Solar cells, assemblies, systems and methods for producing solar cells

A solar cell and cell technology, applied in the field of solar cells, can solve the problems of low welding strength, poor reliability and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

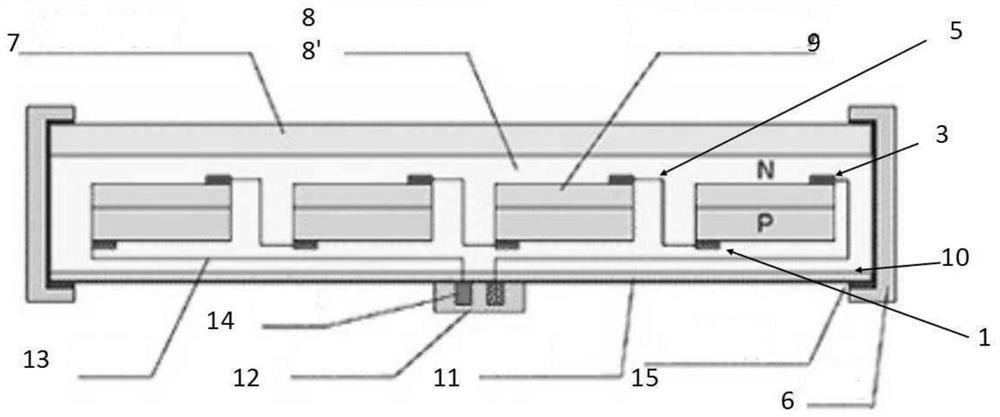

[0150] According to the preparation method of the present invention, the sintering temperature of the front silver electrode is 750-1000°C; the sintering temperature of the aluminum back field is 450-650°C. Preferably, the sintering temperature of the front silver electrode is 800-950°C; the sintering temperature of the aluminum back field is 550-650°C. In a specific embodiment, the sintering temperature of the front silver electrode is 850°C; the sintering temperature of the aluminum back field is 580°C. Of course, the simultaneous sintering of the front silver electrode and the aluminum back field can be realized after drying separately, and one sintering is completed.

[0151] In the method of the present invention, the curing condition is to keep a constant temperature for 20 seconds to 5 hours at a temperature of 90-250° C., more preferably to cure in an oven at a temperature of 140-180° C. for 0.5 to 1.5 hours, or more preferably at 140° C. Curing at -180°C for 20 secon...

Embodiment 1

[0177] In this embodiment, epoxy resin-based conductive adhesive is used. Specifically, the epoxy resin is prepared according to the following method.

[0178] The components used to prepare the conductive adhesive are as follows:

[0179] 6 parts of epoxy resin DER-354 (Dow Chemical), 4 parts of epoxy resin DER-852 (Dow Chemical), 2 parts of curing agent diaminodiphenylsulfone (Nanjing Chemical Reagent Co., Ltd.), 1 part of diluent , 10 parts of 4-butanediol diglycidyl ether (Aladdin reagent), 75 parts of flake silver powder (METALOR), 2 parts of curing accelerator 1,1-dimethyl-3-phenylurea (Aladdin reagent) , 0.5 parts of conduction accelerator succinic acid (Aladdin reagent), 0.5 parts of coupling agent Z6040 (DOWCORNING), the sum of the above components is 100 parts.

[0180] The preparation method of conductive adhesive is as follows:

[0181] First mix the above epoxy resin with the above diluent and coupling agent evenly, then add the above curing agent, the above con...

Embodiment 2

[0188] Prepared according to the same method as Example 1, except that only 5 parts of epoxy resin DER-354 is used, no other epoxy resin is used, and the amount of 1,4-butanediol diglycidyl ether diluent is changed to 5 parts Part, 1 part of diaminodiphenyl sulfone curing agent, 1 part of 1,1-dimethyl-3-phenylurea curing accelerator is changed into 1 part, and flake silver powder is changed into 88 parts, according to the same as embodiment 1 The conductive adhesive was prepared in this way.

