Stamping die with in-die tapping deviation rectifying structure and deviation rectifying method

A stamping die and tapping machine technology, applied in forming tools, manufacturing tools, pushing out equipment, etc., can solve problems such as unpunctured teeth, incomplete tapping, tooth hole burning, etc., to solve the problem of tooth hole deviation, overcome Vibration of the fuselage to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] see Figure 1 to Figure 5 , the figure shows a stamping die with an in-mold tapping deviation correction structure provided by Embodiment 1 of the present invention, which includes:

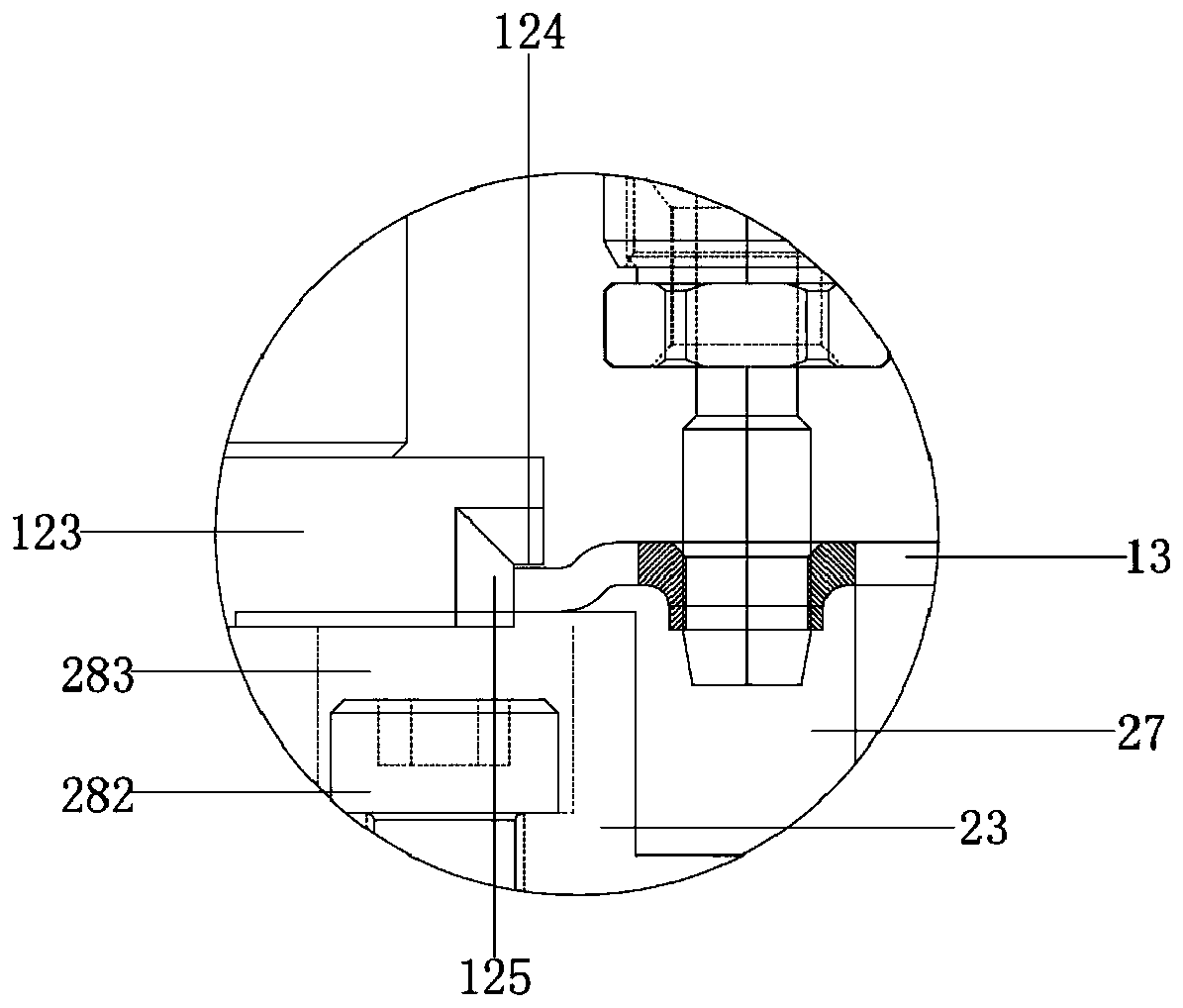

[0035] The upper mold mechanism 1 includes an upper mold base 11 and a plurality of floating pressing mechanisms 12, and the floating pressing mechanism 12 includes an inverted nitrogen gas spring 121, an inverted ejector block 122, and a strip positioning and adjusting block 123, an inverted nitrogen gas spring 121 Fixedly installed on the upper mold base 11, the anti-jacking block 122 is connected with the anti-jacking nitrogen spring 121, the material belt positioning and adjusting block 123 is fixedly connected with the anti-jacking block 122, and the bottom of the material belt positioning and adjusting block 123 has a function to hold down the material belt 13. The positioning notch 124 is provided with an elastic step surface 125 for adjusting the positioning of the material belt an...

Embodiment 2

[0050] see Figure 1 to Figure 5 , the figure shows a stamping die with an in-mold tapping deviation correction structure provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: The belt positioning and adjusting block 123 is a rectangular block, and the positioning notch 124 is a rectangular notch located on the bottom corner of the rectangular block, and the elastic step surface 125 is L-shaped in a plan view. Through the setting of the above structure, the shape of the corner of the material strip can be adapted to ensure the stability of positioning.

