Interdigital electrode for solar battery

A technology of interdigitated electrodes and solar cells, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to use back-contact solar cells, high cost, and low welding tension to achieve optimal design, increase open circuit voltage, Effect of reducing series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

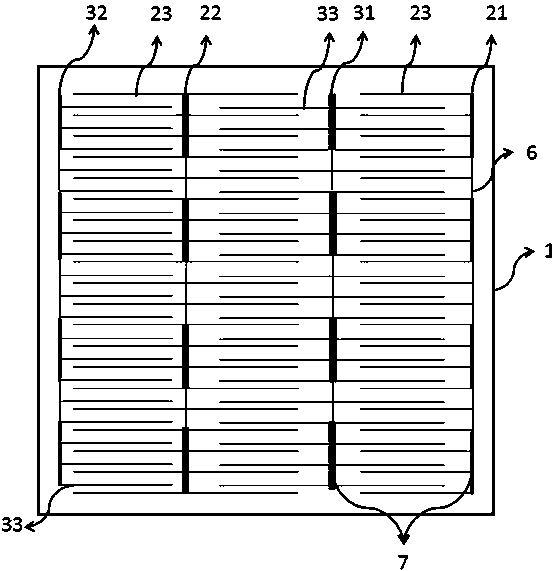

[0024] The width of the rough grille section of the positive main grid 21 on the edge of the solar cell chip is 2mm; the width of the rough grille section of the other main grid line 22 of the positive pole main grid line is 1.2mm.

[0025] The width of the rough grille section of the negative main grille line 32 located on the edge of the solar cell chip is 2mm; the width of the rough grille section of other negative main grille line 31 is 1.2mm.

[0026] The width of the fine grid line between the thick grid segments connected to the main grid line is 45 microns.

[0027] The width of the auxiliary grid line is 45 microns.

[0028] Do a dazing label 4 in a certain part of the solar cell film. In order to distinguish the positive and negative pole of the solar cell grid line, the manual is attached to Figure 4 It can be seen that the electrode design method can be easily connected by welding band 5 to the solar cell.

[0029] In the back of the back contact heterogeneous knot Sun...

Embodiment 2

[0033] The width of the rough grille section of the positive grille line 21 on the edge of the solar battery chip is 1mm; the width of the rough grille section of the other main grid line 22 of the positive pole main grid line is 0.6mm.

[0034] The width of the rough grille section of the negative main grille line 32 located on the edge of the solar cell chip is 1mm; the width of the rough grille section of other negative main grille line 31 is 0.4mm.

[0035] The width of the fine grid line between the thick grid segments connected to the main grid line is 20 microns.

[0036] The width of the auxiliary grid line is 15 microns.

[0037] Example 3

[0038] A fork finger electrode of a solar cell, the fork finger electrode is set in a solar cell piece 1, the fork finger electrode consists of positive and negative electrodes, and the positive and negative electrodes are composed of the main grid line and the auxiliary grid line, respectively.The auxiliary grid line is vertical and ...

Embodiment 3

[0040] The width of the rough grille section of the positive main grid 21 on the edge of the solar cell chips is 1.5mm; the width of the rough grille section of the other main grid line 22 of the positive pole main grid line is 0.2mm.

[0041] The width of the rough grille section of the negative main grille line 32 located on the edge of the solar cell chip is 1.5mm; the width of the rough grille section of other negative main grid line 31 is 0.2mm.

[0042] The width of the fine grid line between the thick grid segments connected to the main grid line is 80 microns.

[0043] The width of the auxiliary grid line is 80 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com