Stamping die with adaptive cooling mechanism and cooling method

A technology of cooling mechanism and stamping die, which is applied in the field of stamping dies, can solve the problems of incomplete cooling and uniform cooling in the working area, and achieve the effect of reducing the phenomenon of excessive undershooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

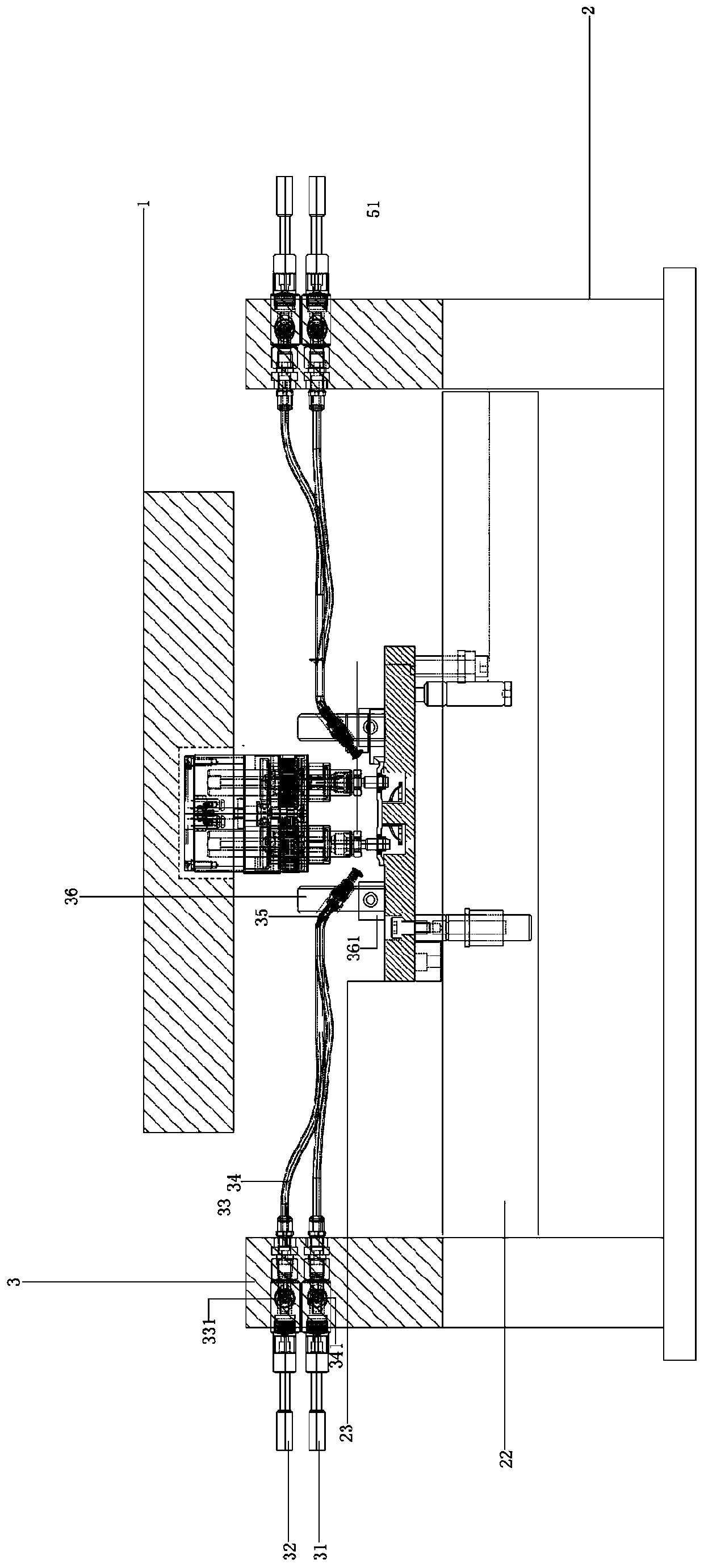

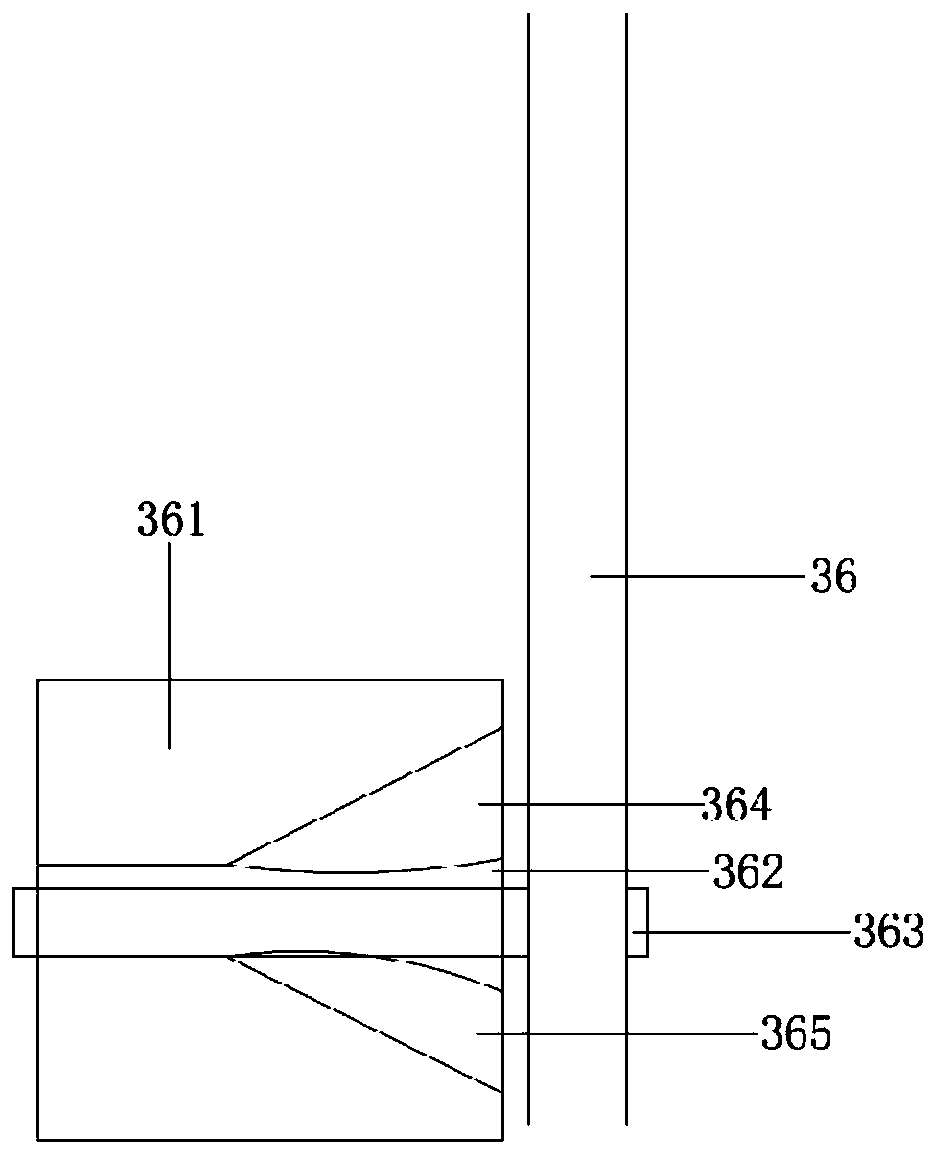

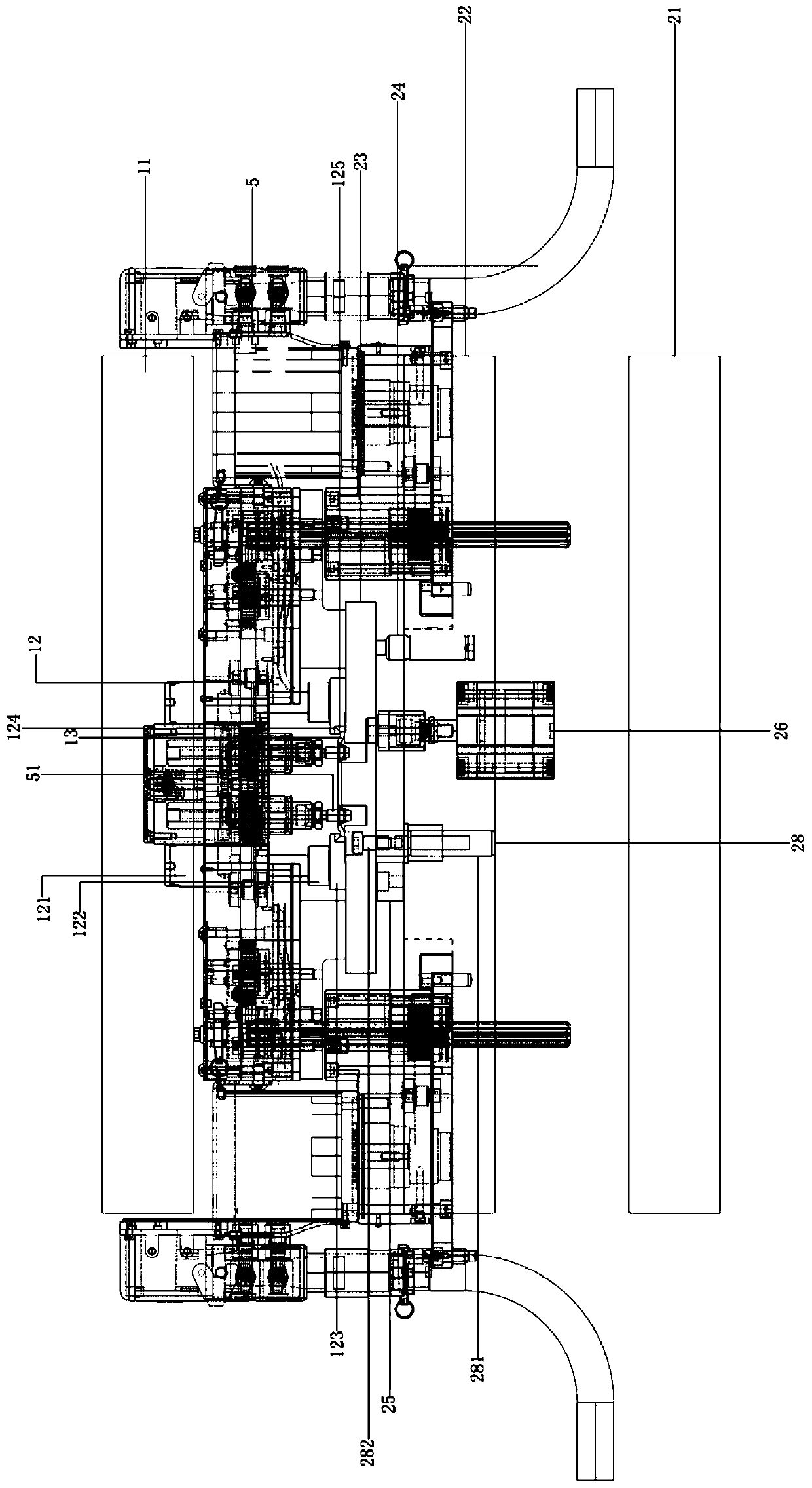

[0030] see Figure 1 to Figure 3 , the figure shows a stamping die with an adaptive cooling mechanism provided by Embodiment 1 of the present invention, which includes:

[0031] The upper mold mechanism 1 includes an upper mold base 11 and a plurality of floating pressing mechanisms 12, and the floating pressing mechanism 12 includes an inverted nitrogen gas spring 121, an inverted ejector block 122, and a strip positioning and adjusting block 123, an inverted nitrogen gas spring 121 Fixedly installed