Large sheet metal stretch formed piece correcting device

A stretch forming and correction device technology, which is applied in the field of sheet metal stretching, can solve the problems of labor-consuming and time-consuming correction work, difficult operation, difficult to ensure accuracy, etc., and achieve the effects of simplifying operation, eliminating deformation rebound, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

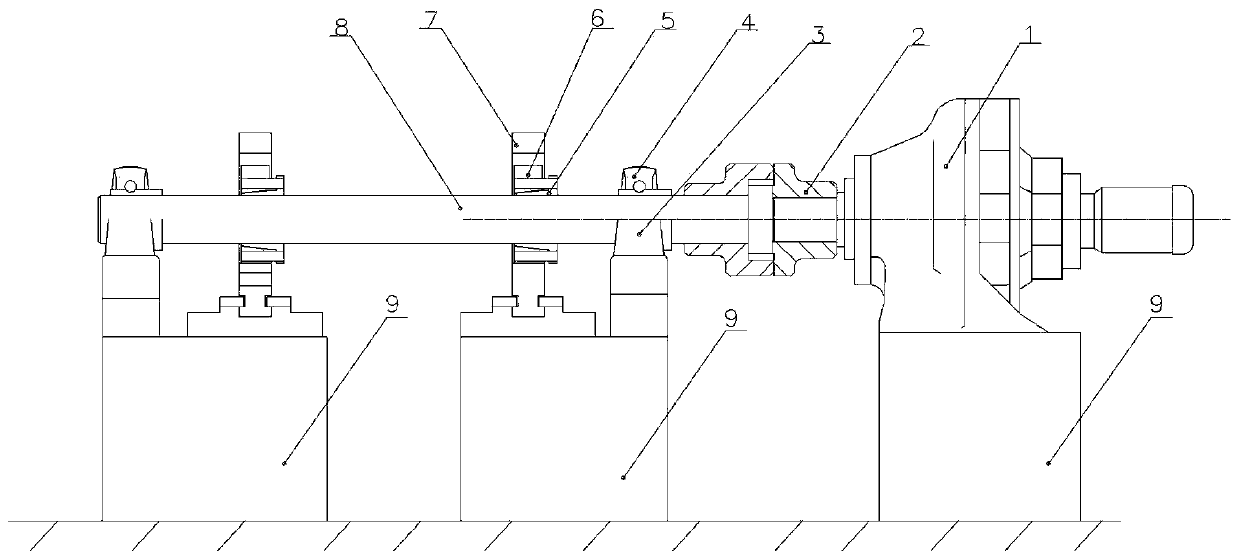

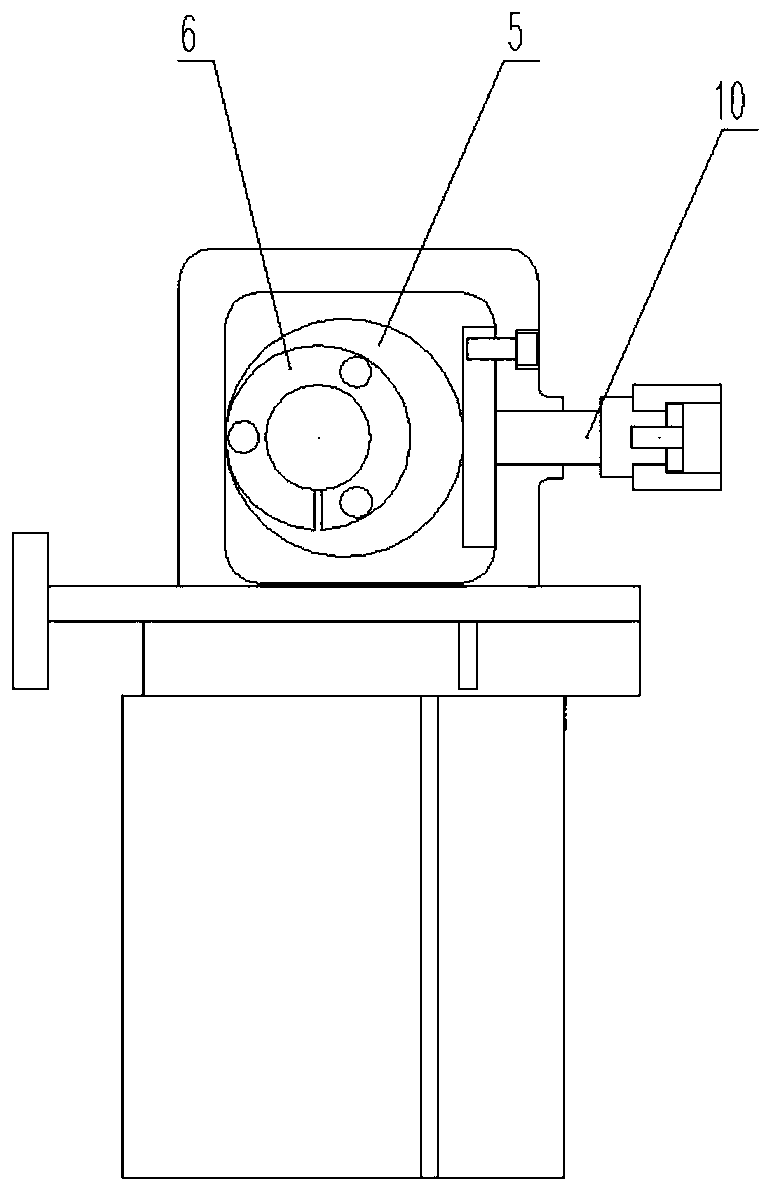

[0012] The technical details involved in the technical method of the present invention will be described in detail below in conjunction with the drawings and embodiments. It should be pointed out that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

[0013] Such as figure 1 with figure 2 As shown, the correction device for large-scale sheet metal stretched formed parts of the present invention includes a base 9, a cycloidal gear reducer 1, a transmission shaft 8, and a first bearing support device and a first slide roller arranged in sequence along the transmission shaft 8 Pressing device, second sliding seat rolling device, second bearing supporting device.

[0014] The cycloidal gear reducer 1 is fixed on the upper surface of the base 9 . The first bearing supporting device and the first sliding seat rolling device are fixed in the linear chute on the upper surface of the base 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com