Correcting receiving mechanism and ultra-thin multi-compatibility receiving feeder

An ultra-thin and flying technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problem that it is difficult to ensure that the second jig, that is, the material tray, is accurately moved to the loading area, takes up a large space, and cannot Realize the automatic supply of empty trays and other issues, and achieve the effects of reducing labor intensity, high work efficiency, and reducing volume constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

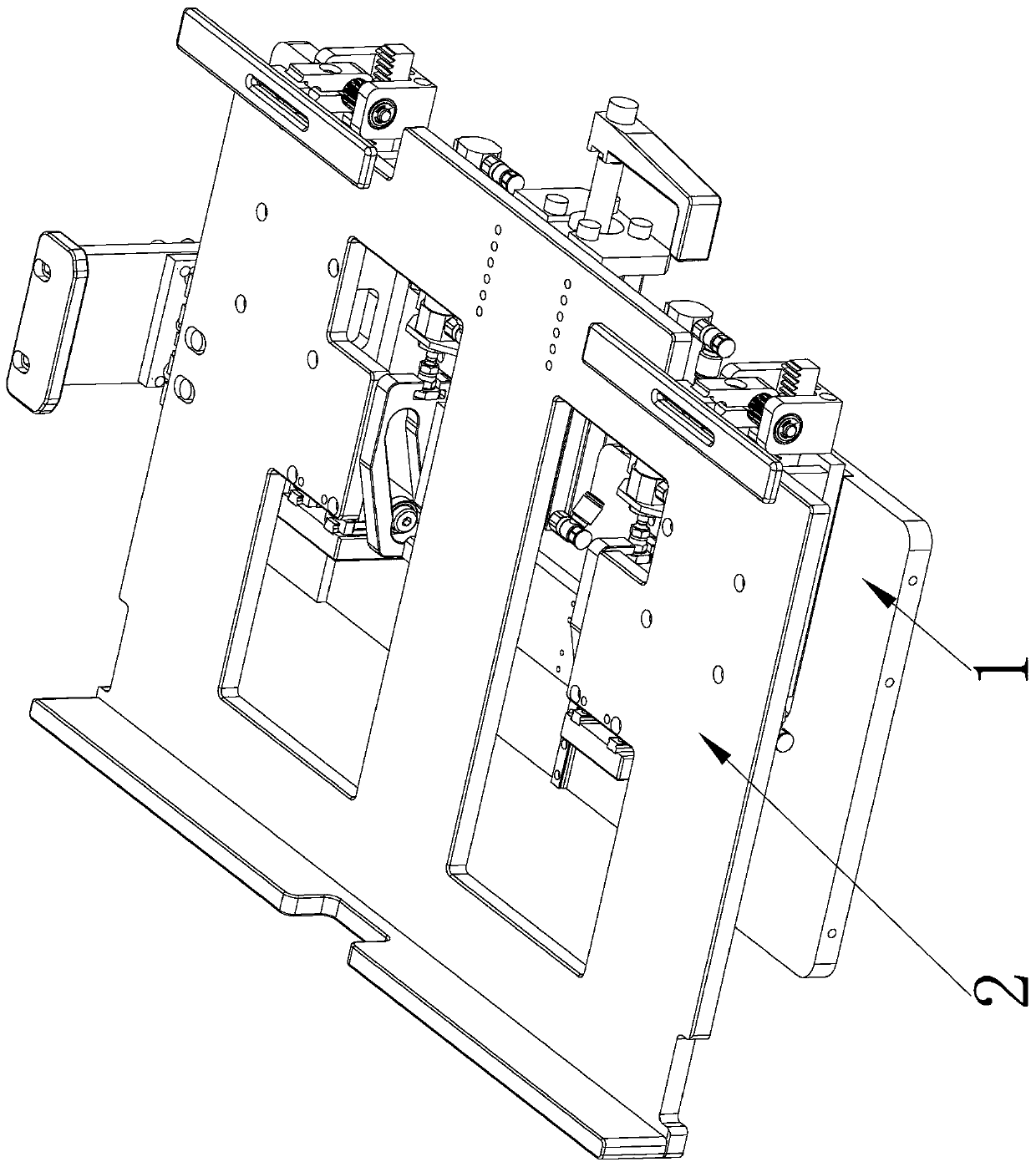