on the upper mold base 11, the anti-jacking block 122 is connected with the anti-jacking nitrogen spring 121, the material belt positioning and adjusting block 123 is fixedly connected with the anti-jacking block 122, and the bottom of the material belt positioning and adjusting block 123 has a function to hold down the material belt 13. The positioning gap 124 is provided with an elastic step surface 125 for adjusting the positioning of the material belt and the downward pressur...

Embodiment 2

[0043] see Figure 1 to Figure 3 , the figure shows a stamping die with an adaptive cooling mechanism provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: Tapping head 51 is provided with a floating nut 4 at the connection position with the tapping machine, and the floating nut 4 is eccentrically sleeved on the connecting shaft of the tapping machine through a spring, and the floating nut 4 is connected to the driving wheel by transmission, and the driving wheel is connected to the micro motor; When performing deviation correction, the micro motor starts and drives the floating nut to rotate, and the floating nut drives the tapping head 51 to return to the vertical position or to the concentric position with the tapping groove 27, during which the tapping tap in-position sensor continuously detects the tapping head 51 position, until the tapping head 51 is adjus...

Embodiment 3

[0045] see Figure 1 to Figure 3 , the figure shows a stamping die with an adaptive cooling mechanism provided by Embodiment 3 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: strip positioning And the adjusting block 123 is a rectangular block, and the positioning notch 124 is a rectangular notch located on the bottom corner of the rectangular block, and the elastic step surface 125 is L-shaped in a plan view. Through the setting of the above structure, the shape of the corner of the material strip can be adapted to ensure the stability of positioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com