Copper foil removing equipment for UWB positioning base station substrate production

A technology for positioning base stations and substrates, applied in the field of electronics, can solve problems such as increased production costs, and achieve the effect of ensuring the effect of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

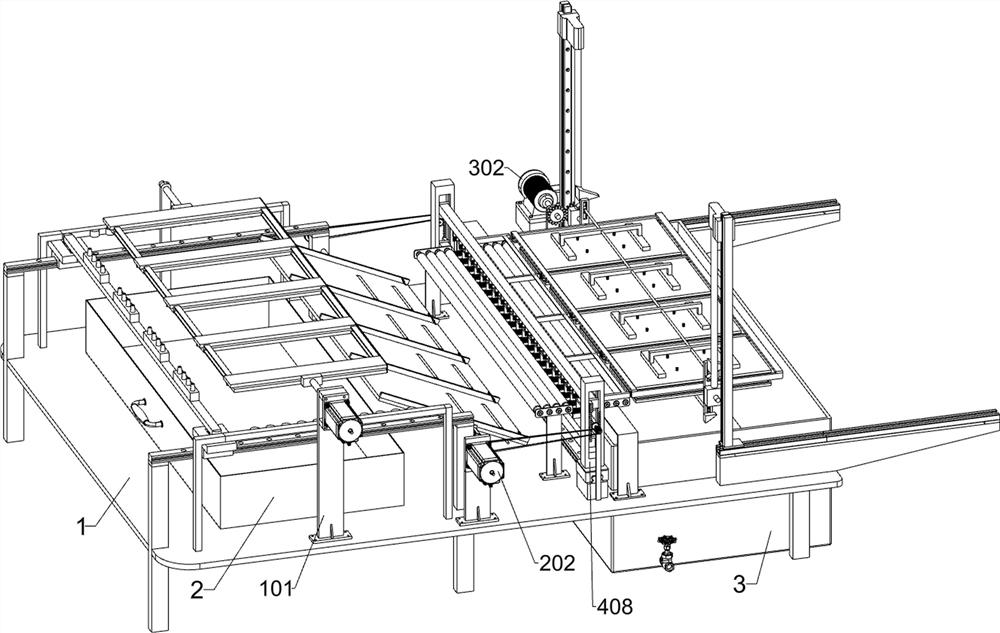

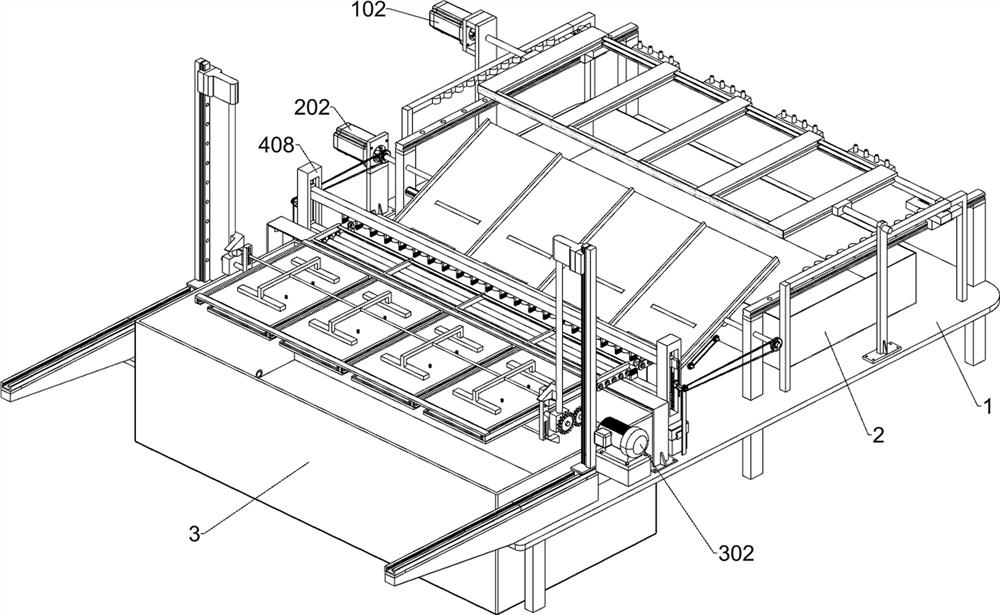

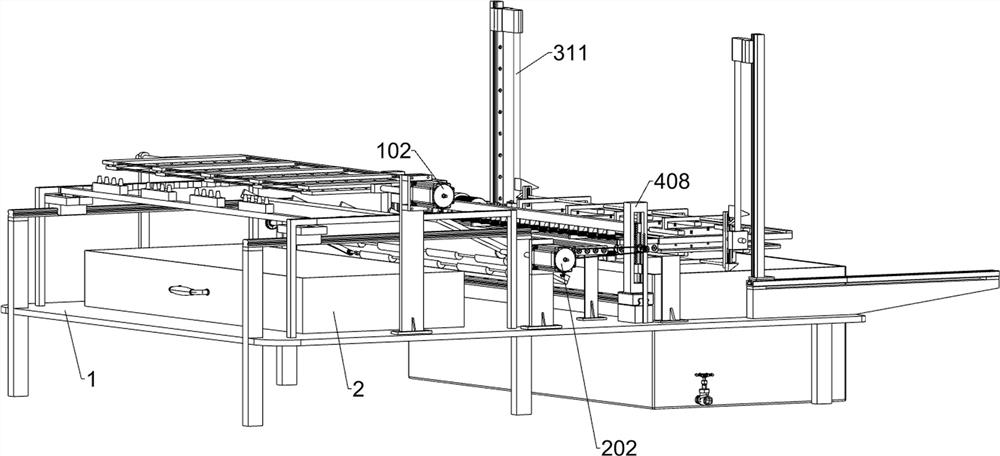

[0037] A copper foil removal equipment for UWB positioning base station substrate production, such as Figure 1-15 As shown, it includes a bottom frame 1, a collection box 2, an etching box 3, a smear removal component, a conveying component and an etching component; the upper left part of the bottom frame 1 is connected to the collection box 2; the right side of the bottom frame 1 is connected to the etching box 3. The upper left part of the bottom frame 1 is connected with a scum removal component, which is located above the collection box 2; the upper left part of the bottom frame 1 is connected with a conveying component; the upper right part of the bottom frame 1 is connected with an etching component .

[0038] The scum removal assembly includes a first fixed plate 101, a first auxiliary motor 102, a first transmission rod 103, a connecting plate 104, a second transmission rod 105, a second fixed plate 106, a first support plate 107, and a bump plate 108 , the second su...

Embodiment 2

[0049] On the basis of Example 1, such as figure 1 and Figure 16-17 As shown, it also includes a water film spraying assembly, the upper middle part of the chassis 1 is connected with a water film spraying assembly, and the water film spraying assembly includes a third transmission wheel 401, a fourth transmission wheel 402, and a sixth transmission rod 403 , the fifth support plate 404, the third spur gear 405, the fourth electric guide rail 406, the fourth electric slider 407, the limit slide rail 408, the fourth mounting plate 409, the nozzle 410, the brush plate 411 and the rack 412; A third transmission wheel 401 is fixedly connected to the opposite side of each third transmission rod 203; a fourth electric guide rail 406 is fixedly connected to the middle part of the upper side of the chassis 1 through a connecting block; two second electric guide rails 406 are slidably connected to each other. Four electric sliders 407; each of the two fourth electric sliders 407 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com