Patents

Literature

85results about How to "Increase opening pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

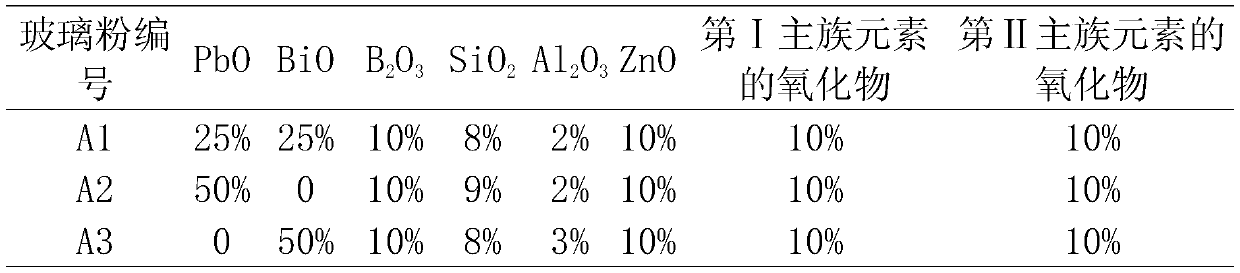

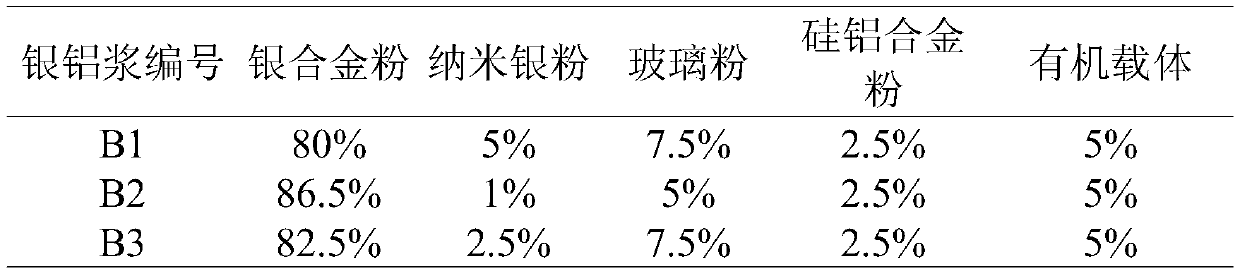

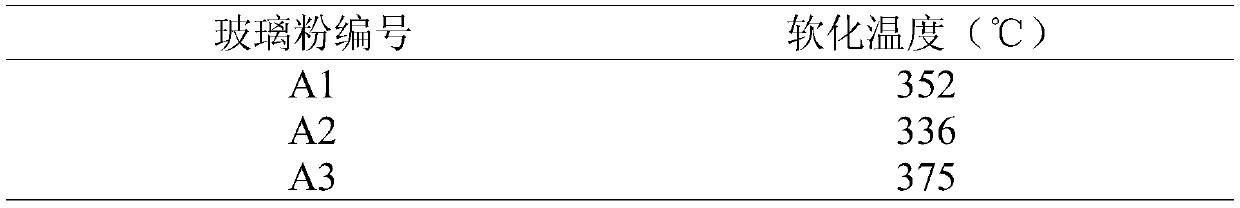

Glass powder and silver aluminum paste comprising glass powder and used on positive side of N-type double-sided solar cell

PendingCN110040968ALow softening temperatureIncrease the degree of vitrificationTransportation and packagingMetal-working apparatusMass ratioSilicon solar cell

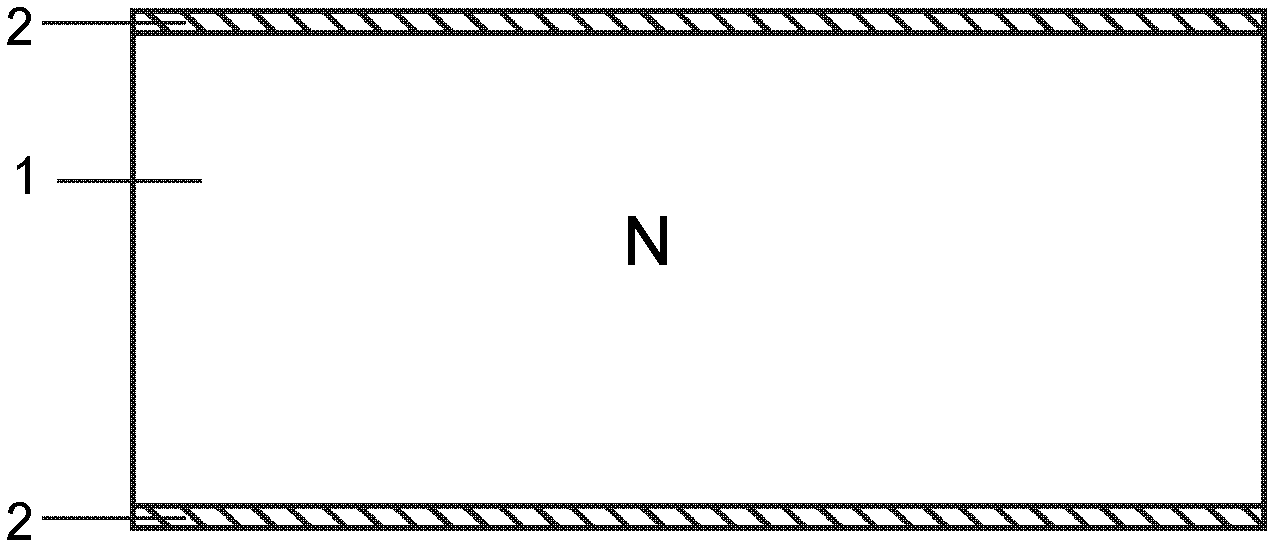

The invention discloses glass powder and silver aluminum paste which comprises the glass powder and used on the positive side of an N-type double-sided solar cell. The silver aluminum paste comprisesconductive silver powder, silicon aluminum alloy powder, the glass powder and an organic carrier, wherein the glass powder is prepared from the following components in percentage by weight: 0-50% of PbO, 0-50% of BiO, 5-15% B2O3, 8-9% of SiO2, 2-3% of Al2O3 and 5-15% of ZnO; the mass ratio of silicon to aluminum in the glass powder is (4-5) to 1; the content of the conductive silver powder is 80wt% to 90wt%; the conductive silver powder comprises nano silver powder and silver alloy powder in a mass ratio of 1 to (18-90). The glass powder not only guarantees the corrosiveness of SiNx, but alsodoes not cause relatively strong metallized composition. The silver aluminum paste prepared by using the glass powder solves the problem of the contradiction between contact resistance and open circuit voltage when the silver aluminum paste is printed on the positive side of an N-type crystalline silicon solar cell.

Owner:NANTONG T SUN NEW ENERGY CO LTD

Heterojunction with intrinsic thin layer (HIT) solar cell structure with heterogeneous floating junction back passivation, and preparation process thereof

ActiveCN102437243AReduce surface recombination rateIncrease the open circuit voltagePhotovoltaic energy generationSemiconductor devicesHeterojunctionAmorphous silicon

The invention relates to the technical field of solar cells, in particular to a heterojunction with intrinsic thin layer (HIT) solar cell structure with heterogeneous floating junction back passivation, and a preparation process thereof. P-type amorphous silicon layers are deposited on the upper surface and the lower surface of an N-type crystal silicon substrate so as to form heterogeneous P-N junction structures; a mask is manufactured on the heterogeneous P-N junction structure on the lower surface; selective etching is performed so as to form isolated heterogeneous P-N junction structures; the mask layer is removed and an insulation thin film layer is deposited on the lower surface; a mask is manufactured on the insulation thin film layer; secondary selective etching is performed, so that the side surface and the back surface of the heterogeneous P-N junction structure on the lower surface of the N-type crystal silicon substrate are encircled by the insulation thin film layer, and a floating junction back passivation structure is formed; and an N-type amorphous silicon back electrode and a P-type amorphous silicon floating junction back passivation structure are strictly separated from each other by the insulation thin film layer. Compared with an HIT standard process and a structure of the Sanyo, the HIT solar cell structure has the advantages that: the floating P-N junction back passivation structure is introduced into the back surface of the N-type crystal silicon, so that the surface compounding rate is lower and the open-circuit voltage is higher.