Embodiment 3

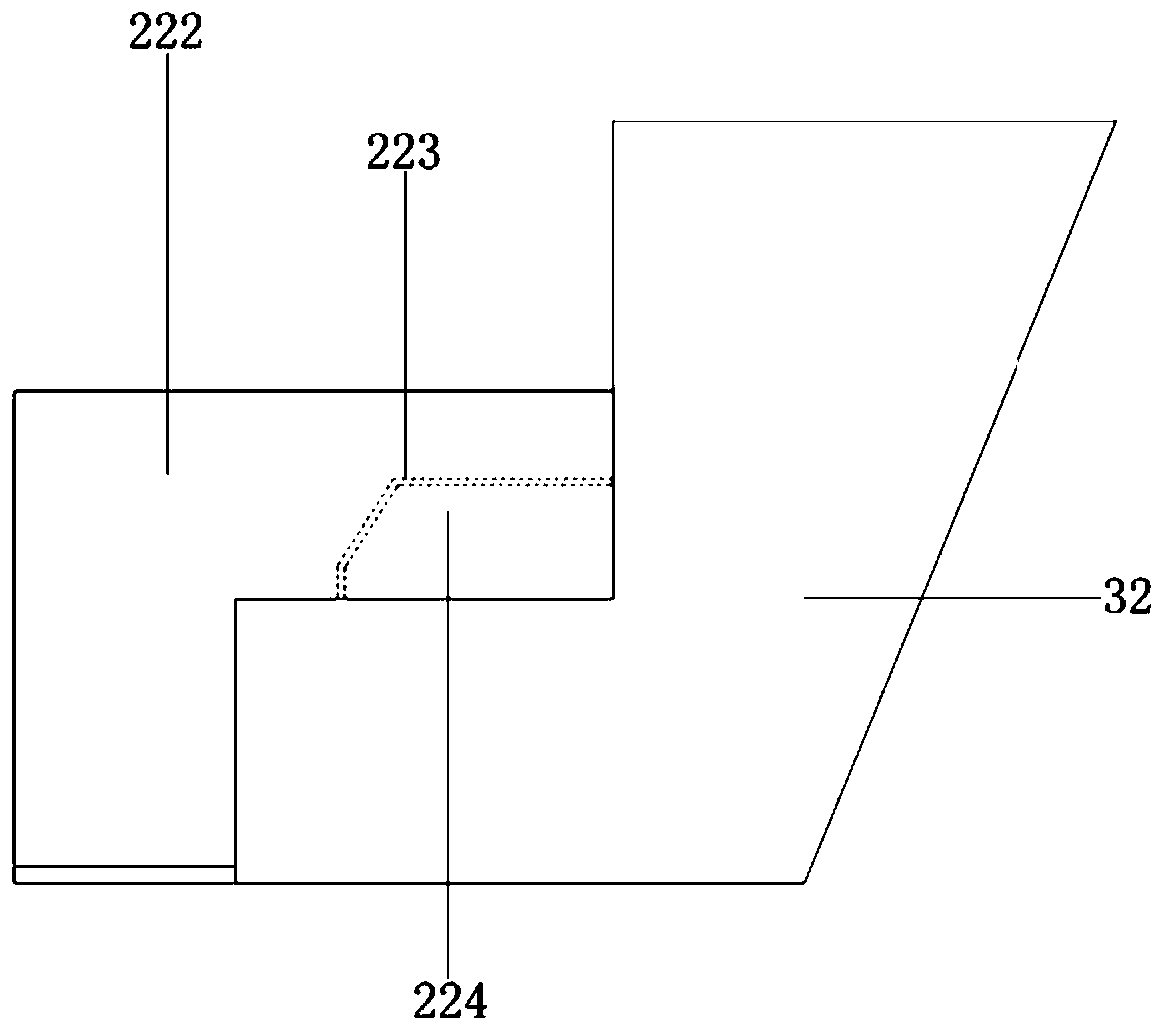

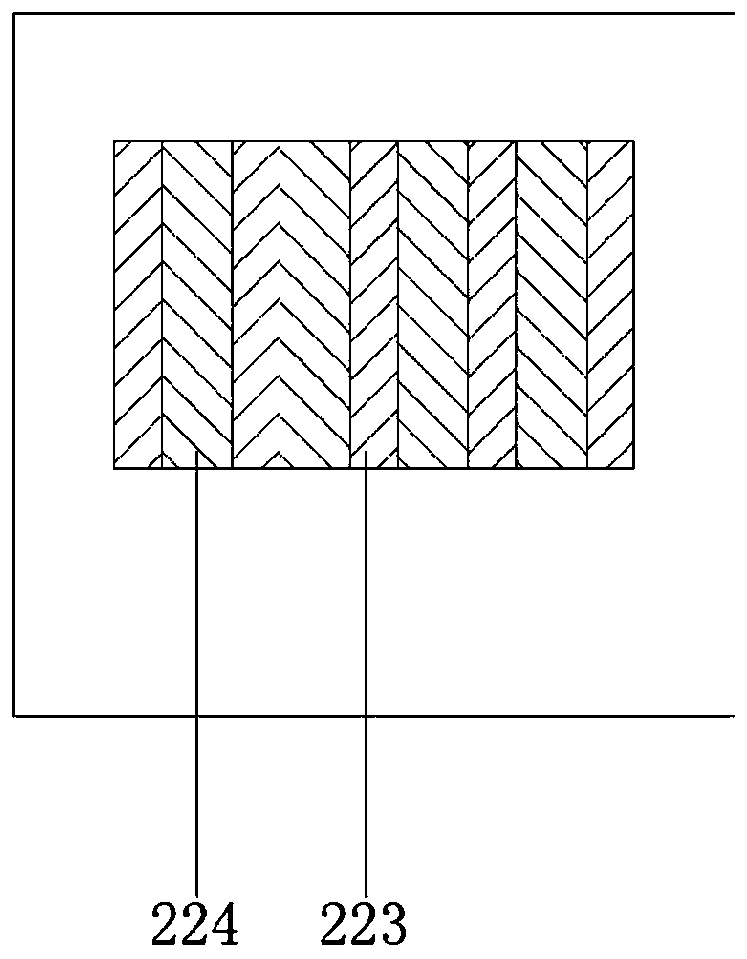

[0052] see Figure 1 to Figure 5 , the figure shows a stamping die with an in-mold tapping deviation correction structure provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: L The L-shaped positioning adjustment block 222 is rotatably connected in the notch 221 through a pin 225 , and an elastic pad 226 is provided between the bottom of the L-shaped positioning adjustment block 222 and the notch 221 . Through the setting of the above structure, the effect of buffering and eliminating the vibration of the L-shaped positioning adjustment block on the tapping machine can be formed, and the stability of the installation of the L-shaped positioning adjustment block can be ensured. At the same time, the rotatable feature of the L-shaped positioning adjustment block can be easily removed. shape positioning adjustment block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com