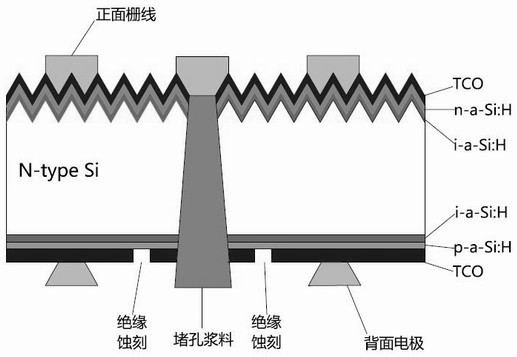

MWT heterojunction solar cell and preparation method thereof

A heterojunction battery and battery technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reduced PN junction effective area, large PN junction failure area, and reduced battery efficiency, so as to improve the passivation effect and improve Effect of opening pressure, conversion efficiency, and area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: experimental group

[0029] 1. Silicon wafer: use N-type single crystal silicon wafer as the substrate

[0030] 2. Laser drilling: According to the 6×6 hole dot matrix pattern, holes are drilled on the silicon wafer to form circular holes with a diameter of 0.2mm.

[0031] 3. Polishing and oxidation: Polish the silicon wafer on both sides after drilling, use tubular thermal oxygen oxidation on the front of the silicon wafer, the oxidation temperature is 180°C, the oxygen flow rate is 2000 sccm, and a 5nm oxide layer is formed on the front

[0032] 4. Texturing and cleaning: Alkali and single-sided texturing additive (TS03) are used for single-sided texturing to remove the damaged layer on the surface of the silicon wafer and reduce the recombination rate of photogenerated carriers; at the same time, uniform texture is formed on the front side of the silicon wafer The surface can trap light and improve light absorption; RCA cleaning improves the cleanlines...

Embodiment 2

[0039] Embodiment 2: comparison group

[0040] 1. Silicon wafer: use N-type single crystal silicon wafer as the substrate

[0041] 2. Laser drilling: According to the 6×6 hole dot matrix pattern, holes are drilled on the silicon wafer to form circular holes with a diameter of 0.2mm.

[0042] 3. Texture making and cleaning: Alkali and conventional texturing additives (TS01) are used for double-sided texturing to remove the damaged layer on the surface of the silicon wafer and reduce the recombination rate of photogenerated carriers; at the same time, a uniform textured surface is formed on the front side of the silicon wafer , can play the role of trapping light and improve the absorption of light; RCA cleaning improves the cleanliness of the silicon wafer surface.

[0043] 4. Intrinsic amorphous silicon layer deposition: use PECVD to deposit 3nm intrinsic amorphous silicon film on the front and back of the silicon wafer

[0044] 5. Deposition of N-type amorphous silicon on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com