Owner:TRINA SOLAR CO LTD

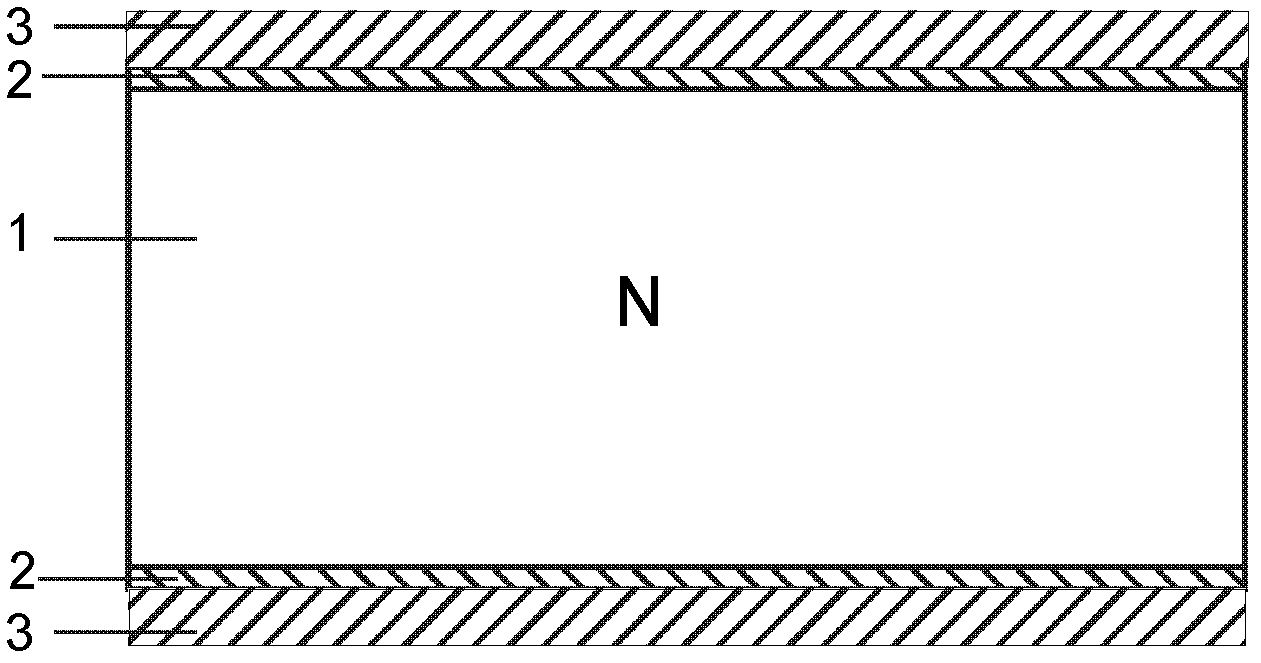

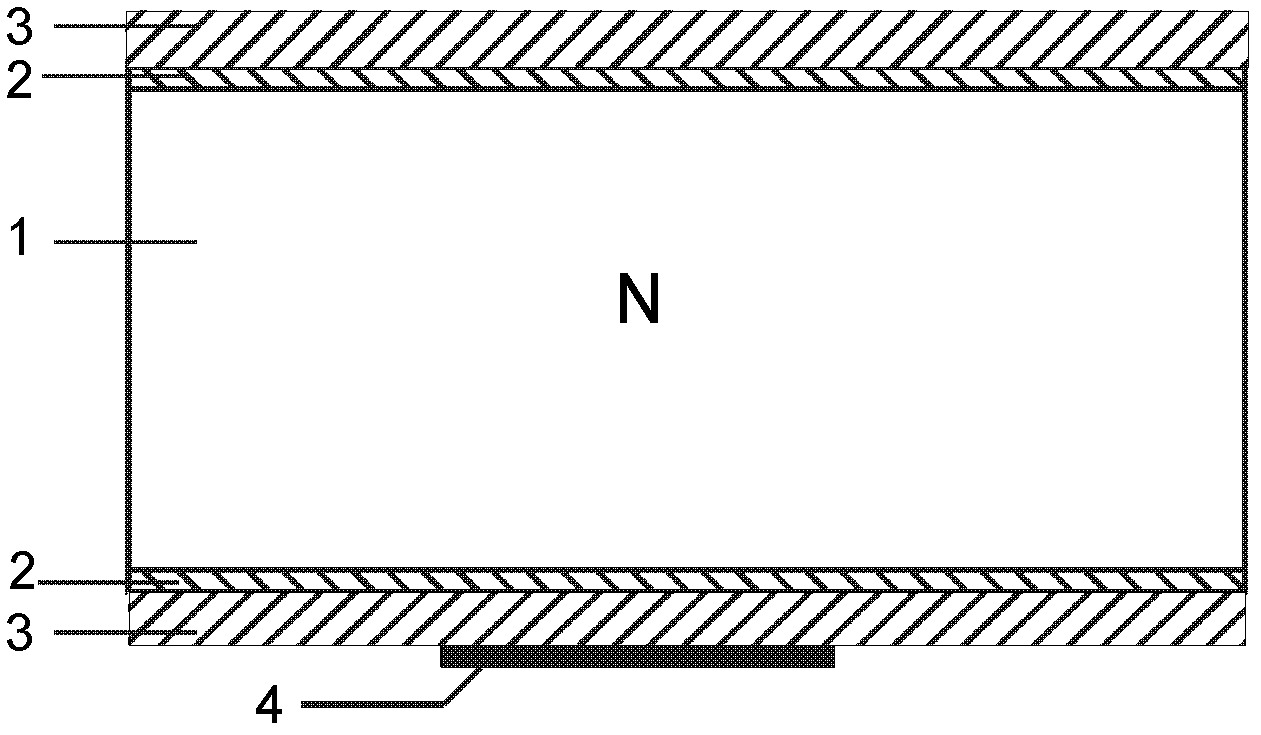

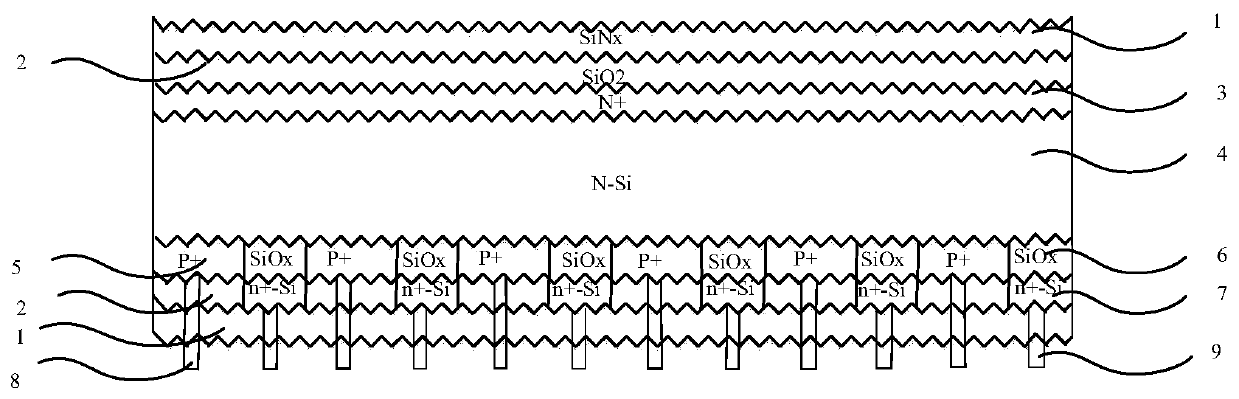

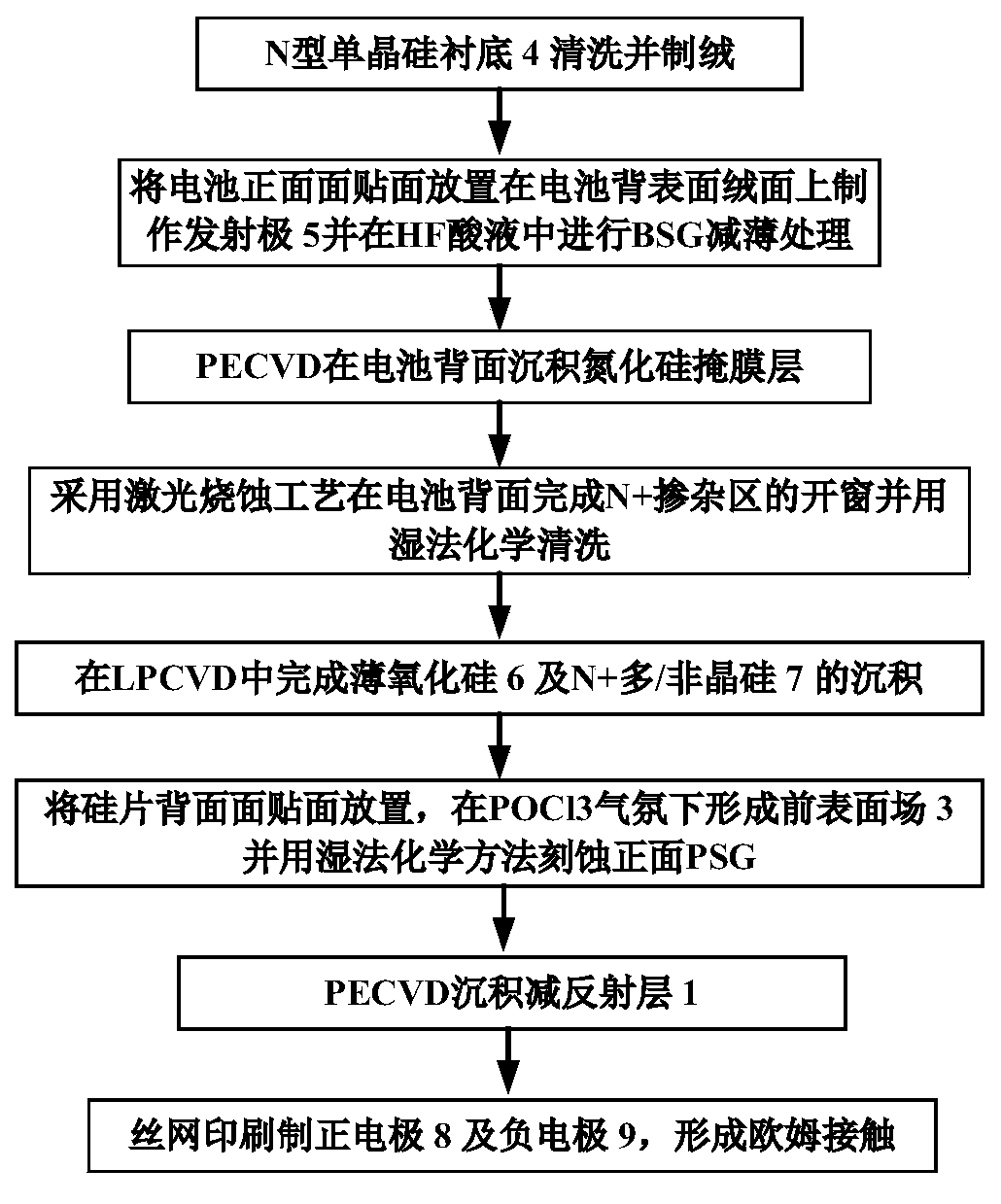

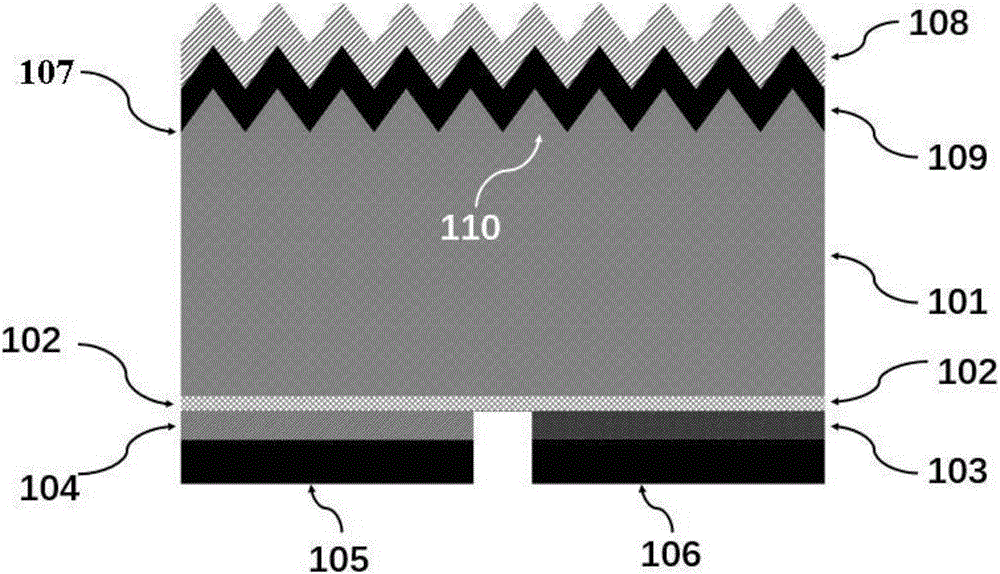

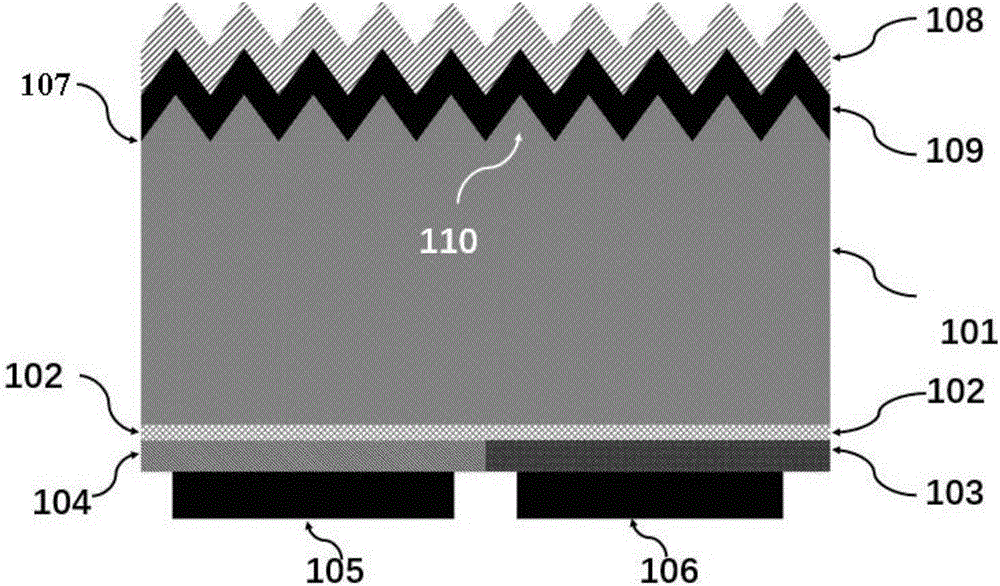

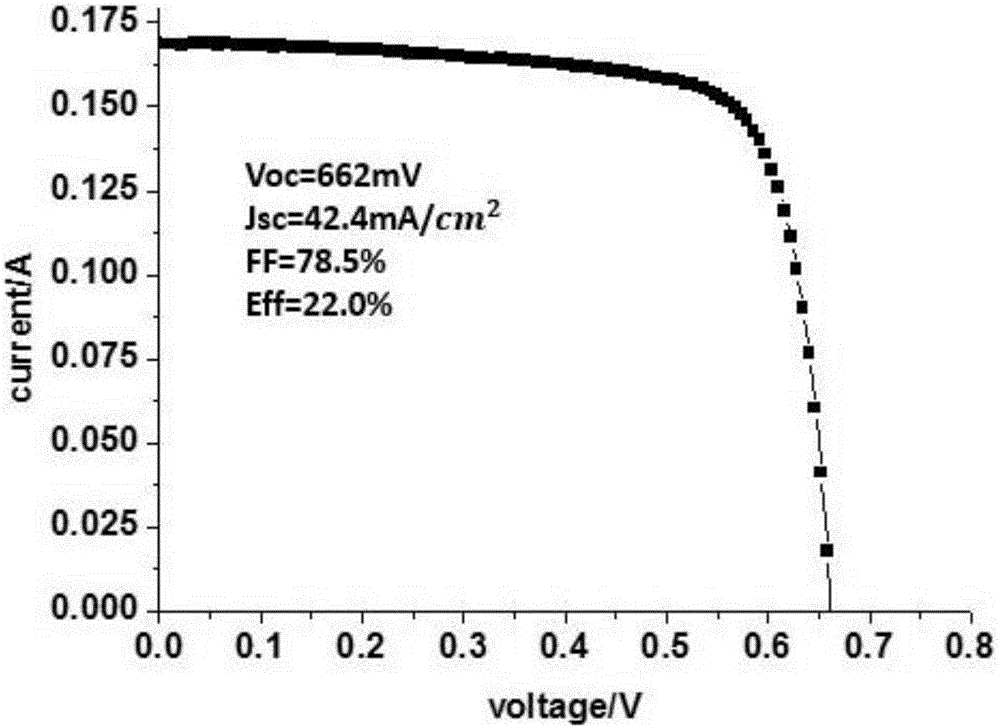

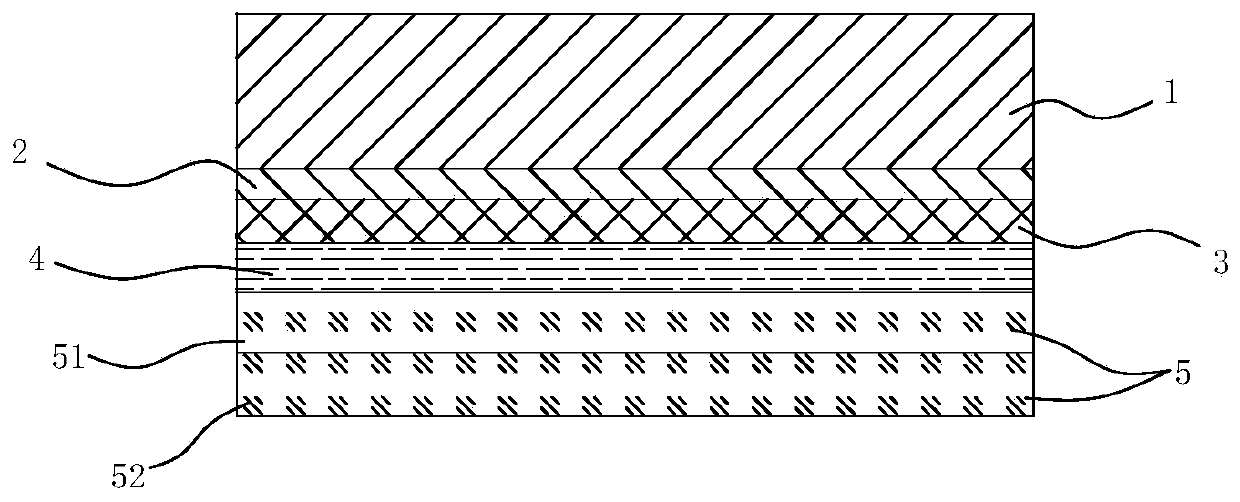

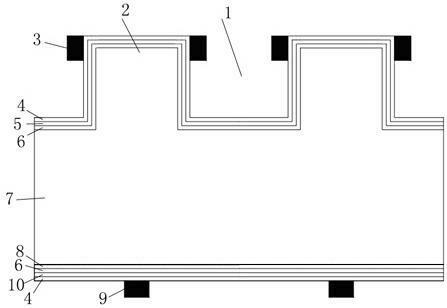

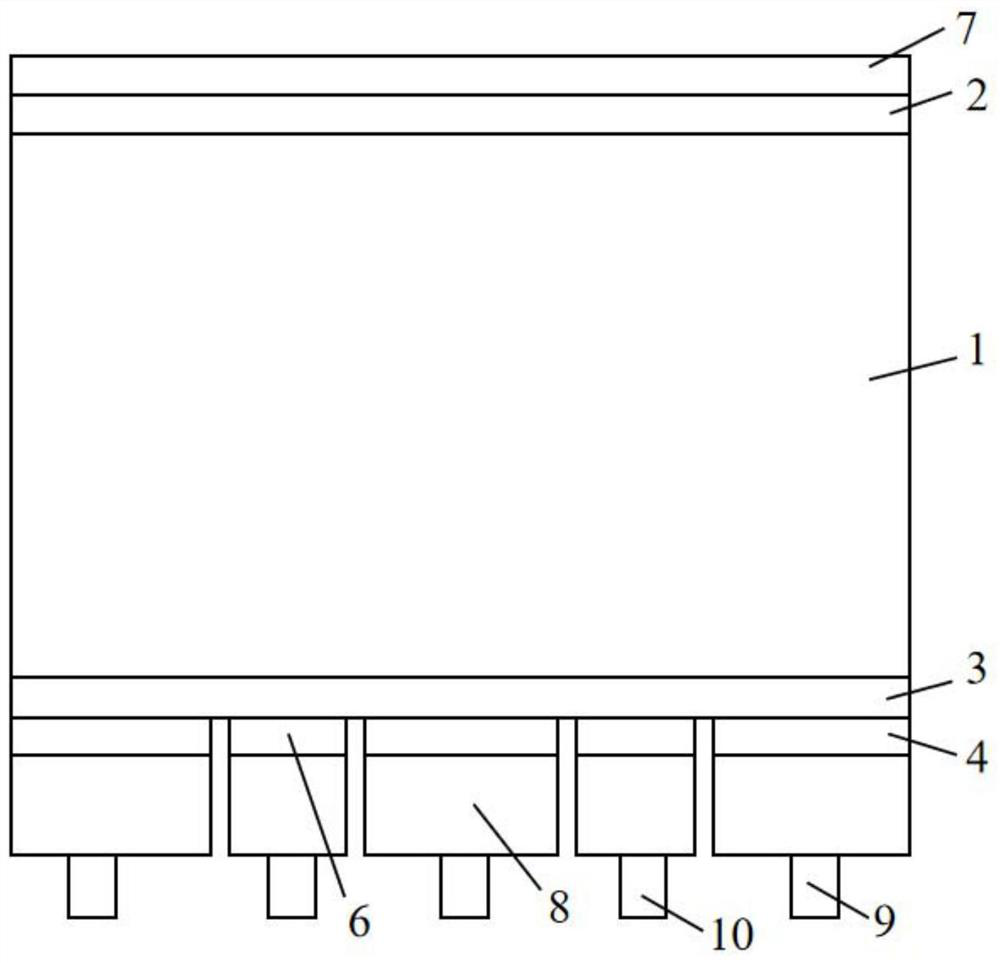

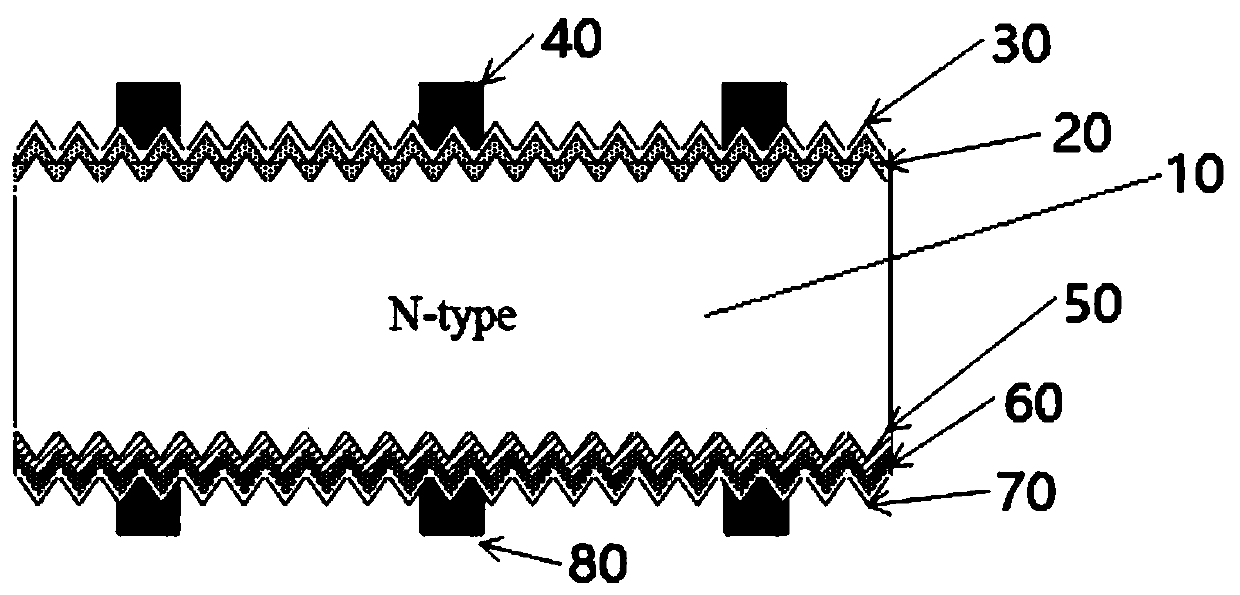

Back junction and back contact solar cell structure and preparation method thereof

ActiveCN111564503AIncrease opening pressureReduce electricity costsFinal product manufacturePhotovoltaic energy generationEngineeringSolar battery

The invention provides a back junction and back contact solar cell structure and a preparation method thereof. The cell structure sequentially comprises an anti-reflection layer (1), a passivation film (2), an N+ doped layer (3), an N type silicon substrate (4), a back P+ doped layer (5), a Topcon structure and cell electrodes from top to bottom, wherein the back P+ doped layer (5) and the Topconstructure are distributed on the same layer in a crossed manner, the Topcon structure comprises an ultrathin oxide layer (6) and an N+ polycrystalline silicon / amorphous silicon layer (7), the cell electrodes comprise a positive electrode (8) and a negative electrode (9), the positive electrode (8) is in contact with the P+ doped layer (5), and the negative electrode (9) is in contact with the N+ polycrystalline silicon / amorphous silicon layer (7). According to the invention, the N+ back doped region of the back doped layer in the prior art is changed into the Topcon structure, so that the complexity of the technological process is not increased while the voltage of the battery is increased, and the kilowatt-hour cost of the battery is fundamentally reduced.

