Surface paper conveying mechanism of paper mounting machine and paper mounting machine thereof

A technology of conveying mechanism and laminating machine, which is applied in the direction of pasting, sending objects, transportation and packaging, etc. It can solve the problems of paper offset, small friction, and incomplete matching of paper, so as to improve production quality and improve alignment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

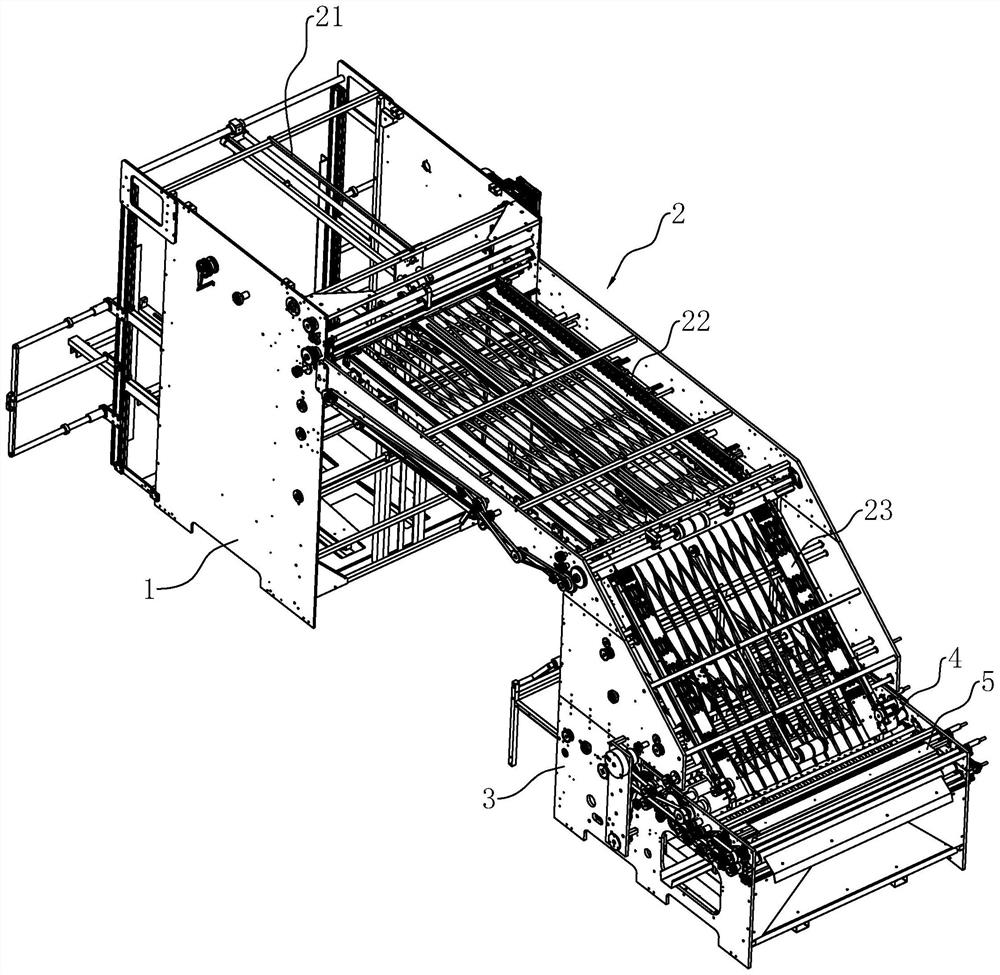

[0037] refer to figure 1 , The tissue conveying mechanism 2 includes a frame 1 and an automatic facial tissue feeding device 21, a facial tissue deviation correction device, and a facial tissue inclined conveying device 23 arranged in sequence; the facial tissue automatic feeding device 21 adopts a feeder elevator.

