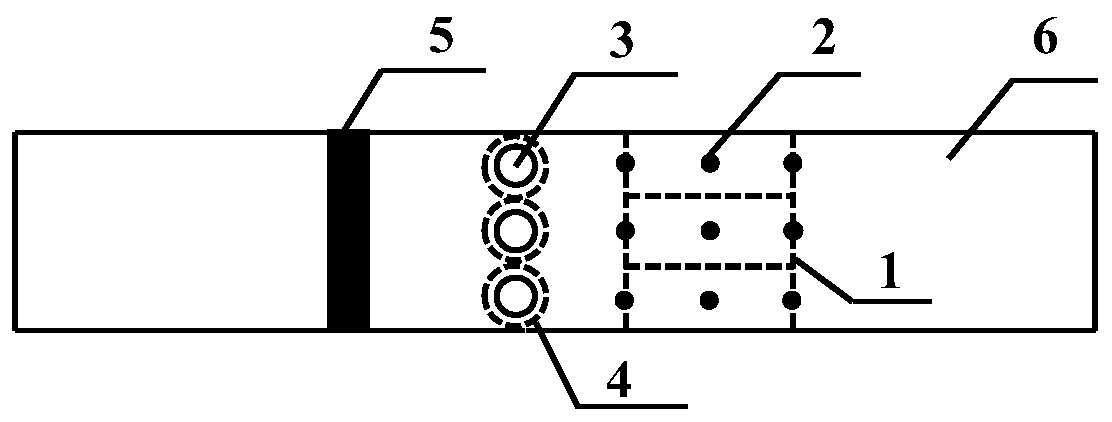

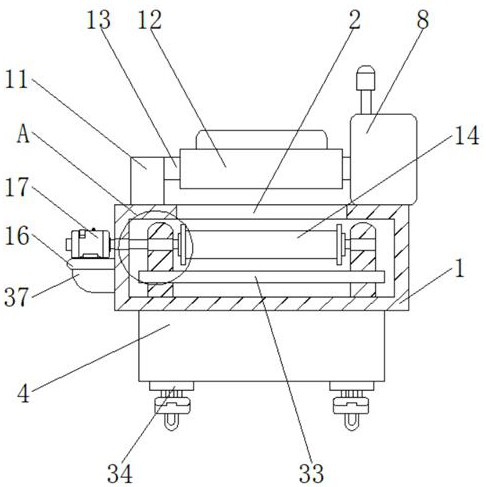

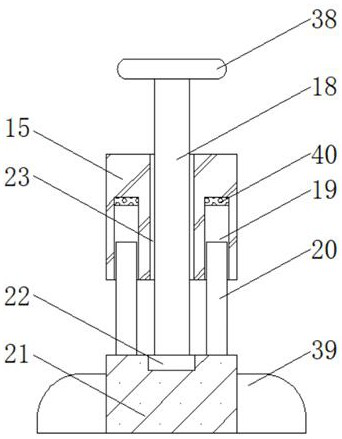

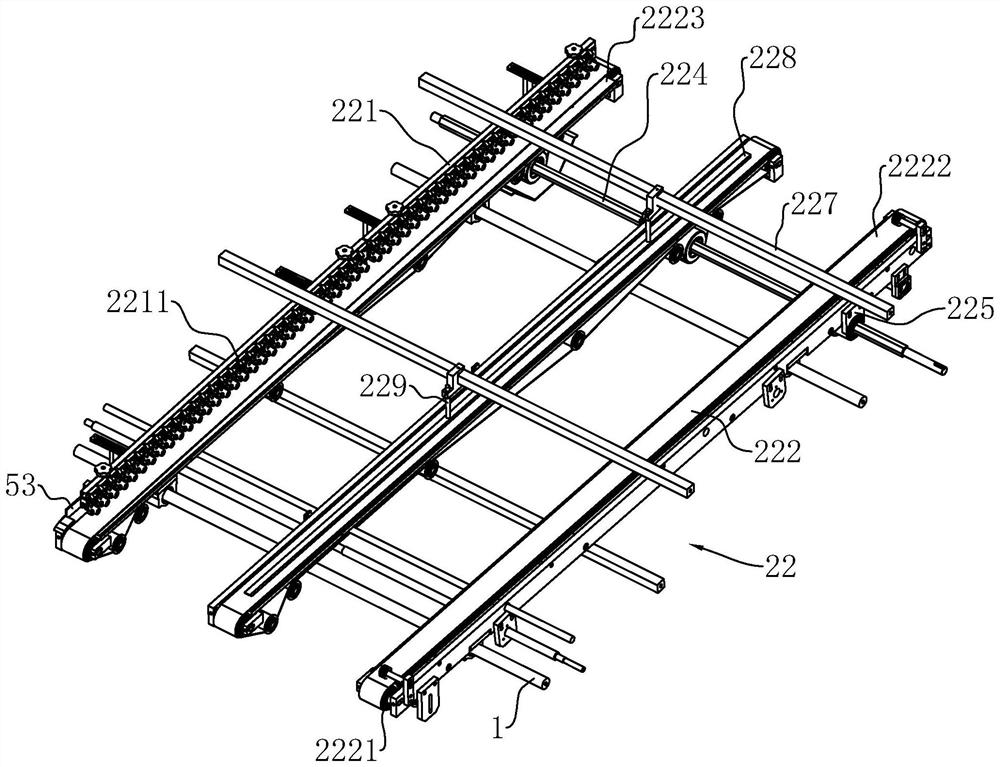

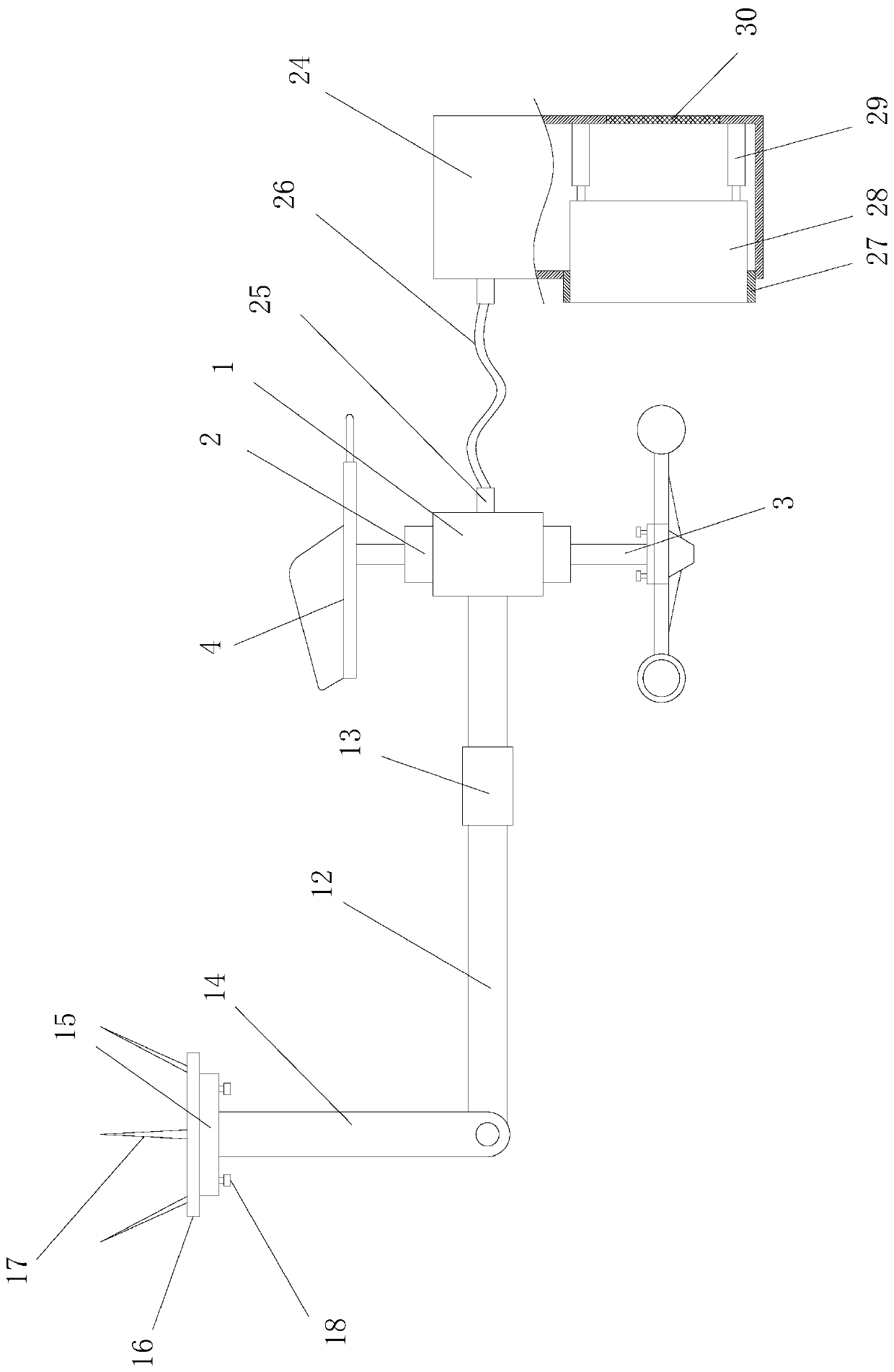

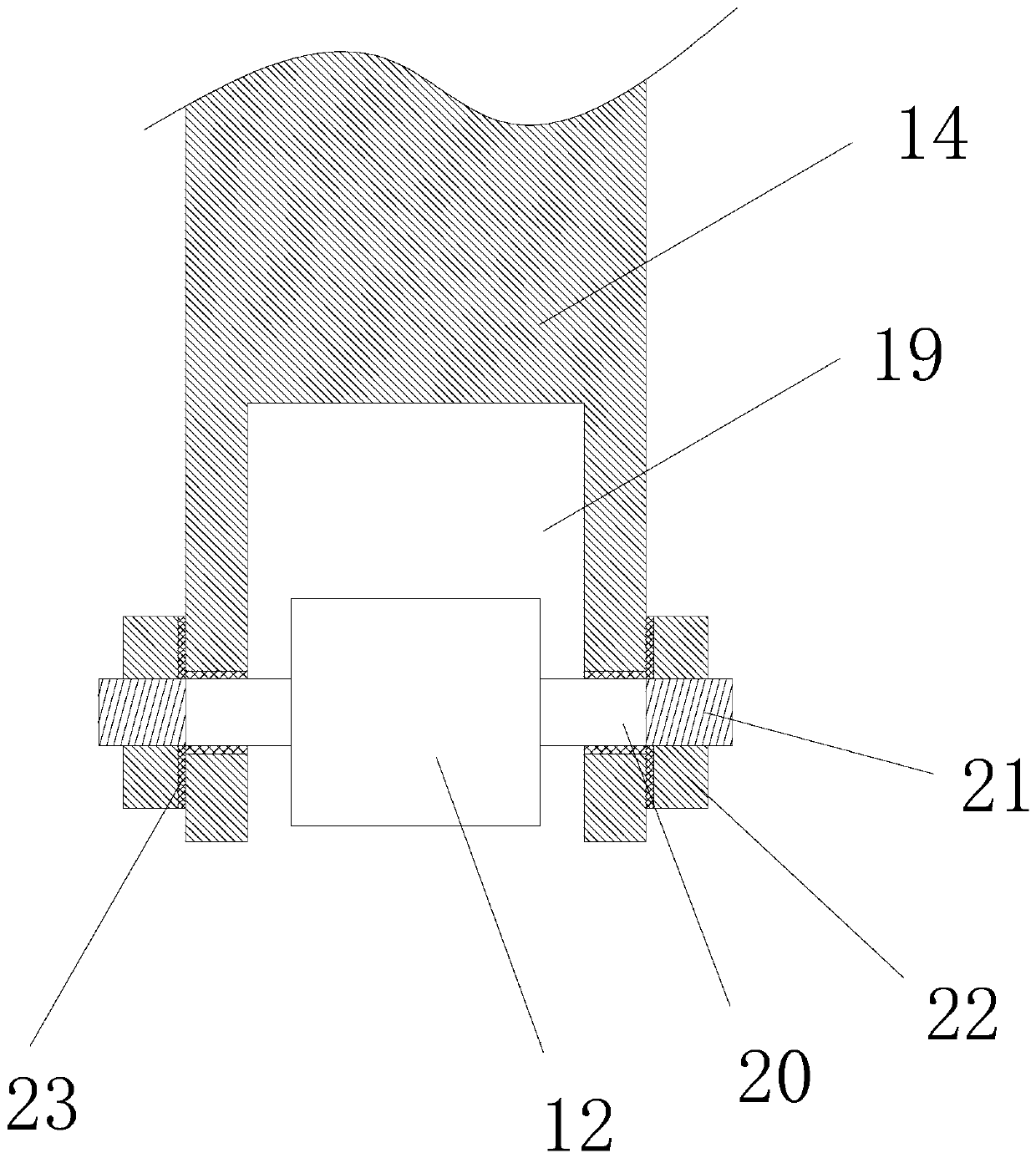

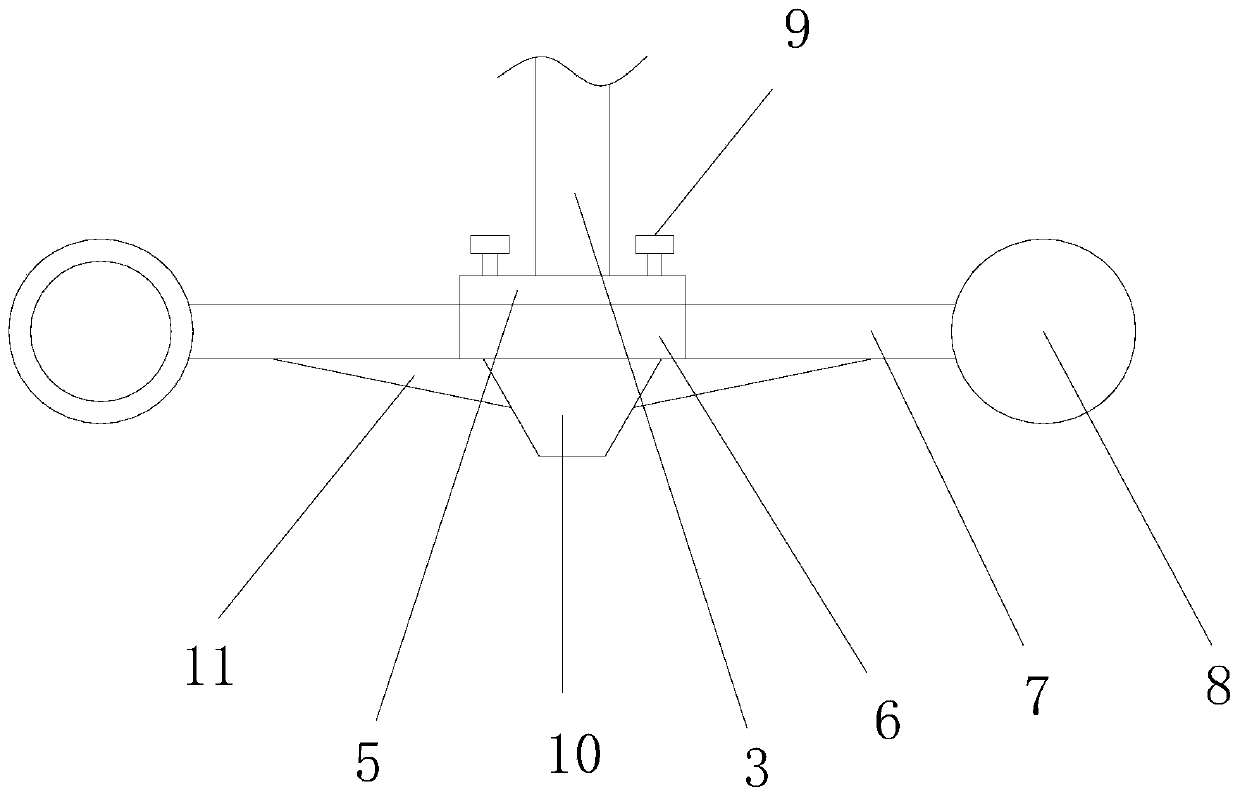

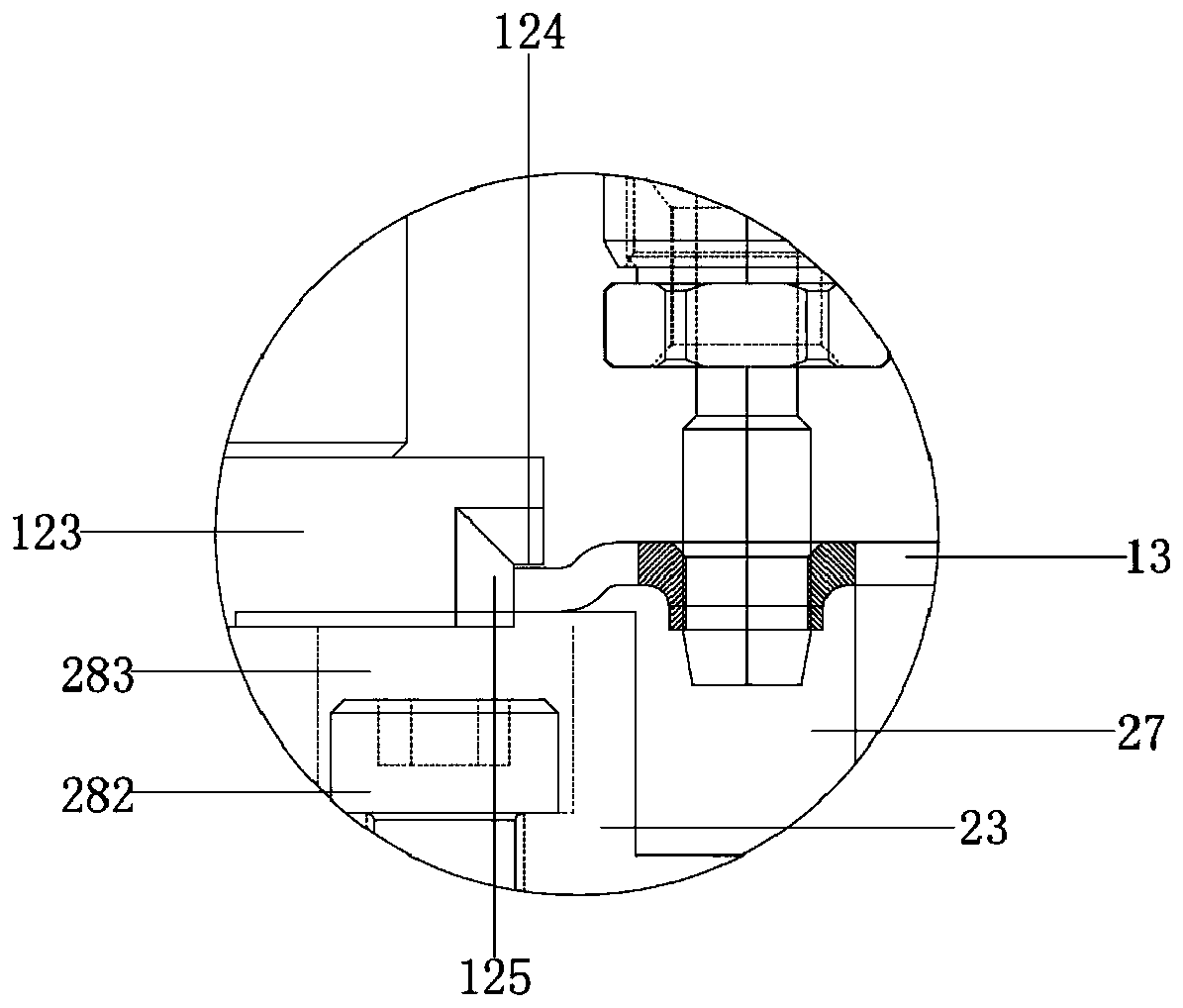

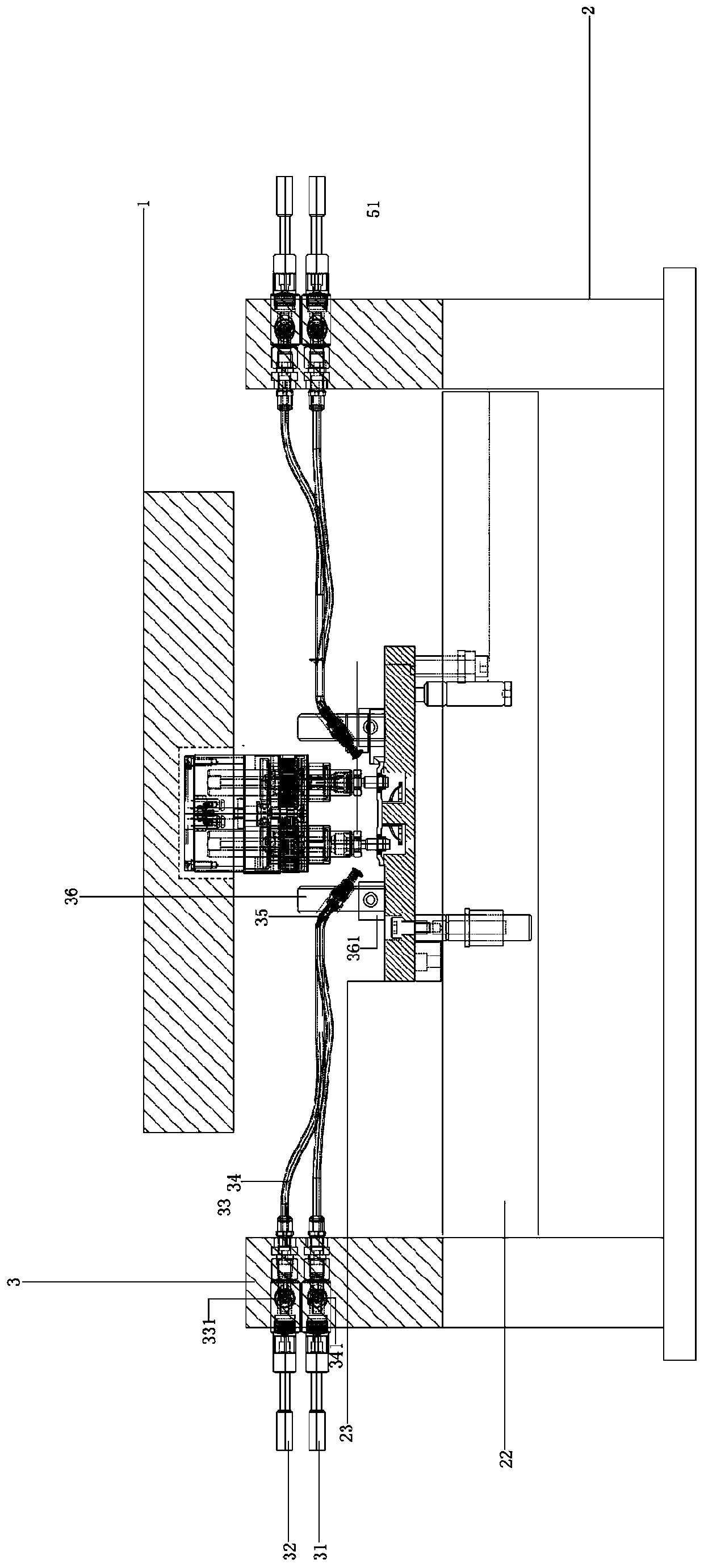

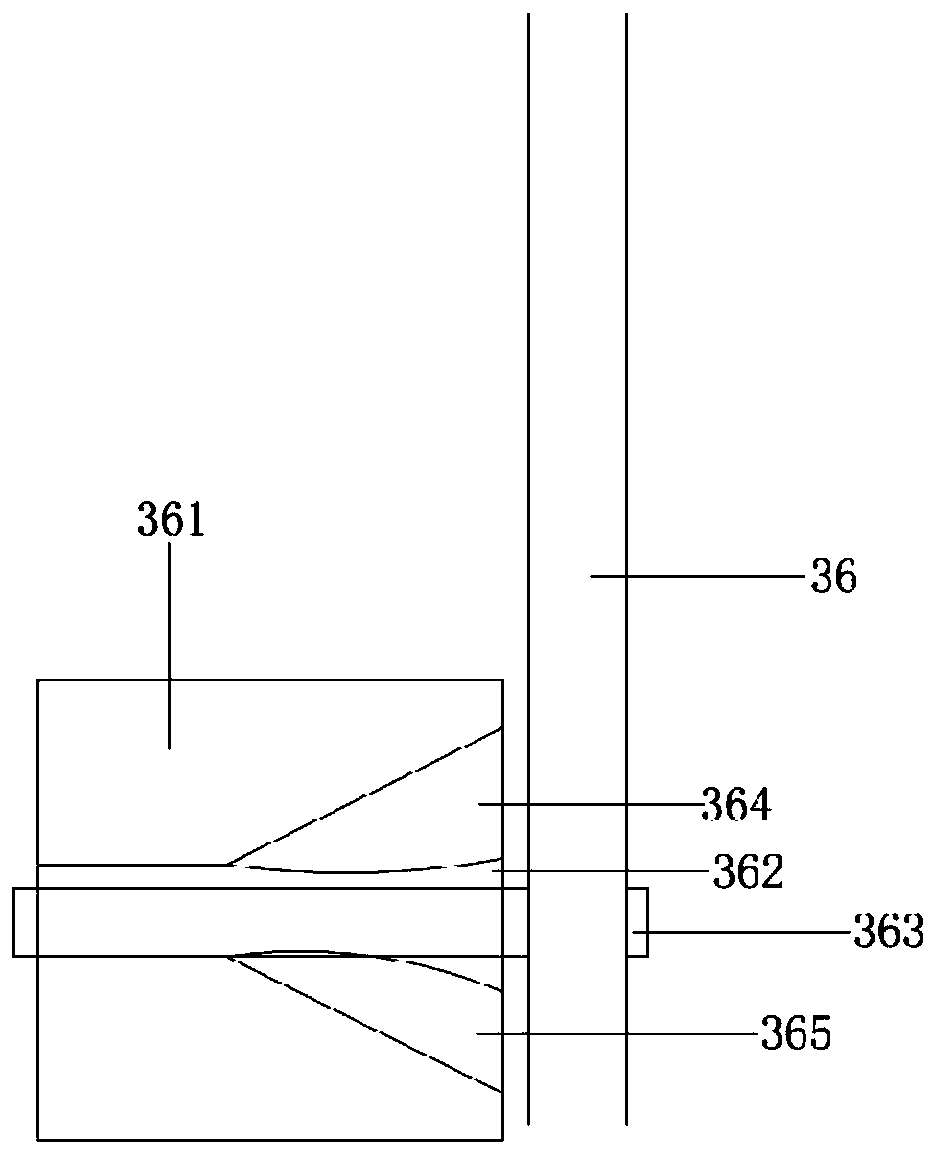

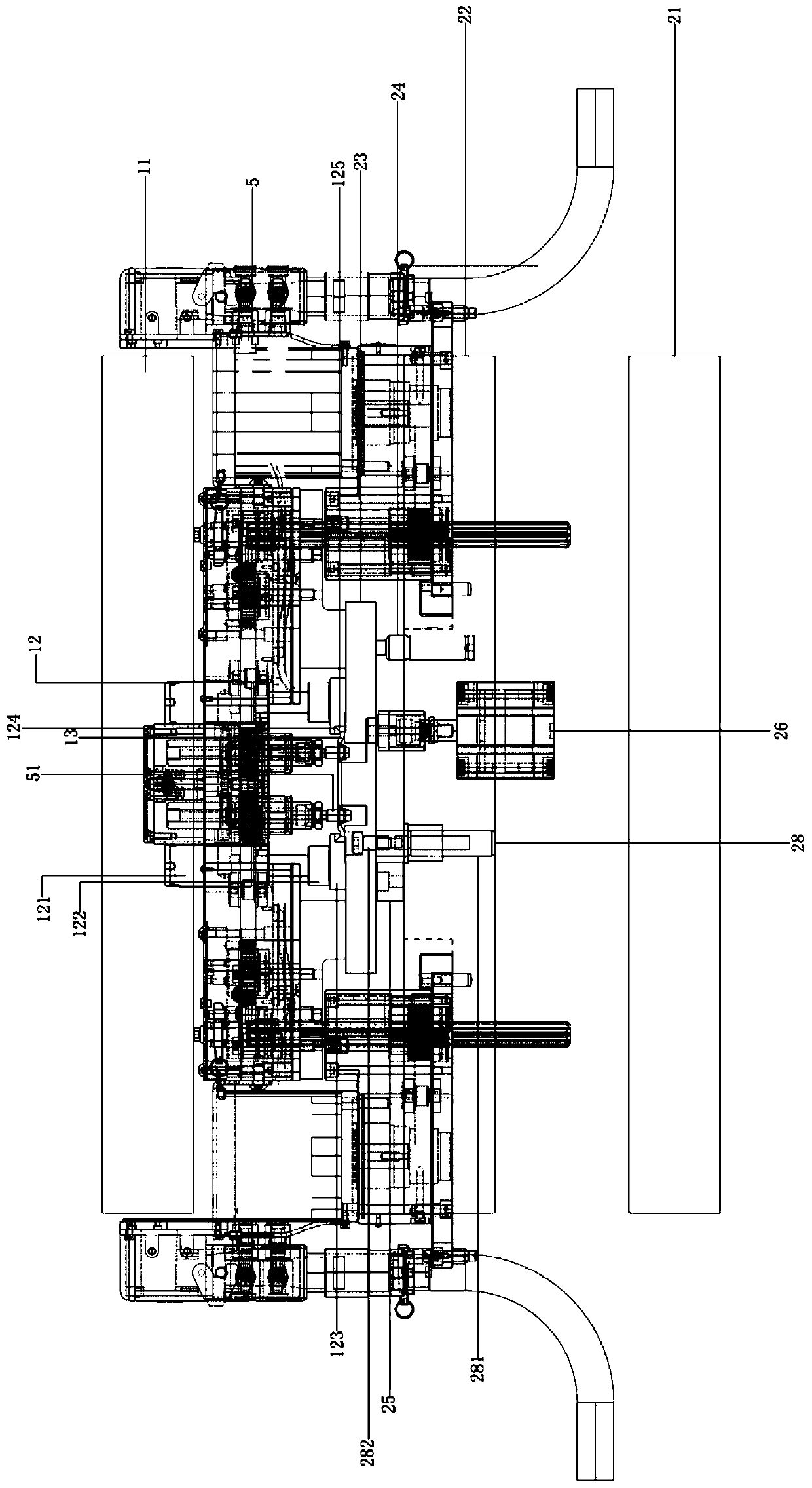

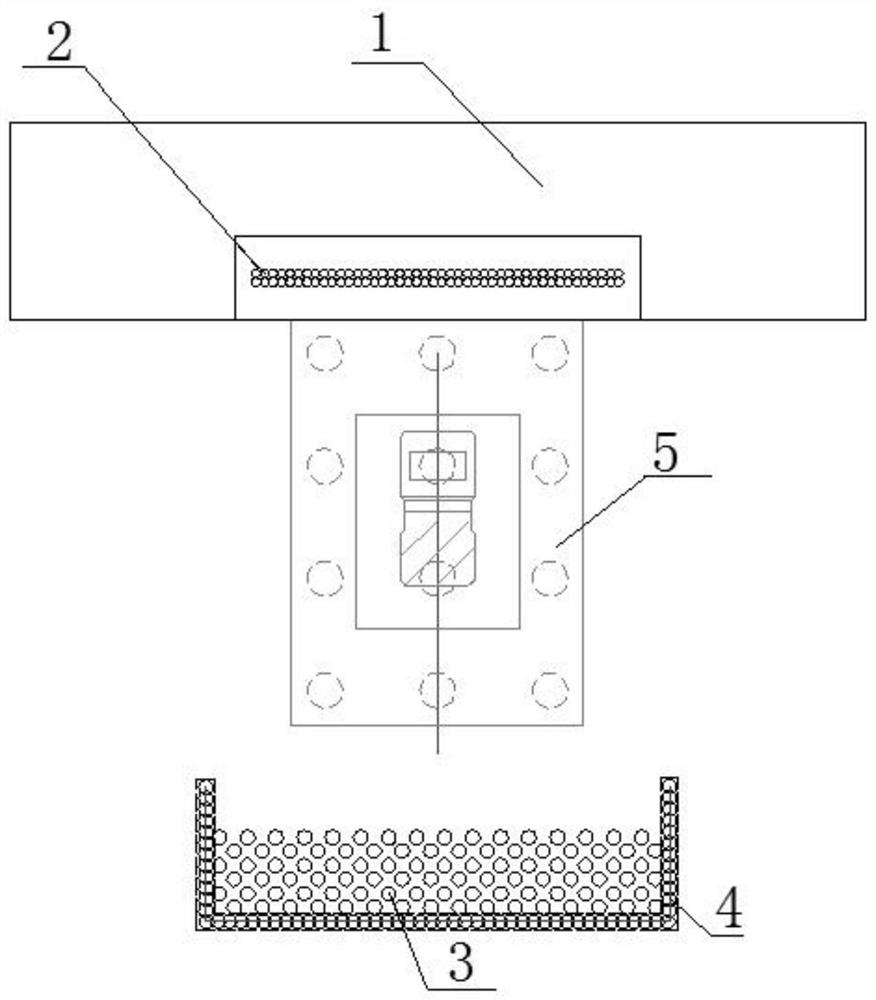

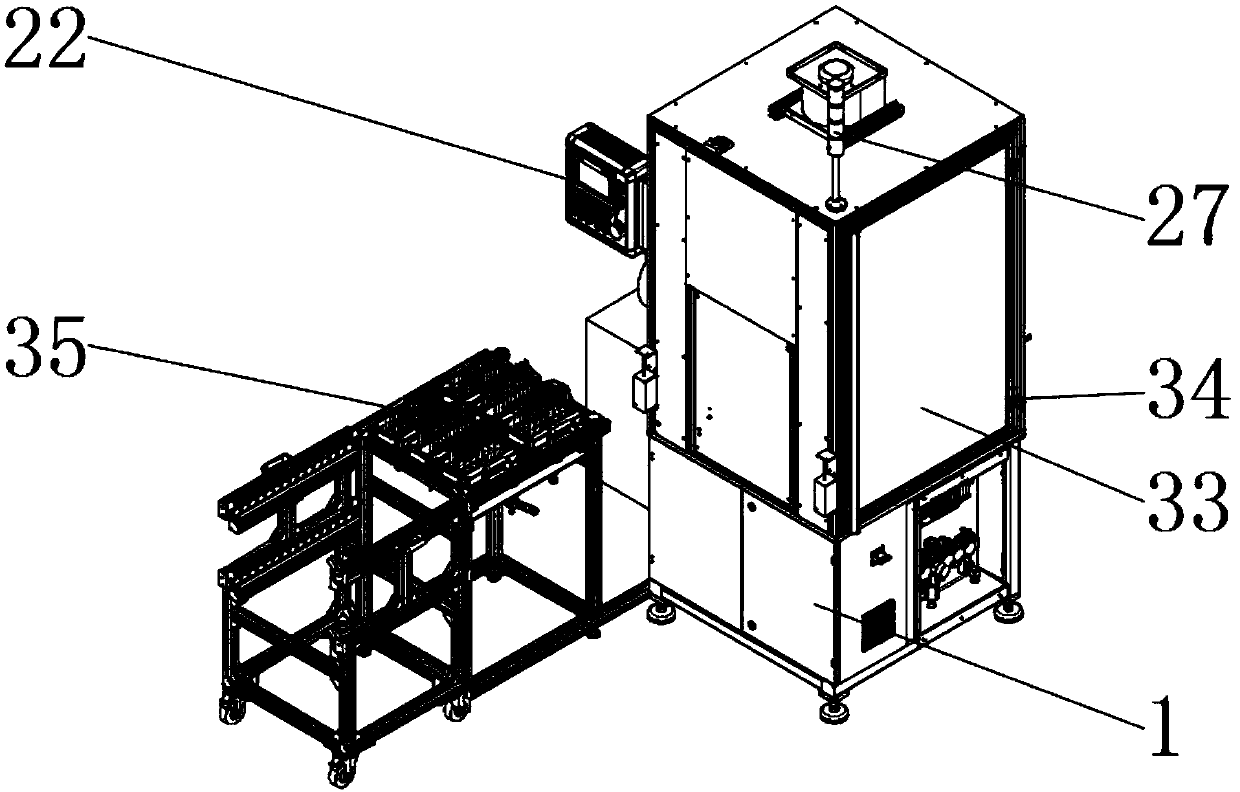

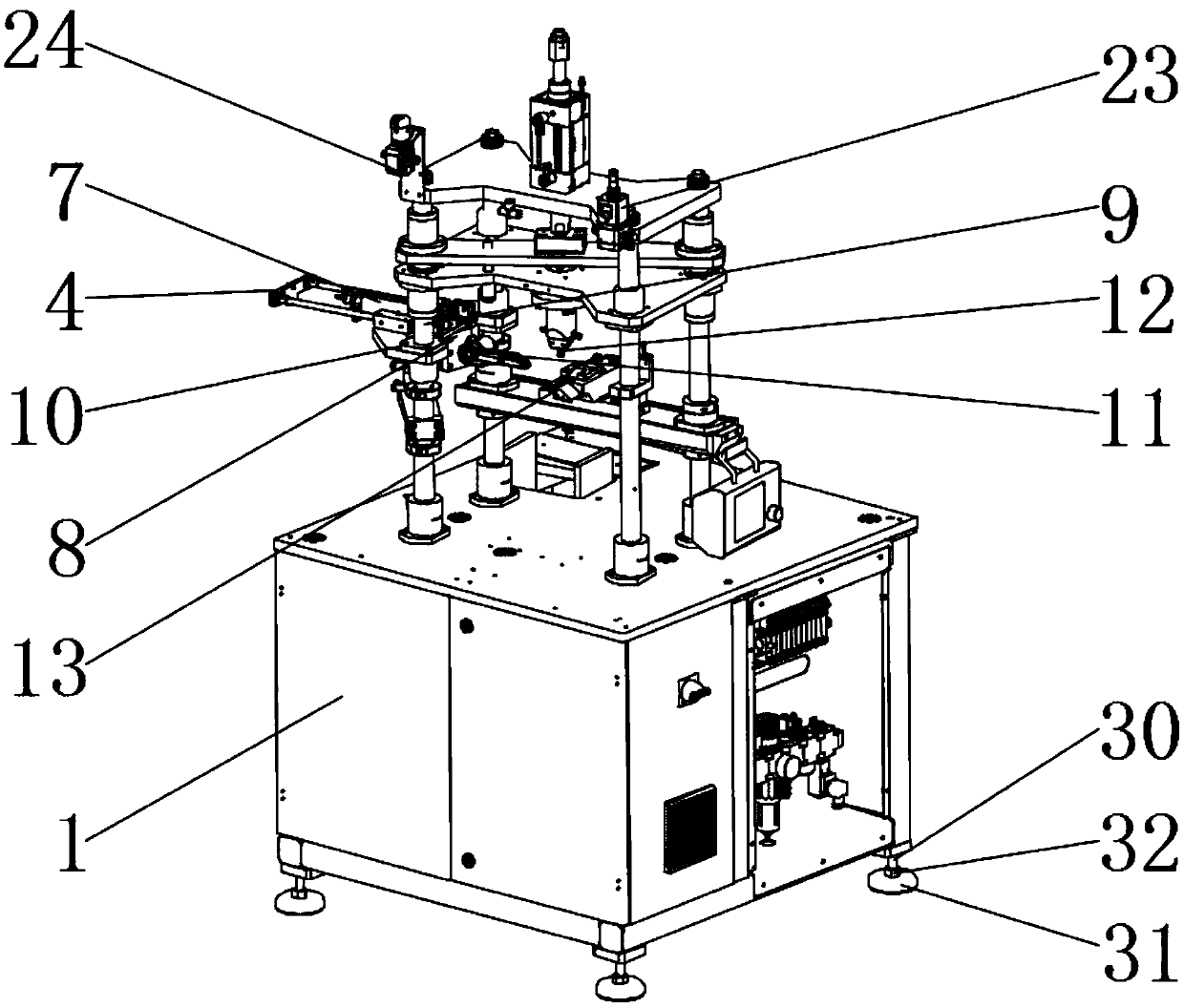

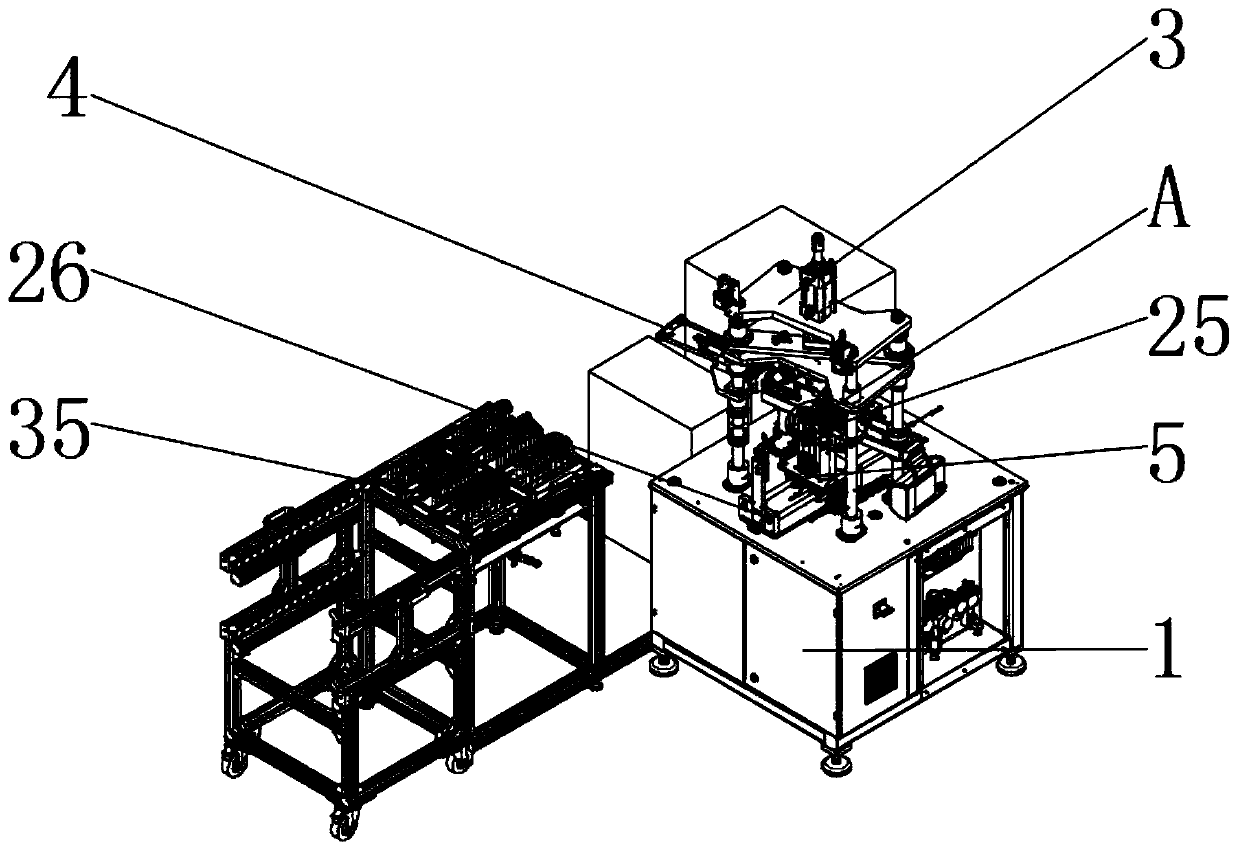

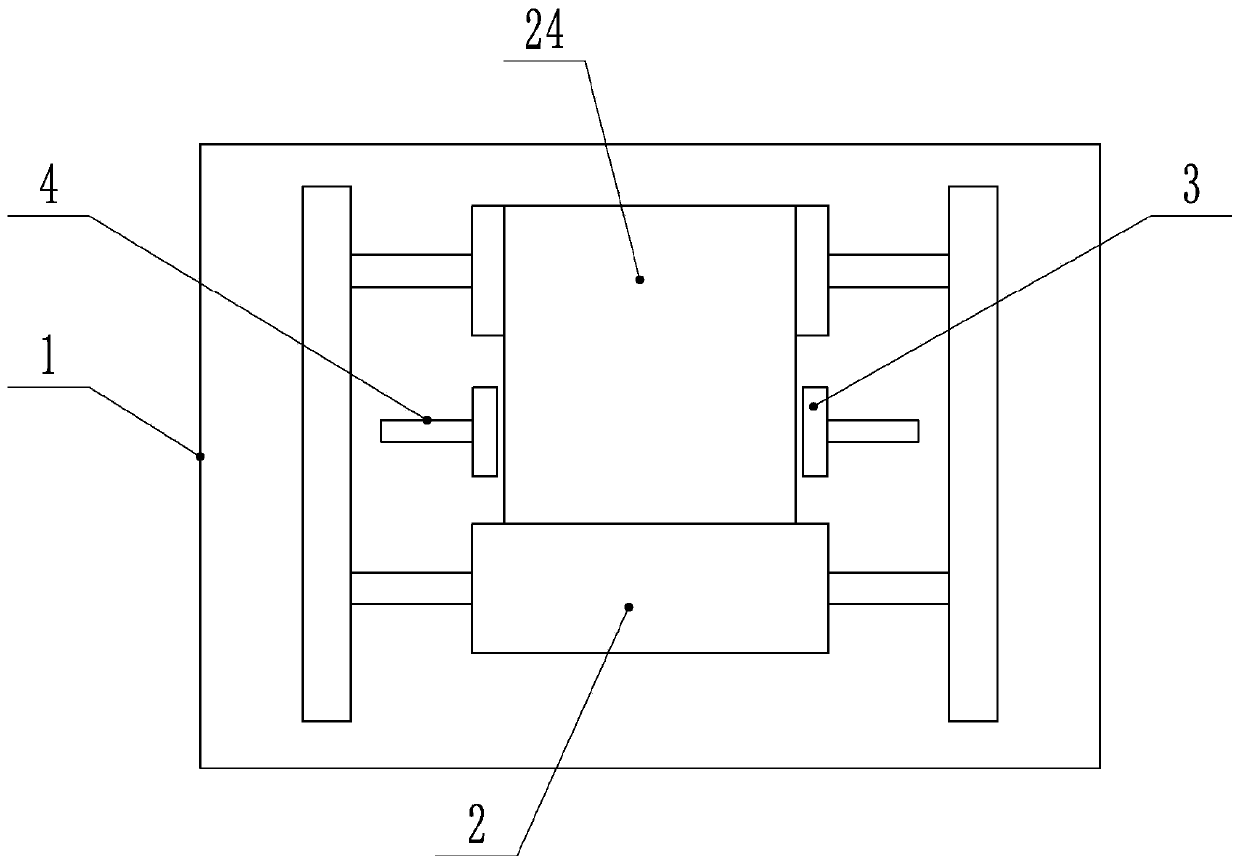

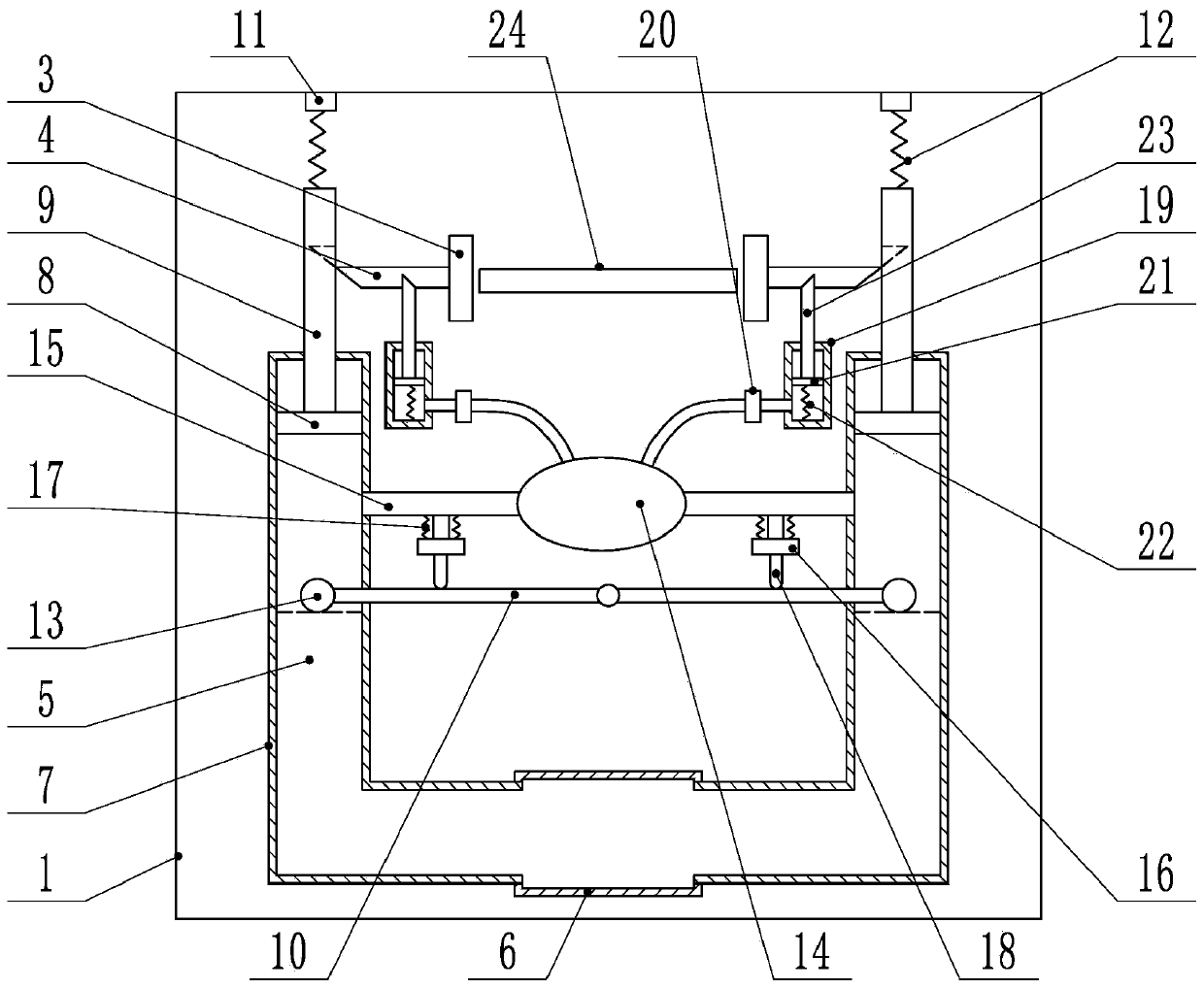

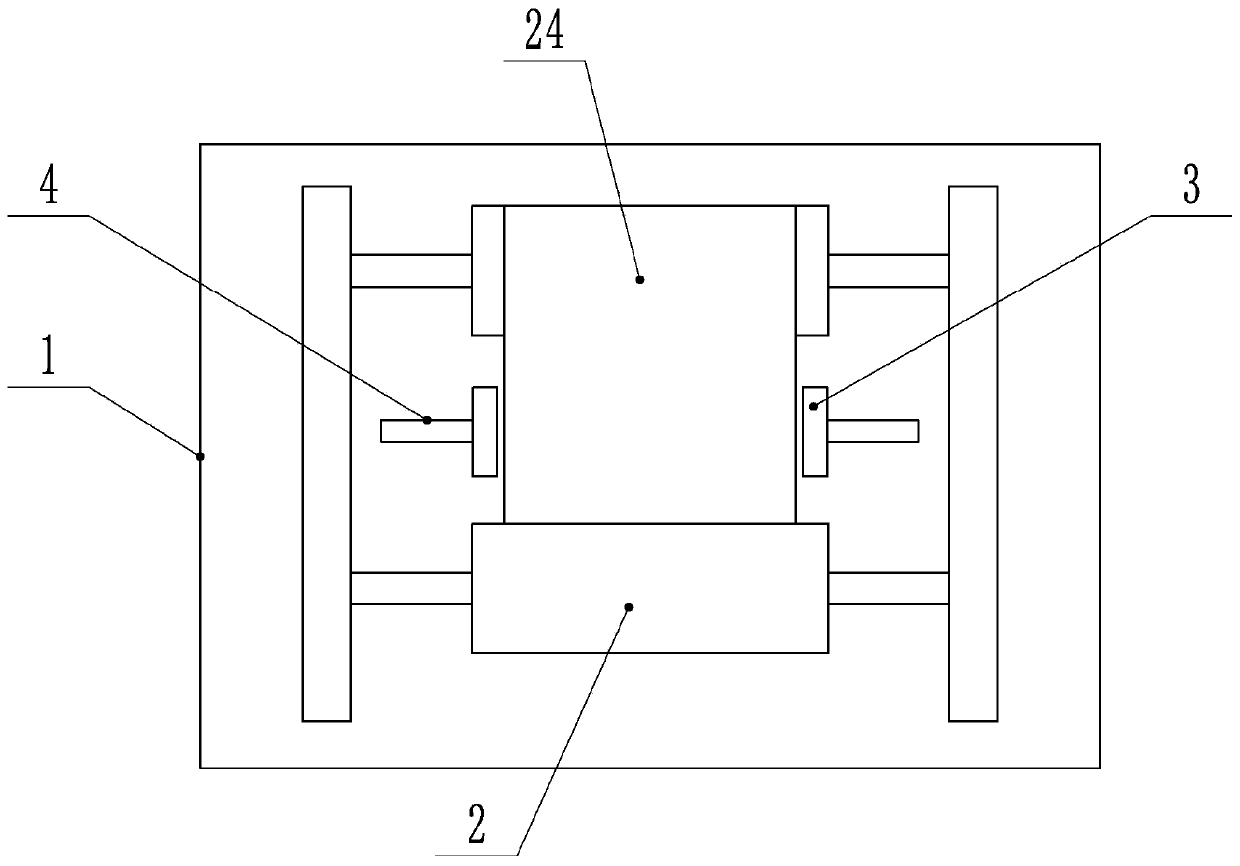

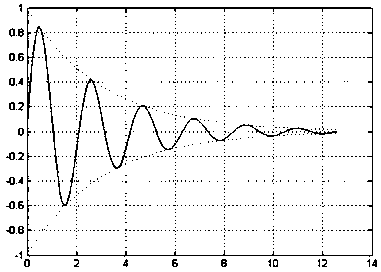

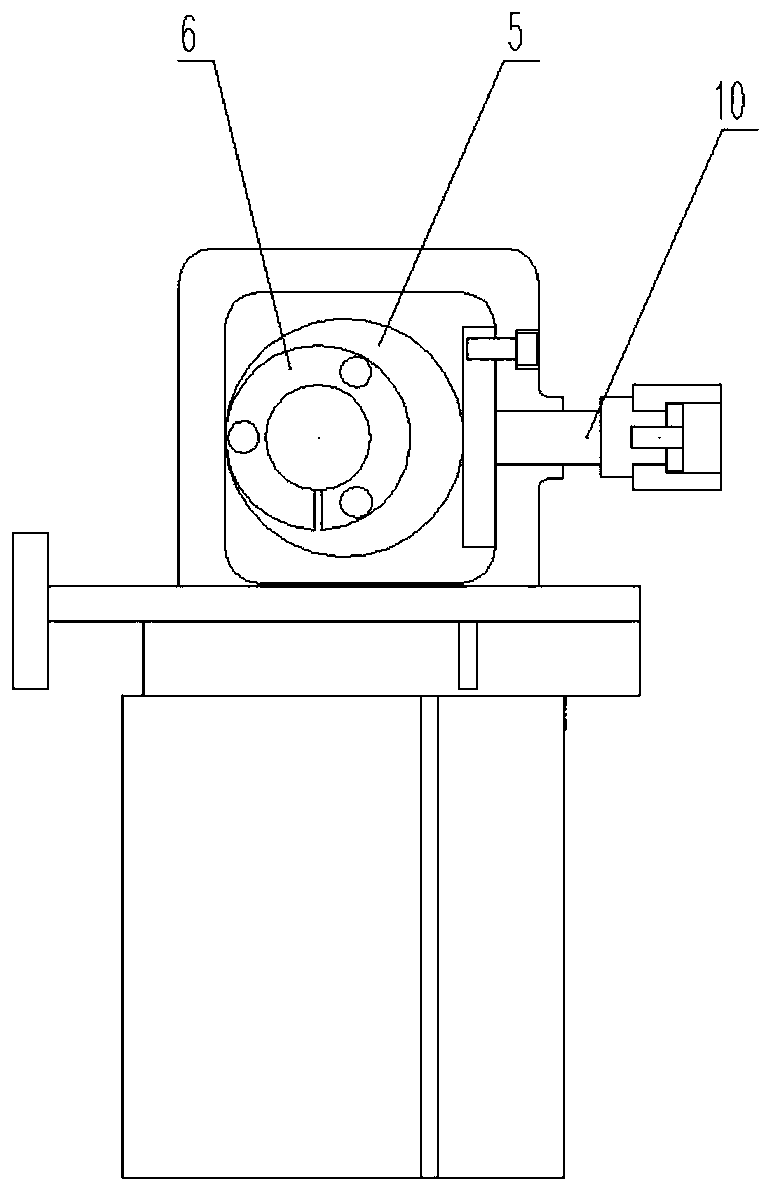

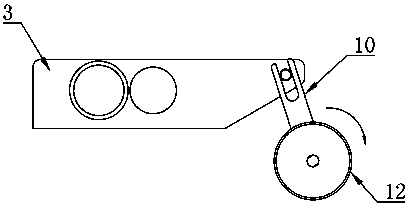

Online automatic rounding device for steel skeleton plastic composite pipe

InactiveCN109351811ATimely and accurate measurementTo achieve the corrective effectMetal working apparatusLaser rangingRounding

The invention discloses an online automatic rounding device for a steel skeleton plastic composite pipe. The online automatic rounding device for the steel skeleton plastic composite pipe is divided into two parts: a detecting mechanism and a calibration mechanism. The detecting mechanism and the calibration mechanism are sequentially fixed at the exit of a tractor. The detecting mechanism is composed of a first frame and eight laser range finders, and the calibration mechanism is composed of a second frame and eight pressure