Owner:SPIC XIAN SOLAR POWER CO LTD +3

Cleaning technology after polycrystalline silicon solar cell silicon wafer acid texturing

ActiveCN103394484AImprove photoelectric conversion efficiencyReduced compound centerAfter-treatment detailsFinal product manufactureSurface structureOxidizing agent

The invention discloses a cleaning technology after polycrystalline silicon solar cell silicon wafer acid texturing. A polycrystalline silicon wafer is cleaned through an acid solution containing an oxidizing agent or a base solution containing the oxidizing agent after acid texturing. According to the cleaning technology, the surface structure of the silicon wafer is optimized, residual composition on the surface of the silicon wafer is removed, texturing liquid remaining on the surface of the silicon wafer after the silicon wafer is textured can be cleaned, porous silicon can be removed as well, so that the recombination centers on the surface of the silicon wafer are greatly reduced, the short-circuit current and start voltage are improved, and the effect that the photoelectric conversion efficiency of a solar cell is improved is achieved. After the cleaning technology after polycrystalline silicon solar cell silicon wafer acid texturing is adopted, the porous silicon generated after acid texturing can be removed, pointed structures on the textured face are reduced, the color and the luster of the appearance of the silicon wafer are even, the difference between different crystalline grains is small, and the polycrystallization degree is not enhanced. In addition, the cleaning technology after polycrystalline silicon solar cell silicon wafer acid texturing is simple, easy to operate, compatible with an existing technology and good in repeatability.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Back junction backcontact solar cell

InactiveCN106653887AReduce manufacturing costIncrease compound ratePhotovoltaic energy generationSemiconductor devicesElectrical resistance and conductanceCharge carrier

The invention provides a back junction backcontact solar cell. The back junction backcontact solar cell comprises a substrate, a composite layer, a tunneling oxide layer, a P-type doped semiconductor layer, an N-type doped semiconductor layer, a positive electrode and a negative electrode, wherein the composite layer is combined on a front surface of the substrate, the tunneling oxide layer is combined on a back surface of the substrate, the P-type doped semiconductor layer and the N-type doped semiconductor layer are combined on the tunneling oxide layer, the positive electrode is arranged on the P-type doped semiconductor layer, and a negative electrode is arranged on the N-type doped semiconductor layer. The invention proposes a back junction backcontact solar cell employing a tunneling oxide layer passivation contact structure; with the adoption of the tunneling oxide layer passivation contact structure, direct contact of a metal electrode and the substrate is prevented, the combination of a carrier on a metal contact interface is effectively reduced, and an opening voltage of the cell is increased; and moreover, combination addition cannot brought by metal contact, the vast majority of areas of an emission field and a back field can be covered by metal contact, transverse transmission of the carrier is prevented, the series resistance is favorably reduced, and the cell efficiency is further improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

PERC (Passivated Emitter and Rear Contact) solar cell

InactiveCN106057920AReduce compoundingIncrease opening pressurePhotovoltaic energy generationSemiconductor devicesP–n junctionSolar cell

The invention discloses a PERC (Passivated Emitter and Rear Contact) solar cell. The PERC solar cell comprises a silicon wafer layer with a PN junction, and a passivation layer and a metal layer which are arranged in sequence on a back side of the silicon wafer layer, wherein the passivation layer is provided with an open area; the surface of the solar cell is provided with a back electrode; and based on a plane on which a silicon wafer is positioned, the position of the back electrode does not coincide with the position of the open area. The position of the back electrode does not coincide with the position of the open area, so that compounding between metal and naked silicon on an opening is reduced, and an open voltage of the cell is increased. As proved by experiments, compared with an existing structure, the structure of the PERC solar cell has the advantages that the cell conversion efficiency can be increased by 0.1 percent, and an unexpected effect is achieved.

Owner:CSI CELLS CO LTD

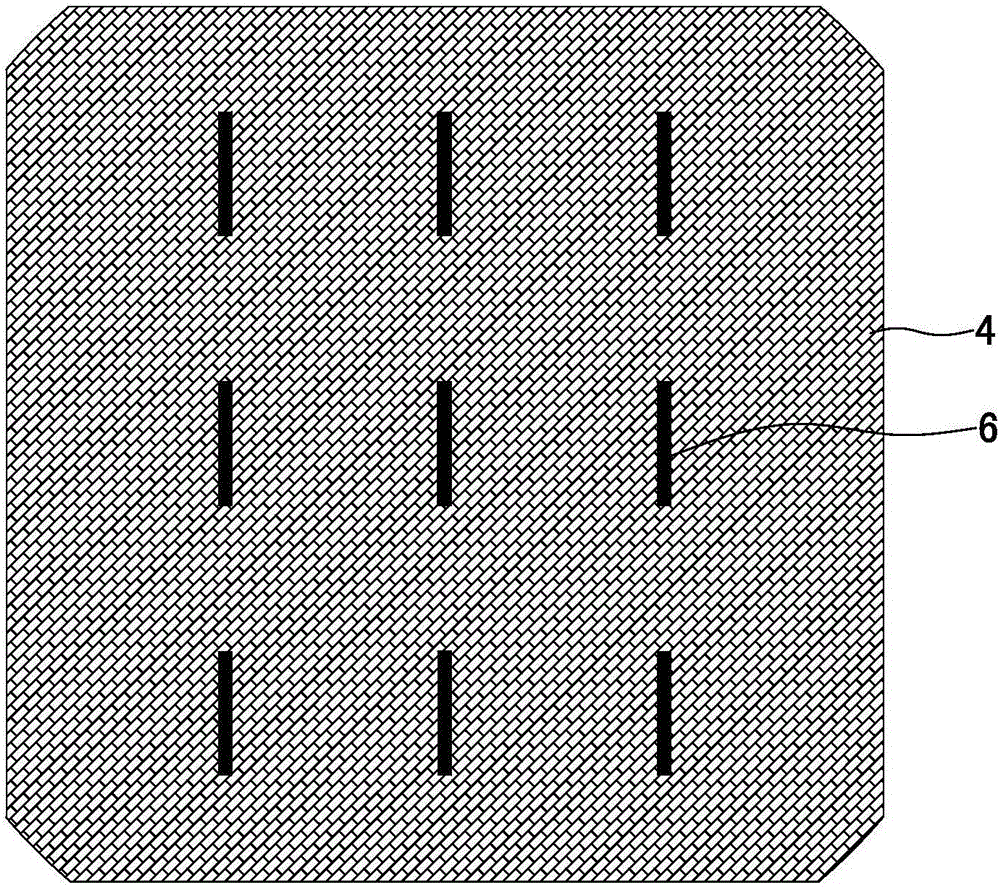

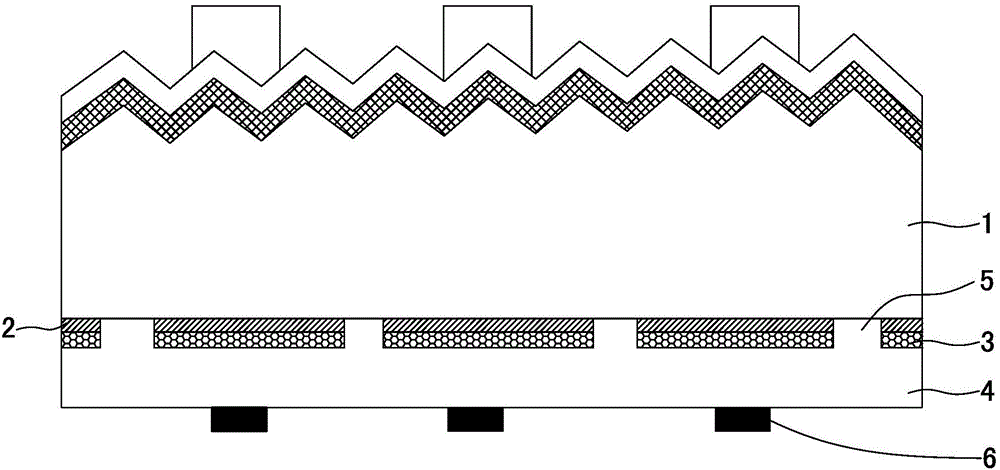

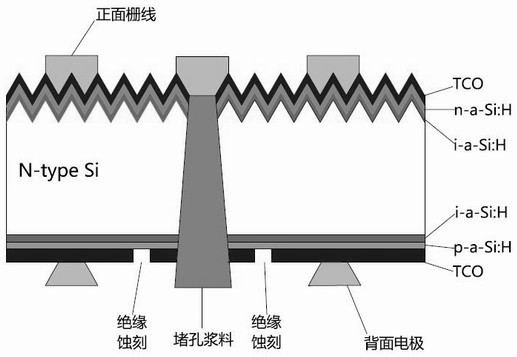

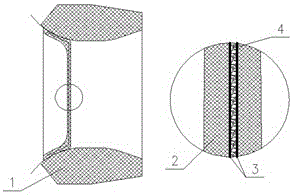

MWT heterojunction solar cell and preparation method thereof

PendingCN113113501AImprove passivation effectIncrease opening pressureFinal product manufacturePhotovoltaic energy generationHeterojunctionAmorphous silicon

The invention discloses an MWT heterojunction solar cell and a preparation method thereof, the MWT heterojunction solar cell sequentially comprises a front conductive TCO layer, a front N-type doped amorphous silicon layer, a front intrinsic amorphous silicon layer, a monocrystalline silicon substrate, a back intrinsic amorphous silicon layer, a back P-type doped amorphous silicon layer and a back TCO conductive layer, the front surface is a textured structure, and the back surface is a polished surface. According to the preparation method of the cell provided by the invention, the special etching slurry for the TCO is used for insulating the conductive TCO between the positive electrode and the negative electrode of the back surface to replace laser insulation, so that the insulation effect is better, the electric leakage failure ratio is reduced, the yield is improved, the damage of laser insulation isolation to a silicon substrate can be avoided, and the open voltage and conversion efficiency of the MWT heterojunction cell are improved.

Owner:JIANGSU SUNPORT POWER CORP LTD

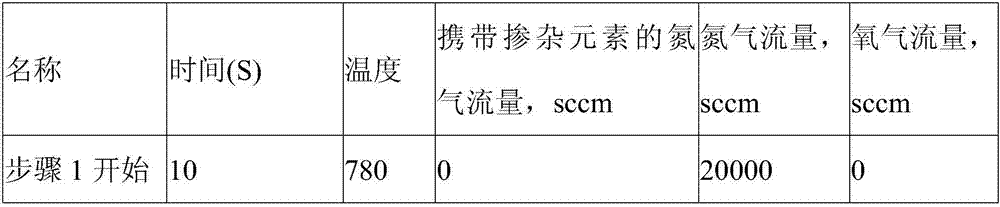

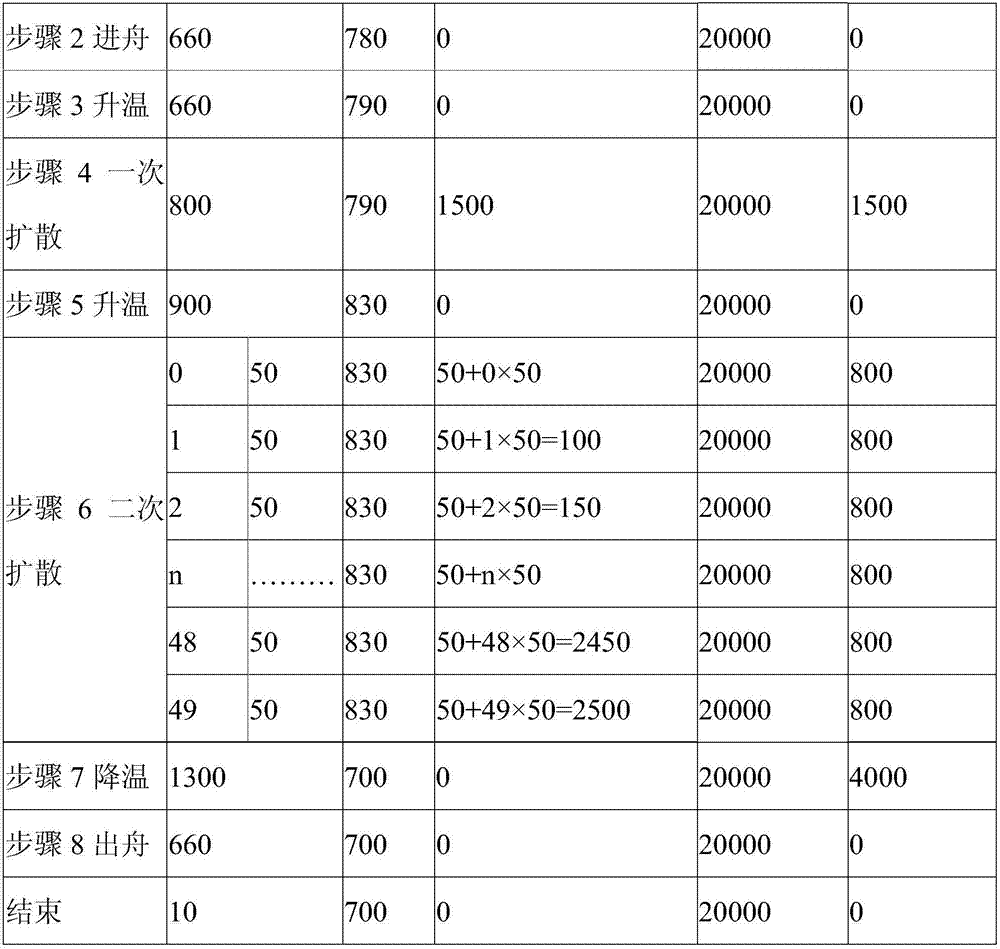

Solar cell crystal silicon wafer phosphorus diffusion method

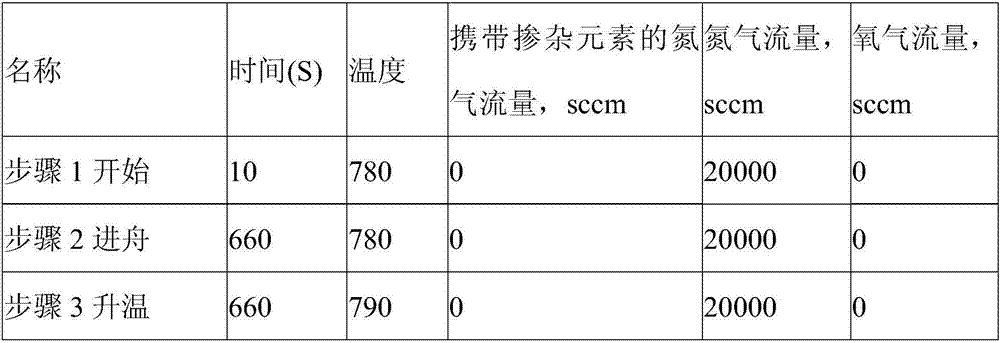

InactiveCN107331731ASimple methodReduce gas usageFinal product manufactureSemiconductor/solid-state device manufacturingChemistryNitrogen gas

The invention discloses a solar cell crystal silicon wafer phosphorus diffusion method. The method comprises the following steps: 1) a to-be-processed crystal silicon wafer is placed in a diffusion furnace, temperature is raised, and nitrogen carrying a phosphorus source, dry oxygen and large nitrogen are introduced, constant-source diffusion is carried out; 2) introduction of the nitrogen carrying the phosphorus source is stopped, temperature is raised, the dry oxygen and the large nitrogen are introduced to perform propelling; 3) the nitrogen carrying the phosphorus source and the dry oxygen are introduced, and low-temperature diffusion is carried out; 4) the introduction of the nitrogen carrying the phosphorus source is stopped, and constant-temperature propelling is carried out; 5) temperature is raised, the nitrogen carrying the phosphorus source and the dry oxygen are introduced, and constant-source diffusion is carried out; 6) the introduction of the nitrogen carrying the phosphorus source is stopped, and oxygen-existing limited-source diffusion is performed; 7) temperature is lowered, the nitrogen carrying the phosphorus source, the dry oxygen and the large nitrogen are introduced, and cooling diffusion is carried out; and 8) temperature is lowered, and the crystal silicon wafer is taken out from a boat. The phosphorus diffusion method is simple and is easy to do, and the phosphorus diffusion method is widely used; and photoelectric conversion efficiency of the silicon wafer can be effectively improved through adoption of the method, electric performance of a solar cell is improved, and the phosphorus diffusion method is suitable for promotion and application.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

Nozzle rubber cover of missile engine

The invention relates to an assembly structure capable of effectively improving the opening pressure of a nozzle rubber cover, and discloses a creative double-layer or multi-layer cloth-inserted rubber cover capable of effectively improving and stabilizing opening pressure. The rubber cover comprises a throat lining, a rubber layer and a cloth-inserted layer, is shaped like a bowl and is bonded with the throat lining through 730 glue at a convergent section. Two or more layers of inserted cloth are buried in the middle of the rubber layer so as to achieve reinforcement, the rubber layer is made of nitrile rubber materials, and the inserted cloth of the cover is butyronitrile oil-resistant rubber cloth. By means of the scheme, on the basis of keeping an original cover processing mold unchanged, the strength of a cover body is improved by increasing the number of layers of the inserted cloth, so that change of the design scheme of the cover is completed in a short period. The scheme is tested in experiments, the nozzle rubber cover of the missile engine is reasonable, simple, safe and reliable in structure, and a creative design concept and technical accumulation are provided for research of the nozzle cover.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

