Circuit board positioning device and mounting method of LED placement machine

A technology of LED placement machine and positioning device, which is applied in the direction of assembling printed circuits with electrical components, and can solve the problems of uncorrectable parts tilt, low efficiency, and increased labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

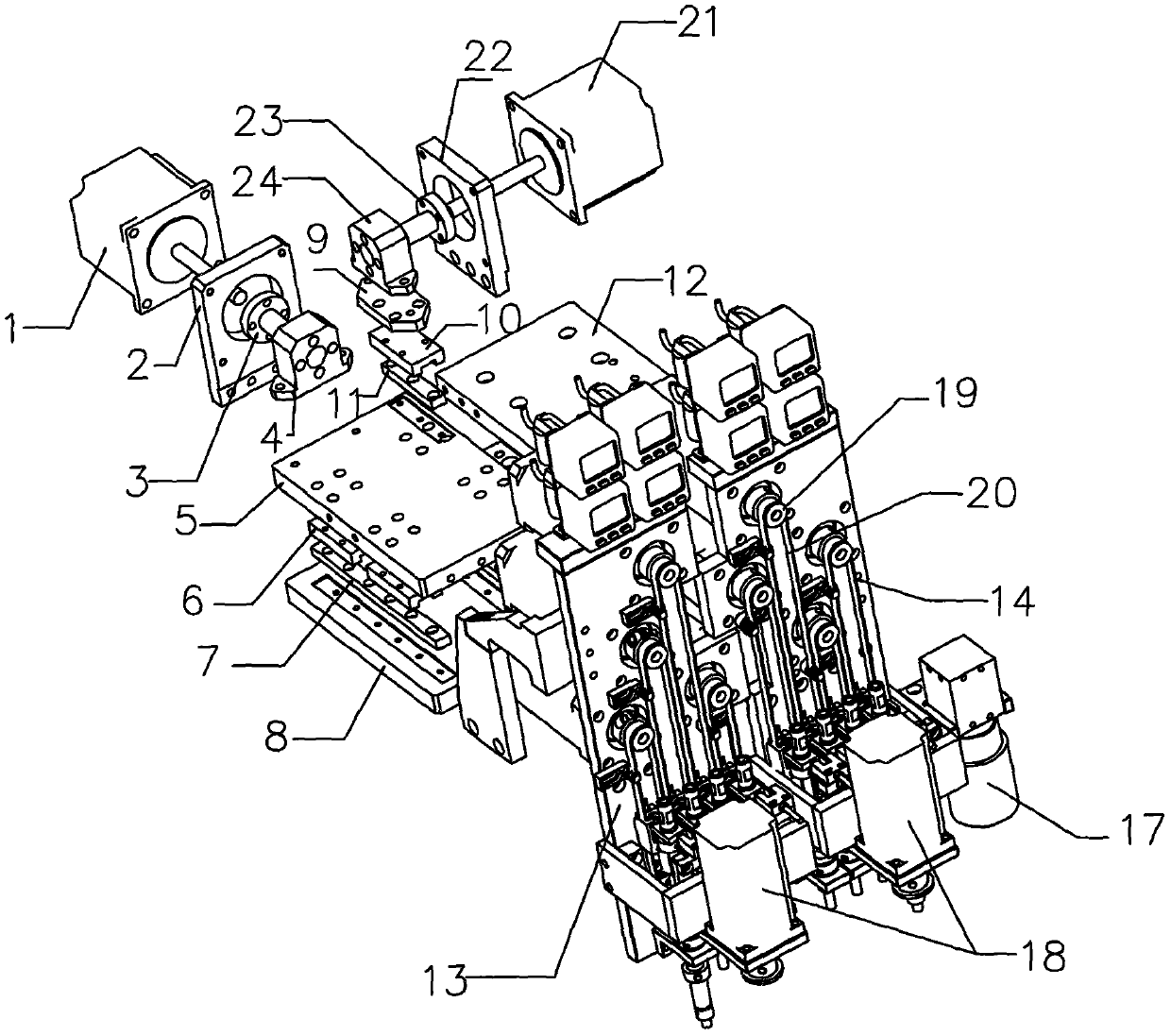

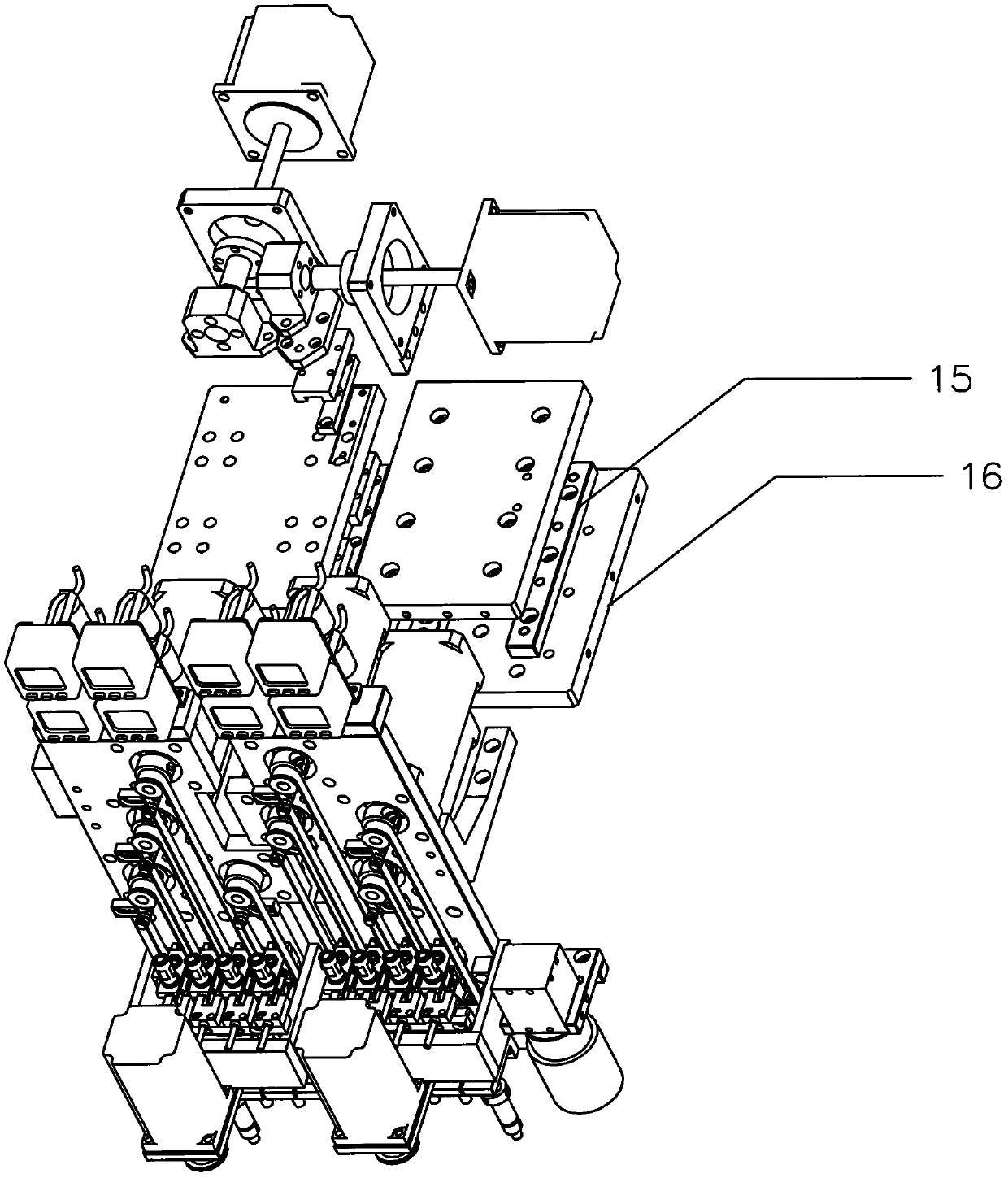

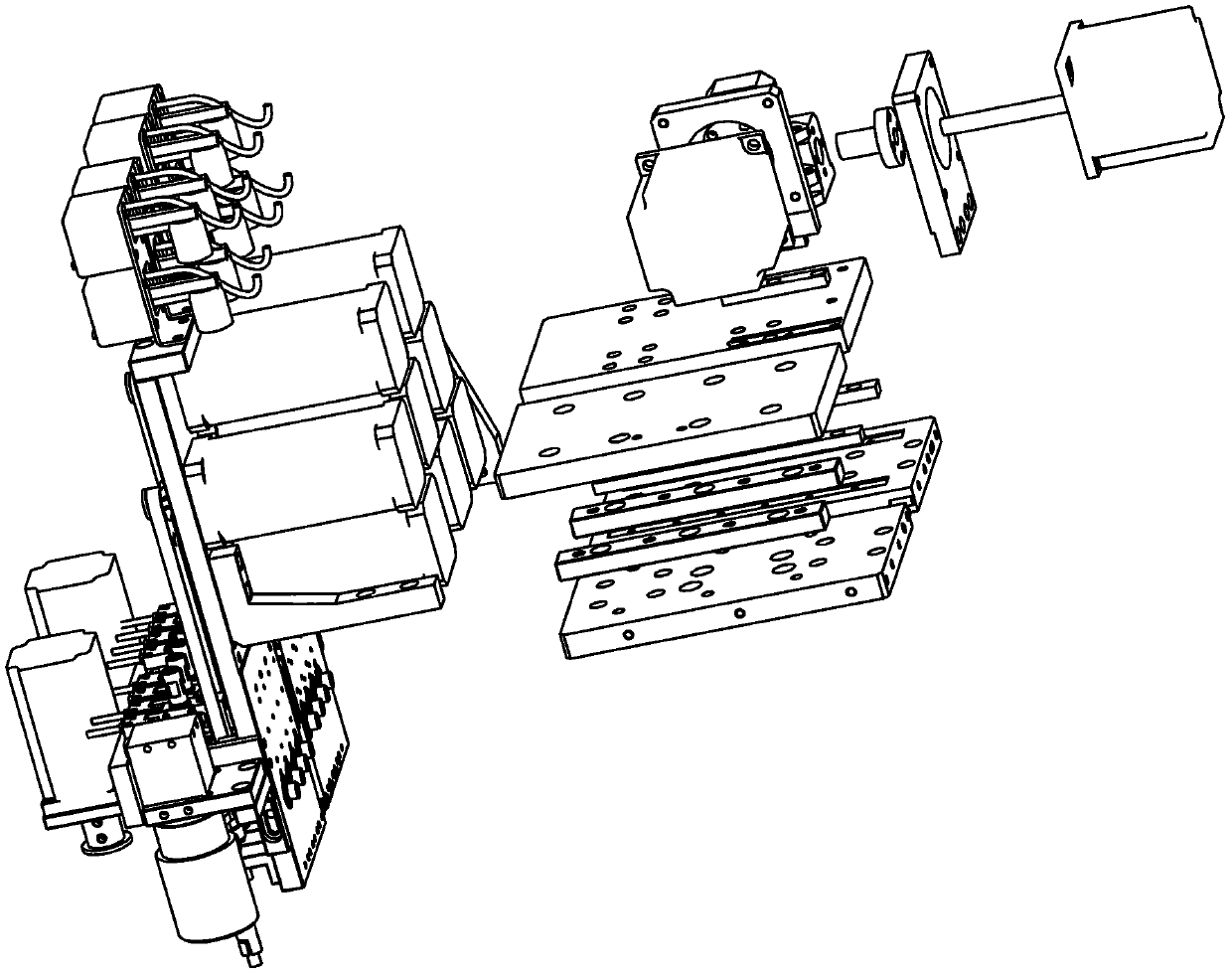

[0031] Such as Figure 1-3 As shown, the circuit board positioning device of the LED placement machine in this embodiment. It includes at least two groups of panel components, and each group of panel components is connected to a group head; each group head is connected with a front and rear drive motor 18 that controls its forward and backward movement; every two group heads are connected with a horizontal drive that controls the horizontal distance between the group heads motor17.

[0032] The panel assembly includes a first panel assembly and a second panel assembly; the group head includes a left Z group head 13 linked with the first panel assembly; a right Z group head 14 linked with the second panel assembly; one side of the right Z group head 14 is fixed A horizontal drive motor 17 that controls the horizontal distance between the left Z group head 13 and the right Z group head 14 is installed; the left Z group head 13 and the right Z group head 14 bottom end faces each...

Embodiment 2

[0039] Such as Figure 4 As shown, this embodiment discloses a method for mounting the circuit board positioning device of the LED chip mounter of the present invention, including steps:

[0040] Start the placement process;

[0041]Query the remaining points of placement; if the remaining points of placement are less than 2, mount them separately until the remaining points are zero, and complete the placement process once; if the remaining points are greater than or equal to 2, go to the following steps;

[0042] Calculate the offset of the placement point;

[0043] Correct the positional offset of the components;

[0044] Perform placement operations on at least two components at the same time; until the remaining points are zero, complete a placement process.

[0045] Such as Figure 5 As shown, this method also includes the mounting steps of components:

[0046] Mark and position the circuit board of the component;

[0047] Query the unmounted point; if the placement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com