rolls. When working, the ellipticity of the pipe at the exit of thetractor in the continuous production process is detected firstly. When the ellipticity of the pipe exceeds the standard value, a signal is fed back to the calibration mechanism, and then the calibration mechanism corrects the ellipticity of the pipe. By means of the online automatic rounding device for the steel skeleton plastic composite pipe, the elliptic problem of the steel skeleton plastic composite pipe during the production process is solved, and the online automatic rounding is achieved. The online automatic rounding device for the steel skeleton plastic composite pipe is suitable forthe technical field of steel skeleton plastic composite pipe production.

Owner:HUACHUANG TIANYUAN IND DEVING

Endoscope target object size calculating method and analysis system

ActiveCN109730683AIn line with the habitAid in readingImage analysisEndoscopesUnit sizeComputer vision

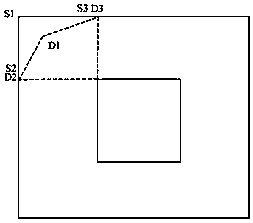

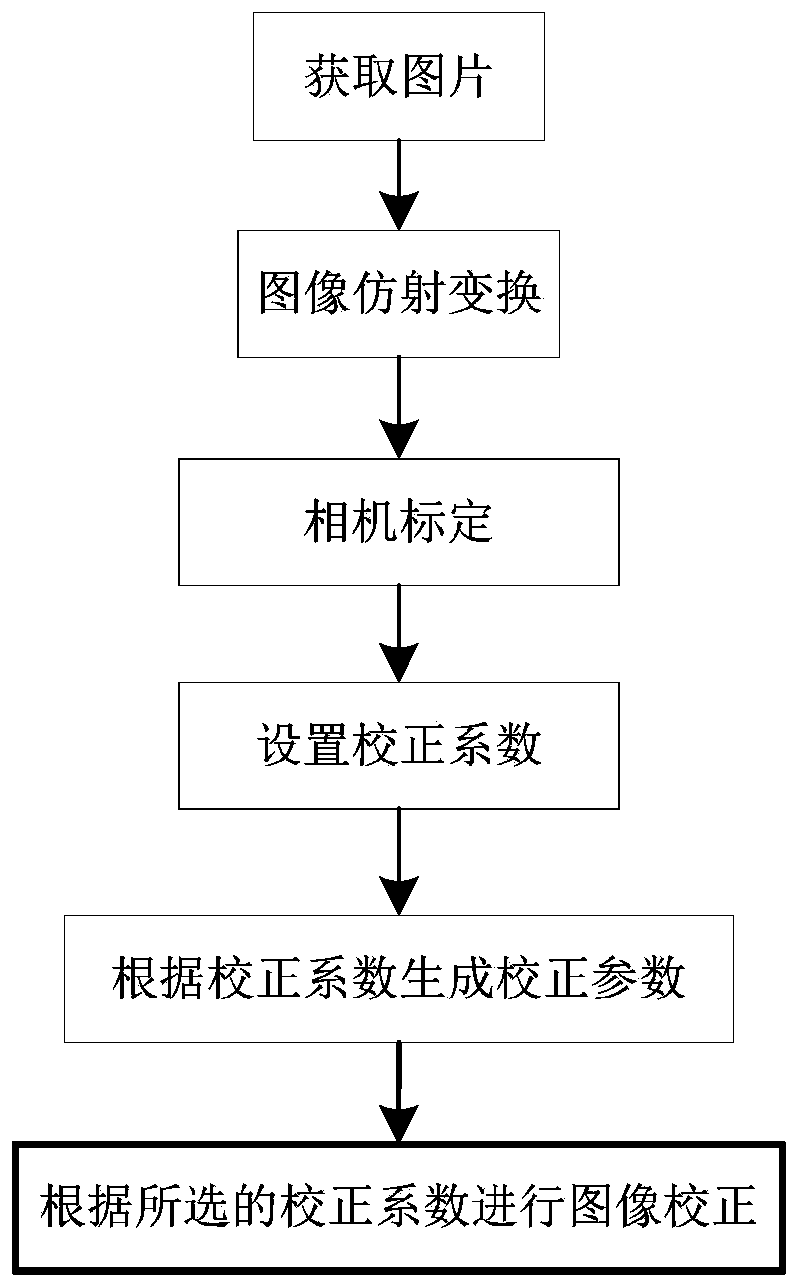

The invention provides an endoscope target object size calculating method and an analysis system. The method includes the following steps of establishing the distance-pixel unit size mathematical relation model of the unit pixel size of an endoscope in different distances; collecting the distance d between the endoscope and a target object; taking an image of the target object through the endoscope, and correcting the distortion of the image; obtaining the number of pixels of the target object in the corrected image, detecting the size of the corresponding unit pixels in the distance