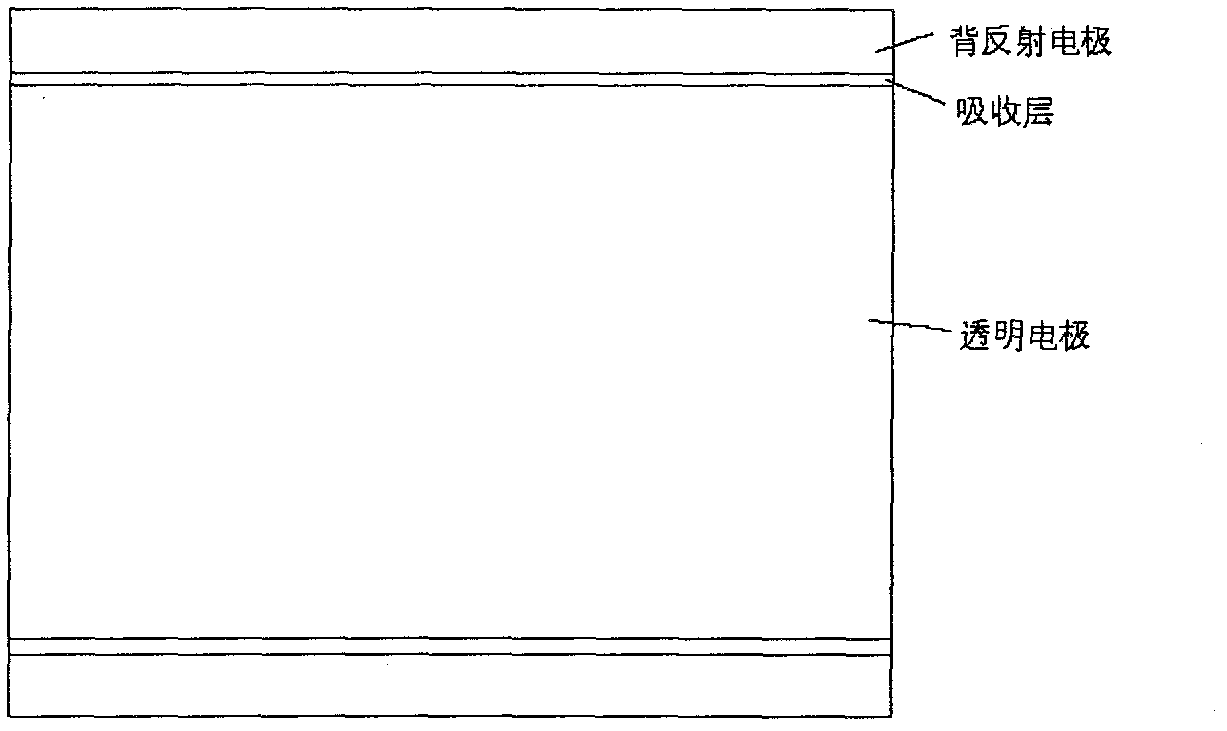

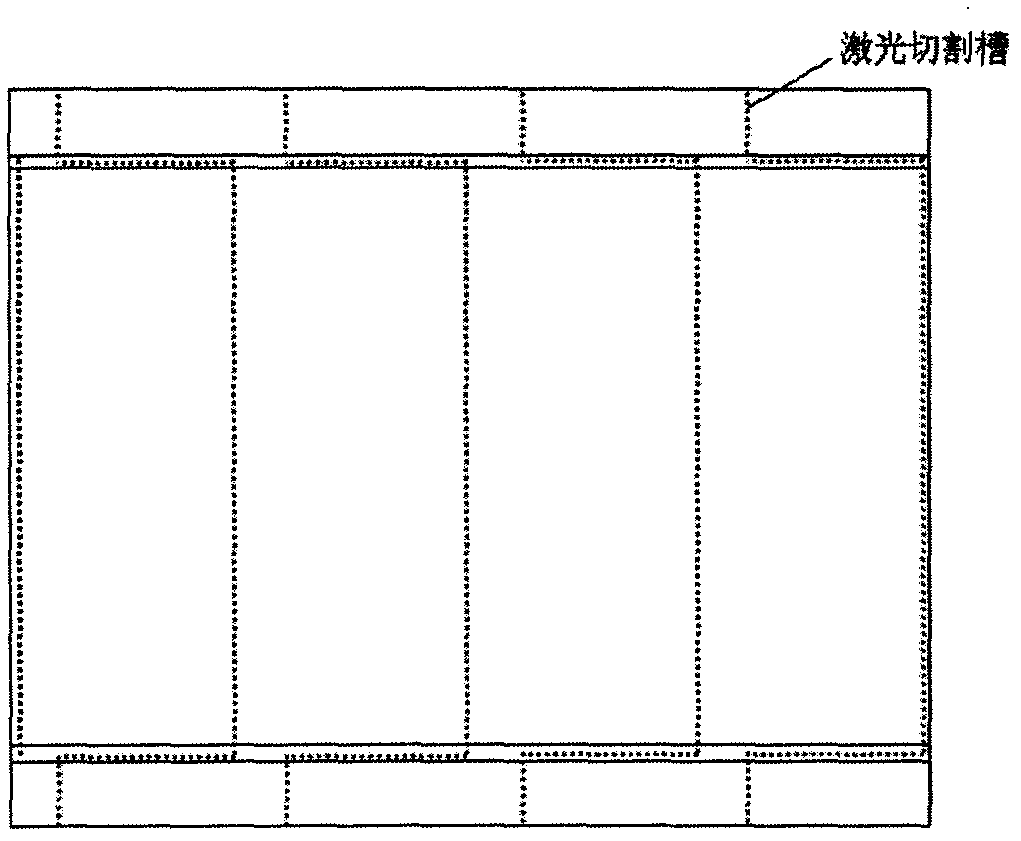

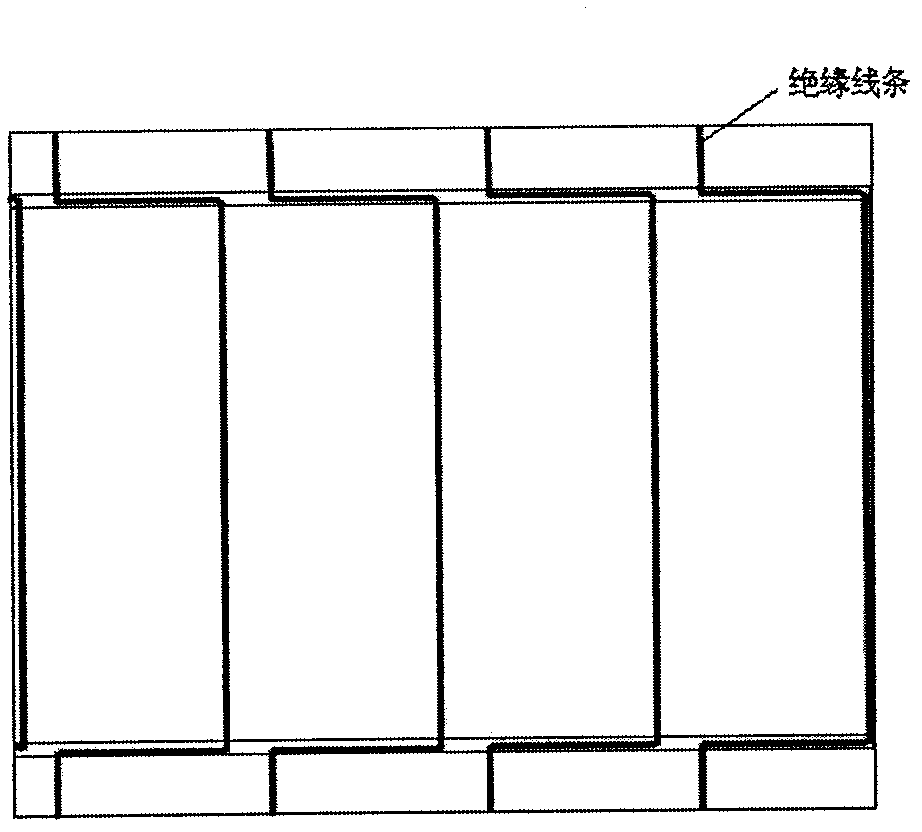

Method for manufacturing soft silicon-based thin film solar cell integrated component

InactiveCN102856425AIncrease opening pressureSimplify complexityFinal product manufactureSemiconductor devicesLaser scribingEngineering

The invention discloses a method for manufacturing a soft silicon-based thin film solar cell integrated component. The method includes that a composite back reflection bottom electrode, a silicon-based thin film layer and a transparent electric conduction layer are manufactured by a vacuum method, a laser scribing process and a screen printing process are combined, and finally the soft silicon-based thin film solar cell integrated component is obtained. According to the method for manufacturing the soft silicon-based thin film solar cell integrated component, the laser scribing and the screen printing are performed after the vacuum plating process is finished, the pollution of the antivacuum process to the vacuum process is prevented, the substrate can be directly etched by the laser scribing, the difficulty is small, and the method is easy to implement, the grid line is manufactured by relatively simple screen printing process, and the interconnection is achieved. Besides, the manufacturing difficulty of the soft silicon-based thin film solar cell integrated component is greatly reduced, the cost is low, and the industrial production is easy to achieve.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Polycrystalline velvet additive-matched surface treatment technology after felting

InactiveCN103696021APrevent looseningImprove uniformityAfter-treatment detailsFinal product manufactureHigh concentrationScreen printing

The invention discloses a polycrystalline velvet additive-matched surface treatment technology after felting. The technology comprises the following steps: (a) putting a silicon slice into a system to which a novel polycrystalline velvet additive is added to felt, so as to form a small suede with a better anti-reflection effect; (b) heating a KOH solution to an alkaline bath by using a heat exchanger with large powder, and then spraying the felted silicon slice up and down by using a hot alkaline liquor; (c) cleaning the surface of the silicon slice by using specific concentration of HF / HCL mixed acid. By adopting the technology disclosed by the invention, excessive nanoscale porous silicon can be removed, recombination is effectively reduced, open pressure and parallel resistance are improved, leakage current is reduced, and an aluminum back field also can be effectively prevented from loosening and falling off after a silk screen is printed and sintered. The capillarity on the suede is relieved due to higher concentration of hot alkaline washing, a pile pit is better in homogeneity, the probability of over-etching and P aberration of a pipe is finally reduced, and impurities in the pile pit of the small suede are removed by higher concentration of mixed acid washing. Thus, recombination is greatly reduced.

Owner:TAITONG TAIZHOU IND

Phosphorus diffusion method of crystalline silicon solar cell

ActiveCN105780127AReduced Diffusion Process TimeIncrease productionDiffusion/dopingSemiconductor/solid-state device manufacturingElectrical batteryPhysical chemistry

The invention discloses a phosphorus diffusion method of a crystalline silicon solar cell. The phosphorus diffusion method comprises the following steps: (1) heating a diffusion furnace to 760-780 DEG C, and feeding; (2) adjusting the temperature to 780-790 DEG C; (3) introducing a phosphorus source carrying gas and dry oxygen for low-temperature diffusion; (4) stopping introducing the phosphorus source carrying gas and the dry oxygen, increasing the temperature inside the furnace to 820-840 DEG C, and boosting; (5) performing constant-temperature boosting; (6) reducing the temperature inside the diffusion furnace to 700-750 DEG C, and performing cooling diffusion; and (7) cooling, and discharging. As annealing steps and steps of two times of diffusion are combined, the problem that in the prior art the surface doping solubility caused by annealing is reduced secondarily and impurities are widely distributed can be solved, the impurity distribution meets the shallow junction and narrow impurity requirements, moreover the yield is increased, and the photoelectric conversion efficiency can be improved.

Owner:YANCHENG CANADIAN SOLAR INC

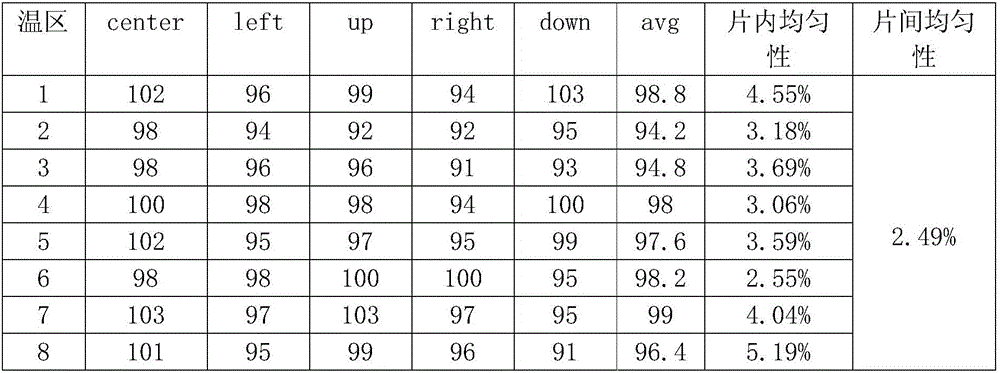

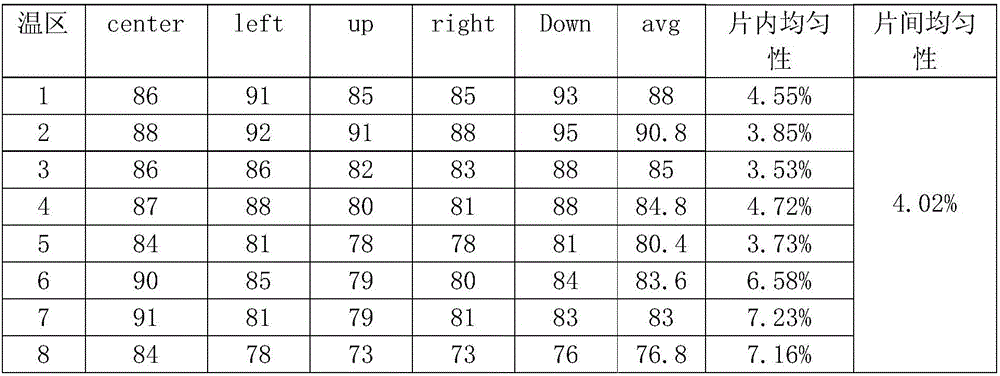

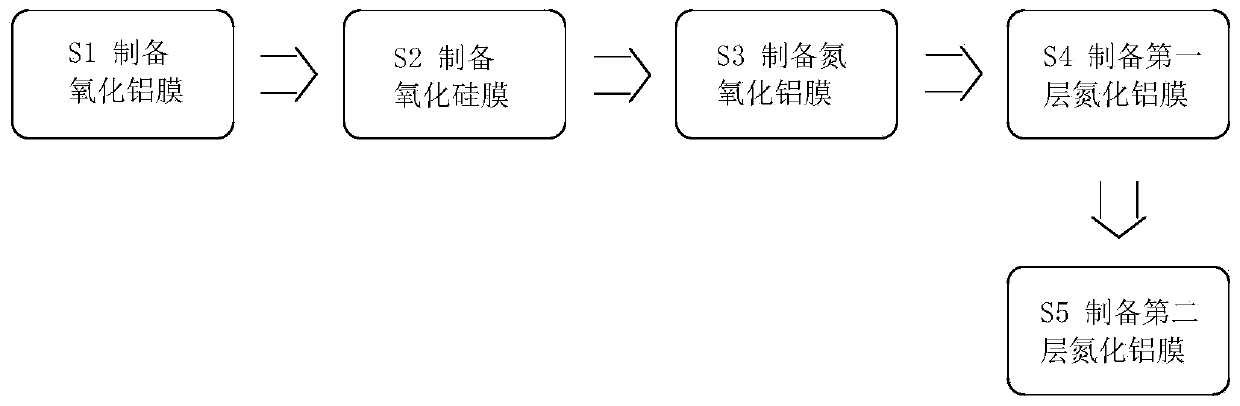

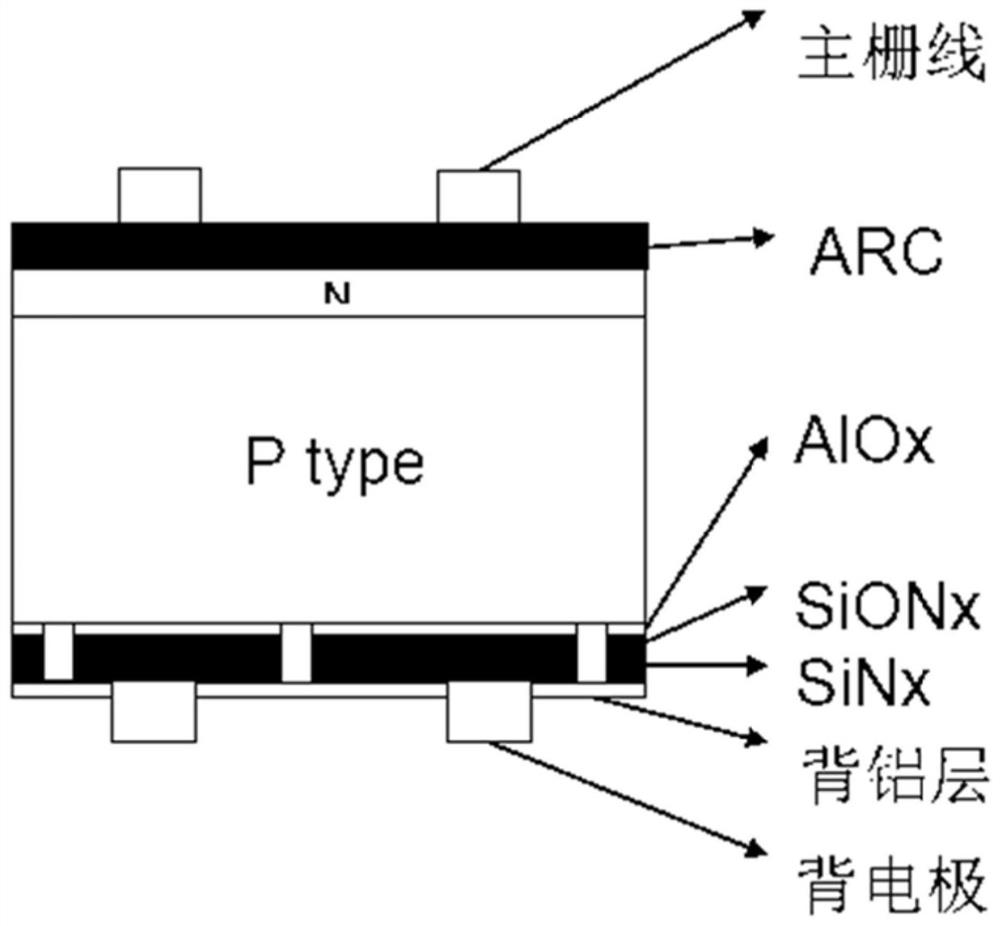

Preparation method of back membrane capable of improving conversion efficiency of single-faced PERC cell

