Etching process of solar energy cell chips capable of reducing NOx emissions

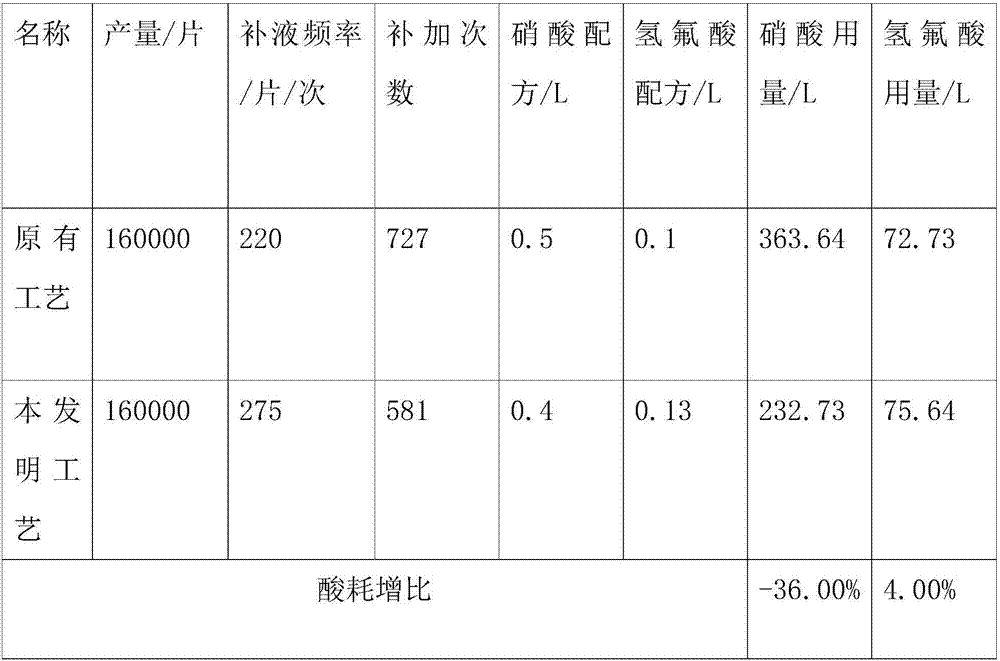

A solar cell and process technology, applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems of NOx pollution caused by etching nitric acid products, negative impact on the appearance and efficiency of silicon wafers, and high processing costs of NOx products. Reduce the cost of NOx treatment, reduce the amount used, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The invention provides a technical solution:

[0024] A solar cell etching process that can reduce NOx emissions, comprising the following steps:

[0025] Step 1: Evenly attach deionized water to the upper surface of the silicon wafer to be etched to form a water film;

[0026] Evenly attach deionized water to the upper surface of the silicon wafer to be etched, and then let it stand for 30 seconds to form a layer of deionized water film on the upper surface, and the water film should completely and uniformly cover the silicon wafer to be etched On the upper surface, there must be no uncovered corners and water breakage to prevent the water film from breaking suddenly during etching.

[0027] Step 2: Adjust the flatness of the rollers in the etching tank to keep all the rollers in the etching tank absolutely level;

[0028] Adjust the etching tank of the etching machine in advance, and adjust the rollers used for support and conduction to keep the rollers absolutely l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com