of d through the distance-pixel unit size mathematical relation model, and calculating the size of the target object according to the calculating method of N*Sd, wherein N represents the number of the pixels of the target object, and the Sd represents the actual area size corresponding to the single pixel in the distance of d in the distance-pixel unit size mathematical relation model. The method is high in calculating speed and can rapidly and accurately calculates the size of the target object of the endoscope.

Owner:重庆金山医疗技术研究院有限公司

A deviation correction system for a folder-gluer

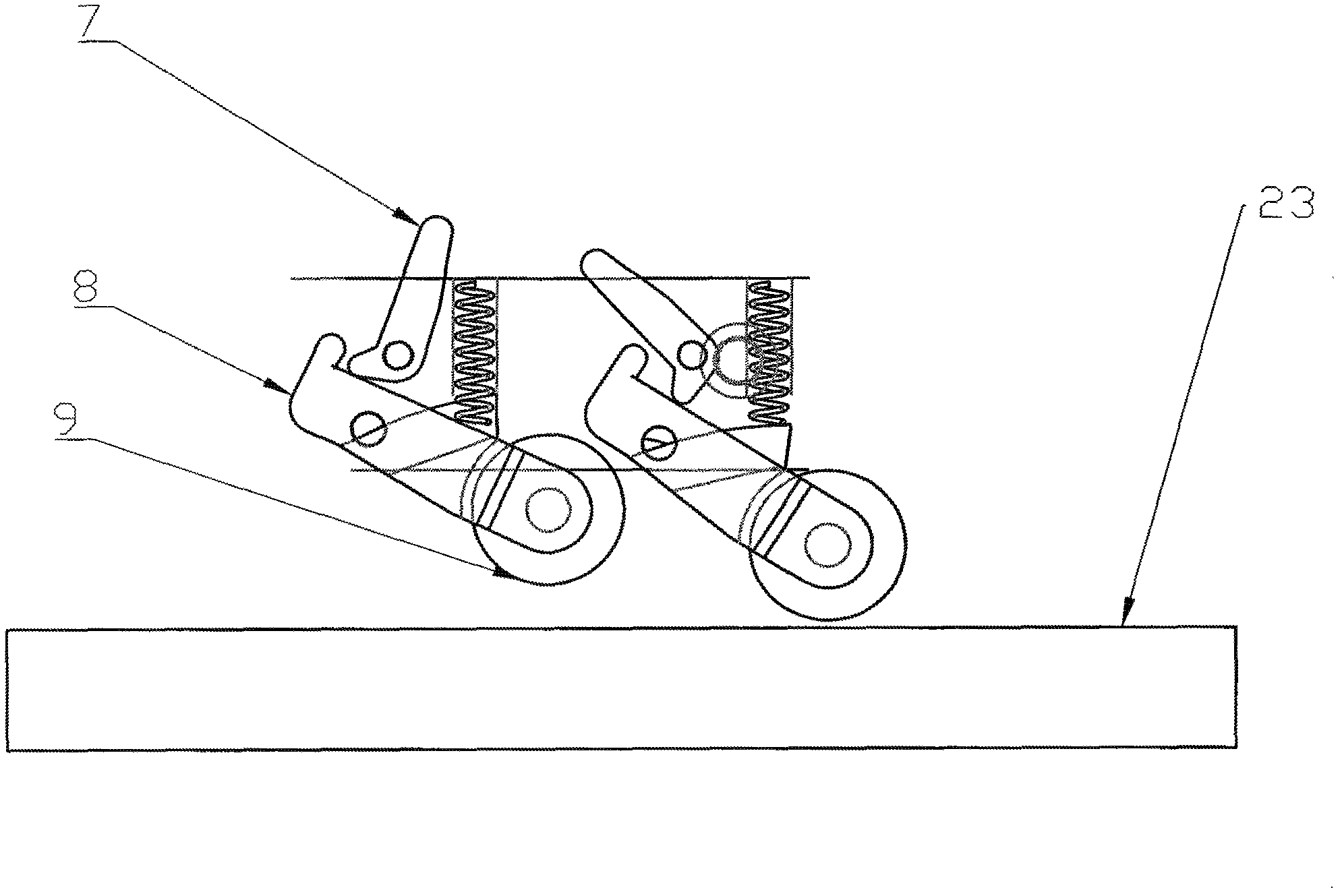

InactiveCN102285150AImprove pass rateTo achieve the corrective effectPaper-makingBox making operationsSkew angleCarton

The invention relates to a deviation correction system for a folder gluer, which includes an outer wall panel, a transmission device, and a transmission device. It is characterized in that a deviation correction device is installed above the transmission device. There is a deviation correcting baffle parallel to the moving direction of the conveying device and more than one deviation correcting pressing wheel; through this technical scheme, the rolling direction of the deviation correcting pressing wheel forms a deflection angle with the conveyor belt, thereby generating the force of the paper moving closer to the deviation correcting baffle, Until the edge of the paper is parallel to the deviation correction baffle, so as to achieve the deviation correction effect, improve the qualified rate of the carton, and reduce the loss caused by product scrapping.