InactiveCN111378958AIncrease reflectionPromote absorptionFinal product manufactureChemical vapor deposition coatingRefractive indexEngineering

The invention relates to a preparation method of a back membrane capable of improving conversion efficiency of a single-faced PERC cell. The method includes the steps of preparing an aluminum oxide membrane, preparing a silicon oxide membrane on the back face, preparing a silicon oxynitride membrane on the back face and preparing a double-layer silicon nitride membrane on the back face. A siliconwafer back membrane structure obtained by an existing production process generally is only provided with an aluminum oxide layer and a silicon nitride layer, while the method provided by the inventionadds the high-density silicon oxynitride membrane and silicon oxide membrane on the back membrane. The silicon oxynitride membrane with the high refraction index can well increase reflection of long-waveband sunlight by the back face of the cell, so long wave light enters a silicon wafer body again, absorption of the long wave light is increased, and therefore open-circuit voltage and current ofthe cell are increased so as to finally improve the conversion efficiency. Meanwhile, the silicon oxynitride membrane with the high refraction index and the silicon oxide membrane added on the back face can well prevent efficiency attenuation caused by moisture and metal ions entering a battery piece, and product quality is improved.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD

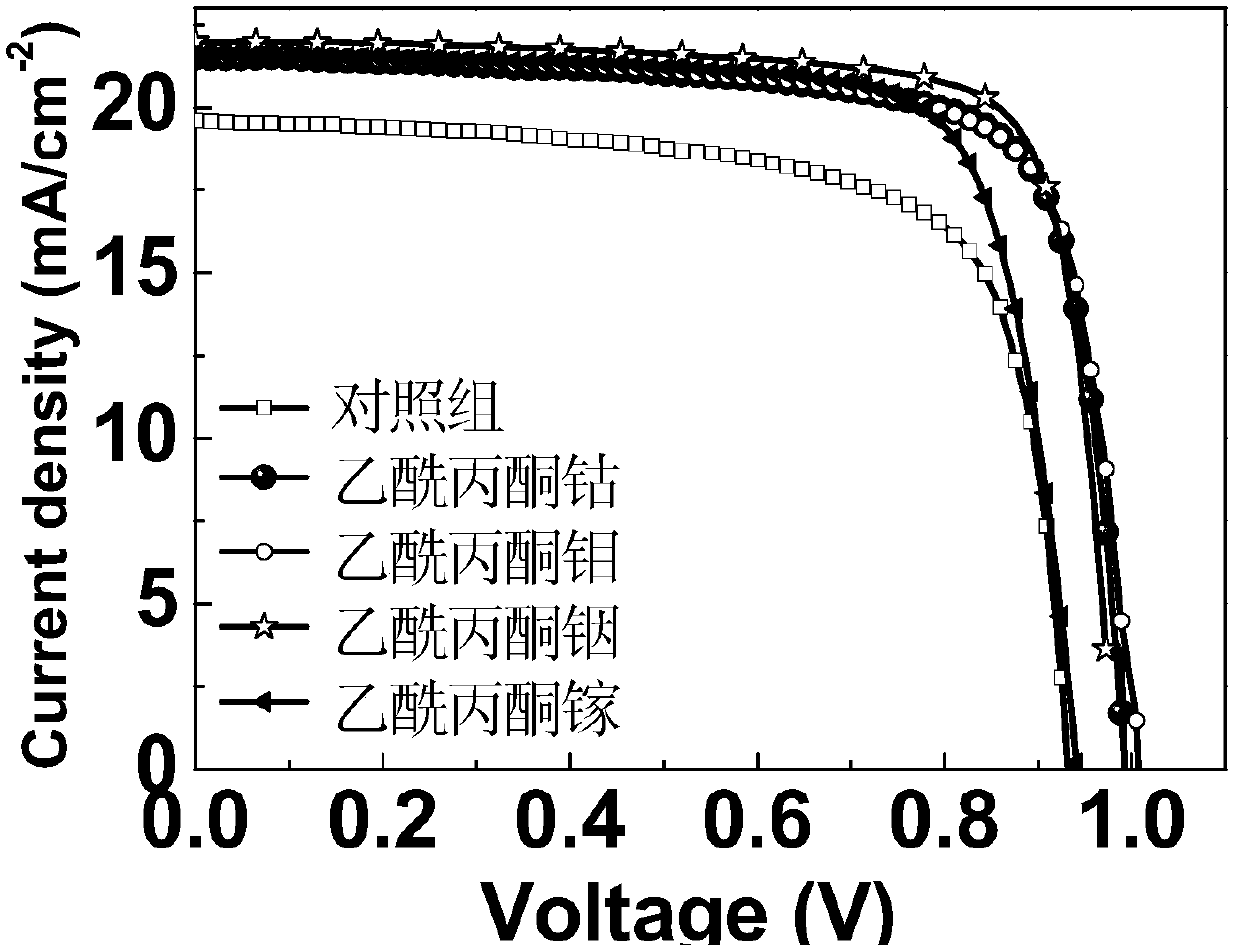

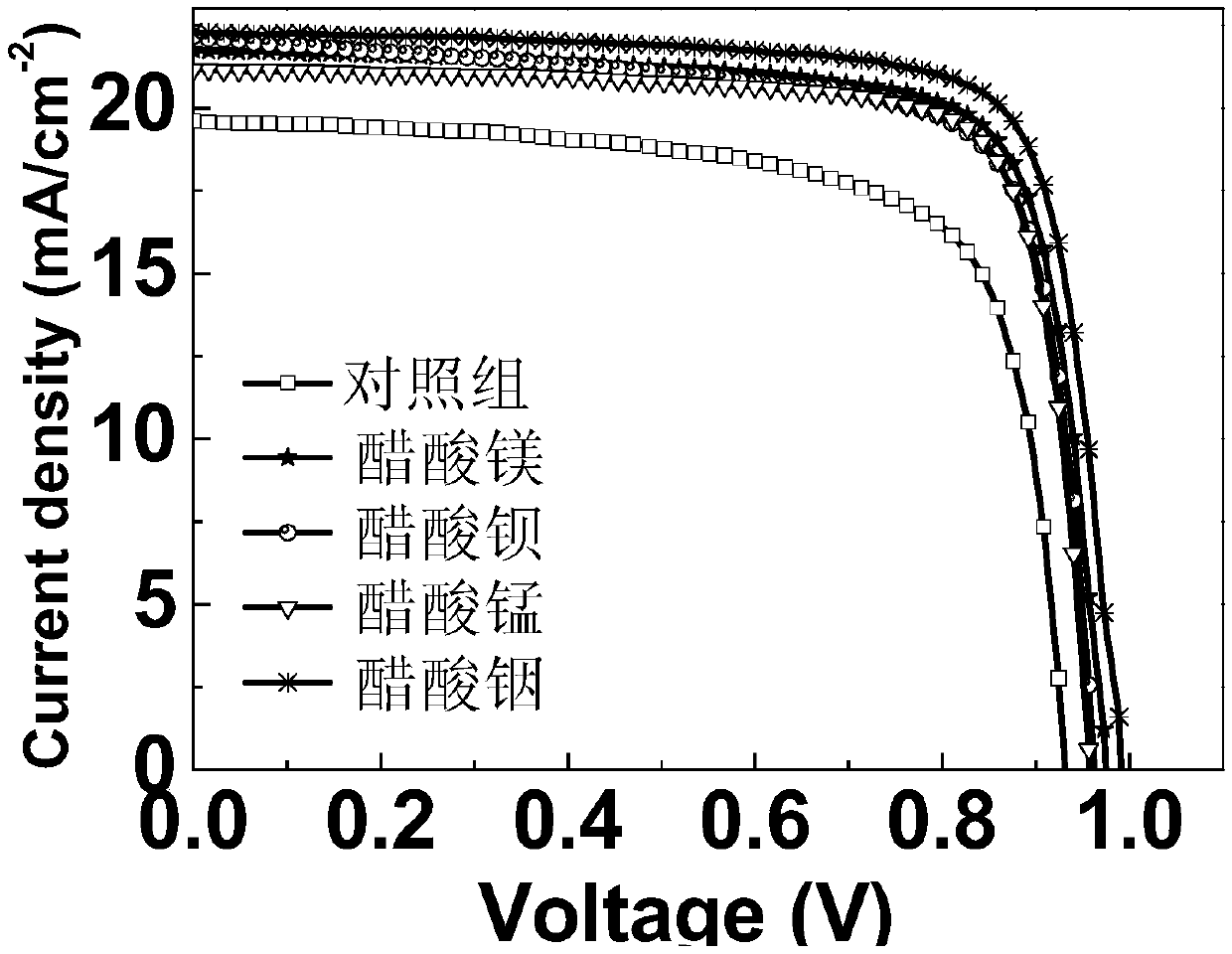

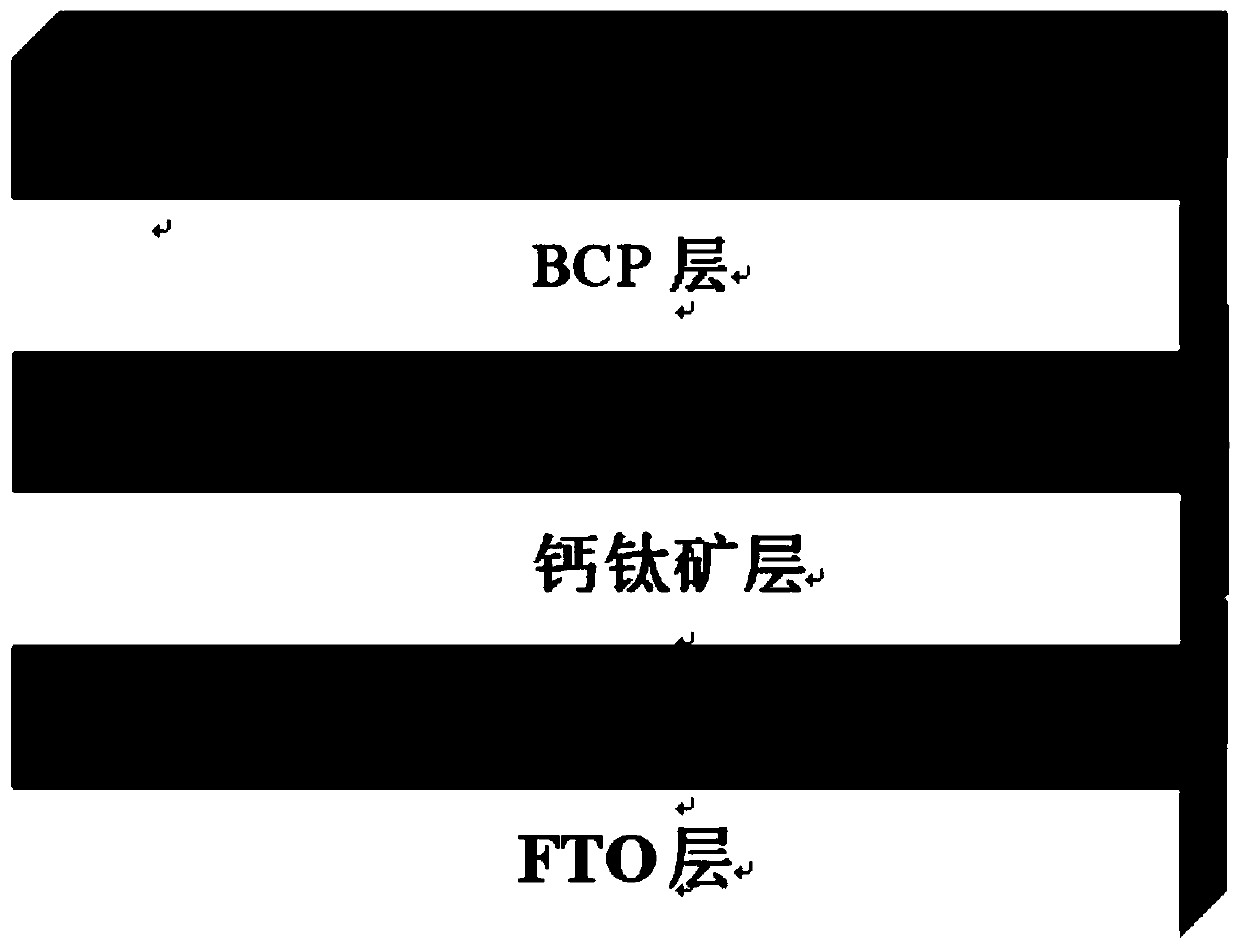

Perovskite solar cell and preparation method of modified layer of perovskite solar cell

ActiveCN108039411AEnergy level matchingImprove conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionHole transport layer

The invention discloses a perovskite solar cell and a preparation method of the modified layer of the perovskite solar cell. The perovskite solar cell includes an FTO, a hole transport layer, a modified layer, a perovskite layer, an electron transport layer, a BCP layer, and an electrode; the hole transport layer is made of NiO; and the modified layer is made of at least one material selected fromacetylacetone metal salt and acetate; and the modified materials can increase electron injection efficiency, change the work function of the hole transport layer, and increase the short-circuit current, fill factor, and open-circuit voltage of a device. The perovskite solar cell and the preparation method of the invention have the advantages of cheap materials, simplicity and easiness in control,and provide a new idea for the study of the interface behaviors of perovskite solar cells.

Owner:广东脉络能源科技有限公司

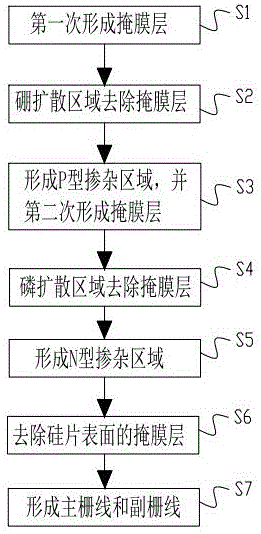

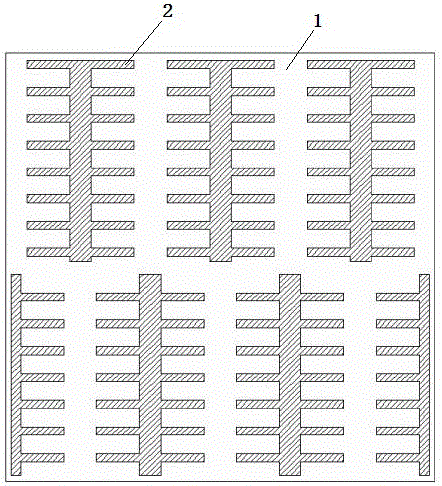

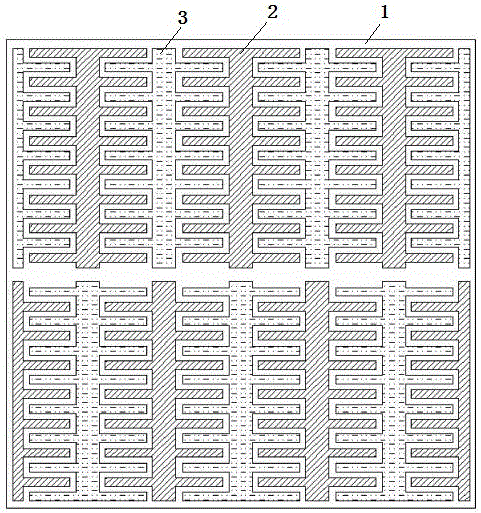

IBC battery, battery pack and preparation method

ActiveCN106158990AIncrease opening pressureGuaranteed conversion efficiencyFinal product manufacturePhotovoltaic energy generationElectrical resistance and conductanceElectrical battery

The invention discloses an IBC (Interdigitated back contact) battery, a battery pack and a preparation method, and relates to the technical field of solar cell. The battery comprises an N-type silicon chip, the backlight surface of the N-type silicon chip is divided into upper part and lower part, each part comprises a row and several columns P-type doped area, a N-type doped area is arranged between P-type doped areas or P-type doped areas and an edge of the silicon chip to form the P-type doped areas and the N-type doped area which are arranged in an alternatively adjacent way, each doped area of the upper part is connected with a corresponding doped area of the lower part through the same main grid line, each main grid line comprises a plurality of auxiliary grid lines which is used for connecting auxiliary grid areas on the doped areas. Under a premise of maintaining battery photoelectric conversion efficiency of the IBM battery, the pressure opening of the battery can be increase, the electric current can be reduced, and the power loss caused by a welding strip resistance during component packaging can be reduced.

Owner:YINGLI ENERGY CHINA

Single crystal alkali polishing additive, polishing solution and polishing method

InactiveCN113322008AImprove reflectivityQuick responsePolishing compositionsActive agentPhysical chemistry

The invention discloses a single crystal alkali polishing additive, a polishing solution and a polishing method, and the additive comprises the following components in percentage by mass: 0.1%-10% of organic silicon, 0.1%-10% of a brightener, 0.05%-1% of a fluorocarbon surfactant and the balance of water. When the single crystal alkali polishing additive provided by the invention is applied to a single crystal polishing process, a single crystal with a bright back surface can be obtained, and meanwhile, the reflectivity is greatly increased; and the single crystal alkali polishing additive affects the polishing flatness and enhances the reaction speed.