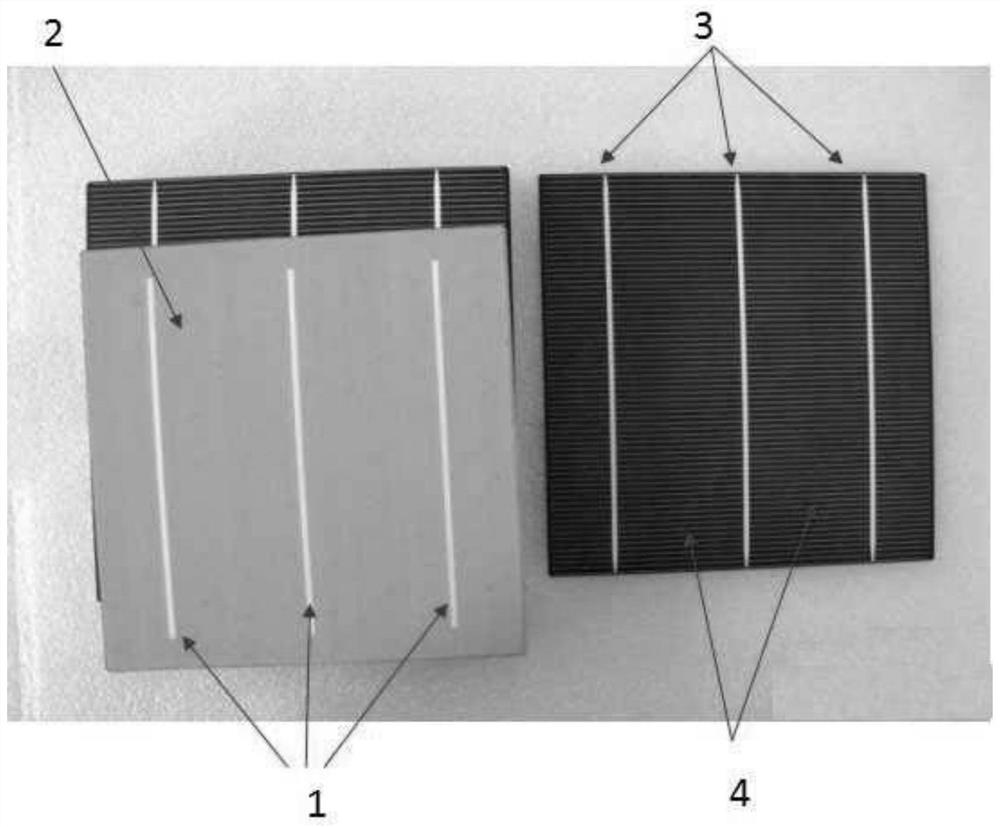

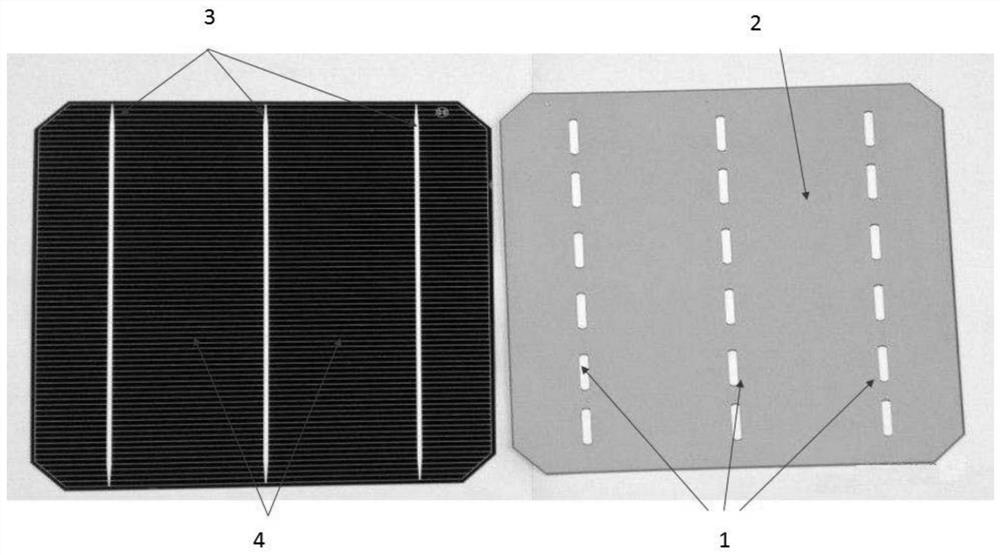

[0189] The crystalline silicon substrate was processed in the same manner as in Example 1, and what was used here was an N-type single-sided single-crystal cell (wherein the difference from Example 1 was only in the diffusion process, and powdered boron nitride Press the tablet for diffusion, the diffusion temperature is 950-1000°C, and the diffusion time is 15-30min). In addition to coating 3 spacer lines with a width of 2mm and a total length of 120mm on the aluminum back field, the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com