Owner:温州市高田包装机械有限公司

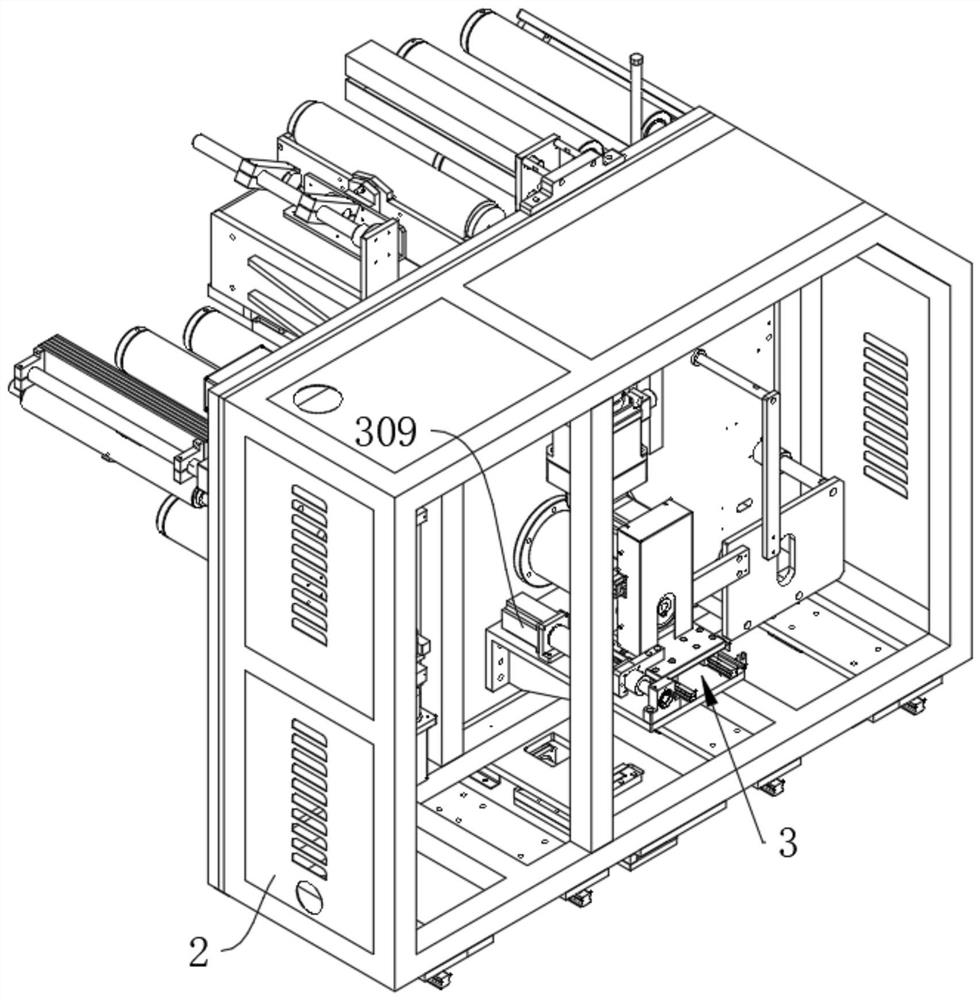

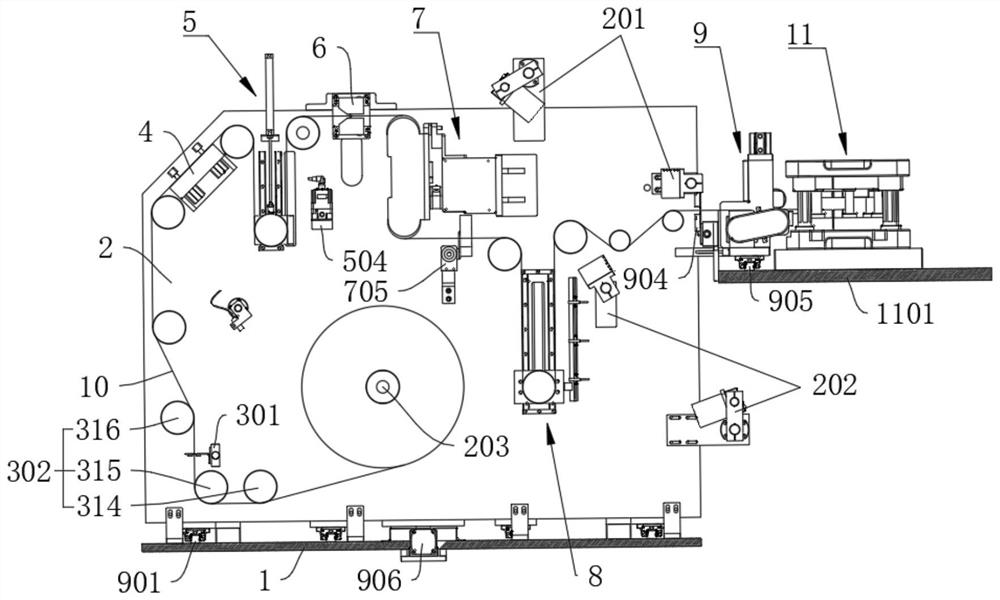

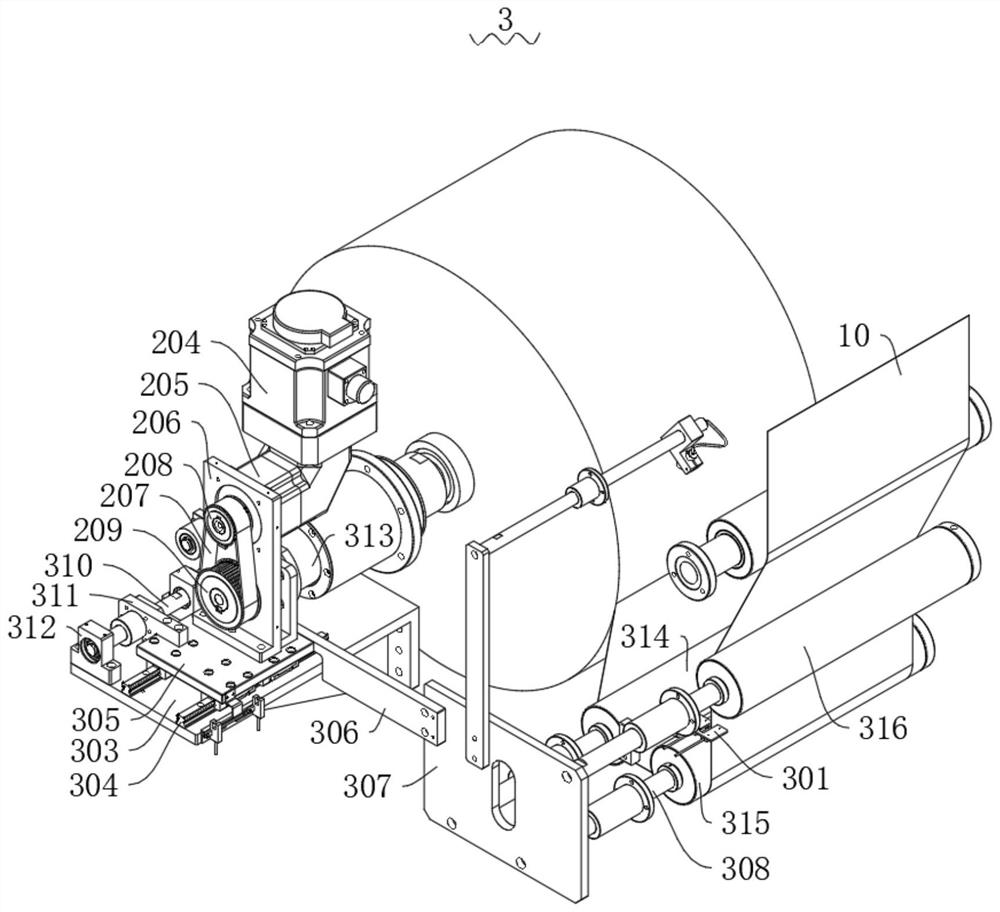

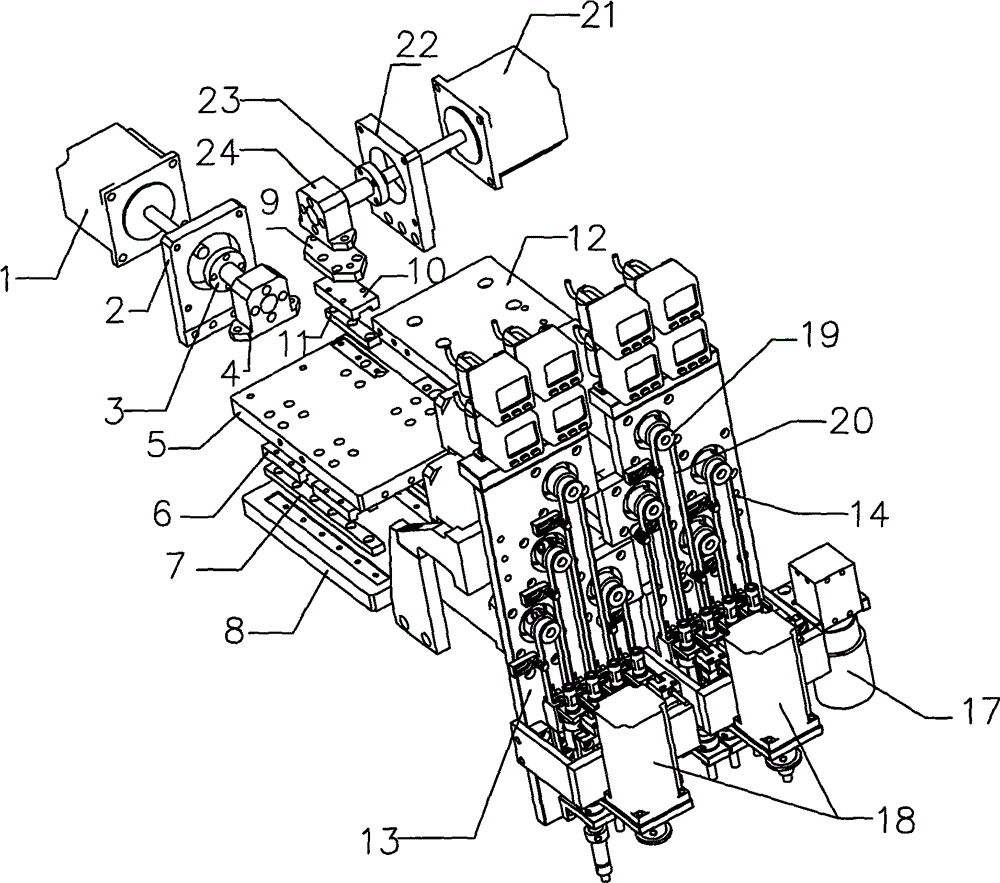

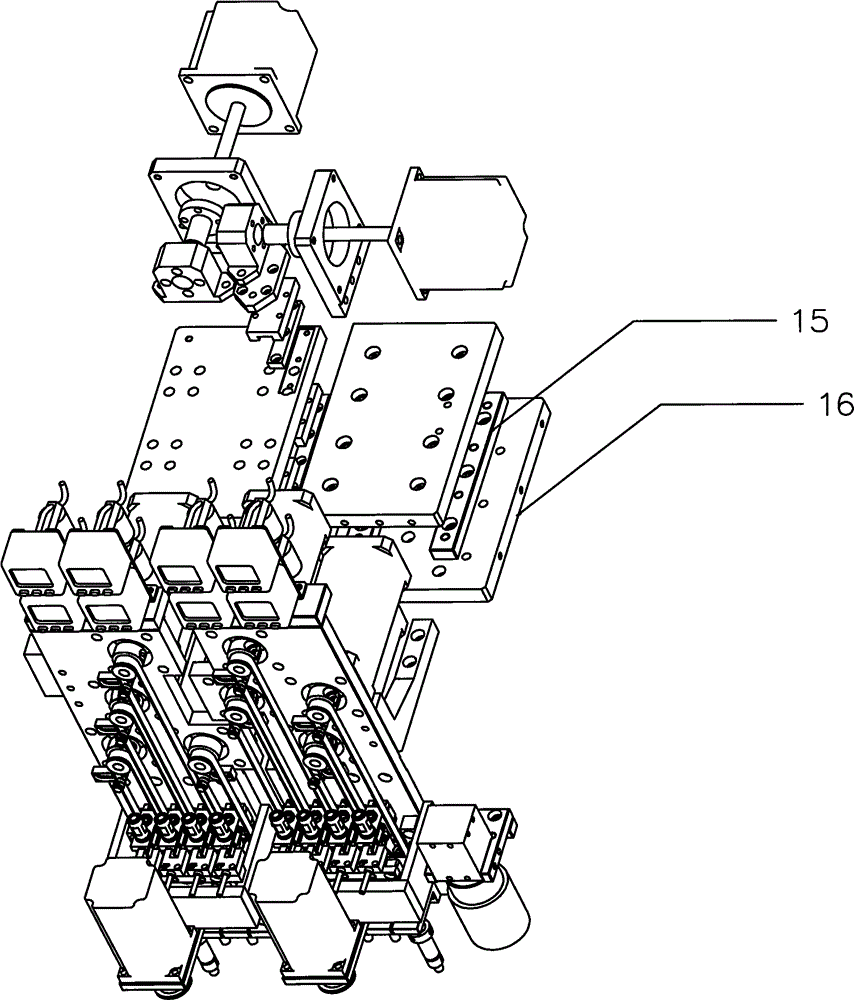

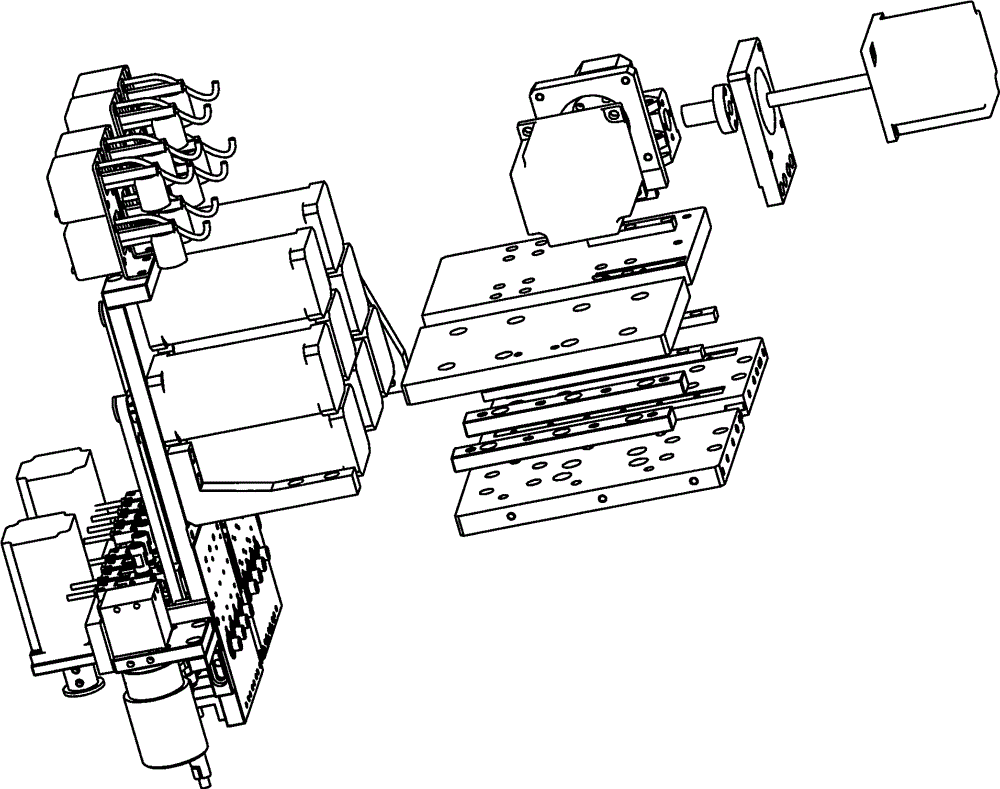

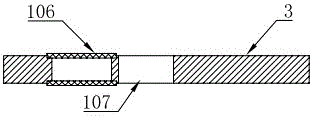

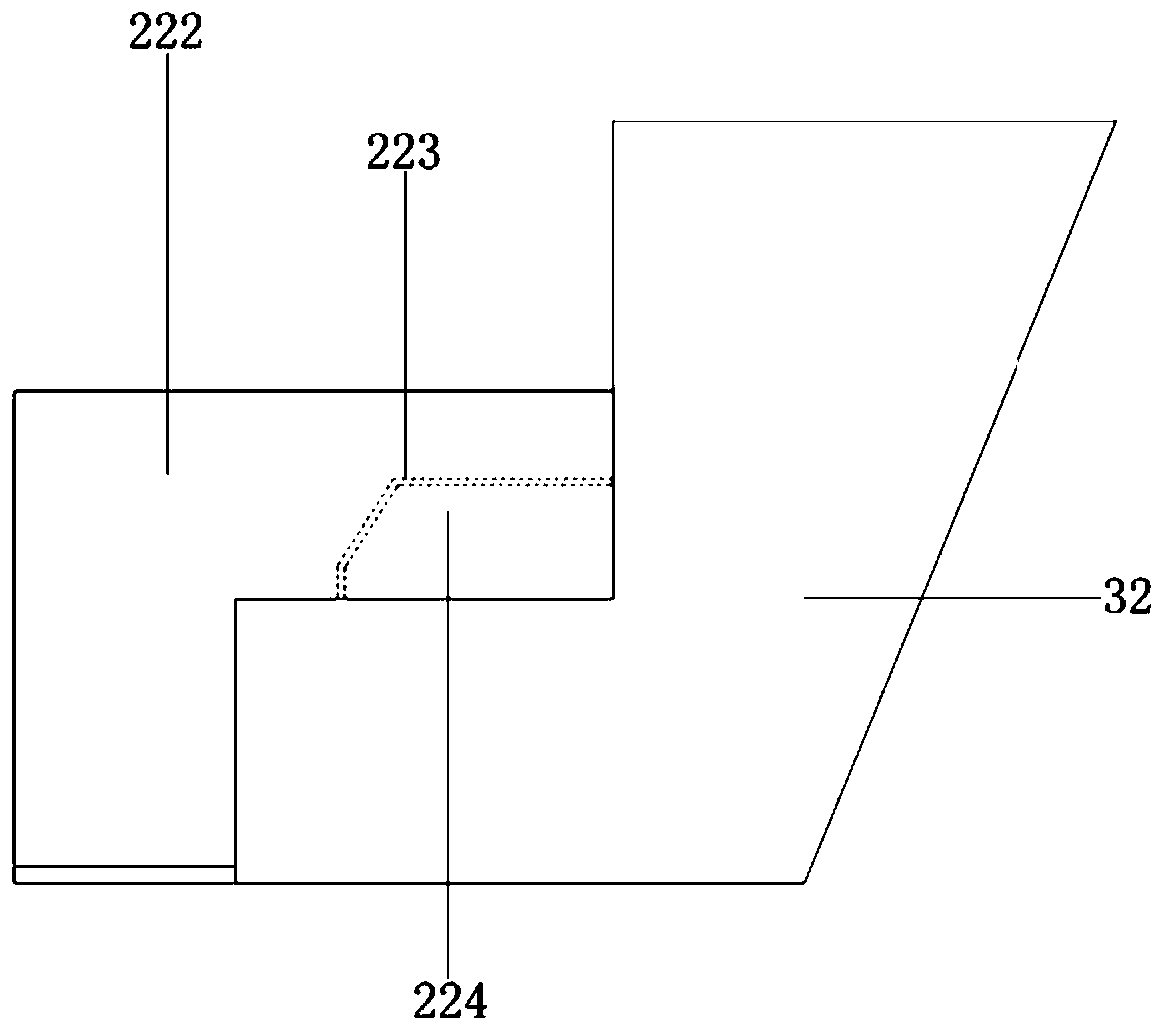

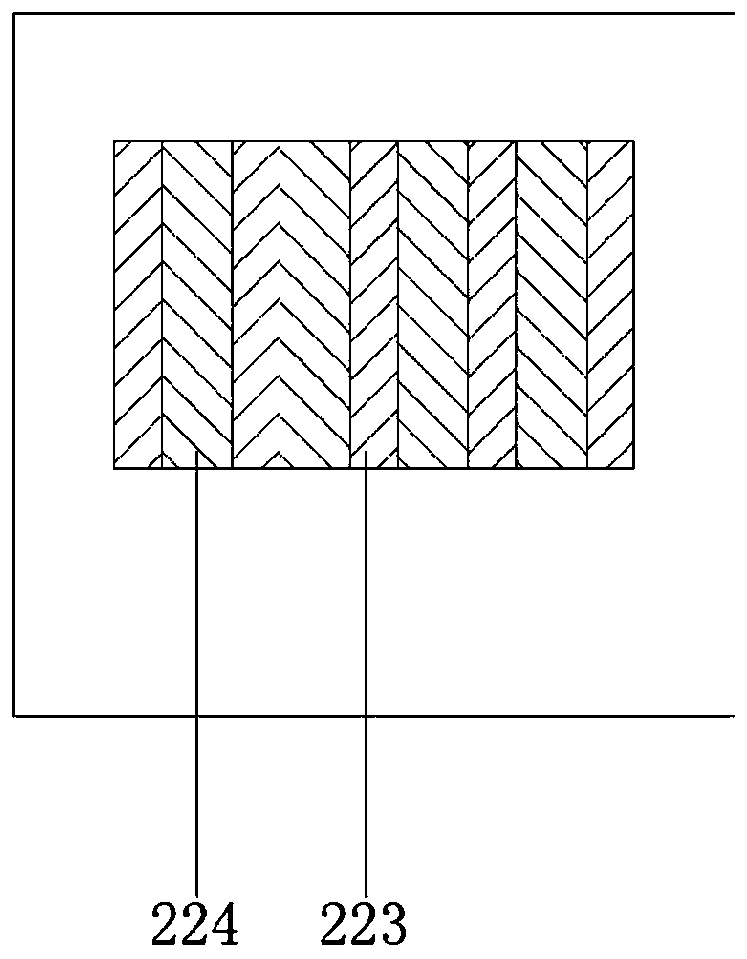

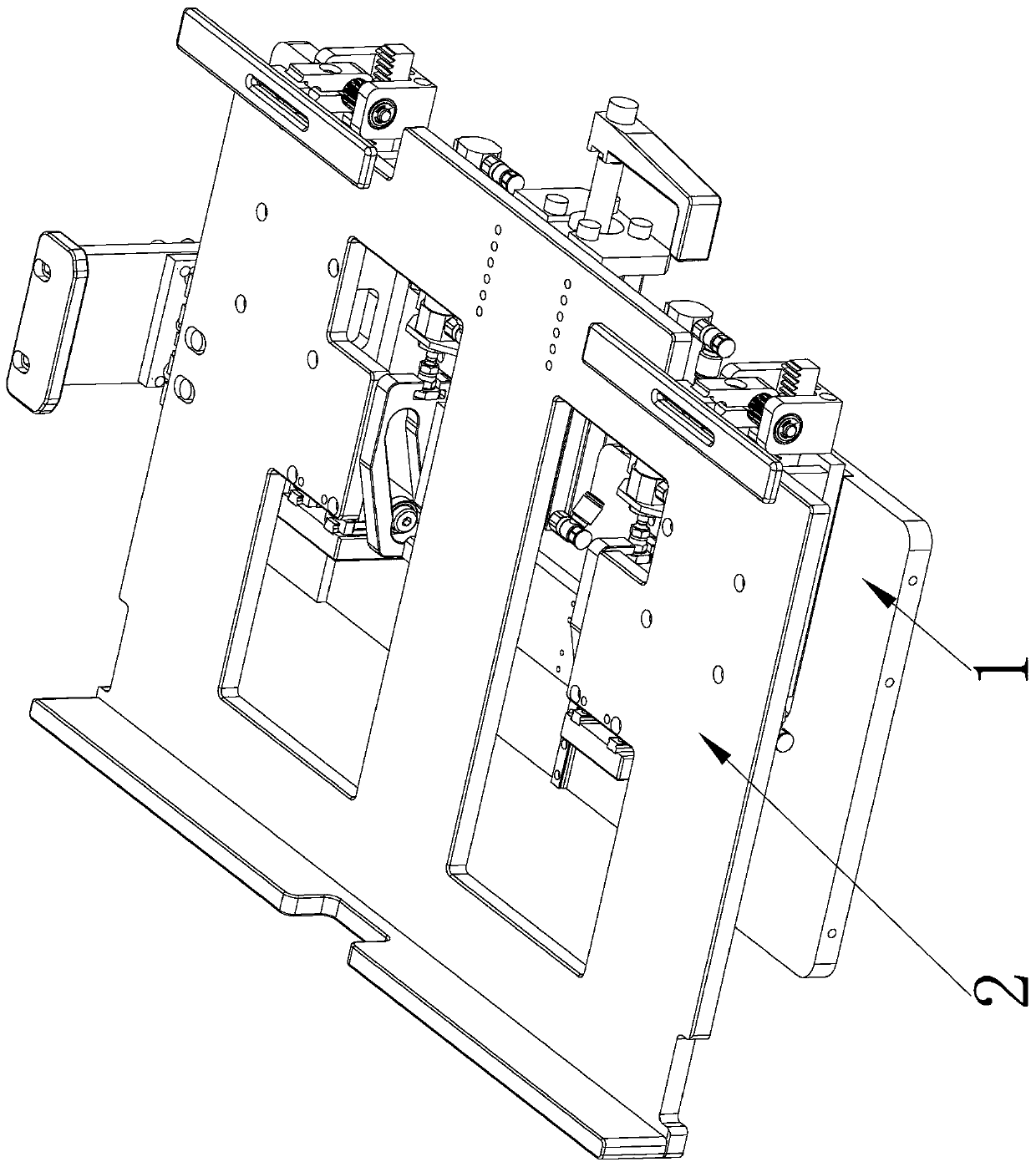

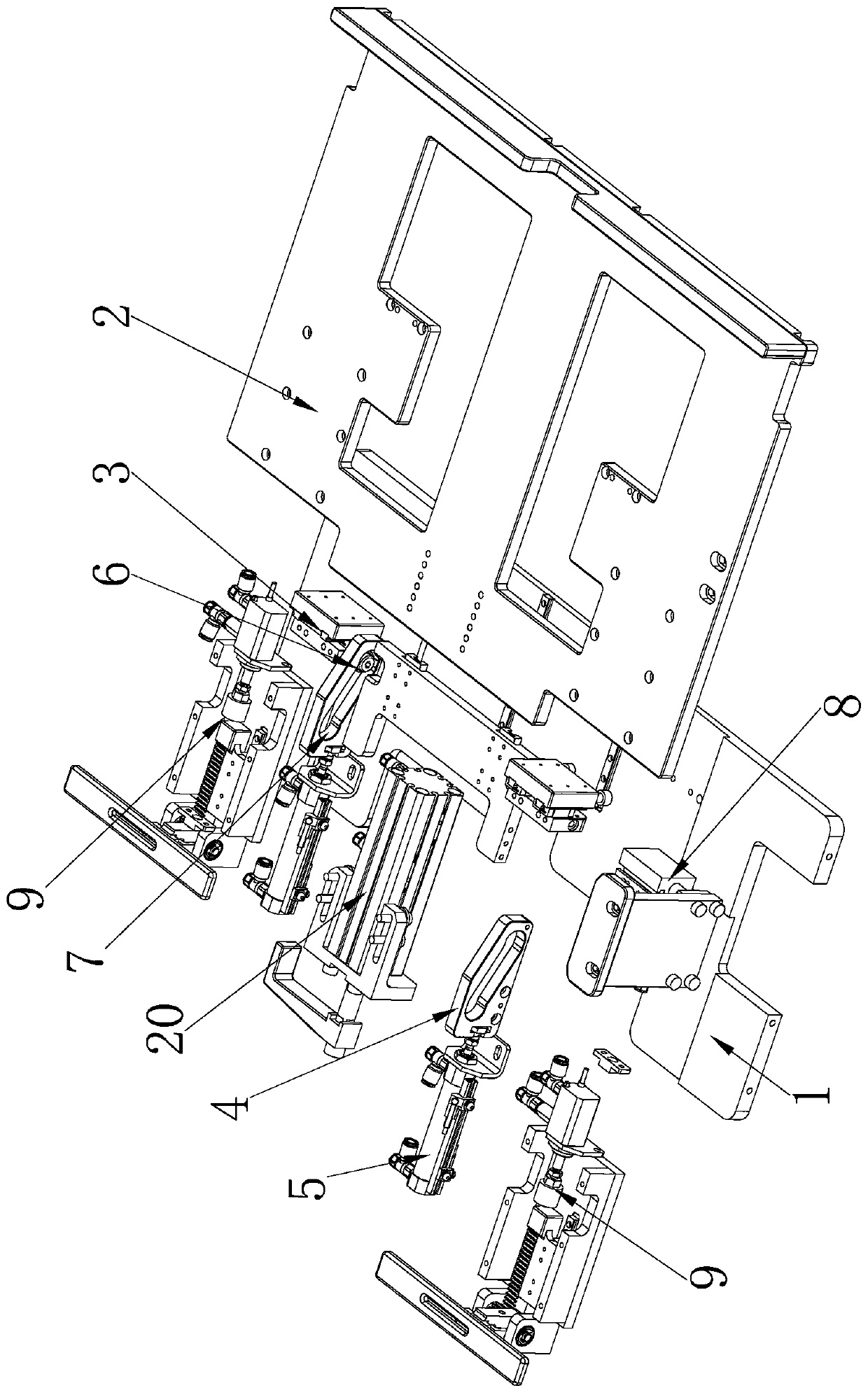

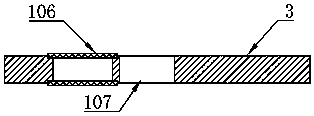

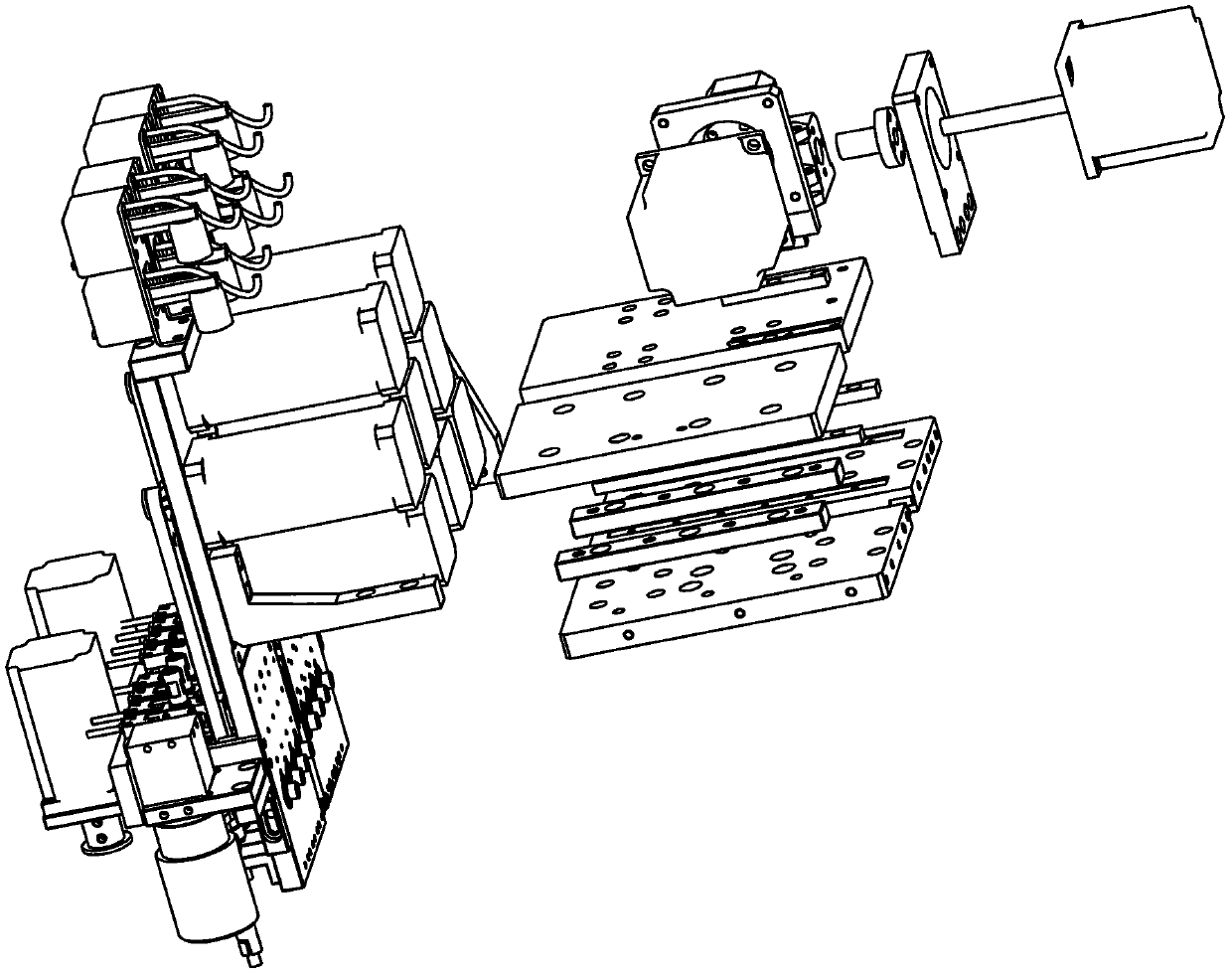

Unwinding mechanism

PendingCN111702032AHigh precisionQuality assuranceMetal-working feeding devicesMetal working apparatusStructural engineeringPole piece

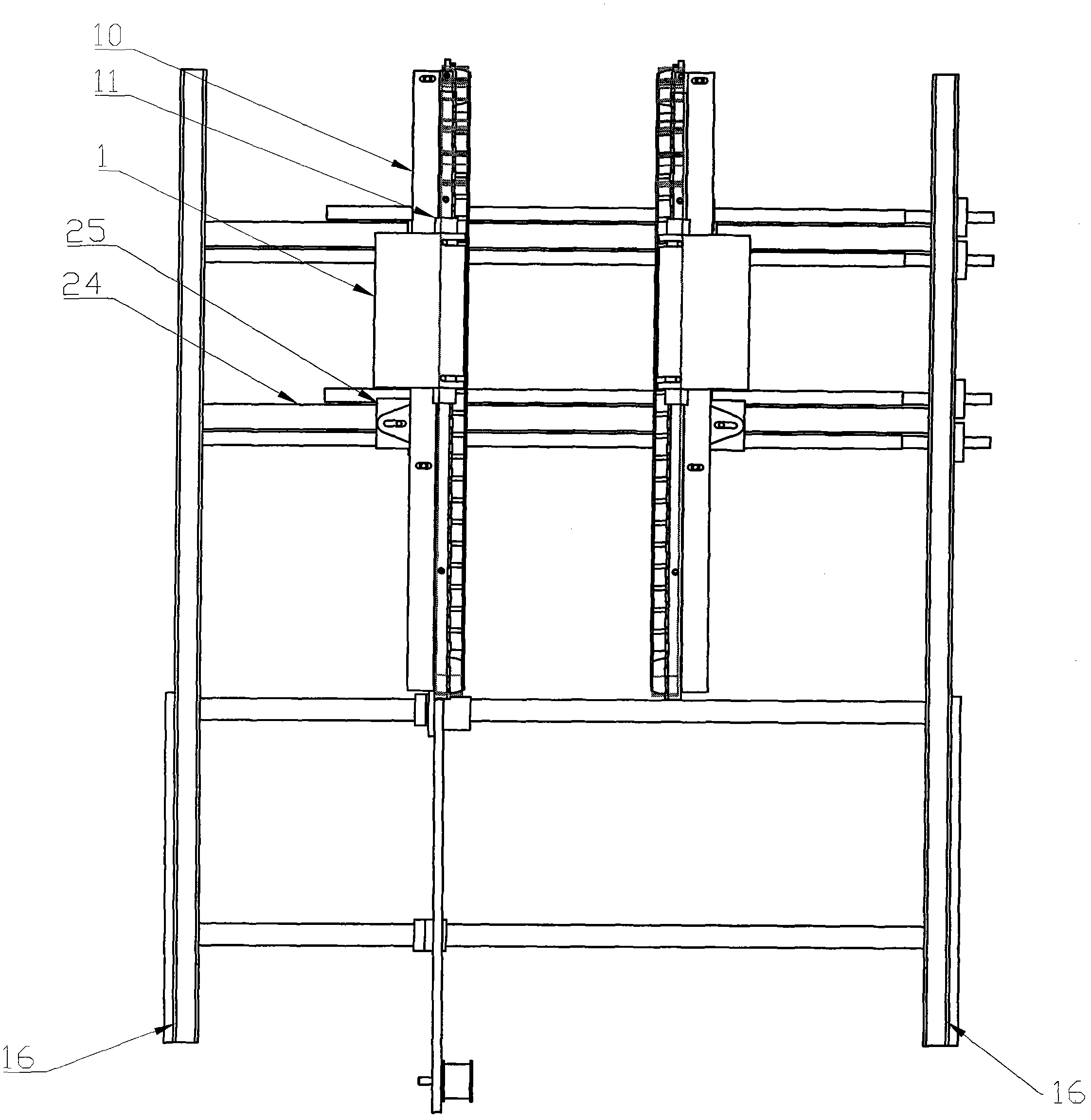

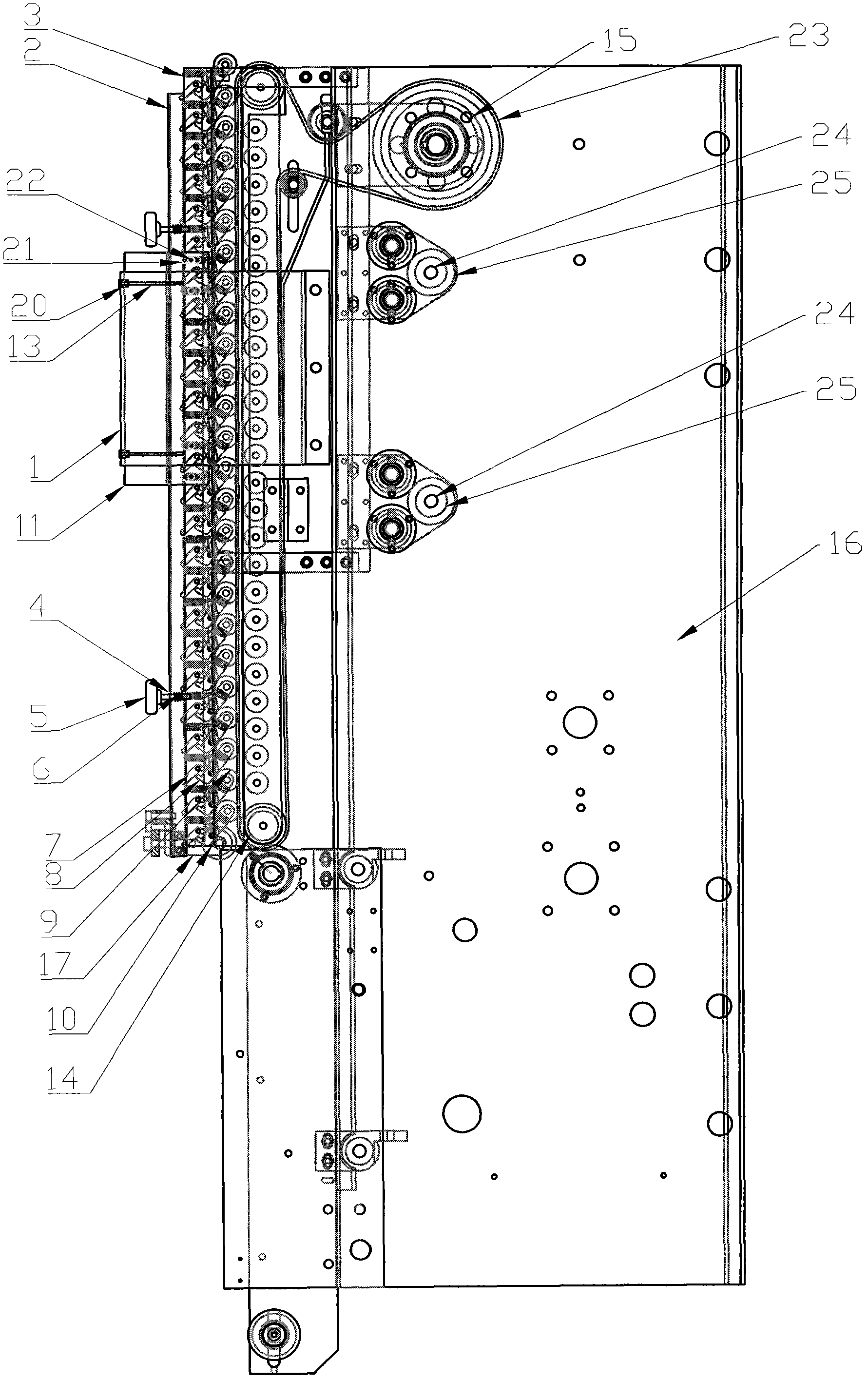

The invention discloses an unwinding mechanism, and belongs to the field of pole piece die-cutting machines. The unwinding mechanism comprises a large plate, an unwinding frame arranged on the large plate, an air expansion shaft connected to the unwinding frame in a sliding manner along the axis direction, and an unwinding assembly for driving the air expansion shaft to wind out a pole piece, theunwinding frame is provided with a first deviation rectifying device, a second deviation rectifying device and a third deviation rectifying device, and the pole piece is conveyed to a die cutting mechanism after being rectified by the first rectifying device, the second rectifying device and the third rectifying device in sequence. According to the unwinding mechanism, the problems that a two-stage deviation rectifying mechanism is adopted in a traditional die-cutting machine, due to the fact that part machining errors and assembly errors exist in a passing roller or a temporary storage roller, the position of the pole piece cannot be quite accurate before the pole piece enters a die, large deviation of the appearance size of a finished pole piece is caused, and risks of battery explosionand like are increased are solved.