Owner:南京卓胜自动化设备有限公司

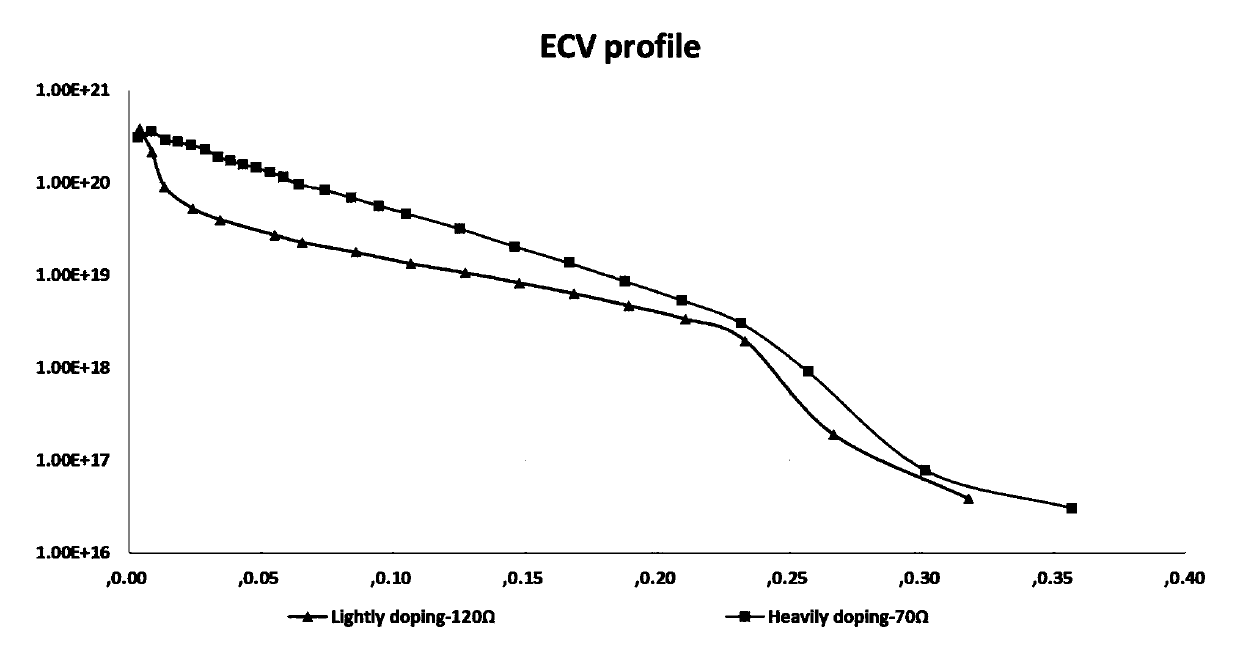

Diffusion method suitable for selective emitter

ActiveCN109786511AIncrease contactIncrease widthFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsHigh concentration

The invention discloses a diffusion method suitable for a selective emitter. The diffusion method comprises multi-time deposition and multi-time driving, and a temperature in a furnace tube begins tobe lowered from the second step of first-time driving. By use of a three-step diffusion deposition and driving way used by the invention, a PSG (Phosphosilicate Glass) layer containing high phosphorusconcentration is formed on the surface of a silicon wafer so as to be favorable for pushing a phosphorus source in the PSG into the silicon wafer during heavy doping, and a high-concentration heavy doping zone is formed so as to be favorable for ohmic contact to improve an FF (Fill Factor); the relative concentration of a shallow doping zone without heavy doping is low so as to be favorable for improving open-circuit voltage; a driving process capable of gradually lowering the temperature forms gradient doping in the silicon wafer, the width of a P-N shallow junction zone is widened, open-circuit voltage is improved, meanwhile, a shallow junction corresponds to a short wave band spectrum in sunlight, the spectrum in the range contains a large photon number, a better blue wave response canbe obtained, so that short circuit current Isc is improved, and in addition, sheet resistance uniformity is good due to the driving process capable of gradually lowering the temperature.

Owner:HANWHA SOLARONE QIDONG

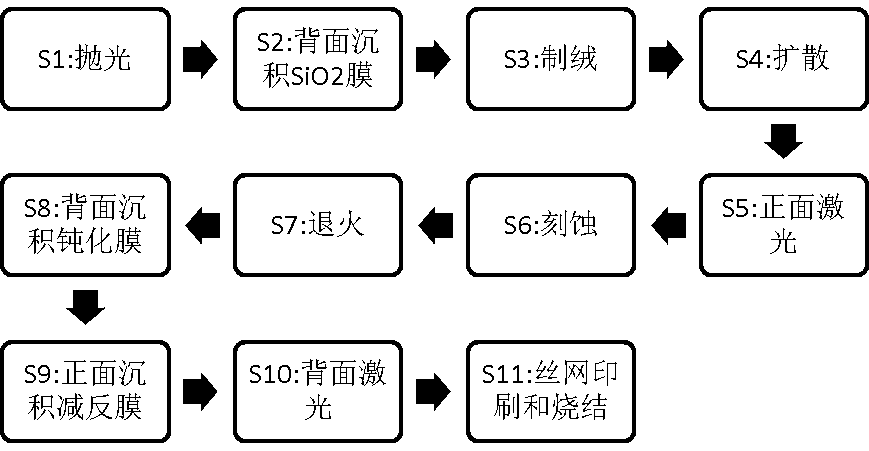

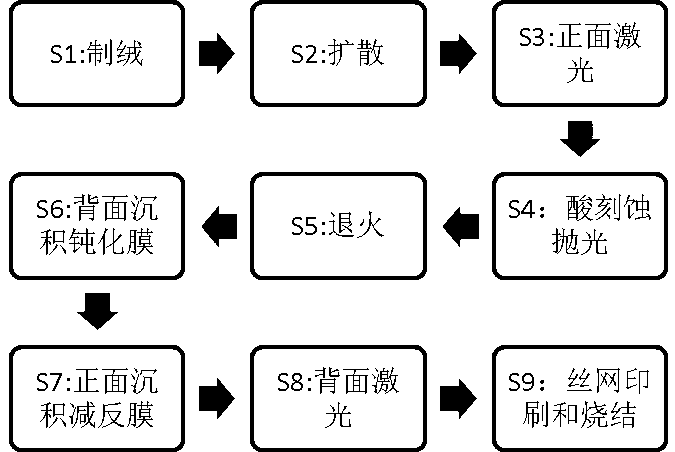

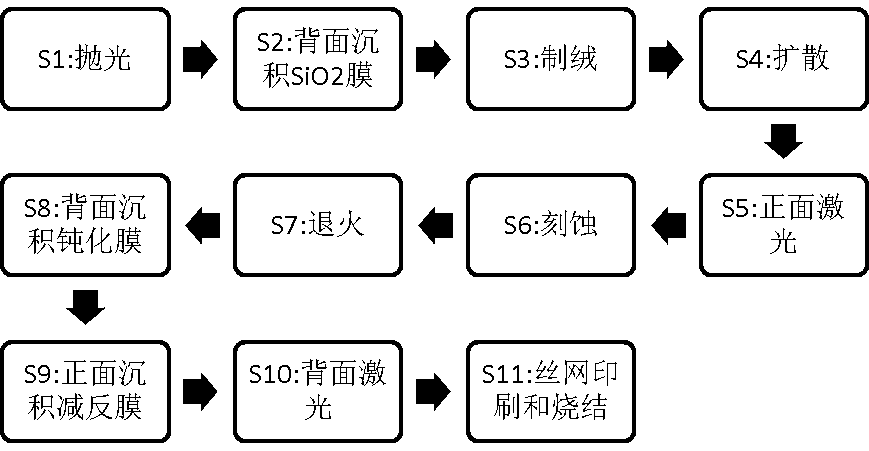

Alkali polishing preparation method of PERC solar cell

InactiveCN111129221AImprove conversion efficiencyReduce transmission lossAfter-treatment detailsFinal product manufacturePotassium hydroxideSolar cell

The invention discloses an alkali polishing preparation method of a PERC solar cell. The method comprises texturing, diffusion, front laser processing, etching, annealing, back passivation film processing, front passivation film processing, back laser processing, silk-screen printing and sintering. The method is characterized in that, before the texturing step, an alkali polishing step and a silicon dioxide film deposition step are further included, wherein in the alkali polishing step, a potassium hydroxide solution is adopted to polish the silicon wafer, in the back surface silicon dioxide film deposition step, a layer of silicon dioxide mask is plated on the back surface of the silicon wafer by adopting a PECVD technology, and in the texturing step, a potassium hydroxide additive is added for texturing. According to the method, the flatness of the back surface of the prepared battery piece is improved, the passivation effect of the back film is improved, the open-circuit voltage isimproved, and the conversion efficiency of the battery is further improved.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD

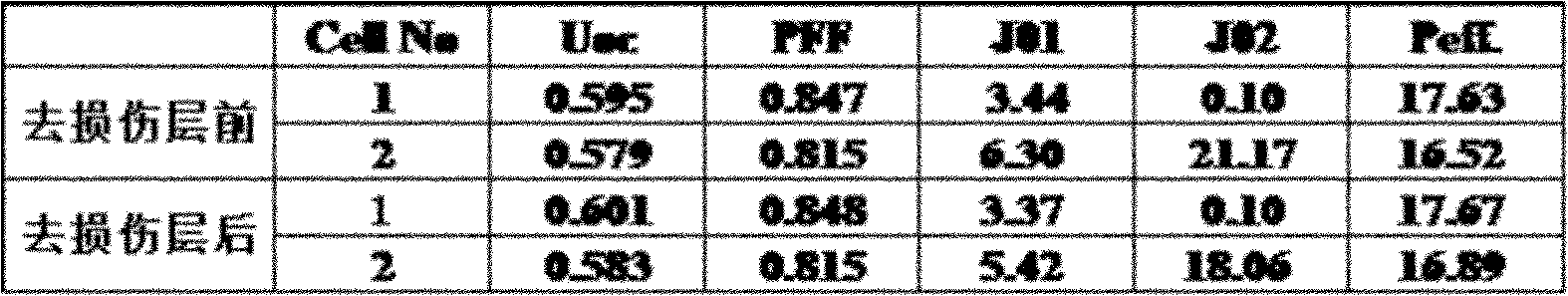

Wash solution for removing laser damage layers

ActiveCN102157616AReduce leakage currentOpening pressure riseFinal product manufactureSemiconductor/solid-state device manufacturingOxideSpace charge

The invention relates to the manufacture technology of solar batteries, in particular to a wash solution for removing laser damage layers The wash solution comprises water, ammonium fluoride, hydrofluoric acid and nitric acid, wherein the wash solution is prepared by adding 60-80g of ammonium fluoride, 10-20ml of hydrofluoric acid solution and 10-20ml of nitric acid solution into 1L water and mixing the constituents; the wash solution related by the invention can effectively remove the oxides and most of metal elements on the surfaces of silicon slices, can reduce PN (positive and negative) node leakage currents (also called as reverse saturation current or space charge region leakage currents), so that opening voltages are increased.

Owner:TRINASOLAR CO LTD

Heterojunction solar cell of inclined metal contact structure based on N type silicon wafer

InactiveCN102709340AAvoid the problem of large shading areaIncrease opening pressurePhotovoltaic energy generationSemiconductor devicesHeterojunctionScreen printing

The invention relates to a heterojunction solar cell of an inclined metal contact structure based on an N type silicon wafer. The heterojunction solar cell of the inclined metal contact structure based on the N type silicon wafer comprises an N type mono-crystalline silicon base body, a positive electrode, a negative electrode, transparent conductive films and a plurality of film layers manufactured and formed on the front face and the back face of the N type mono-crystalline silicon base body, wherein each film layer manufactured and formed on the back face of the N type mono-crystalline silicon base body comprises an N<+> heavily-doped layer, forming N<+> / N high-low junctions; one layer of transparent conductive film is manufactured and formed on the outermost layer of each of the front face and the back face of the N type mono-crystalline silicon base body; a recess is arranged on the front face of the N type mono-crystalline silicon base body; the positive electrode of the cell is put in the recess; and the negative electrode of the cell is put on the back face of the N type mono-crystalline silicon base body. Generating no drastic light failure phenomenon of the heterojunction solar cell constituted by the routine P type crystalline silicon and the crystalline silicon of a non-crystalline silicon film, the heterojunction solar cell of the inclined metal contact structure based on the N type silicon wafer is better in spectral response, and further is greatly thinned; the shading area of grid lines is decreased from 6% to 1% of the routine silk-screen printing mode, so that the conversion efficiency of the solar cell is improved; and additionally, with the adoption of a low temperature production process, the production cost is reduced.

Owner:ZHEJIANG JINKO SOLAR CO LTD

N-type battery structure and preparation method thereof

PendingCN113078232AImprove contactEasy to fillFinal product manufacturePhotovoltaic energy generationEngineeringElectric current flow

The invention discloses an N-type battery structure and a preparation method thereof. The structure comprises an N-type silicon body material and a metal grid line electrode formed on the surface of the N-type silicon body material, and is characterized in that the back surface of the N-type silicon body material is provided with a suede part and a polished surface part, and the contact position of the metal grid line electrode and the N-type silicon body material is located in the suede part. The back metal grid line electrode adopts a suede structure, so the contact area between the metal grid line and silicon is increased, and the contact resistance is improved; the flat surface of the polished area can improve the back passivation effect, reduce the surface recombination rate, enhance the internal reflection of long waves and improve the front current.

Owner:CSI CELLS CO LTD +1

Glass powder for crystalline silicon solar positive silver paste as well as preparation method and application of glass powder

ActiveCN112777938ALower contact potentialIncrease contactPhotovoltaic energy generationSemiconductor devicesSlurrySilicon cell

The invention discloses glass powder for crystalline silicon solar front silver paste, which comprises the following raw materials: TeO2, PbO, Tl2O3, Bi2O3 and Li2O, selectively comprises one or more of WO3, ZnO, MgO, B2O3, CaO, TiO2, Fe2O3, Al2O3, Ag2O, ZrO2, Na2O, K2O and MoO, and selectively comprises an adhesion additive or a corrosion additive. According to the glass powder for the crystalline silicon solar positive silver paste, Tl2O3 is added, and the Tl2O3 and other raw materials are in a special formula proportion, so that the softening temperature of the glass powder is reduced, the conductivity is increased, and the dielectric loss is relatively small. A passivation layer, including a silicon nitride film and an aluminum oxide film of a PERC crystal silicon wafer, of the crystal silicon wafer can be etched through at a relatively low temperature. The slurry prepared from the glass can be sintered at 720-800 DEG C, and the attenuation problem of a crystalline silicon cell, especially a PERC crystalline silicon cell piece, under high-temperature sintering is reduced to a certain extent, so that the cell efficiency is improved.

Owner:JIANGXI JIAYIN SCI & TECH LTD

Silver-aluminum paste for front fine grid of high-performance N-type solar cell and preparation method of silver-aluminum paste

InactiveCN113257457AInhibition formationImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationAl powderSilicon alloy

The invention belongs to the field of N-type solar cells, and discloses silver-aluminum paste for a front fine grid of a high-performance N-type solar cell and a preparation method of the silver-aluminum paste. The silver-aluminum paste for the front fine grid of the high-performance N-type solar cell comprises the following raw materials: conductive silver powder, an organic carrier, glass powder and aluminum powder, and the oxygen content of the aluminum powder is 0.5-1%. The preparation method comprises the following steps of: uniformly mixing and stirring the conductive silver powder, the glass powder, the aluminum powder and the organic carrier; and grinding an obtained mixture to obtain the silver-aluminum paste. According to the silver-aluminum paste for the front fine grid of the high-performance N-type solar cell, the aluminum powder with high oxygen content and proper particle size is added, so that the formation of excessive aluminum-silicon alloy can be inhibited, the open voltage is improved, and the photoelectric conversion efficiency of the solar cell is improved after the solar cell is prepared from the silver-aluminum paste.

