Capping machine device for barreled water automatic filling production line

A technology of production line and capping machine, applied in the direction of packaging, etc., can solve the problems that it is not suitable for the capping of small bottled water automatic filling production line, the structure of the capping machine is complicated, and the use effect is not ideal, so as to control the air pump and conveyor belt Convenient, fast and accurate action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

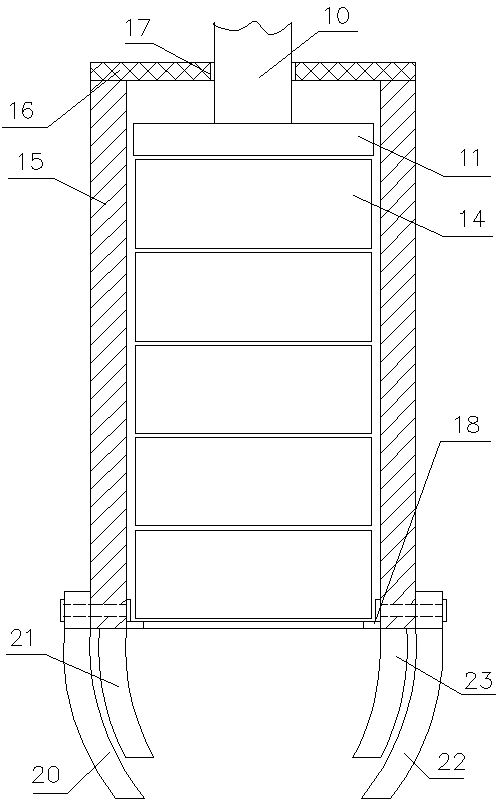

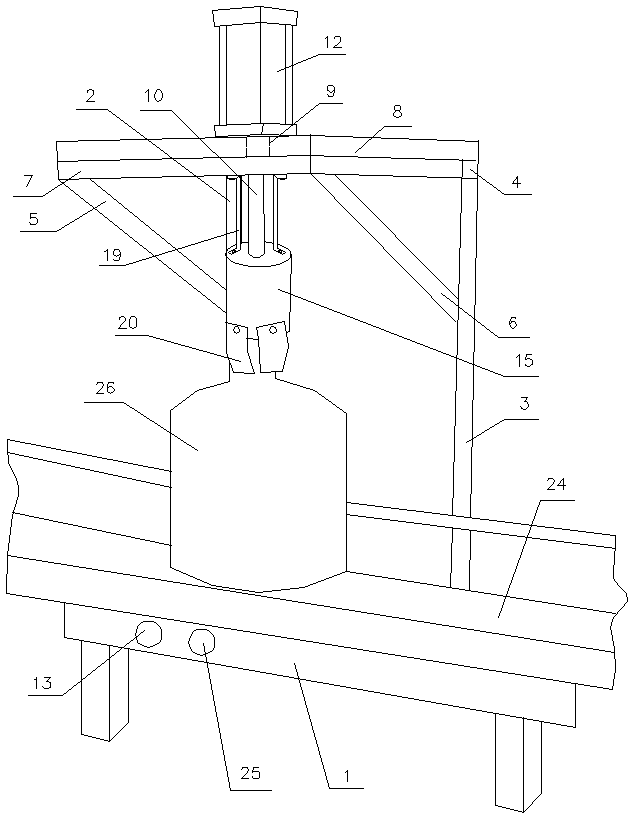

[0018] A bottled water automatic filling production line capping machine device, its composition comprises: workbench 1, described workbench is connected left support column 2 and right support column 3, described left support column and described right support column The columns are connected by beam plates 4 and fixed by screws, the left support column is welded with the left oblique support rod 5, the right support column is welded with the right oblique support rod 6, the left oblique support rod and the described left oblique support rod The right oblique support rods are connected by the front cross beam plate 7, the cross beam plate and the front cross beam plate are connected by the top support plate 8 and fixed by screws, and the top support plate has a round through hole 9. The circular through hole passes through the pneumatic rod 10, the bottom of the pneumatic rod is connected to the push plate 11, the top of the pneumatic rod is connected to the air pump 12, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com