Owner:JIANGSU KATOP AUTOMATION CO LTD

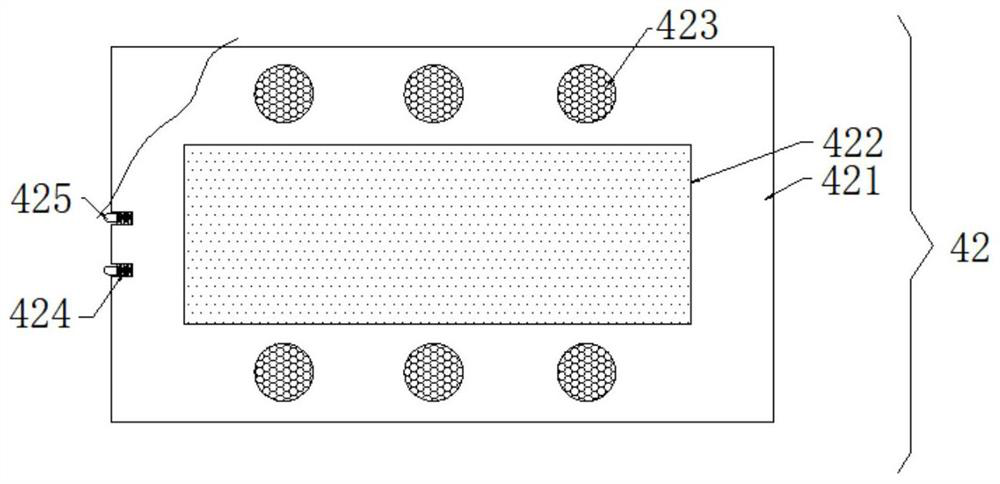

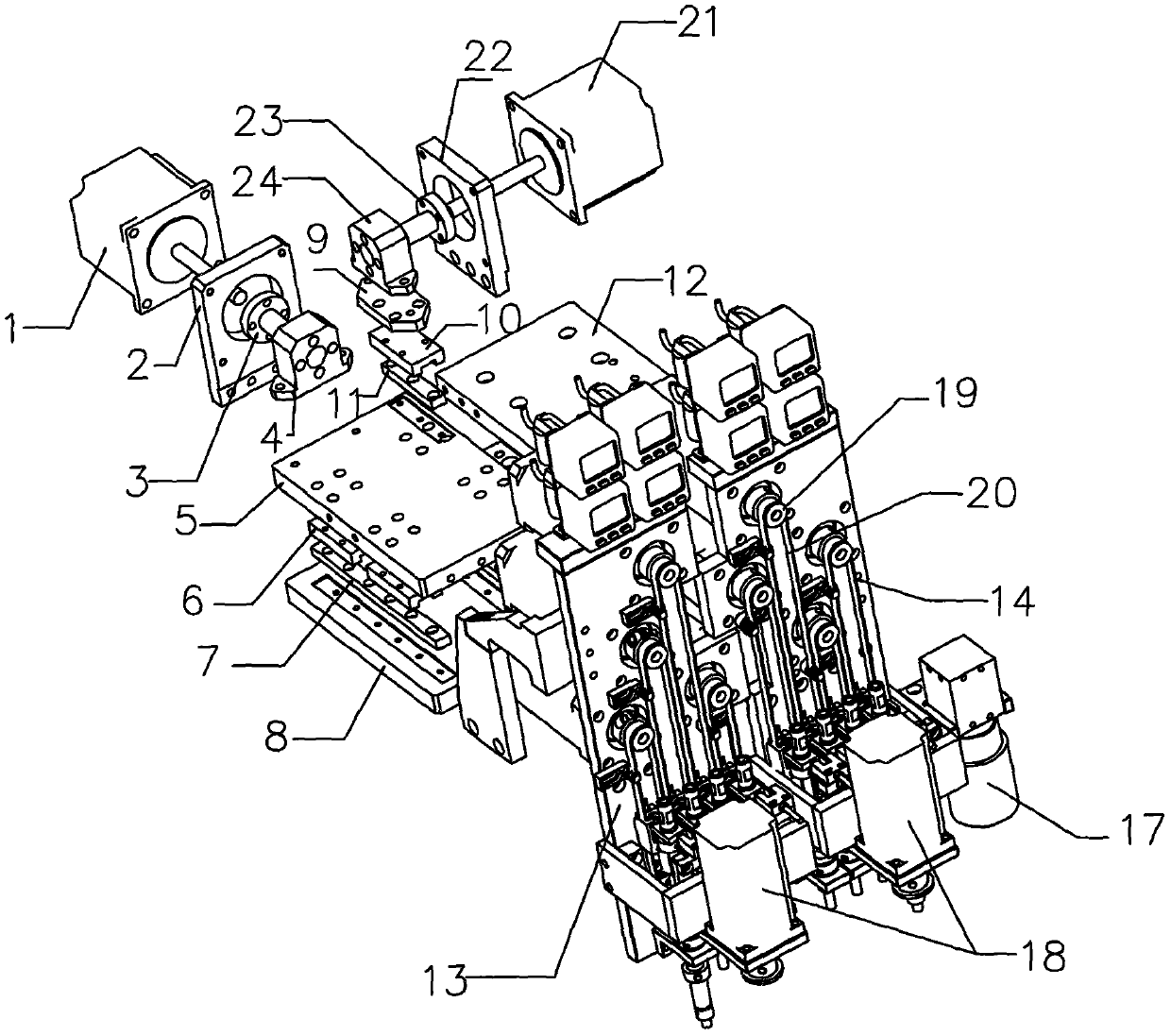

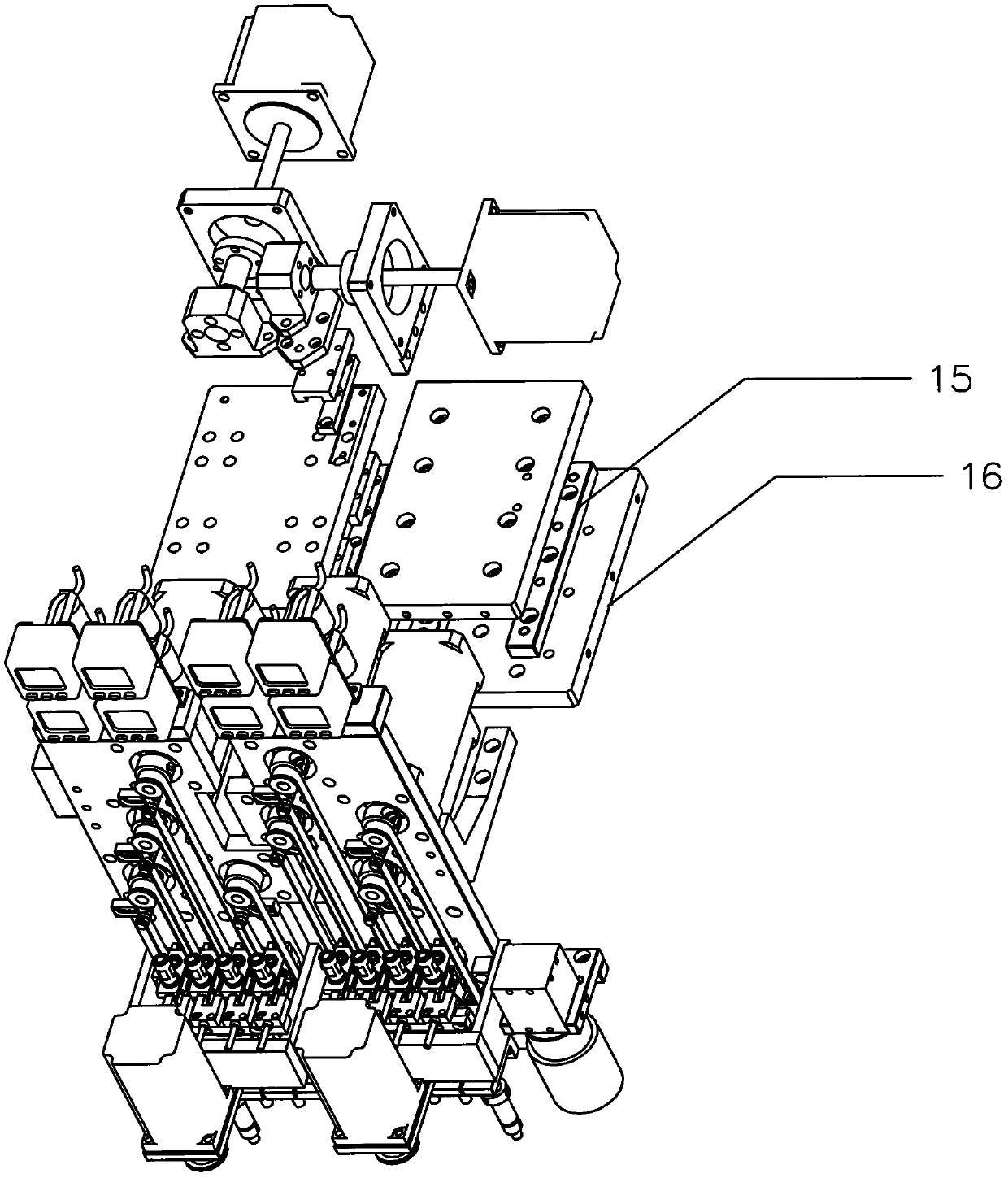

Circuit board locating device of LED chip mounter and mounting method thereof

InactiveCN104619126ATo achieve the corrective effectRealize automatic correction functionPrinted circuit assemblingDrive motorElectrical and Electronics engineering

The invention discloses a circuit board locating device of an LED chip mounter and a mounting method thereof. The circuit board locating device of the LED chip mounter comprises at least two groups of panel components, and each group of panel components is correspondingly connected with a group head; each group head is connected with a transverse drive motor for controlling the transverse move thereof; each two group heads are connected with a horizontal drive motor for controlling the horizontal space between the group heads. Because the circuit board locating device of the LED chip mounter uses the horizontal drive motor, transverse drive motor and at least two groups of group heads, the horizontal drive motor can regulate the space between two adjacent groups of group heads so as to enable the circuit board locating device to adapt to different distances of elements, and the circuit board locating device is capable of regulating the distance between two group heads to be corresponding to different distances between materials to perform chip mounting for the circuit board. The transverse drive motor is capable of transversely moving the group head to correct materials, for example, when materials on the panel are placed in a crooked state (one is located at the front while the other is located at the back), the materials can be corrected through the fine adjustment of the transverse drive motor.

