Real-time feedback grouting method for correcting horizontal deformation of subway tunnel

A technology of horizontal deformation and real-time feedback, applied in the test, construction, instrument and other directions of the basic structure, it can solve the problem of not being able to feedback the control direction of the slurry in real time, and achieve the effect of avoiding excessive deviation correction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

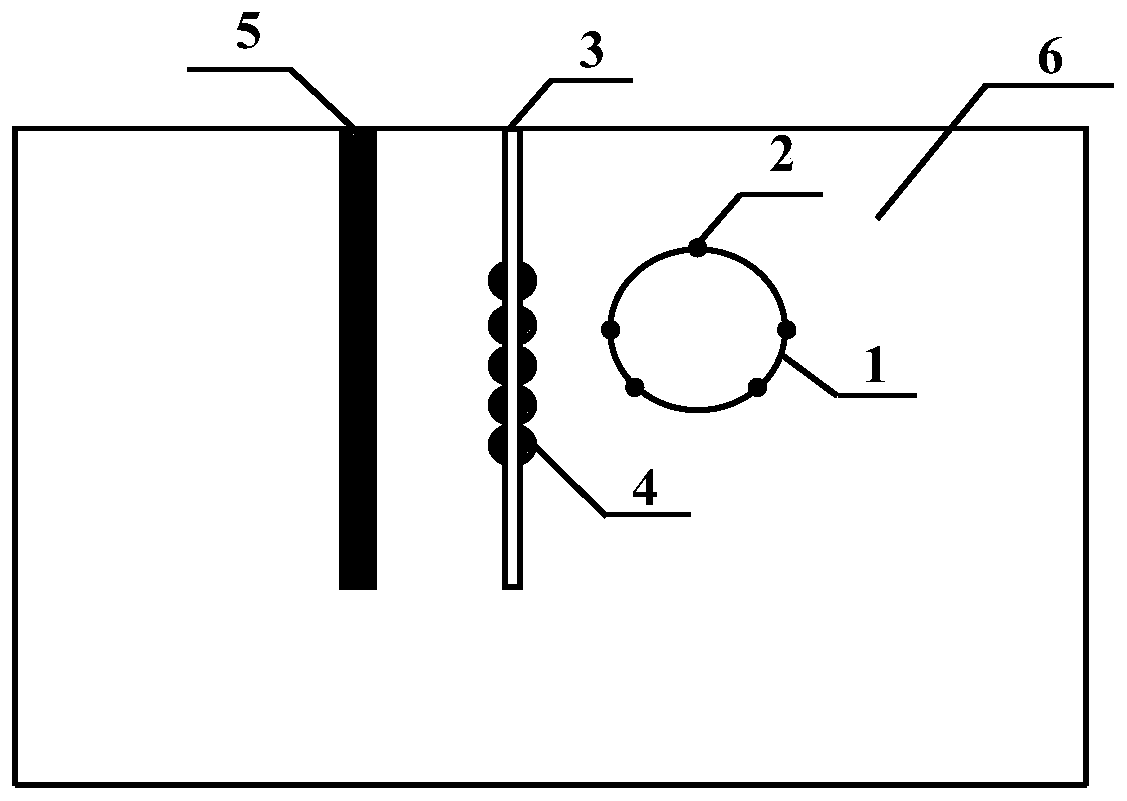

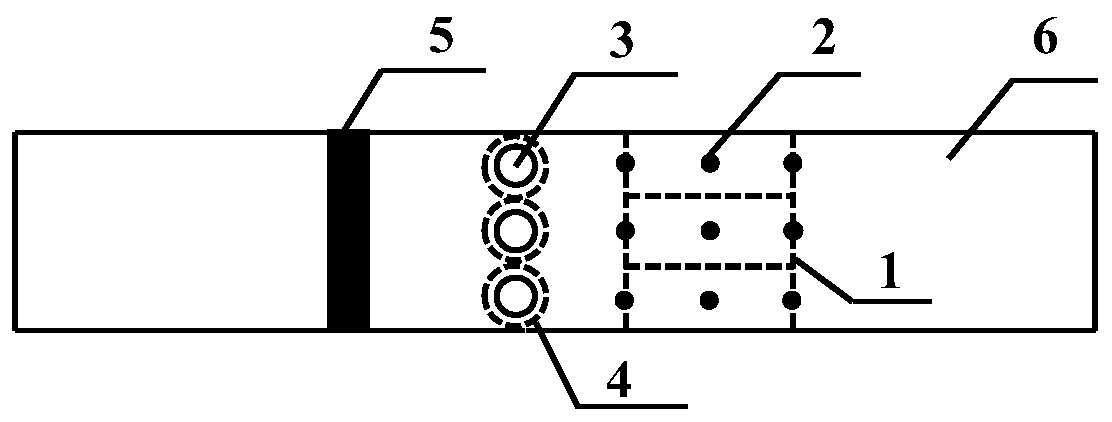

[0031] as attached figure 1 and figure 2 As shown, the present invention is a real-time feedback grouting device for correcting horizontal deformation of subway tunnels. During construction, firstly, a TRD cement-soil mixing wall 5 is constructed in the soil body 6 adjacent to the tunnel 1 that has undergone horizontal unilateral tensile deformation. The net distance is 3-5m. During the construction process, in order to reduce the further disturbance and deformation of tunnel 1, the construction speed of TRD was reduced to the minimum. At the same time, cement, alkali slag and fly ash are uniformly mixed according to the mass ratio of 5:3:2 to carry out the construction of TRD mixing wall 5. After the construction is completed, wait until the cement-soil mixing wall 5 reaches the design strength, and then carry out the pre-embedded construction of the sleeve valve pipe 3 . Drill the pre-embedded sleeve valve pipe 3 between the TRD cement-soil mixing wall 5 on the site and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com