Owner:浙江奕成科技有限公司

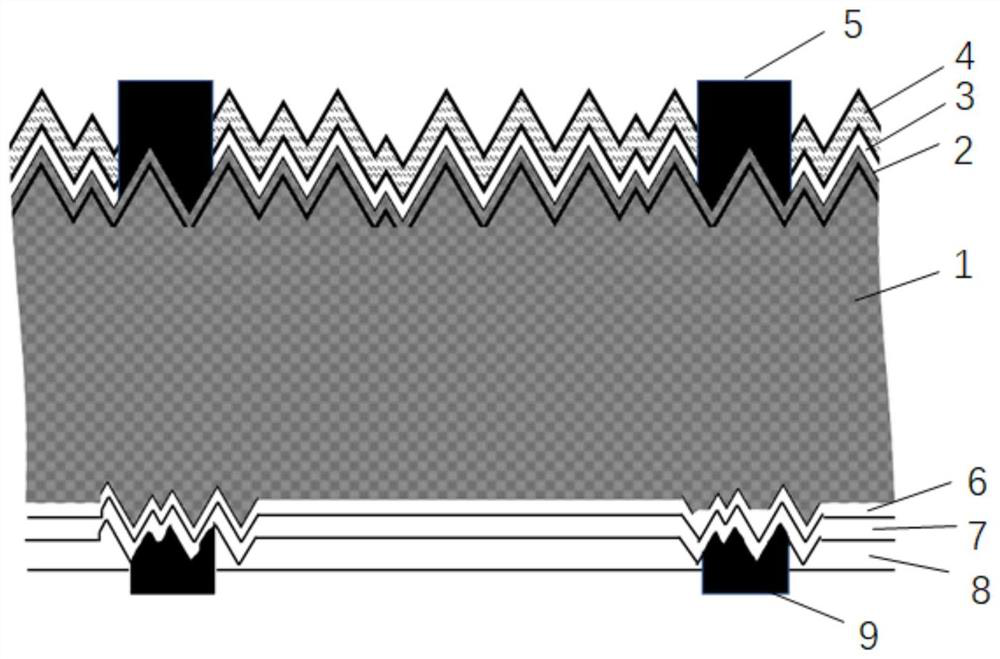

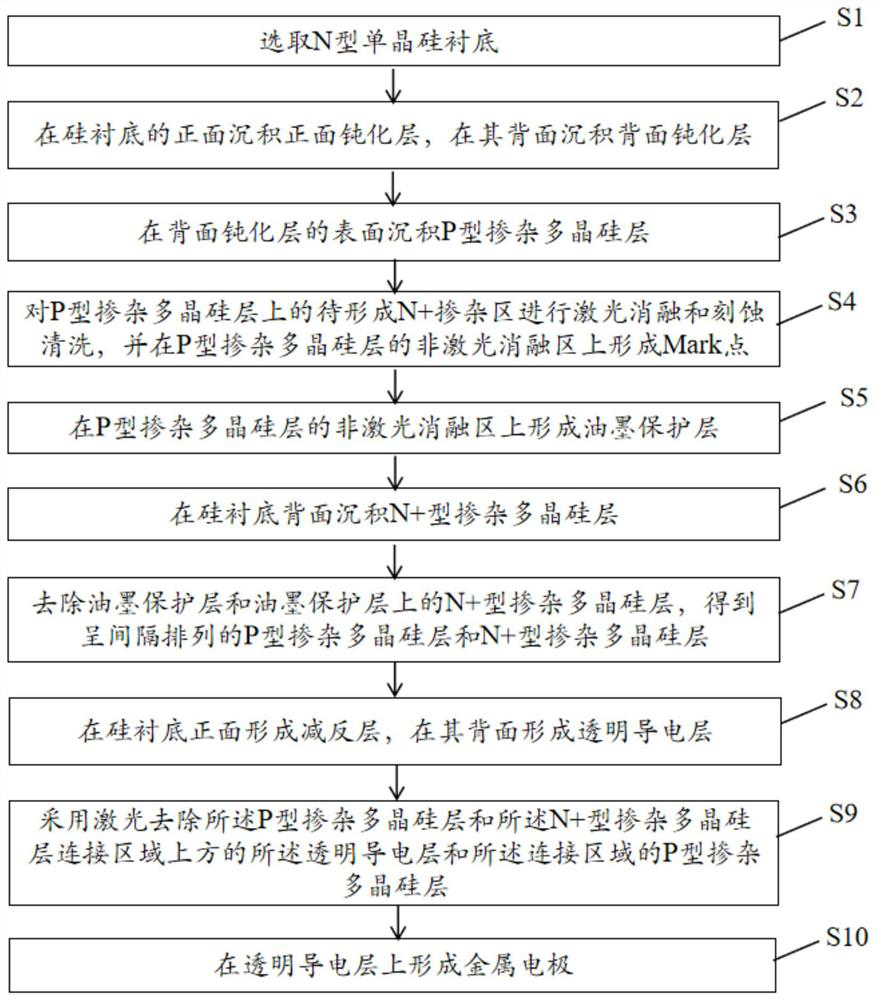

N-type monocrystalline silicon HBC solar cell preparation method

InactiveCN112490324AReduce process stepsLow costFinal product manufactureSemiconductor/solid-state device detailsPhysicsMonocrystalline silicon

The invention discloses an N-type monocrystalline silicon HBC solar cell preparation method, and the method comprises the steps: employing LPCVD equipment and Mark point positioning technology, employing a laser ablation technology to cooperate with an ink protection layer to prepare a P-type doped polycrystalline silicon layer and an N+type doped polycrystalline silicon layer which are arranged at intervals in an interdigital manner, and obtaining an HBC cell with better passivation, higher open-circuit voltage, higher efficiency and lower cost. By adopting the method, the preparation methodof the N-type monocrystalline silicon HBC solar cell is simplified, the N-type monocrystalline silicon HBC solar cell which is good in passivation effect, high in starting voltage and high in efficiency is obtained, and the simple-process, low-cost and high-efficiency large-scale production of the N-type monocrystalline silicon HBC solar cell is realized.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +2

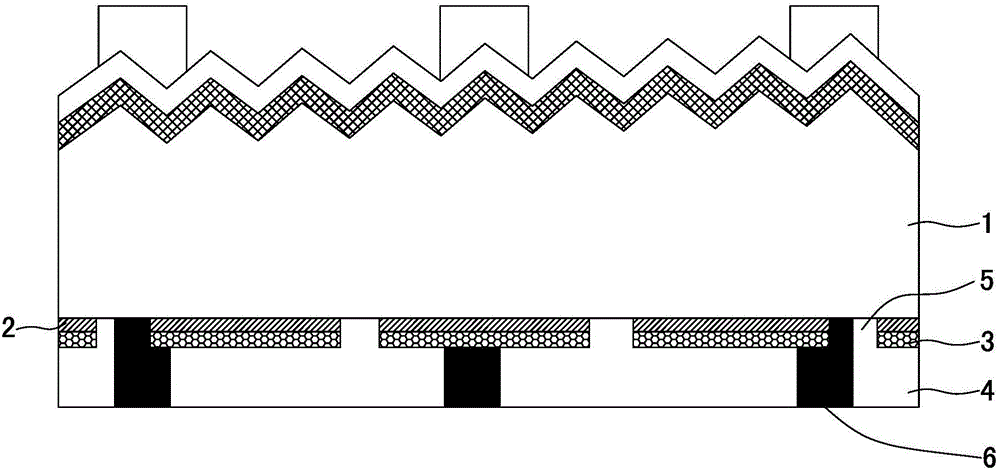

Passivated contact N type back junction solar cell and preparation method thereof

InactiveCN111477720AIncrease opening pressureImprove efficiencyFinal product manufacturePhotovoltaic energy generationCrystalline siliconSilicon chip

The invention aims to disclose a passivated contact N type back junction solar cell and a preparation method thereof. The passivated contact N type back junction solar cell comprises an N type crystalsilicon wafer, wherein an N + front surface field doped region, a front surface passivation antireflection layer and a metal contact electrode are sequentially arranged on the front surface of the Ntype crystal silicon wafer from inside to outside, and a tunneling oxide layer, a P + doped polycrystalline silicon region, a back surface passivation antireflection layer and a metal contact electrode are sequentially arranged on the back surface of the N type crystal silicon wafer from inside to outside. Compared with the prior art, the passivated contact N type back junction solar cell of the invention has the following characteristics that P + doped polycrystalline silicon is applied to the back surface of the N type cell and is used for passivating an emitter junction and a metal contactregion, carrier enters the doped P type polycrystalline silicon layer through the tunneling oxide layer to achieve selective transmission and collection, surface recombination, especially metal contact area recombination, of an emitter junction is greatly reduced by means of the excellent passivation performance of polycrystalline silicon, the open-circuit voltage and efficiency of the cell are improved, and the purpose of the invention is achieved.

Owner:SPIC XIAN SOLAR POWER CO LTD +3

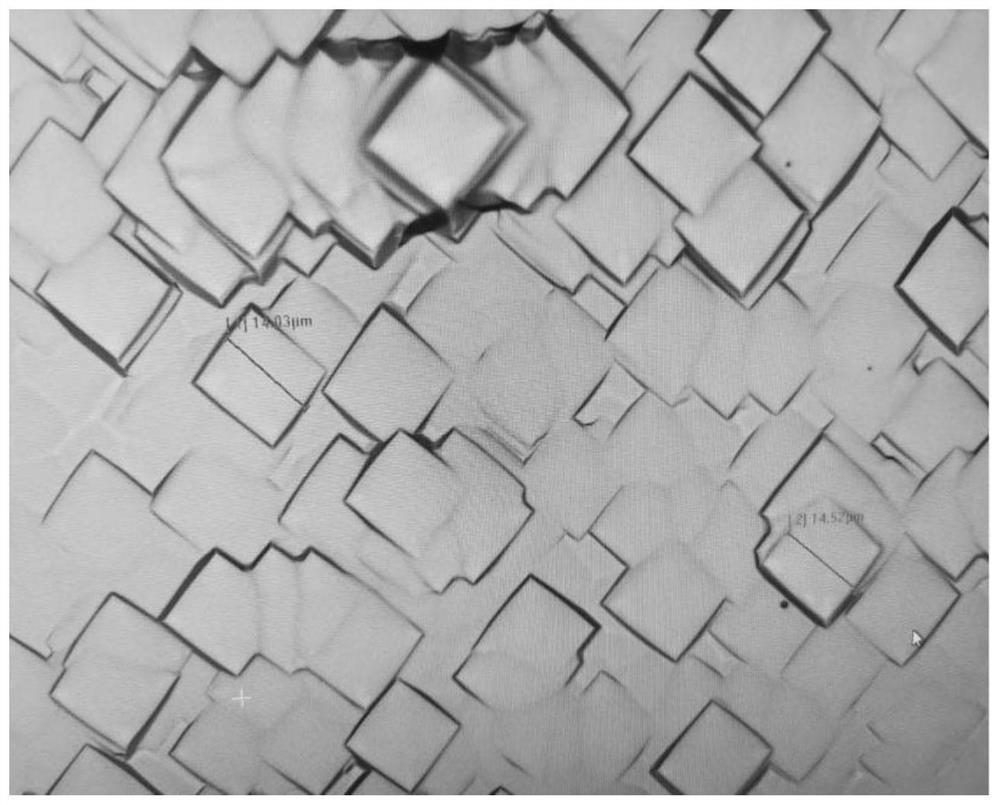

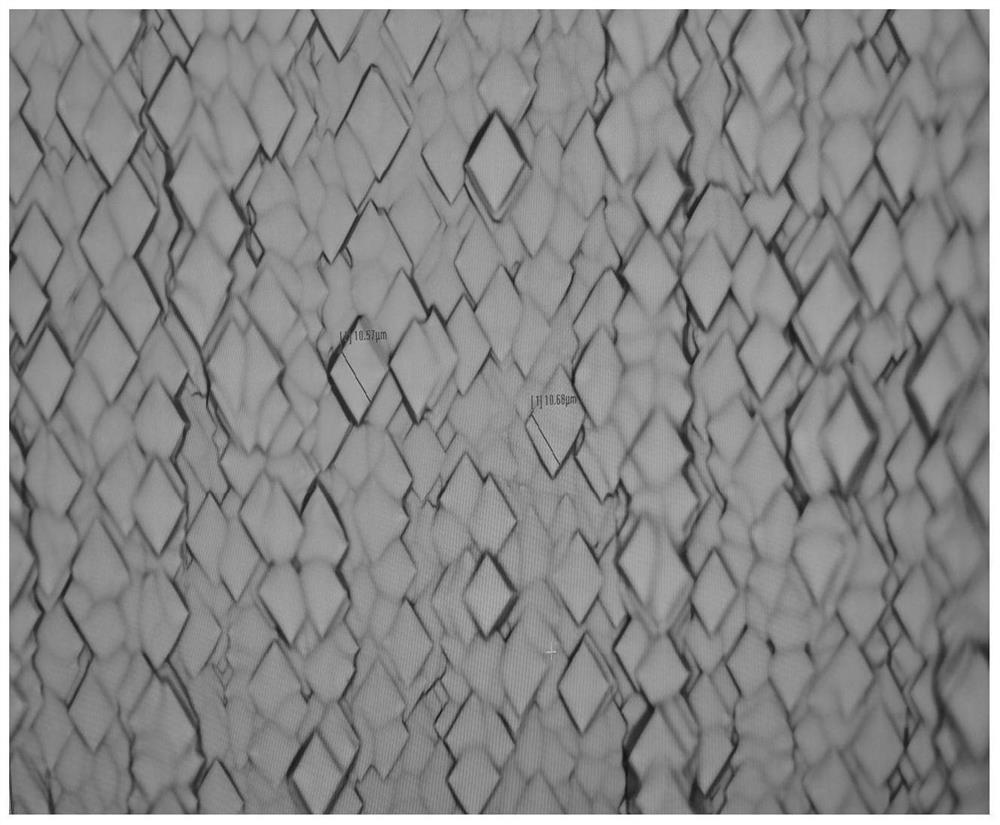

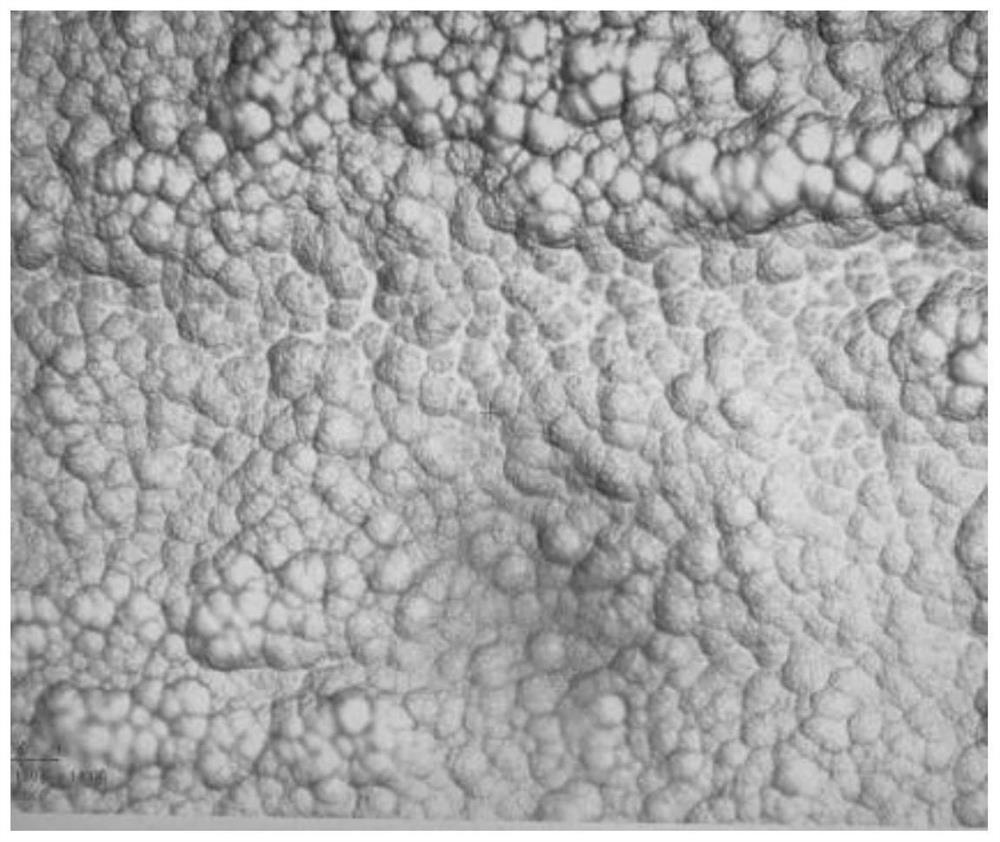

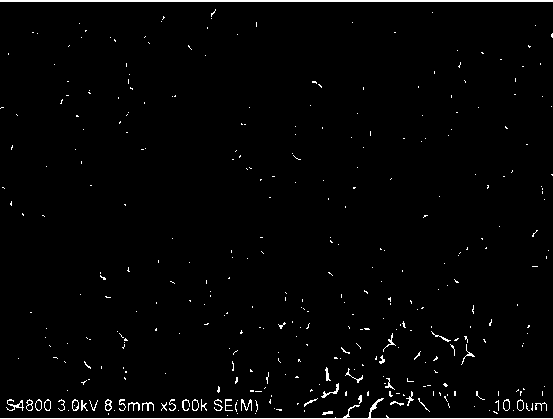

Reaming process of polycrystalline black silicon

ActiveCN107805845AGood lookingImprove efficiencyPolycrystalline material growthAfter-treatment detailsEtchingCorrosion

The invention discloses a reaming process of polycrystalline black silicon. Firstly, metal-assisted wet-process chemical etching is adopted to prepare polycrystalline black silicon with nano holes from diamond cut polycrystalline silicon wafers; and then reaming treatment is carried out on the polycrystalline black silicon with the nano pores in two steps. According to the invention, the two-groove two-step reaming process is adopted, so that the reaming reaction is controllable, the corrosion depth and corrosion effect of pre-reaming and reaming can be controlled respectively, and thus the polycrystalline black silicon with good appearance, high CTM and honeycomb-structure holes is obtained.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