Owner:SHENZHEN TONGLISHENG PHOTOELECTRIC EQUIP

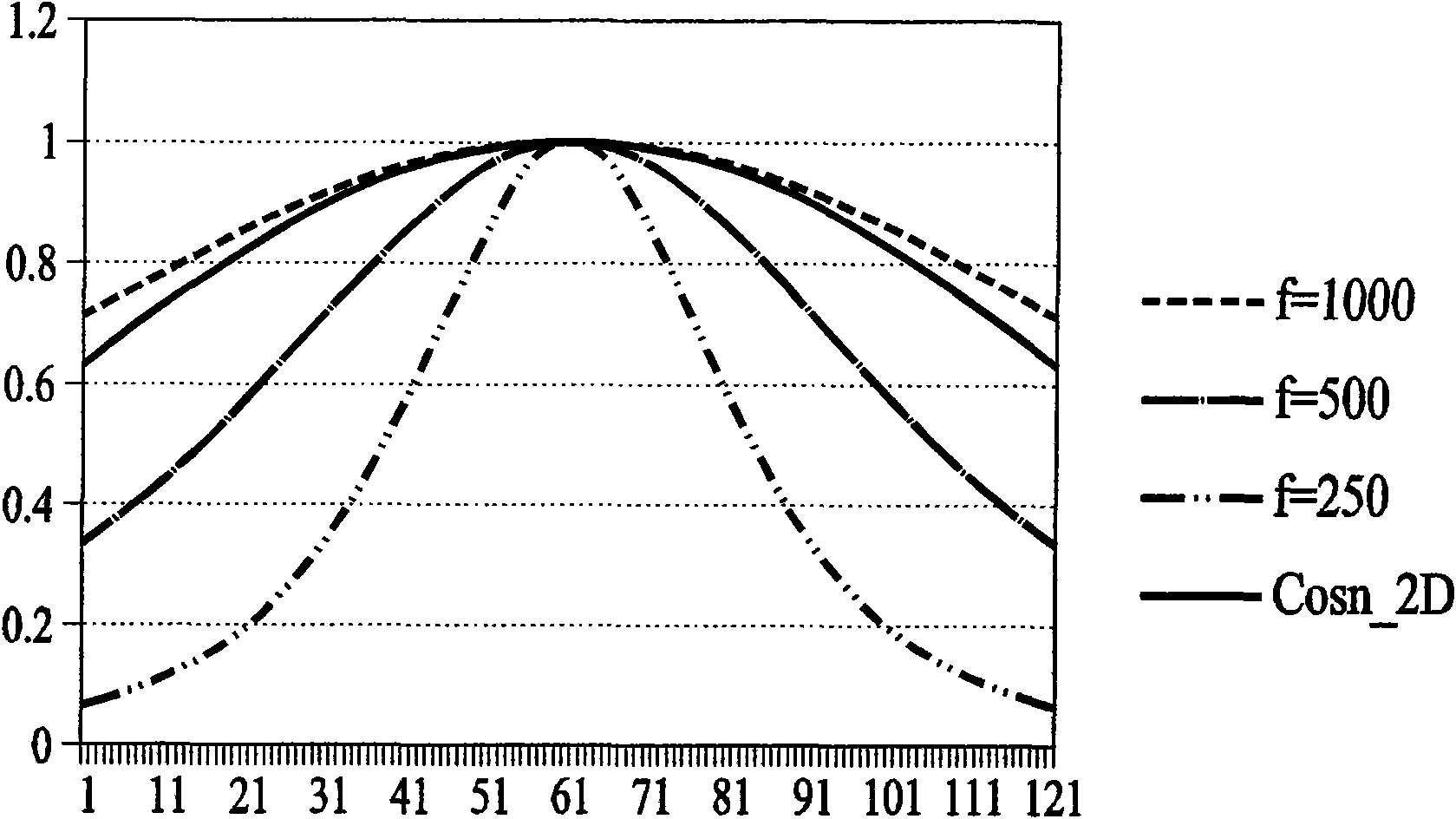

Luminance compensation method using multiwire interpolated lens

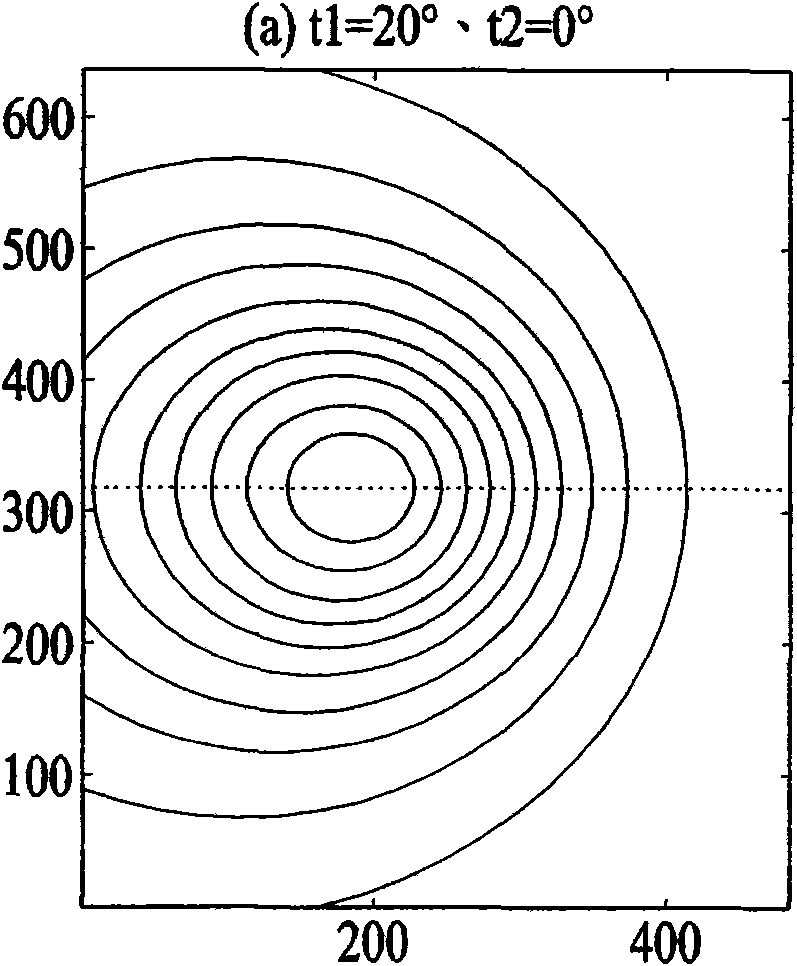

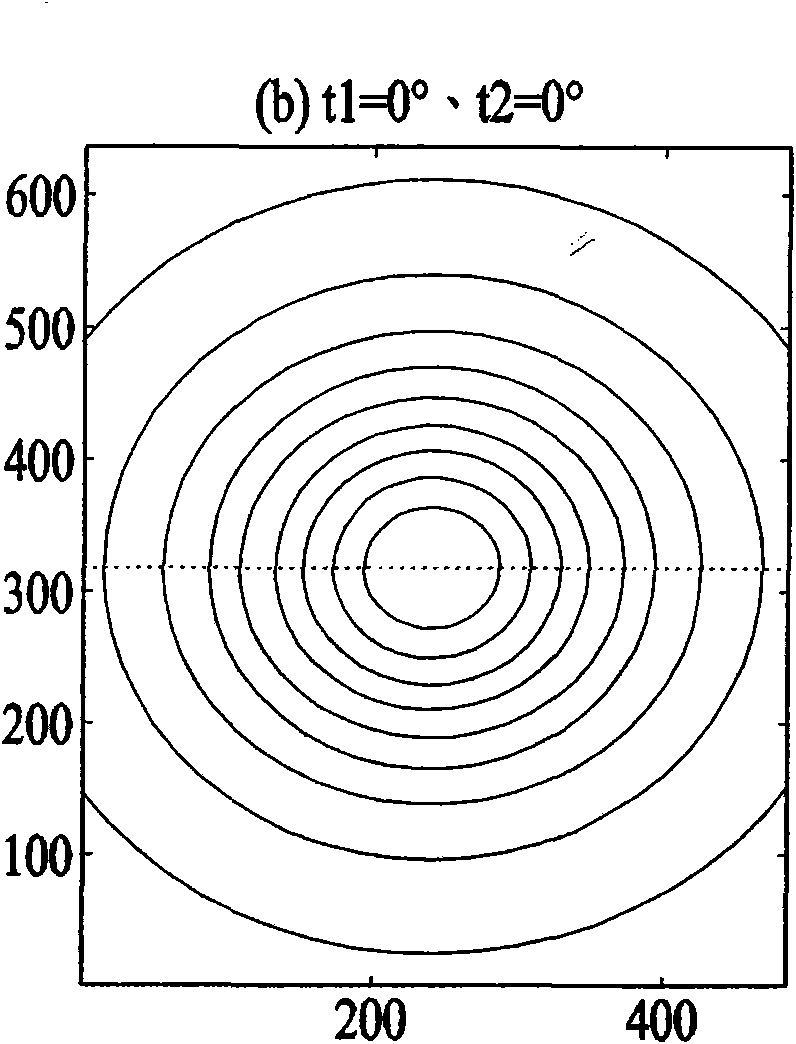

InactiveCN101873436ASimple designTo achieve the corrective effectTelevision system detailsColor television detailsCamera lensImage correction

The invention discloses a luminance compensation method using a multiwire interpolated lens, which mainly utilizes multiple radial directional lines designed on a lens curved surface, arranges a plurality of equidistant or non-equidistant sampling points on line in each direction, then judges luminance compensation target point positions, utilizes gradient to calculate adjacent directional lines, calculates corrected value and interpolation weight, and utilizes interpolation to restore the whole image correction plane. In a preferable embodiment, the mode for calculating the corrected value can be that polynomial equations of two directional lines are utilized to obtain two corrected values with bi-directional on-line same radius distance, or a table lookup is utilized to obtain two corrected values of bi-directional on-line same radius position, thus the symmetrical lens compensation or non-symmetrical lens compensation is performed on the camera lens.

Owner:SERVICE & QUALITY TECHNOLOGY CO LTD

Zero-pollution conveying system of spray coater

PendingCN107857088AClean in timeKeep surfaces cleanConveyorsCleaningSpray coatingEnvironmental engineering

The invention relates to a zero-pollution conveying system of a spray coater. The zero-pollution conveying system of the spray coater comprises a spray coating chamber and a conveying group. The conveying group sequentially penetrates through a feed end, an inner cavity and a discharge end of the spray coating chamber, and comprises a front conveying mechanism, a middle conveying mechanism and a rear conveying mechanism; the front conveying mechanism is exposed on the feed end of the spray coating chamber; the middle conveying mechanism is arranged in an inner cavity of the spray coating chamber; the rear conveying chamber is exposed on the discharge end of the spray coating chamber; conveying surfaces of the front conveying mechanism, the middle conveying mechanism and the rear conveyingmechanism are on the same plane at least during work; the front conveying mechanism and / or the rear conveying mechanism are hinged with the spray coating chamber; a conveyor belt cleaning mechanism for cleaning the middle conveying mechanism is arranged under the middle conveying mechanism, and is integrally and slidably arranged on the spray coating chamber; and the conveyor belt cleaning mechanism is exposed on the feed end or the discharge end of the spray coating chamber when sliding to a certain position. The zero-pollution conveying system of the spray coater provided by the invention can be used for cleaning a conveyor belt and recovering a coating in time, and is convenient to maintain daily, reliable in performance and cost-saving.

Owner:GUANGDONG SHUNDE DIFENG MACHINE CO LTD

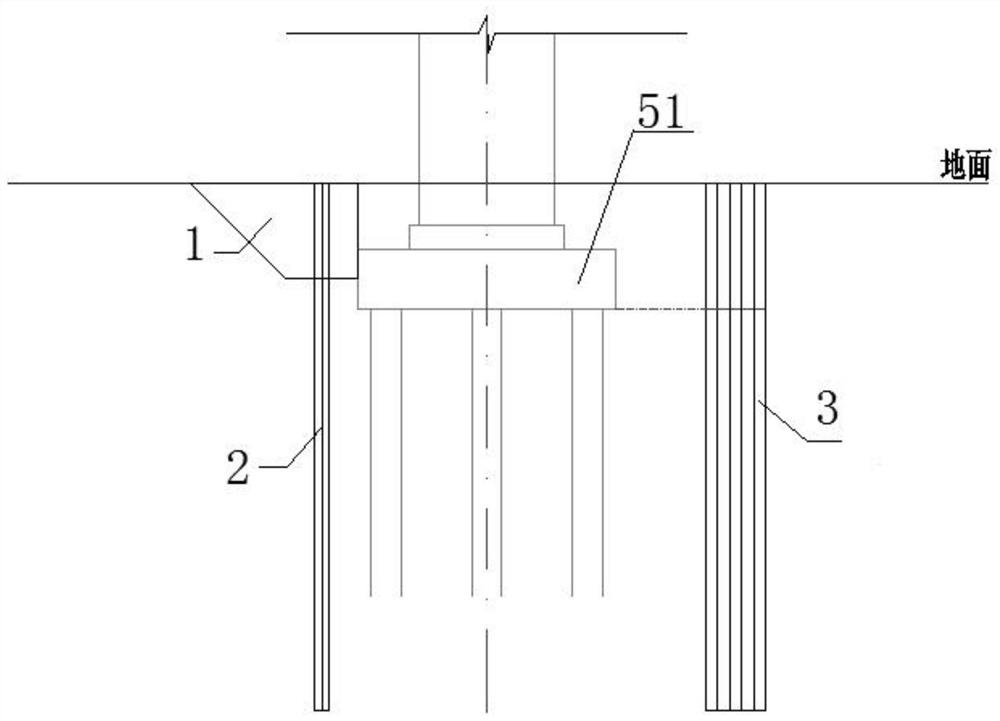

Real-time feedback grouting method for correcting horizontal deformation of subway tunnel

InactiveCN110106883AExcellent grouting correction effectAvoid Excessive Correction SituationsFoundation testingUsing optical meansSlagSleeve valve

The invention discloses a real-time feedback grouting method for correcting horizontal deformation of a subway tunnel. The real-time feedback grouting method comprises the steps that (1) a cement-soilmixing wall made of improved materials is arranged on one side in the opposite direction of a sleeve valve pipe-tunnel; (2) sleeve valve pipes are pre-embedded in the adjacent side of a deformed tunnel; (3) a real-time monitoring device is installed on the tunnel section, and tunnel deformation is fed back in real time in the grouting process; and (4) grouting construction is carried out, grouting parameters are adjusted in real time based on measured data. According to the real-time feedback grouting method for correcting the horizontal deformation of the subway tunnel, the deformation of the target tunnel is monitored and fed back in real time, the grouting construction parameters can be adjusted in real time, and the purpose of accurately correcting the deformation of the tunnel is achieved by cooperatively using novel double-liquid slurry with added sodium silicate. Meanwhile, a one-sided slag-fly ash cement-soil mixing wall is adopted to control the direction of slurry action, and a grouting deformation control effect is fed back to the greatest extent.

Owner:TIANJIN UNIV

Building jacking system and jacking method of building jacking system

ActiveCN104989122AChange verticalityTo achieve the corrective effectBuilding repairsHorizontal forceArchitectural engineering

The invention discloses a building jacking system and a jacking method of the building jacking system. A horizontal direction displacement deviation correcting device is arranged between a distribution beam and a jack; when a building generates horizontal direction deviation in the jacking process, a wedge-shaped deviation correcting plate is added and plugged through the deviation correcting device and is used for changing the perpendicularity degree of the jack, so that the horizontal force which is controllable in the horizontal direction is formed; the opposite horizontal force is exerted for the horizontal force causing the deviation of the building, so that the horizontal displacement of the building is changed due to the change of the horizontal force; the deviation correcting effect is finally achieved; and the safety and the reliability of the jacking process are ensured.

Owner:上海天演建筑物移位工程股份有限公司

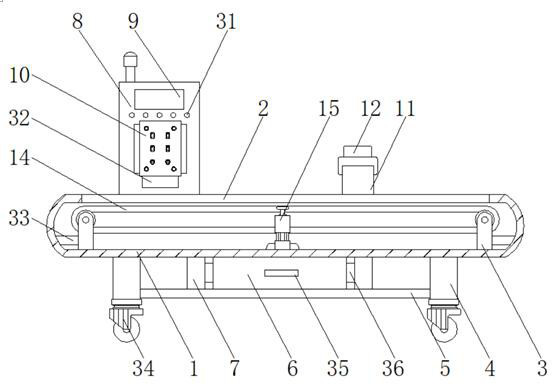

Conveying belt for food logistics carrying

InactiveCN112047008AEasy to controlEasy to understandConveyorsControl devices for conveyorsLogistics managementLap joint

The invention belongs to the technical field of logistics, and particularly relates to a conveying belt for food logistics carrying. The belt comprises a conveying box, wherein a through opening is provided in the upper surface of the conveying box, two symmetrical supporting plates are fixedly connected to the inner bottom wall of the conveying box, symmetrical supporting legs are fixedly connected to the bottom face of the conveying box, the side faces, close to each other, of the two supporting legs are jointly and fixedly connected to a carrier plate, a storage frame is placed on the uppersurface of the carrier plate, and symmetrical positioning blocks are fixedly connected to the upper surface of the carrier plate. According to the conveying belt, through cooperation of a display screen with a code scanning mechanism, goods below the code scanning mechanism can be displayed in the display screen, the effect that an operator checks logistics information is achieved, the problem that manual code scanning is always adopted on the goods during code scanning and is very troublesome is solved, the effect of correcting the conveying belt is achieved, and the problems that the conveying belt is prone to deviating after long-time work, the goods are caused to be damaged, and a lap joint position is caused to be cracked are solved.

Owner:湖南聚味堂食品有限公司

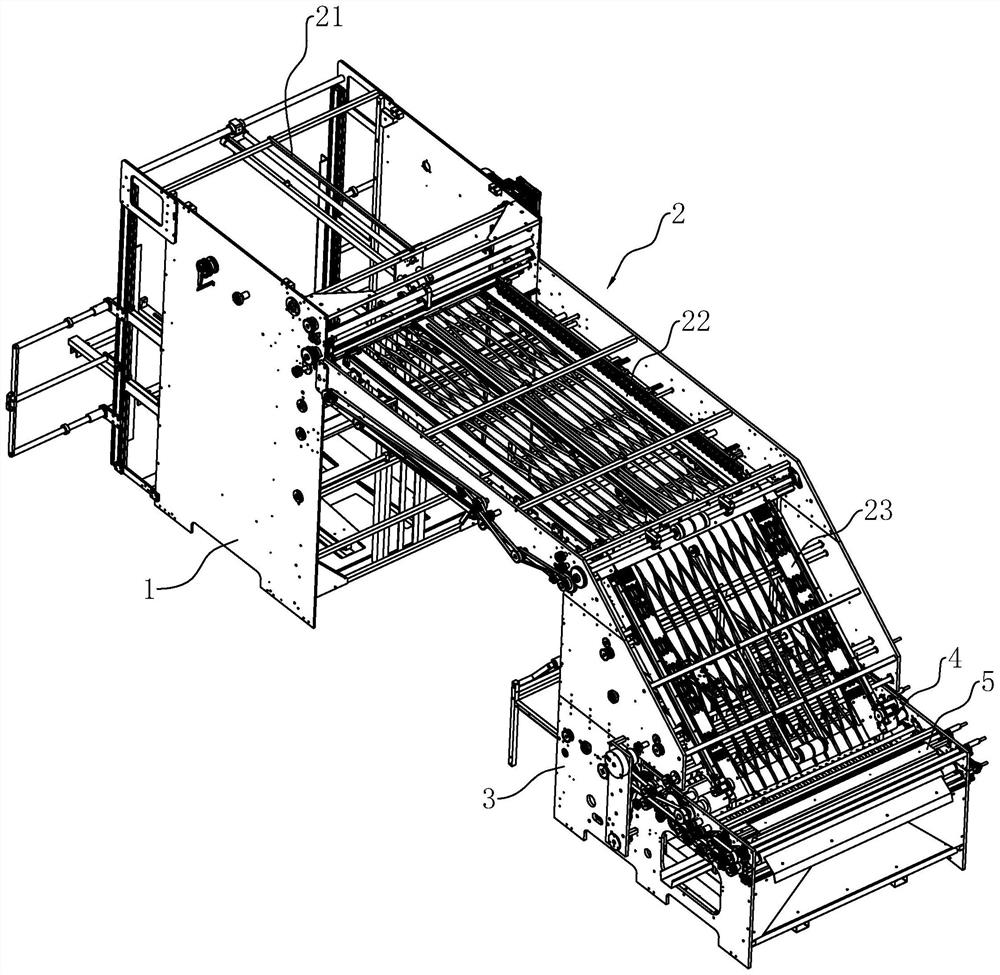

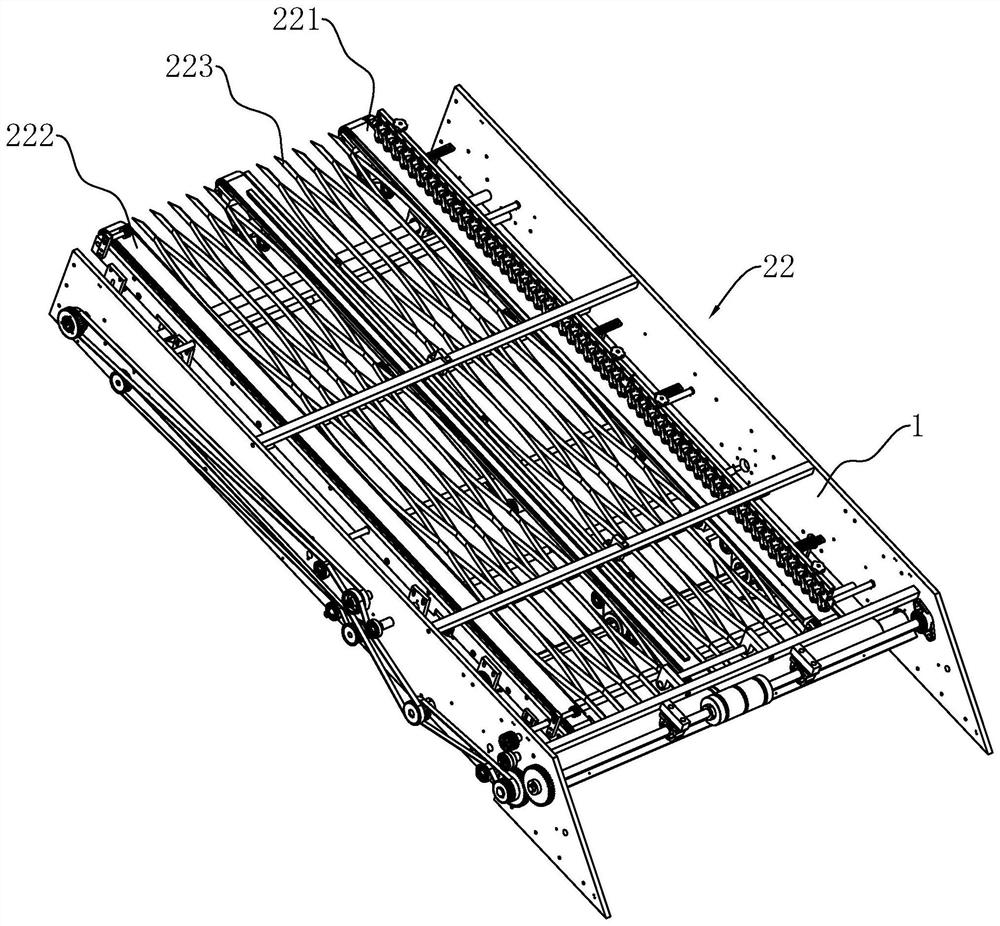

Surface paper conveying mechanism of paper mounting machine and paper mounting machine thereof

PendingCN113753622AImprove flush fitImprove production qualityMechanical working/deformationPaperhangingPaper sheetEngineering

The invention relates to a surface paper conveying mechanism of a paper mounting machine and the paper mounting machine thereof. The surface paper conveying mechanism comprises a rack, a surface paper conveying mechanism, a bottom paper conveying mechanism, a gluing mechanism and a pressing mechanism, wherein the surface paper conveying mechanism comprises an automatic surface paper feeding device, a surface paper deviation correcting device and a surface paper inclined conveying device, the surface paper deviation correcting device comprises a surface paper deviation correcting belt assembly, a conveying belt assembly, a deviation correcting support and deviation correcting guide wheels, the multiple deviation correcting guide wheels are sequentially arranged on the deviation correcting support to form a driven conveying part, the conveying direction of the surface paper deviation correcting belt assembly is inclined relative to the conveying direction of the conveying belt assembly, the conveying direction of the conveying surface is inclined relative to the conveying direction of the conveying belt assembly, the driven conveying part is gradually inclined inwards in the conveying direction of the driven conveying part, and the inclination direction of the surface paper deviation correcting belt assembly is opposite to the inclination direction of the driven conveying part. The surface paper conveying mechanism has the advantages that paper can be conveniently rectified and prevented from deviating, and therefore the paper mounting production quality is improved.

