Regenerated sub-solution reuse method

A technology of regenerated son and regenerated liquid, which is applied in the field of regenerated son liquid reuse, and can solve the problems affecting the etching effect of etching line on copper foil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

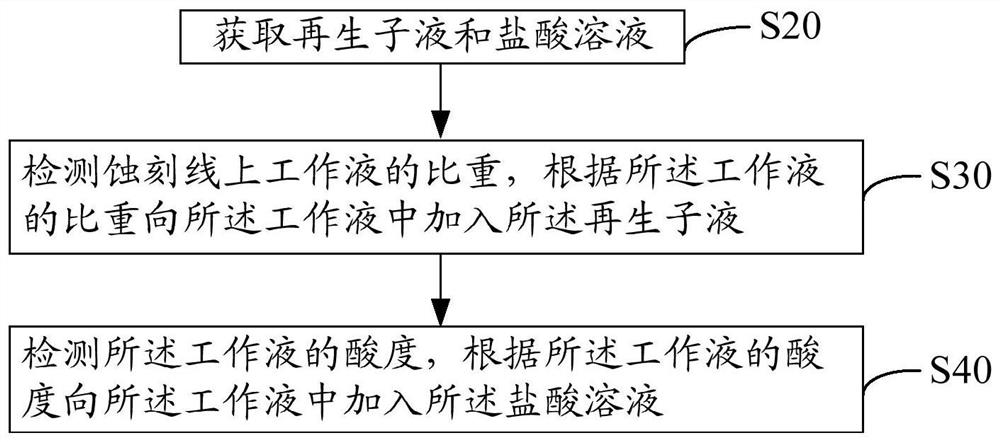

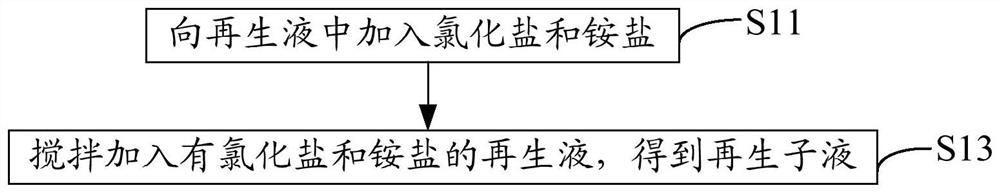

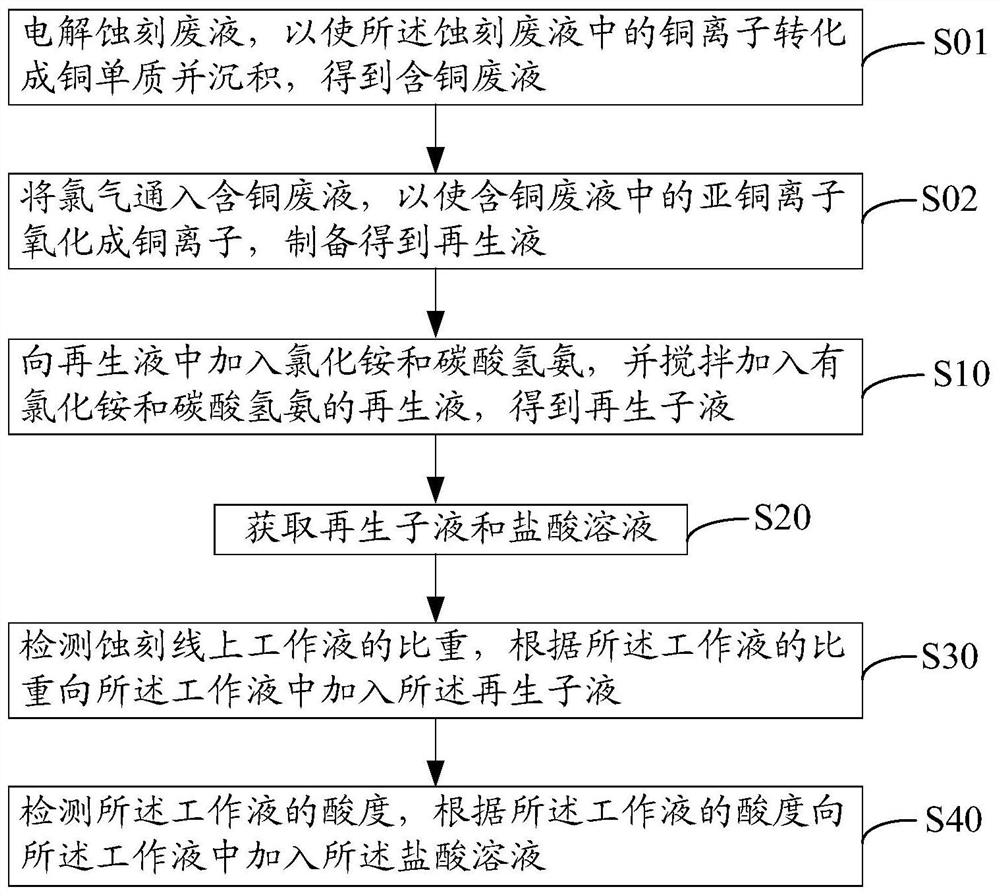

Method used

Image

Examples

Embodiment 1

[0049] Detect the specific gravity and acidity of the working liquid in the etching tank. When the specific gravity of the working liquid reaches 1.2, add the regeneration sub-liquid into the working liquid in the etching tank. Among them, the regeneration sub-solution includes 20g / L of copper ions, 3mol / L of hydrogen ions, 220mol / L of chloride ions and 40g / L of ammonium ions, and the oxidation-reduction potential of the regeneration sub-liquid is 530mV; when the acidity of the working fluid After the temperature is reduced to 0.5 mol / L, a 31% hydrochloric acid solution is added to the working solution in the etching tank. The parameters of the working fluid in the etching tank are controlled as follows: hydrogen ion 0.5mol / L, specific gravity 1.2. Under this condition, after the circuit board was continuously etched for 4 hours with the cosmic level spray etching line, the parameters of the working fluid and the etching rate were tested.

Embodiment 2

[0051] Detect the specific gravity and acidity of the working liquid in the etching tank. When the specific gravity of the working liquid reaches 1.2, add the regeneration sub-liquid into the working liquid in the etching tank. Among them, the regeneration sub-solution includes 