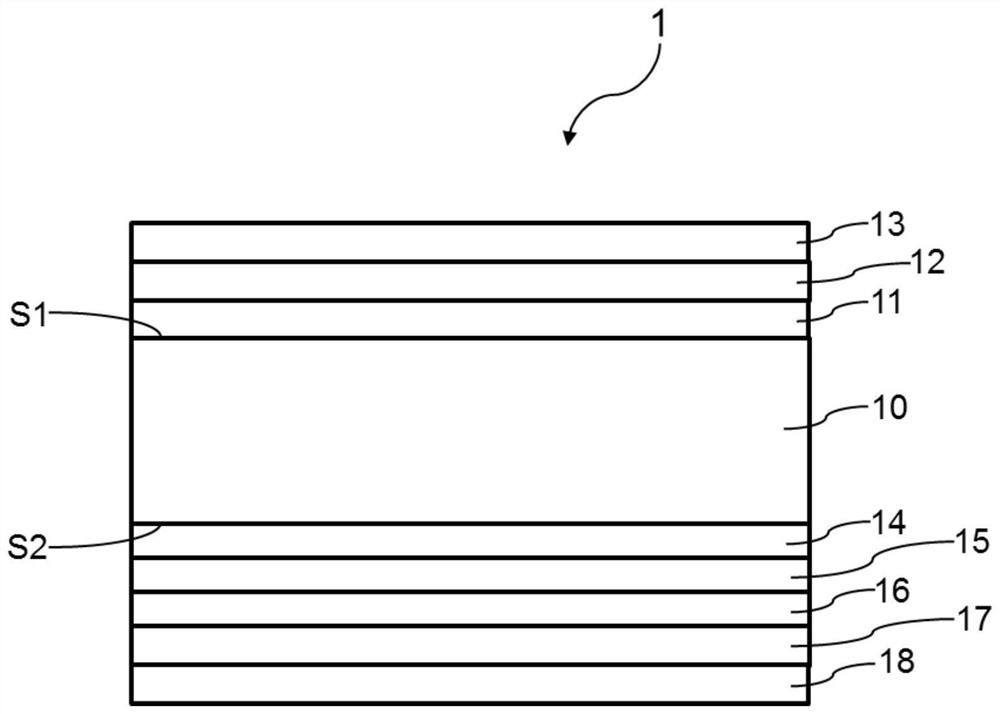

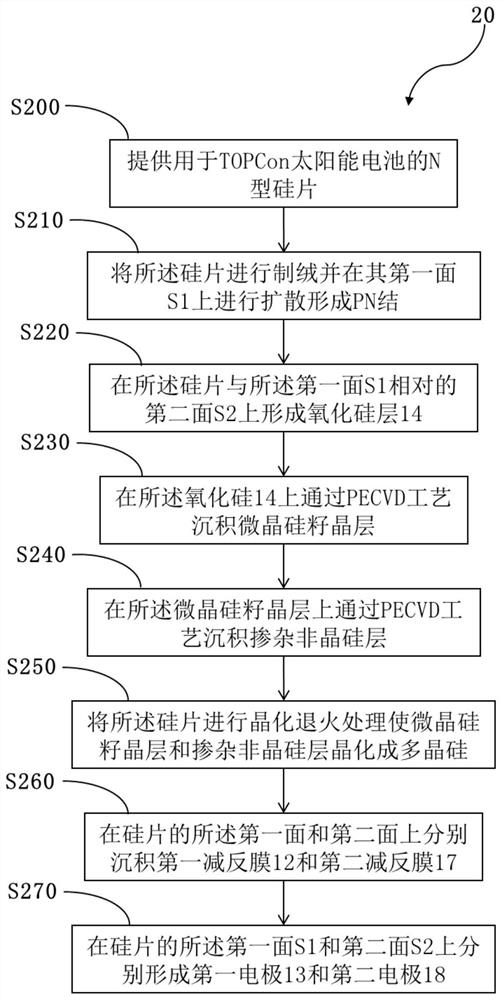

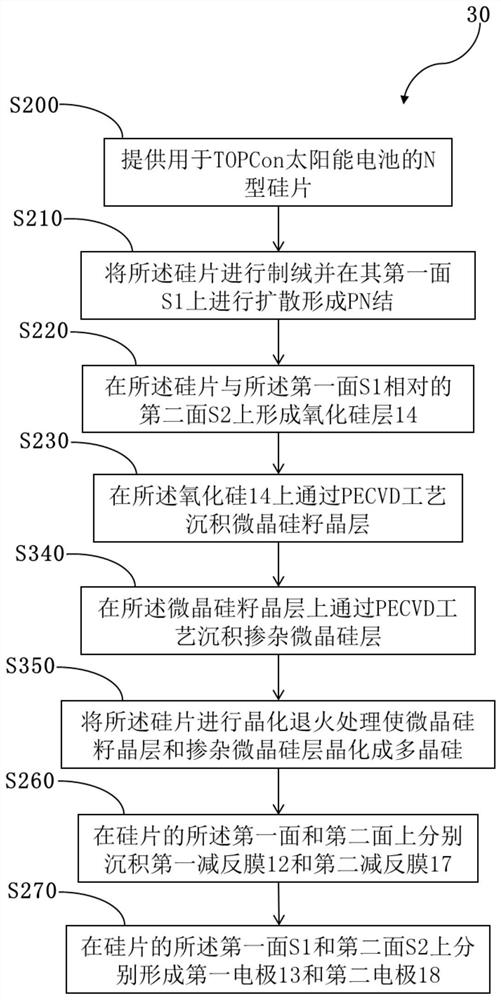

TOPCon solar cell and manufacturing method thereof

PendingCN111987182AReduce film stressSolve the problem of bursting filmFinal product manufacturePhotovoltaic energy generationSilicon oxideSolar battery

The invention provides a TOPCon solar cell and a manufacturing method thereof. The manufacturing method comprises the following steps: (a) providing an N-type silicon wafer for a TOPCon solar cell; (b) texturing the silicon wafer and diffusing on the first surface of the silicon wafer to form a PN junction; (c) sequentially forming a silicon oxide layer, a microcrystalline silicon seed crystal layer, a doped amorphous silicon layer or a doped microcrystalline silicon layer on a second surface, opposite to the first surface, of the silicon wafer; (d) carrying out crystallization annealing treatment on the silicon wafer to crystallize microcrystalline silicon and / or amorphous silicon into polycrystalline silicon; (e) respectively forming a first anti-reflection passivation film and a secondanti-reflection passivation film on the first surface and the second surface of the silicon wafer; and (f) respectively forming a first electrode and a second electrode on the first surface and the second surface of the silicon wafer. According to the invention, the problem of film explosion when the doped amorphous silicon layer or the doped microcrystalline silicon layer reaches a certain thickness can be effectively solved, the leakage current can be effectively reduced, and improvement of the open-circuit voltage, the filling factor and the conversion efficiency of the TOPCon cell can be facilitated.

Owner:IDEAL ENERGY (SHANGHAI) SUNFLOWER THIN FILM EQUIPMENT LTD

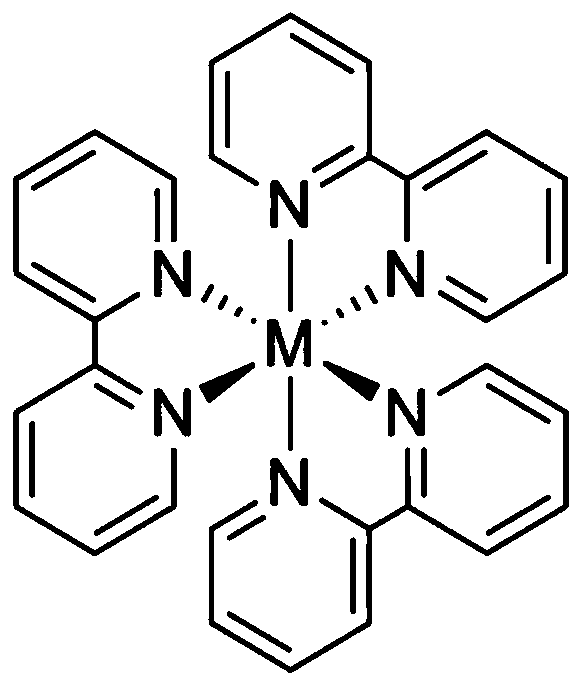

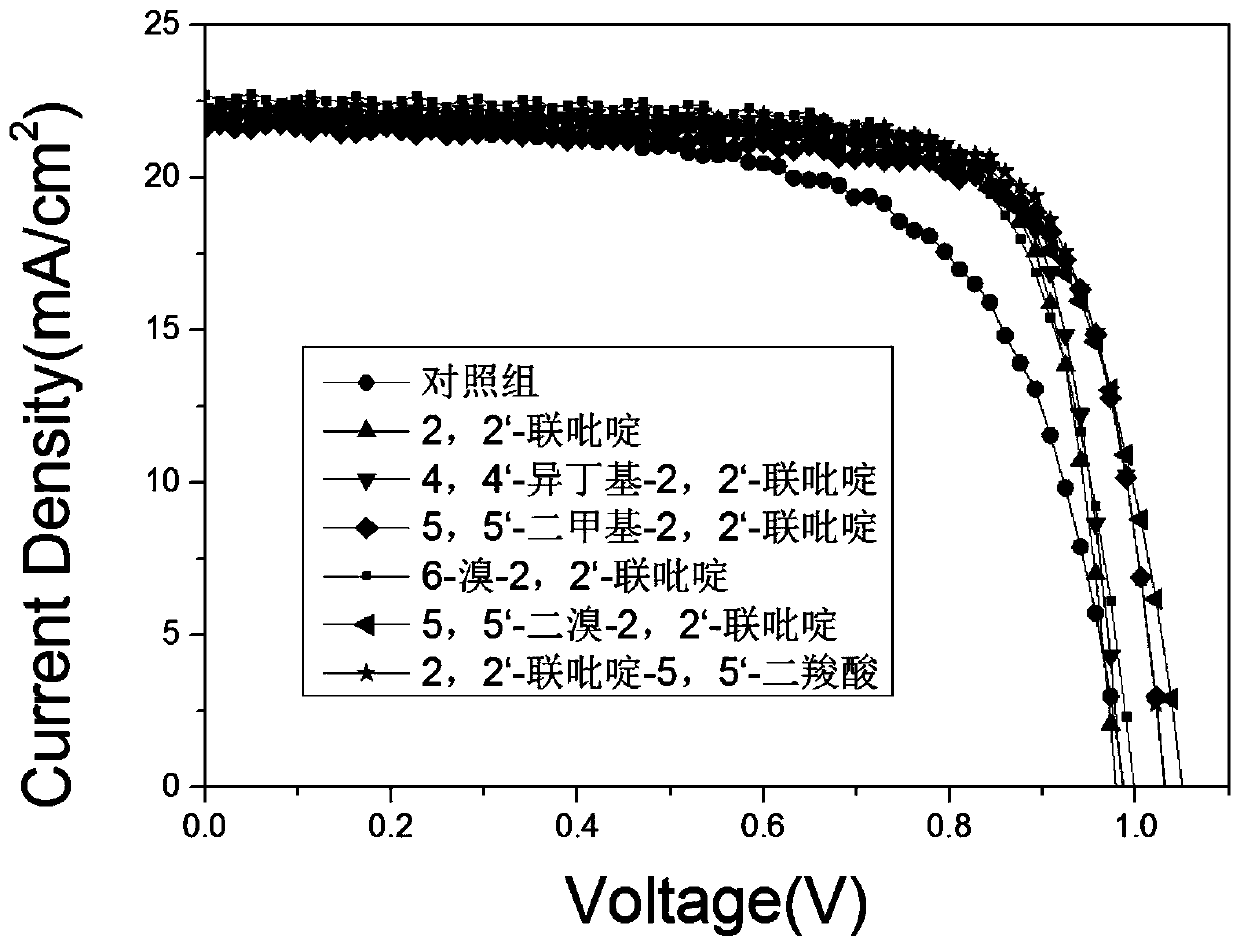

Perovskite solar cell doped with 2,2'-dipyridine and derivative thereof, and preparation method thereof

InactiveCN109802039AEffective isolationInsulate from water vaporSolid-state devicesSemiconductor/solid-state device manufacturingTransport layerPerovskite solar cell

The invention discloses a perovskite solar cell doped with 2,2'-dipyridine and a derivative thereof, and a preparation method thereof. The solar cell comprises an FTO layer, a hole transport layer, aperovskite layer, an electron transport layer, a BCP layer and an electrode which are successively stacked from bottom to top. The perovskite layer is a perovskite layer obtained by doping 2,2'-dipyridine and a derivative thereof. The material of the doped perovskite layer is [Ax((Cs)0.09(NH2CH=NH2)0.91PbI3)1-x], wherein 0<=X<=0.37, and A is 2,2'-bipyridine or a derivative thereof. Such doped material can enhance the stability of the perovskite layer and increase a fill factor and the open circuit voltage. The material is cheap, the operation method is simple and easy to control, and providesa new idea for the study of the stability and the conversion efficiency of the perovskite solar cell.

Owner:JINAN UNIVERSITY

Solar cell diffusion method and solar cell obtained thereby

ActiveCN107093551AIncrease effective dopingReduce formationFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsHigh concentration

The invention relates to a solar cell diffusion method comprising a gradual diffusion step. In the process of element doping, the concentration of doped elements on the surface of silicon gradually varies with time. The volume of doped metal diffused is adjusted to a gradient one, and high-temperature diffusion is carried out at low concentration in the early stage, which can make oxygen precipitation near the surface area fully dissolved (excessive oxygen precipitation is not conducive to impurity removal in an annealing step), and increase the open-circuit voltage of solar cell panels. As the process goes, high-temperature diffusion is carried out at high concentration in the late stage, which can quickly make up for P doping in the surface area and increase effective filling of doped metal. The diffusion method provided by the invention can reduce interstitial atoms formed by sputtering, dislocations, and defects in dead layers.

Owner:CSI CELLS CO LTD +1

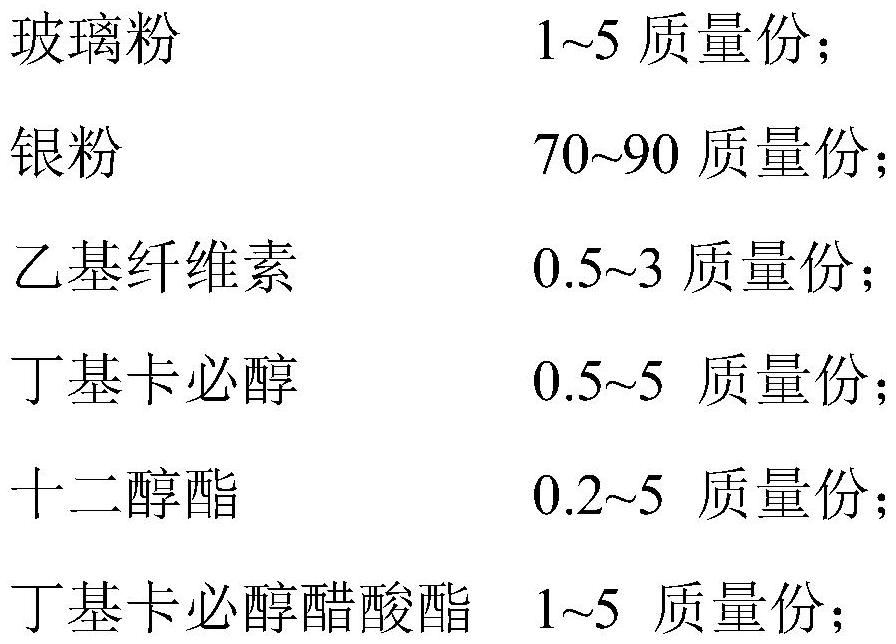

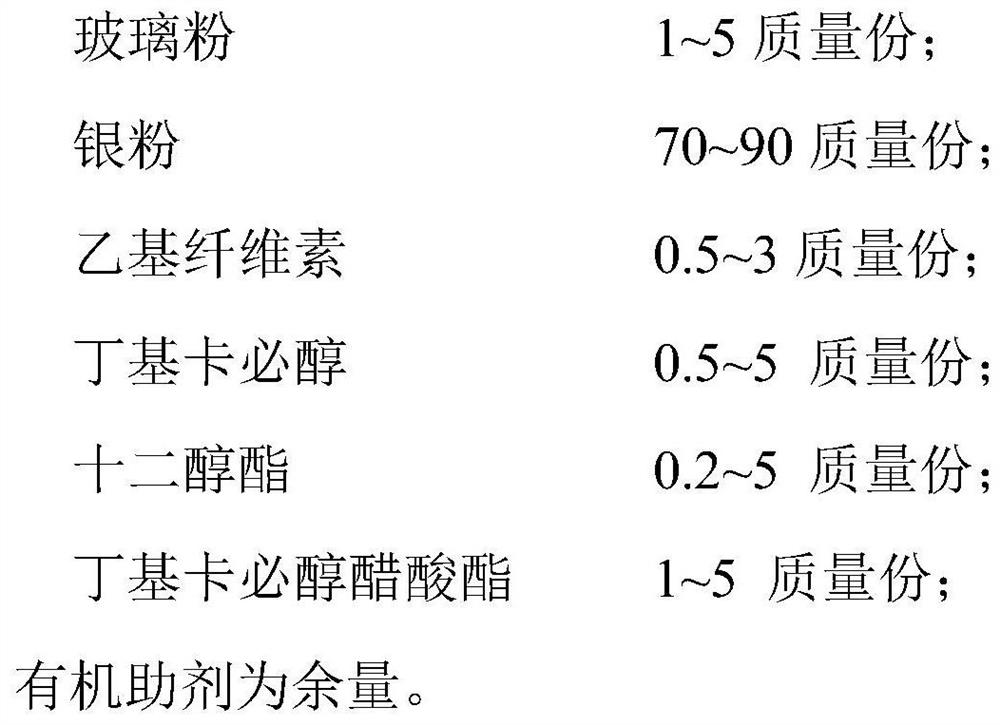

PERC crystalline silicon solar cell main grid slurry and preparation method thereof

ActiveCN113593749ARaise the sintering temperatureLower sintering temperatureNon-conductive material with dispersed conductive materialPhotovoltaic energy generationEthylic acidSilicon solar cell

The invention discloses PERC crystalline silicon solar cell main grid slurry and a preparation method thereof. The PERC crystalline silicon solar cell main grid slurry comprises the following components: 1 to 5 parts by mass of a glass powder, 70 to 90 parts by mass of a silver powder, 0.5 to 3 parts by mass of ethyl cellulose, 0.5 to 5 parts by mass of butyl carbitol, 0.2 to 5 parts by mass of dodecanol ester, 1 to 5 parts by mass of butyl carbitol acetate, and the balance of organic auxiliary agents. The method is simple to operate and easy to implement, the compactness of an electrode conductive network can be improved by the prepared silver electrode sintered by the main grid electrode silver slurry, the damage to silicon nitride is reduced, the filling factor of the battery is improved, and the comprehensive performance of the PERC battery is further improved. The method is simple to operate and easy to implement, the compactness of an electrode conductive network can be improved by the prepared silver electrode sintered by the main grid electrode silver slurry, the damage to silicon nitride is reduced, the filling factor of the battery is improved, and the comprehensive performance of the PERC battery is further improved.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com