Owner:WENZHOU GUDE PRINTING MACHINERY

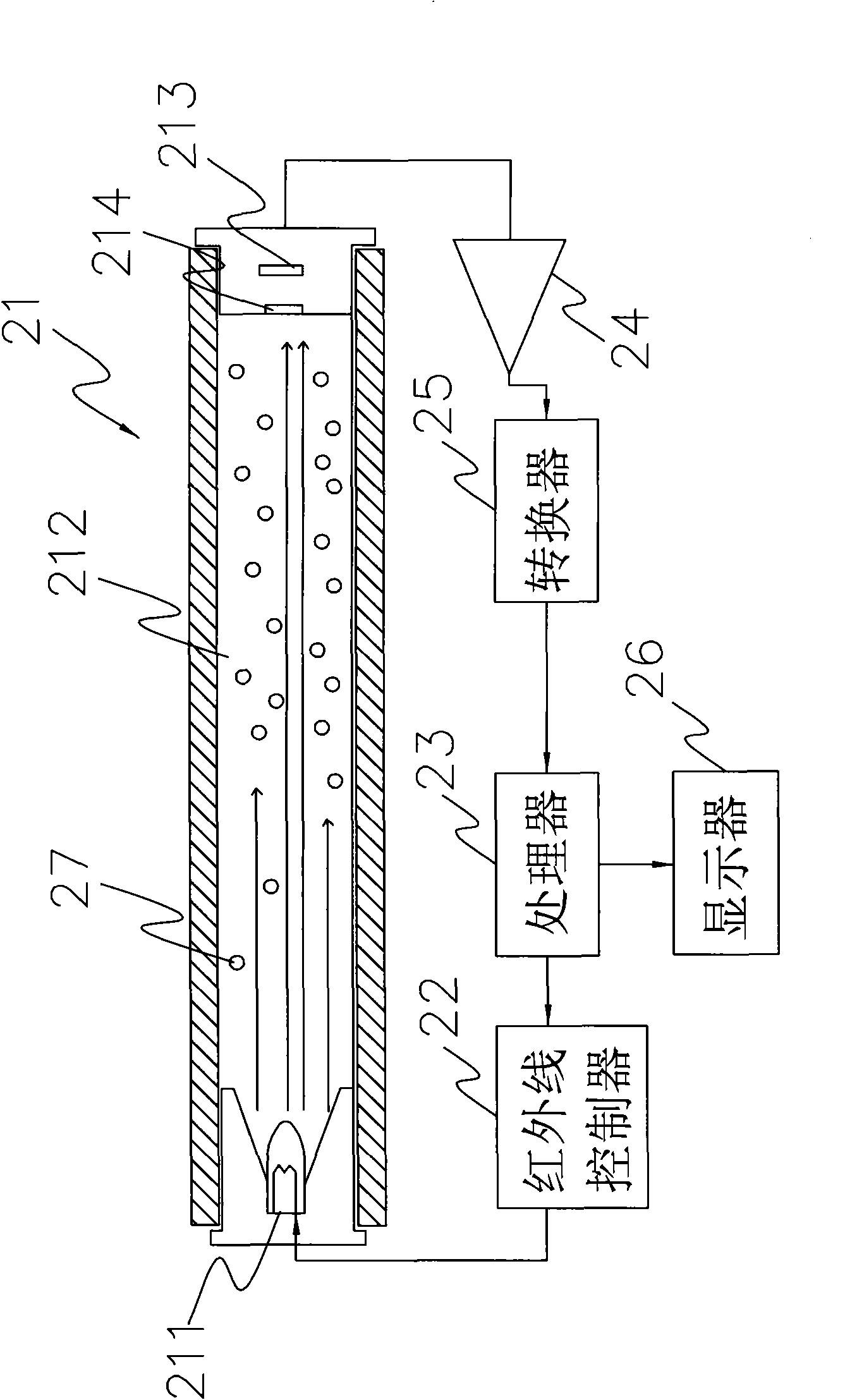

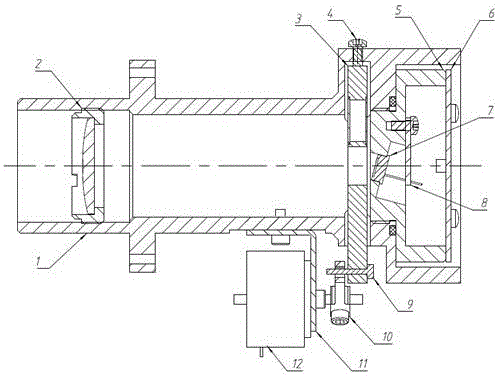

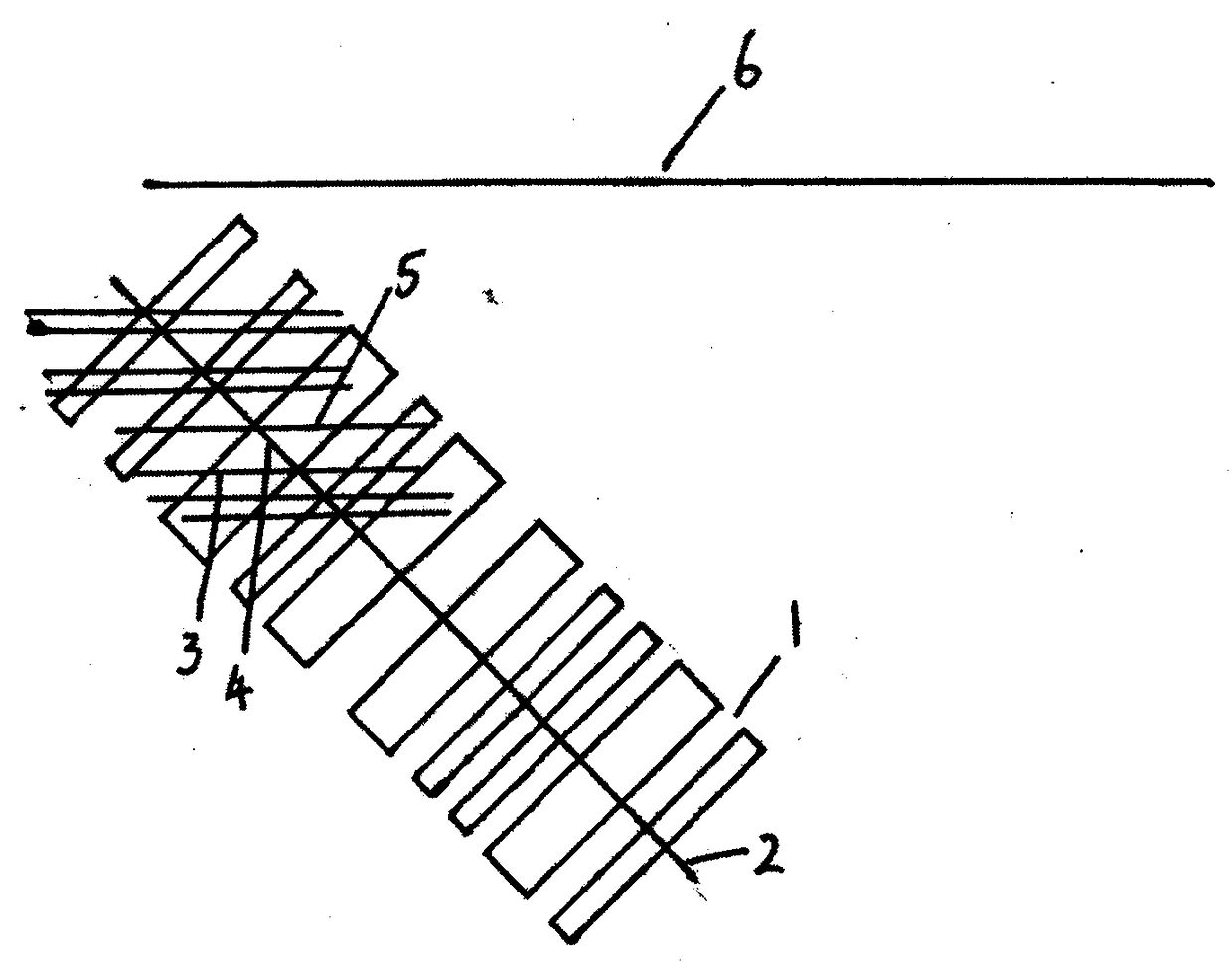

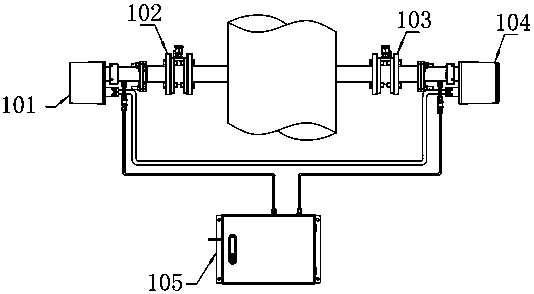

In-situ laser gas analyzer with on-line deviation correction device

ActiveCN106018340AGood effectDoes not affect normal measurementColor/spectral properties measurementsSynchronous motorEngineering

The invention relates to an in-situ laser gas analyzer with an on-line deviation correction device. The in-situ laser gas analyzer comprises a transmitting unit, a receiving unit, a transmitting unit connecting piece, a receiving unit connecting piece and a purging unit; the receiving unit comprises the automatic deviation correction device; the purging unit is provided with a shell with a rainproof function, and a voltage stabilizing and flow controlling device is arranged in the shell; the automatic deviation correction device comprises a receiving installation seat, a lens device, a synchronous motor, a sensor module and a reference gas chamber, the synchronous motor achieves automatic switching of the reference gas chamber in an optical path through software controlling, second harmonic gas can be detected by the laser gas analyzer when the reference gas chamber is sealed, and then the deviation effect is achieved. The laser gas analyzer is simple in structure and high in reliability, and the condition that on a user site, the second harmonic gas is found, and standard gas is introduced is avoided.

Owner:HANGZHOU CHUNLAI TECH

Mining wind speed sensor and correction method thereof

InactiveCN110907659AInstallation suspension position is not restrictedOptimize locationTesting/calibration of speed/acceleration/shock measurement devicesFluid speed measurementAir velocityMechanical engineering

The invention discloses a mining wind speed sensor and a correction method thereof. The sensor comprises a mounting barrel, a wind speed sensor main body is arranged in the mounting cylinder; a rotating rod is arranged on the lower end surface of the wind speed sensor main body; a first mounting plate is arranged at the lower end of the rotating rod; a wind cup part is arranged on the first mounting plate. In the mining wind speed sensor and the correction method thereof, a reinforcing rib, a locking nut, a correction box and the like are arranged; the mounting and hanging positions of the mining wind speed sensor are not limited; the wind speed sensor can be conveniently corrected; the measuring accuracy effect is improved, the problems in the prior art that the support is simple in structure, it cannot guarantee that the installation and suspension positions of the wind speed sensor are not limited, and the sensor needs to be corrected to improve the measurement precision, is disassembled and maintained at present, is sent to a laboratory for correction, and is very troublesome in practice are solved.

Owner:NORTH CHINA INST OF SCI & TECH

Stamping die with in-die tapping deviation rectifying structure and deviation rectifying method

PendingCN110523847AHold down firmlyGuaranteed accuracyShaping toolsThread cutting machinesFuselageNotching

The invention provides a stamping die with an in-die tapping deviation rectifying structure. The stamping die comprises: an upper die mechanism, wherein the bottom of a material belt positioning and adjusting block is provided with a positioning notch for pressing a material belt, the positioning notch is internally provided with an elastic step face used for adjusting the downward pressure of thematerial belt positioning and adjusting block, and a tapping head of a tapping machine is located between every two adjacent floating material pressing mechanisms; a lower die mechanism, wherein notches are further machined in the two opposite ends of a lower base plate, movable L-shaped positioning adjusting blocks are installed in the notches, a machine body of the tapping machine is positionedin the notches, comb tooth structures are machined in steps of the L-shaped positioning adjusting blocks, comb tooth inserts are arranged on the machine body, and the comb tooth inserts and the combtooth structures are meshed with each other. The invention further provides a deviation rectifying method. Compared with the prior art, the problems of missing tapping, tooth hole deviation, incomplete tapping and the like of tapping in an inner die of an existing stamping die can be effectively solved, and especially the phenomena of tooth hole deviation and tooth hole burning are avoided.

Owner:深圳数码模汽车技术有限公司

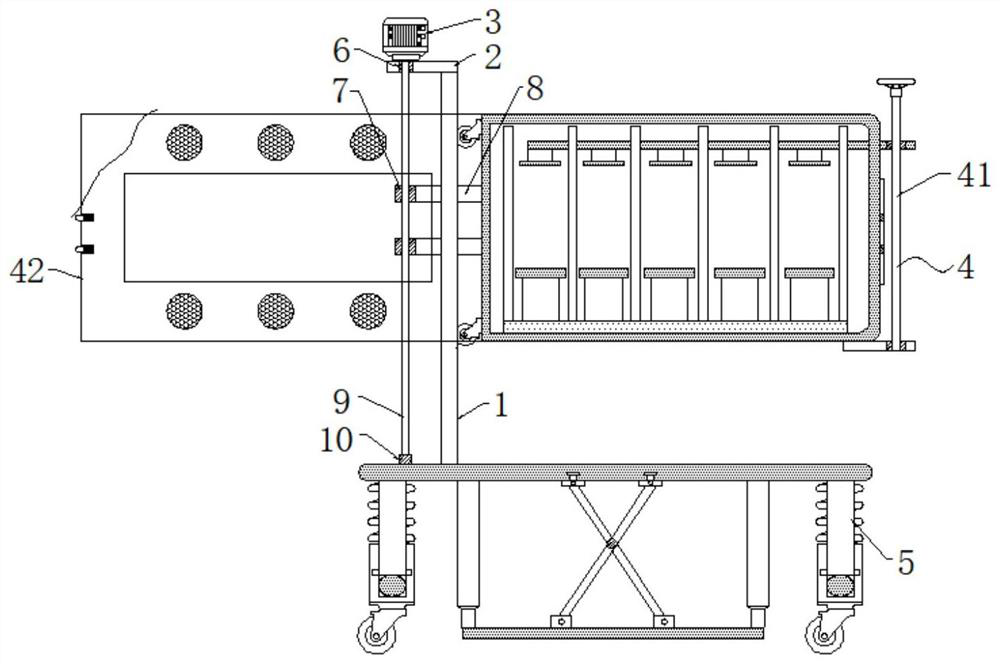

Photoelectric sensor transportation device suitable for uneven road sections and using method

InactiveCN112340201AImprove shipping efficiencyGuaranteed stabilityNon-rotating vibration suppressionCastorsElectric machineryStructural engineering

The invention discloses a photoelectric sensor transportation device suitable for uneven road sections and a using method, and belongs to the technical field of photoelectric sensors. The photoelectric sensor transportation device comprises a vertical plate, a transverse plate is fixedly connected to the top of the vertical plate, a gear motor is connected to the top of the transverse plate, and ascrew rod is arranged on the gear motor; a mounting hole is longitudinally formed at the top of the transverse plate in a penetrating manner, a first bearing matched with the screw rod is fixedly connected to an inner cavity of the mounting hole, the periphery of the screw rod is sleeved with a plurality of sets of first threaded sleeves, and a transportation bottom plate is arranged at the bottom of the vertical plate; and the photoelectric sensor transportation device can conduct damping and buffering treatment on jolt generated in the transportation process, so that it is guaranteed that aphotoelectric sensor is not damaged by jolt vibration in the transportation process, the service life of the photoelectric sensor is prolonged, meanwhile, the photoelectric sensor transportation device can conduct clamping and fixing treatment on the photoelectric sensor in the transportation process, and the photoelectric sensor is prevented from sliding in the transportation process and being collided and damaged, so that the photoelectric sensor is protected.

Owner:朱小松

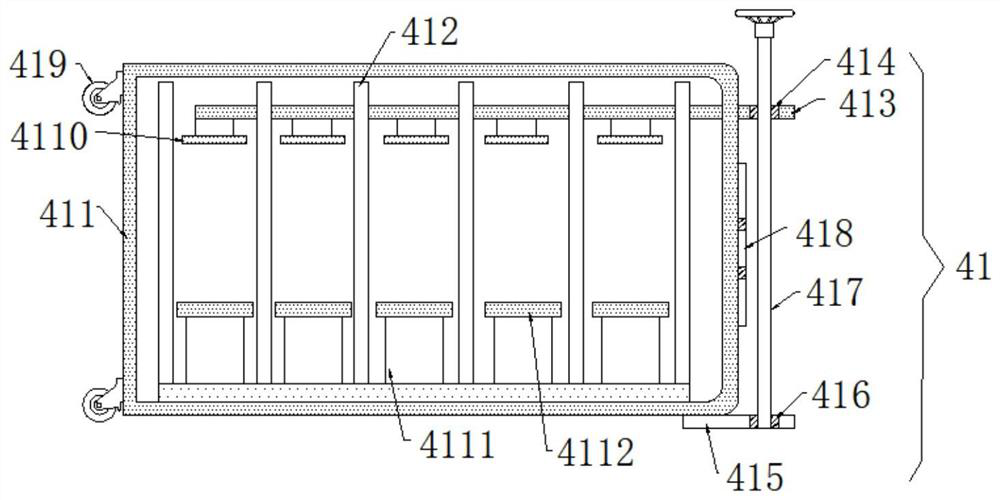

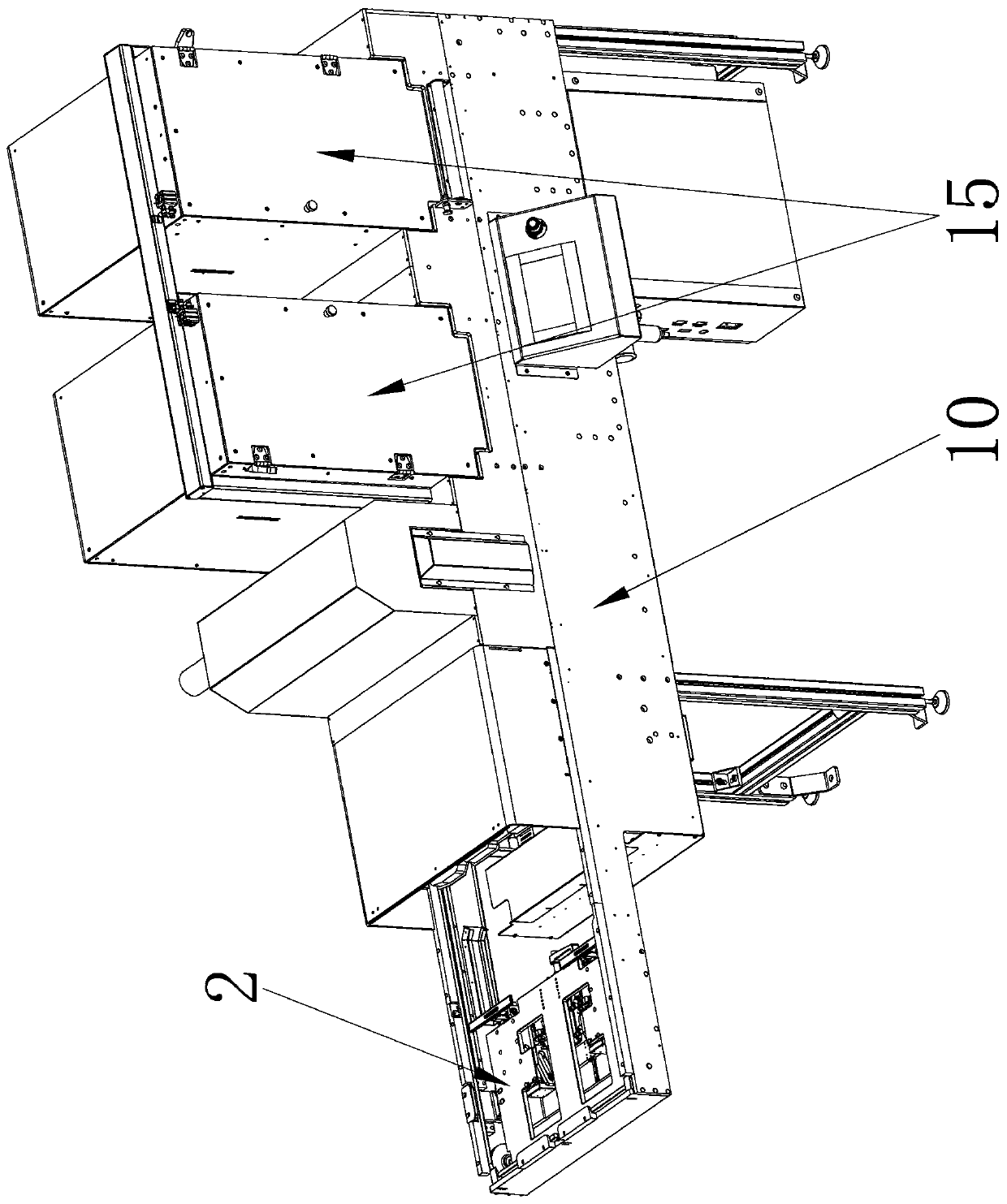

Correcting receiving mechanism and ultra-thin multi-compatibility receiving feeder

PendingCN110790020AHigh movement accuracyReduce thicknessCleaning using gasesDe-stacking articlesEngineeringMachine

The invention aims to provide a correcting receiving mechanism which is small in occupied space and low in manual cost and an ultra-thin multi-compatibility receiving feeder. The ultra-thin multi-compatibility receiving feeder comprises a machine table as well as the correcting receiving mechanism and two groups of tray storing mechanisms sequentially arranged on the machine table, wherein a conveyor belt module is arranged on the machine table; the correcting receiving mechanism and the two groups of tray storing mechanisms are matched with the conveyor belt module; and the correcting receiving mechanism comprises a bottom plate, a lifting plate, a vertical guide rail component, a driving plate and a horizontal air cylinder. The ultra-thin multi-compatibility receiving feeder is applied to the technical field of receiving equipment.