20g / L of copper ions, 3mol / L of hydrogen ions, 220mol / L of chloride ions and 40g / L of ammonium ions, and the oxidation-reduction potential of the regeneration sub-liquid is 530mV; when the acidity of the working fluid After reaching 1.0 mol / L, add a hydrochloric acid solution with a mass fraction of 31% into the working solution in the etching tank. The parameters of the working fluid in the etching tank are controlled as follows: hydrogen ion 1.0mol / L, specific gravity 1.2. Under this condition, after the circuit board was continuously etched for 4 hours with the cosmic level spray etching line, the parameters of the working fluid and the etching rate were detected.

Embodiment 3

[0053] Detect the specific gravity and acidity of the working liquid in the etching tank. When the specific gravity of the working liquid reaches 1.2, add the regeneration sub-liquid into the working liquid in the etching tank. Among them, the regeneration sub-liquid includes 20g / L of copper ions, 3mol / L of hydrogen ions, 220mol / L of chloride ions and 40g / L of ammonium ions, and the oxidation-reduction potential of the regeneration liquid is 530mV; when the acidity of the working liquid is low After reaching 1.5 mol / L, add a hydrochloric acid solution with a mass fraction of 31% into the working solution in the etching tank. The parameters of the working fluid in the etching tank are controlled as follows: hydrogen ion 1.5mol / L, specific gravity 1.2. Under this condition, after the circuit board was continuously etched for 4 hours with the cosmic level spray etching line, the parameters of the working fluid and the etching rate were detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com