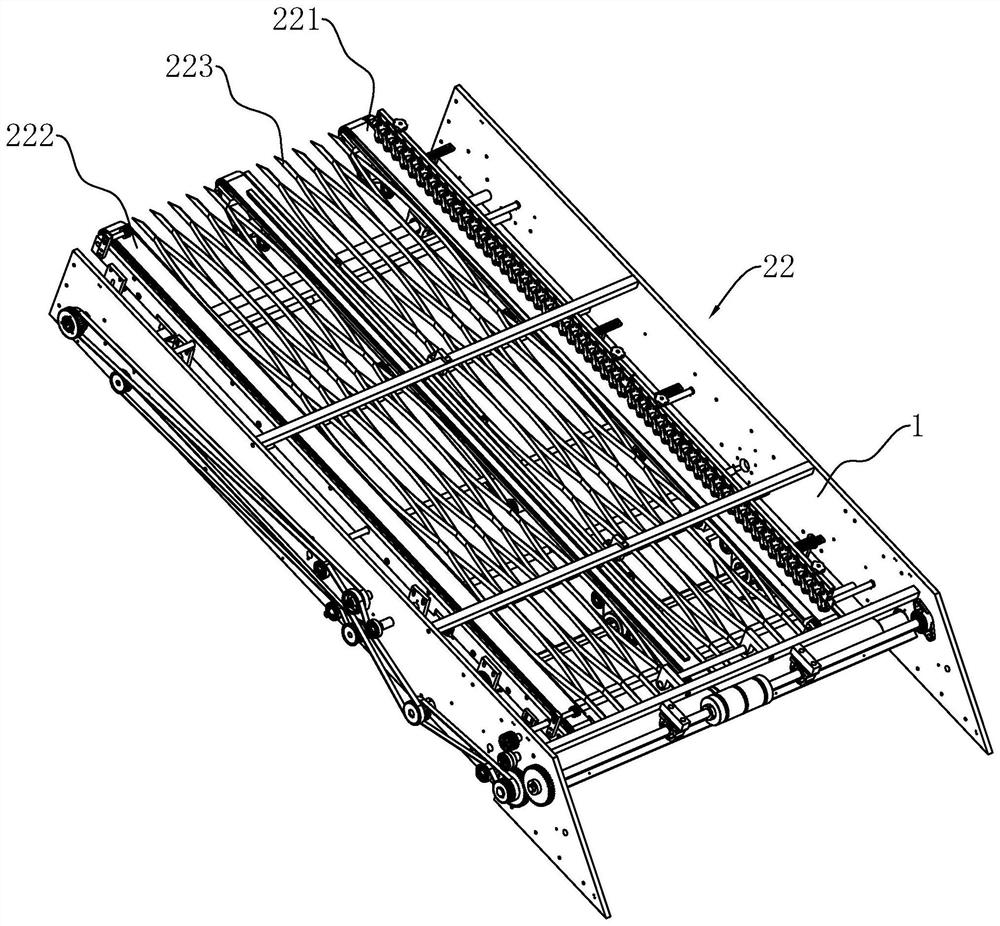

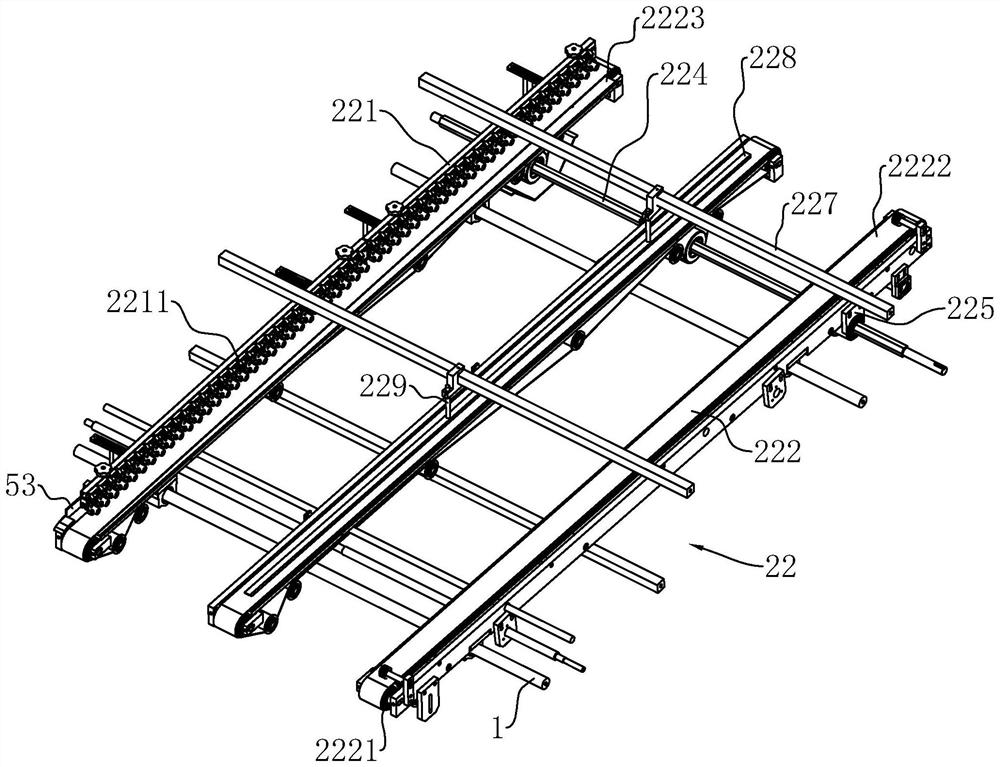

[0038] refer to Figure 2 to Figure 4 , the facial paper horizontal conveying device 22 is composed of a facial paper deviation-correcting belt assembly 221 and a plurality of conveying belt assemblies 222 arranged at intervals, between the facial paper deviation-correcting belt assembly 221 and the conveying belt assembly 222, and adjacent conveying belt assemblies 222. Arc-shaped steel mesh 223, used to support facial tissue conveying; refer to Figure 6 , the arc-shaped steel sheet mesh 223 is composed of a plurality of wavy arc-shaped steel sheet strips 2231 , and the corrugated parts between adjacent arc-shaped steel sheet strips 2231 are connected to form a...

Embodiment 2

[0052] refer to figure 1 , a paper laminating machine, comprising a frame 1 and a bottom paper conveying mechanism 3 arranged on the frame 1, a gluing mechanism 4, a pressing mechanism 5 and the surface paper conveying mechanism 2 in the embodiment 1, the bottom paper The conveying mechanism 3 , the gluing mechanism 4 and the pressing mechanism 5 are arranged in sequence, and the facial paper inclined conveying device 23 is conveyed obliquely downward and the end is connected with the pressing mechanism 5 .

[0053] refer to Figure 2 to Figure 4 , the facial paper horizontal conveying device 22 is composed of a facial paper deviation correction belt assembly 221 and a plurality of conveying belt assemblies 222 arranged at intervals. Arc-shaped steel mesh 223, used to support facial tissue conveying; refer to Figure 6 , the arc-shaped steel sheet mesh 223 is composed of a plurality of wavy arc-shaped steel sheet strips 2231 , and the corrugated parts between adjacent arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com