Owner:珠海市申科谱工业科技有限公司

Stamping die with adaptive cooling mechanism and cooling method

PendingCN110369611AReduce excessive undershootRapid coolingShaping toolsThread cutting machinesCooling effectPetroleum engineering

The invention provides a stamping die with an adaptive cooling mechanism. The stamping die with the adaptive cooling mechanism comprises an upper die mechanism and a lower die mechanism, wherein bothopposite sides of a lower die seat are provided with two first oil gas pipeline mounting frame, and the first oil gas pipeline mounting frames are internally and fixedly provided with an oil path inlet pipe and a gas path inlet pipe in a penetrating mode. The oil path inlet pipe is connected with an oil pipe, the gas path inlet pipe is connected with a gas pipe, and the outlet of the oil pipe andthe gas pipe converge on an oil-gas outlet pipe. The oil-gas outlet pipe obliquely penetrates through second oil gas pipeline mounting frames, wherein the second oil gas pipeline mounting frames are elastically connected to a lower plate, the outlet of the oil-gas outlet pipe extends obliquely towards the direction of a tapping head, and the oil-gas outlet pipe and a horizontal plane form an included angle of 48 degree-68 degree. The invention further provides a cooling method. Compared with the prior art, the problems of incomplete cooling and uniform cooling in an operation area when die tapping is carried out inside the stamping die can be solved, and accordingly the cooling effect is effectively improved.

Owner:深圳数码模汽车技术有限公司

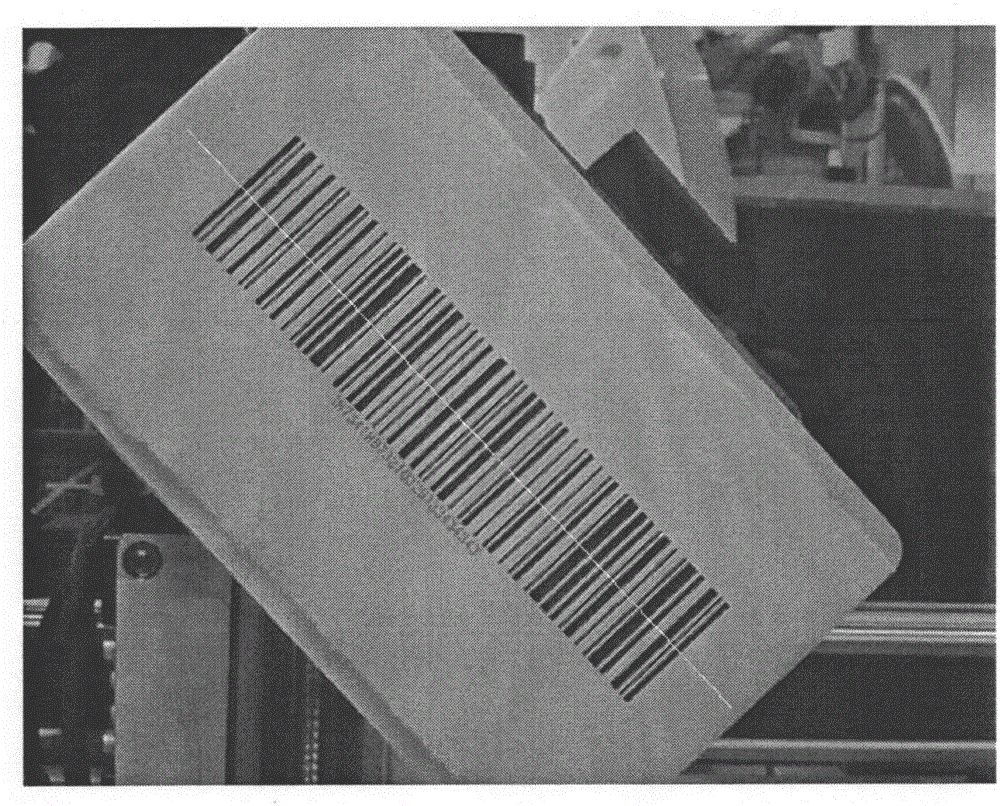

One-dimensional barcode decoding method based on bar vacancy unit amplification

ActiveCN106570438AMeet decoding needsTo achieve the corrective effectSensing by electromagnetic radiationDecoding methodsBarcode

Owner:SHANGHAI HUANGHE INFORMATION TECH CO LTD

Method for correcting pile foundation offset through high-pressure grouting

InactiveCN111622280AImprove the correction effectReduce the impactFoundation engineeringStructural engineeringPressure grouting

The invention discloses a method for correcting pile foundation offset through high-pressure grouting. The method comprises the following steps that a stress releasing structure is arranged on the opposite side at a line offset direction and used for releasing stress and inducing displacement; and a plurality of high-pressure jet grouting piles are constructed on one side at the line deviation direction, the jet pressure of the high-pressure jet grouting piles is used for applying reverse extrusion stress to a to-be-corrected pile foundation so as to achieve the offset correction effect of thebridge pile foundation. According to the method, the extrusion force is applied to the periphery of pile foundation soil through the high-pressure grouting method to move the offset pile foundation so as to achieve the purpose of correcting the displacement of the pile foundation.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

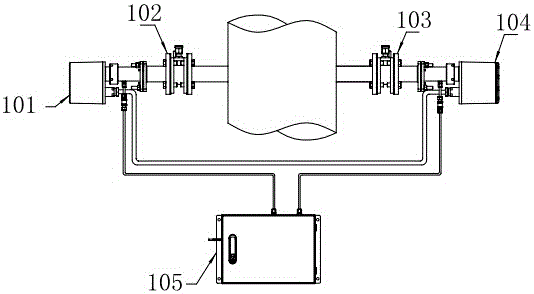

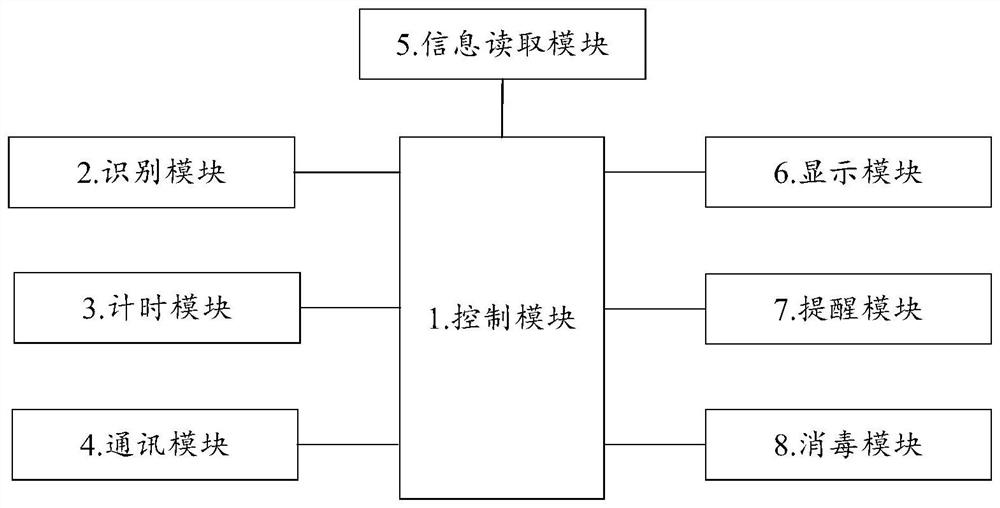

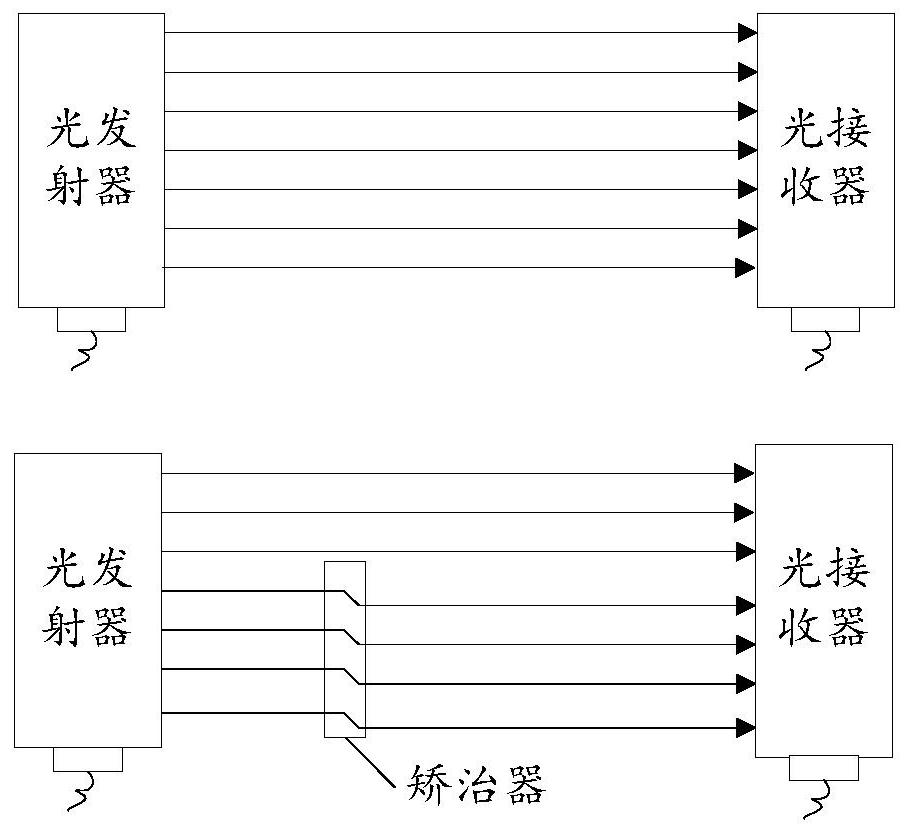

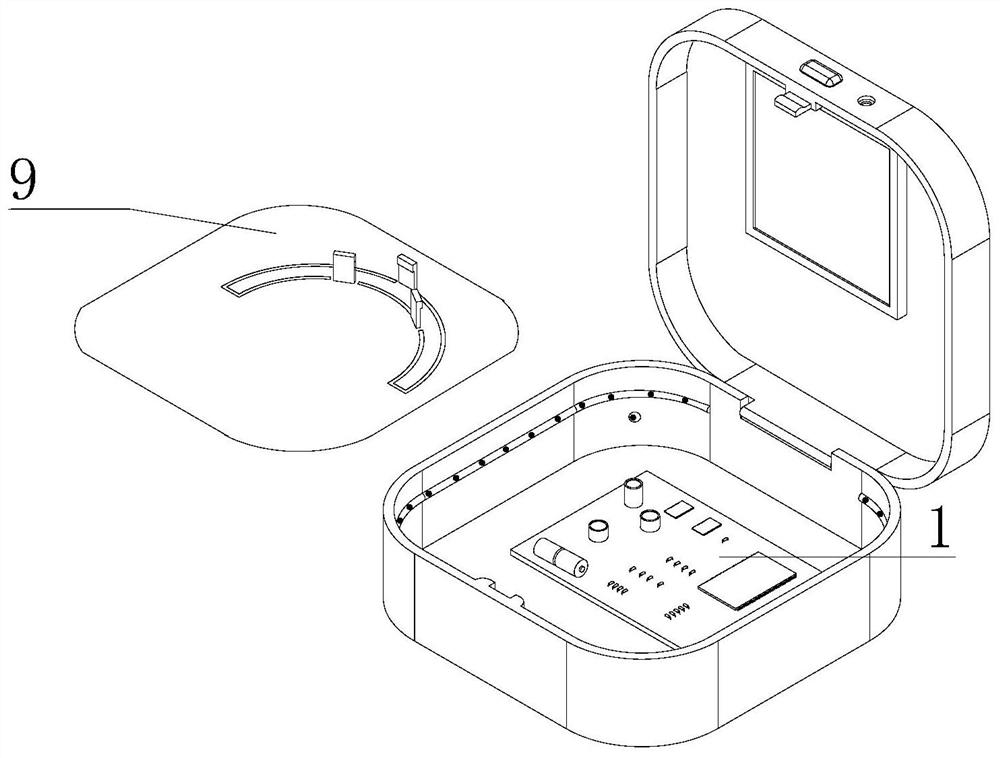

Intelligent monitoring terminal, information acquisition system, and method of shell-shaped dental appliance

ActiveCN110840587BReal-time monitoring of wearing timeEasy to carryOthrodonticsSmart surveillanceEmbedded system

The invention discloses an intelligent monitoring terminal, a wearing information acquisition system, and an intelligent monitoring method of a shell-shaped dental appliance; the invention comprises a control module, an identification module, a timing module and a communication module, and the identification module is used for identifying whether the shell-shaped dental appliance is placed in a container space, and send the identification information to the control module; the control module sends the first trigger signal and / or the second trigger signal to the timing module according to the identification information; the timing module is used for according to the first trigger signal and / or the second trigger signal The signal counts the single wearing time or single placing time of the shell-shaped dental appliance; the communication module communicates with the receiving end, and sends the single wearing time and / or single placing time of the shell-shaped dental appliance to the receiving end . The intelligent monitoring terminal provided by the present invention has the functions of monitoring, communication and reminding, and can publish the single wearing time and single placing time to the receiving end, reminding the patient to wear the shell-shaped dental appliance according to the prescribed wearing time.

Owner:SHANGHAI SMARTEE DENTI TECH CO LTD

Star point line welder

ActiveCN109623079AEasy to adjustAdjusting the fixing cylinder makes it easy to adjust the position of the connecting rod on the connecting plateMetal working apparatusSoldering auxillary devicesFiberEngineering

The invention discloses a star point line welder which can oxidize an upper electrode and a lower electrode to clear, prevents conduction efficiency from reduction, conveniently regulates an abrasiveband clearing mechanism, can straighten a welded part, improves welding efficiency, can quickly replace a fibre belt disc and conveniently clears overlap. The star point line welder comprises a weldermain body, wherein the inner side of the welder main body is fixedly equipped with a fibre belt feeding mechanism and a pressure difference welding mechanism; the front-end outer surface of the fibrebelt feeding mechanism is equipped with a roller; the upper-end outer surface of the roller is equipped with a fixed buckle; one side of the fixed buckle is equipped with a fibre belt disc; one sideof the roller is equipped with a belt feeding rubber wheel; a guide slot is formed in one side of the belt feeding rubber wheel; a pendulum bob assembly is arranged on the upper-end outer surface of the guide slot; one side of the pressure difference welding mechanism is fixedly equipped with a straightening mechanism; one side of the straightening mechanism is fixedly equipped with a positioningblock; and one side of the positioning block is equipped with a pushing clamping cylinder.

Owner:JULI AUTOMATION EQUIP ZHEJIANG CO LTD

Calibration device for invoice printing

InactiveCN108501505BIncrease pressureAct as a correctionRotary pressesInvoicePulp and paper industry

The invention relates to the technical field of invoice printing and discloses a correction device for invoice printing. The correction device comprises a rack. Guide rolls and a correction mechanismare arranged on the rack. The correction mechanism comprises correction plates oppositely arranged on the two sides of a paper sheet. A first wedge rod is fixedly connected to each correction plate. The correction mechanism further comprises a U-shaped tube containing liquid. First pistons are slidably connected to the interiors of the two ends of the U-shaped tube correspondingly. A first pistonrod is fixedly connected to each first piston. Each first piston rod is provided with a first wedge groove allowing the corresponding wedge rod to be inserted in. A balancing bar is rotatably connected to the rack. The two ends of the balancing bar are located in the two ends of the U-shaped tube correspondingly. The two ends of the balancing bar are fixedly connected with buoys located on the liquid level of the U-shaped tube. An airbag is arranged on the rack and communicates with the two ends of the U-shaped tube through guide pipes. Valves with valve rods are mounted on the guide rods correspondingly. Push rods abutting against the balancing bar are fixedly connected to the valve rods of the corresponding valves. The correction device can correct deviated invoices in time and can protect the paper sheet against abrasion caused by hard contact between the correction device and the paper sheet.

Owner:重庆华康印务有限公司

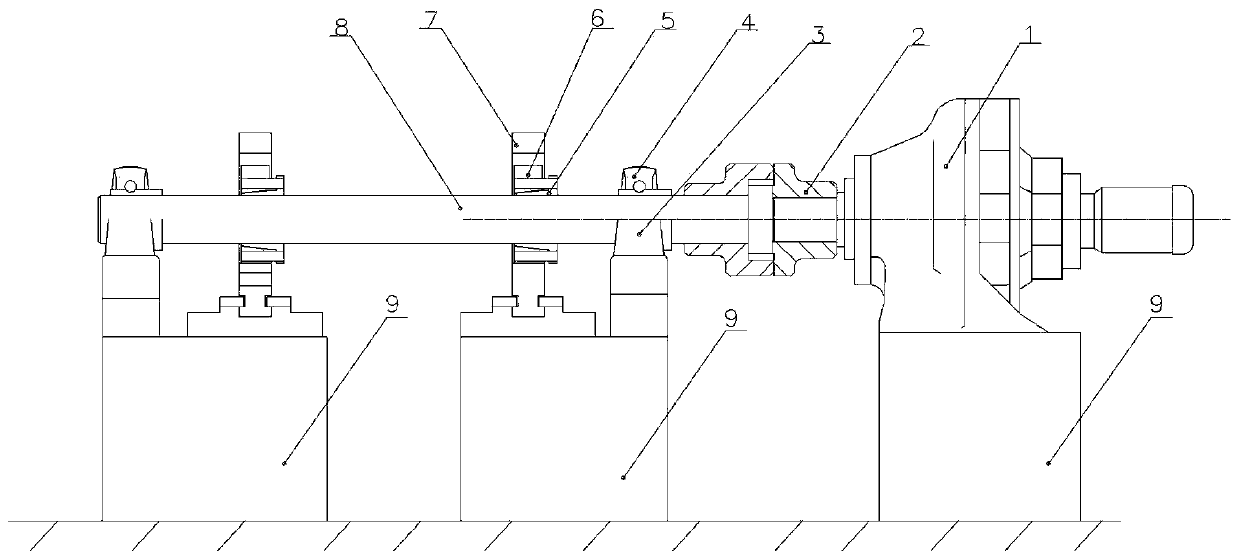

Large sheet metal stretch formed piece correcting device

The invention relates to a large sheet metal stretch formed piece correcting device which comprises a base with a linear chute formed in the upper surface, a cycloid gear reducer installed on the base, a transmission shaft, a first bearing supporting device, a first sliding seat rolling device, a second sliding seat rolling device and a second bearing supporting device; and the first bearing supporting device, the first sliding seat rolling device, the second sliding seat rolling device and the second bearing supporting device are sequentially installed on the base along the transmission shaft. For the large sheet metal stretch formed piece correcting device, a springback edge is corrected and sized by transferring pressure with machinery, the number of ejector rods can be changed according to the size of a workpiece by adopting an electric device, a moving distance of a sliding seat frame is set according to a springback amount of the workpiece, a correction frequency is quickly and flexibly controlled with a speed reducer, the workpiece is extruded to perform a proper quantity of deformation through intermittent pushing, the deformation is gradually converted to plastic deformation at a certain pushing frequency, deformation springback is eliminated, a size reference is returned, and the correction effect is achieved.

Owner:滁州恒昌机械装备制造有限公司

One-dimensional barcode decoding method based on bar and space unit amplification

ActiveCN106570438BMeet decoding needsTo achieve the corrective effectSensing by electromagnetic radiationDecoding methodsBarcode

The invention provides a one-dimensional barcode decoding method based on bar vacancy unit amplification, which is characterized by comprising the steps of positioning the barcode center of a barcode image and determining an inclination angle of a barcode according to existing technologies, and determining a barcode center scanning line according to the inclination angle of the barcode and the barcode center; calculating bar vacancy unit boundary points on the barcode center scanning line, acquiring a width flow, decoding the width flow, and returning decoding information if the width flow is successfully decoded; if the width flow is decoded unsuccessfully and the barcode is horizontal or vertical, returning a decoding failure, if not, getting into a procedure of correcting and amplifying a bar vacancy unit of the barcode, and decoding a new width flow again. The one-dimensional barcode decoding method not only can meet decoding requirements of ordinary barcodes, but also can meet decoding requirements of inclined barcodes with certain decoding difficulty. Meanwhile, when the boundary points on the barcode scanning line are not accurately extracted, the one-dimensional barcode decoding method can achieve a certain correction effect, so that the decoding rate is improved.

Owner:SHANGHAI HUANGHE INFORMATION TECH CO LTD

In-Situ Laser Gas Analyzer with Online Deviation Device

ActiveCN106018340BGood effectDoes not affect normal measurementColor/spectral properties measurementsSynchronous motorEngineering

The invention relates to an in-situ laser gas analyzer with an on-line deviation correction device. The in-situ laser gas analyzer comprises a transmitting unit, a receiving unit, a transmitting unit connecting piece, a receiving unit connecting piece and a purging unit; the receiving unit comprises the automatic deviation correction device; the purging unit is provided with a shell with a rainproof function, and a voltage stabilizing and flow controlling device is arranged in the shell; the automatic deviation correction device comprises a receiving installation seat, a lens device, a synchronous motor, a sensor module and a reference gas chamber, the synchronous motor achieves automatic switching of the reference gas chamber in an optical path through software controlling, second harmonic gas can be detected by the laser gas analyzer when the reference gas chamber is sealed, and then the deviation effect is achieved. The laser gas analyzer is simple in structure and high in reliability, and the condition that on a user site, the second harmonic gas is found, and standard gas is introduced is avoided.

Owner:HANGZHOU CHUNLAI TECH

Circuit board positioning device and mounting method of LED placement machine

InactiveCN104619126BTo achieve the corrective effectRealize automatic correction functionPrinted circuit assemblingEngineeringDrive motor

The invention discloses a circuit board locating device of an LED chip mounter and a mounting method thereof. The circuit board locating device of the LED chip mounter comprises at least two groups of panel components, and each group of panel components is correspondingly connected with a group head; each group head is connected with a transverse drive motor for controlling the transverse move thereof; each two group heads are connected with a horizontal drive motor for controlling the horizontal space between the group heads. Because the circuit board locating device of the LED chip mounter uses the horizontal drive motor, transverse drive motor and at least two groups of group heads, the horizontal drive motor can regulate the space between two adjacent groups of group heads so as to enable the circuit board locating device to adapt to different distances of elements, and the circuit board locating device is capable of regulating the distance between two group heads to be corresponding to different distances between materials to perform chip mounting for the circuit board. The transverse drive motor is capable of transversely moving the group head to correct materials, for example, when materials on the panel are placed in a crooked state (one is located at the front while the other is located at the back), the materials can be corrected through the fine adjustment of the transverse drive motor.

Owner:SHENZHEN TONGLISHENG PHOTOELECTRIC EQUIP

Control method and device for smart household equipment

ActiveCN104597761BTo achieve the corrective effectComputer controlProgramme total factory controlNetwork controlHome control

The invention discloses a control method and device for intelligent household equipment. Wherein, the method includes: reading preset device control rules; collecting user operation behavior data and environmental parameters of smart household devices; Match to obtain the matching result; according to the matching result, obtain the user control scheme corresponding to the equipment control rules; input the user control scheme and current environmental parameters and / or current operating behavior data into the neural network control model to generate equipment control rules The correction value of the control rule; according to the correction value of the control rule, the equipment control rule is modified. The invention solves the problem in the prior art that it is impossible to modify the control rules of each smart home device in the smart home system, resulting in the problem that the smart home system cannot be controlled according to the actual needs of users.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com