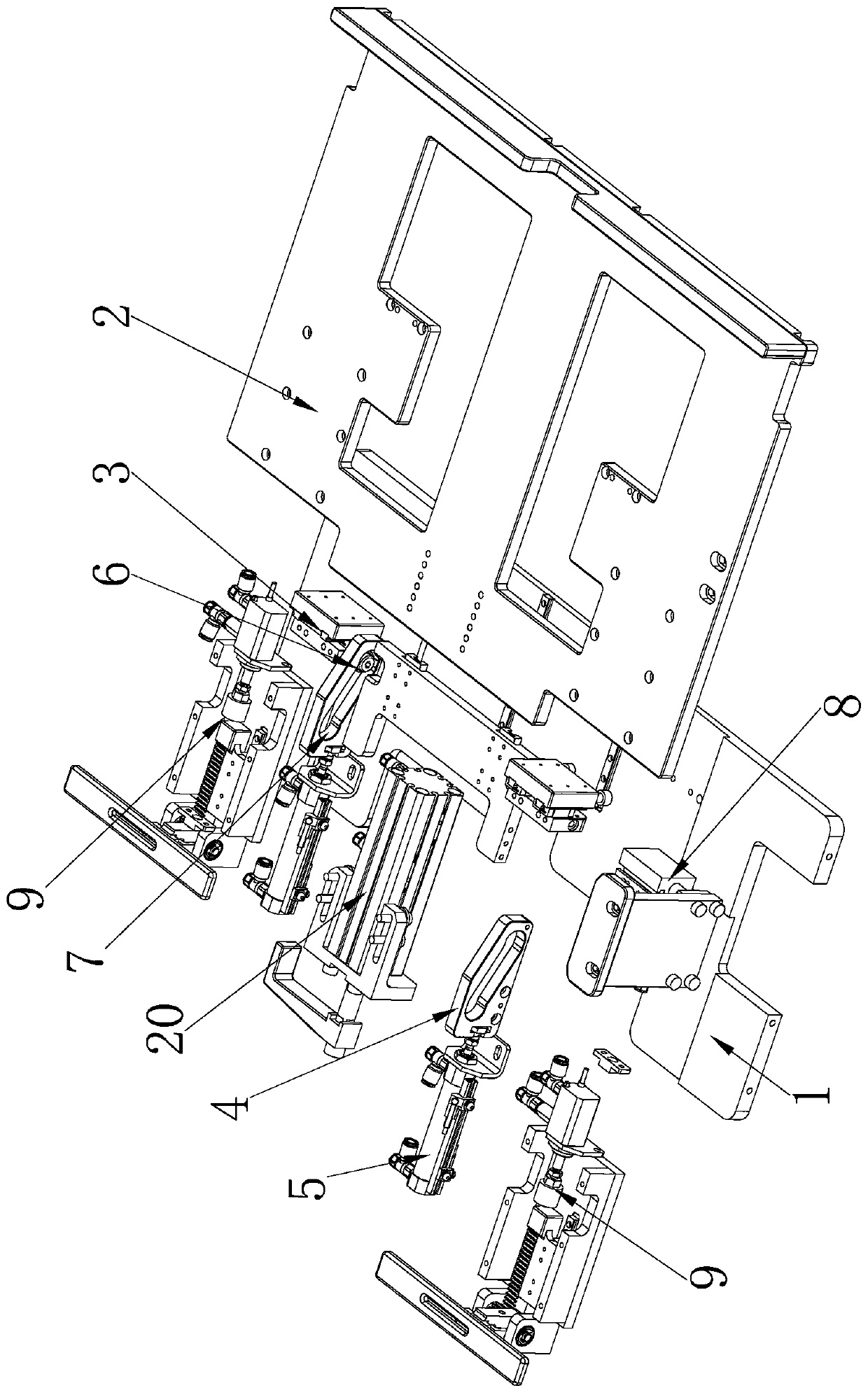

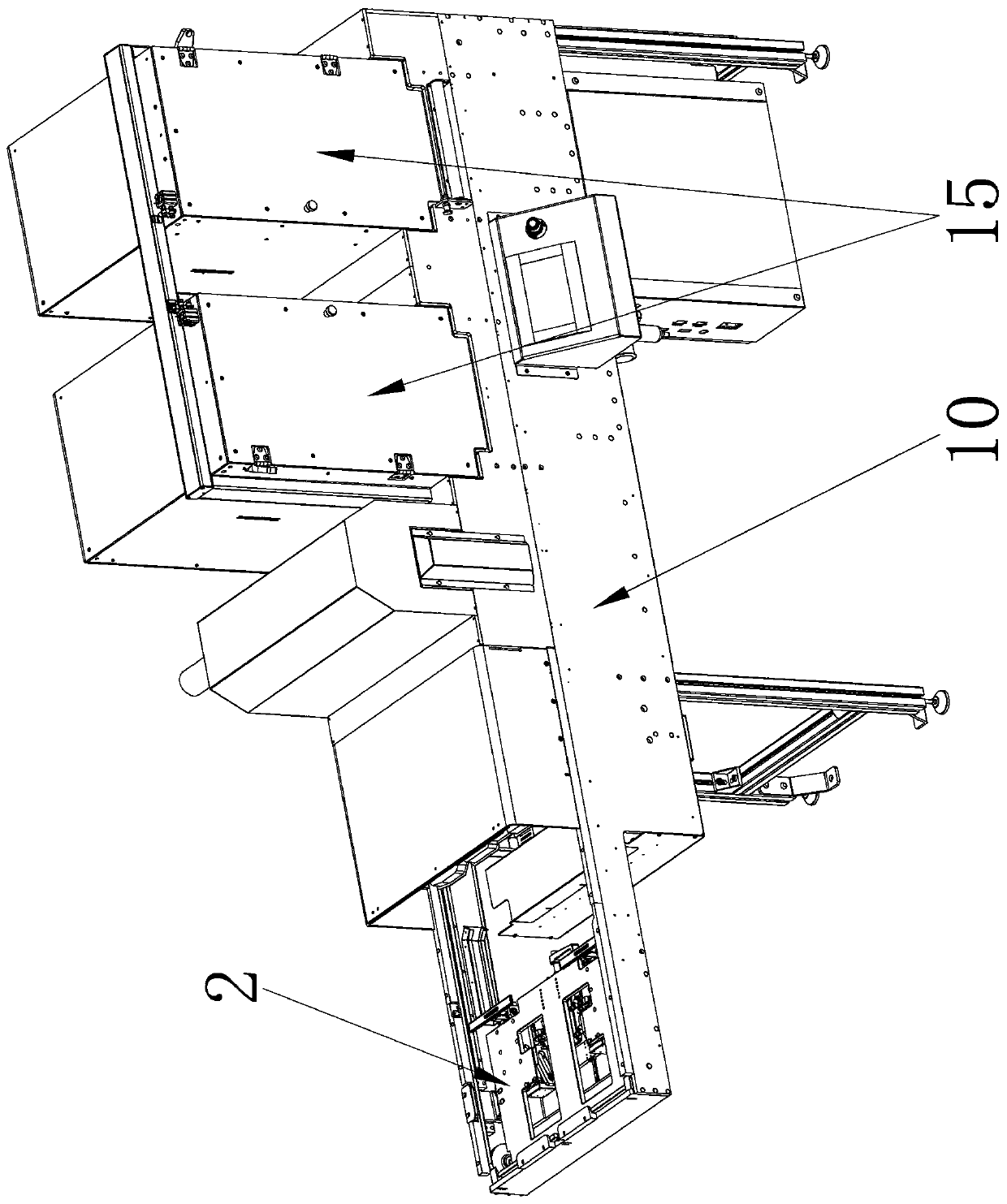

[0024] like Figure 1 to Figure 7 As shown, in this embodiment, the correction material receiving mechanism includes a bottom plate 1, a lifting plate 2, a vertical guide rail assembly 3, a drive plate 4 and a horizontal cylinder 5, and the horizontal cylinder 5 and the vertical guide rail assembly 3 are all fixed on the bottom plate 1, the lifting plate 2 is fixedly connected with the movable part of the vertical guide rail assembly 3, and the movable part of the vertical guide rail assembly 3 is rotatably fitted with a roller 6, and the driving plate 4 Fixed on the movable end of the horizontal cylinder 5, the driving plate 4 is provided with a chute 7 matching with the roller 6, and the opening position of the chute 7 gradually rises in the direction close to the horizontal cylinder 5 , the lifting plate 2 is provided with a correction module for correcting the position of the tray.

[0025] In this embodiment, the vertical guide rail assembly 3, the driving plate 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com