Method for manufacturing soft silicon-based thin film solar cell integrated component

A silicon-based thin film and solar cell technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of expensive wires and equipment, and achieve the effects of reducing difficulty, improving reliability, and protecting areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments. These examples should be understood as only for illustrating the present invention but not for limiting the protection scope of the present invention. After reading the contents of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent changes and modifications also fall within the scope defined by the claims of the present invention.

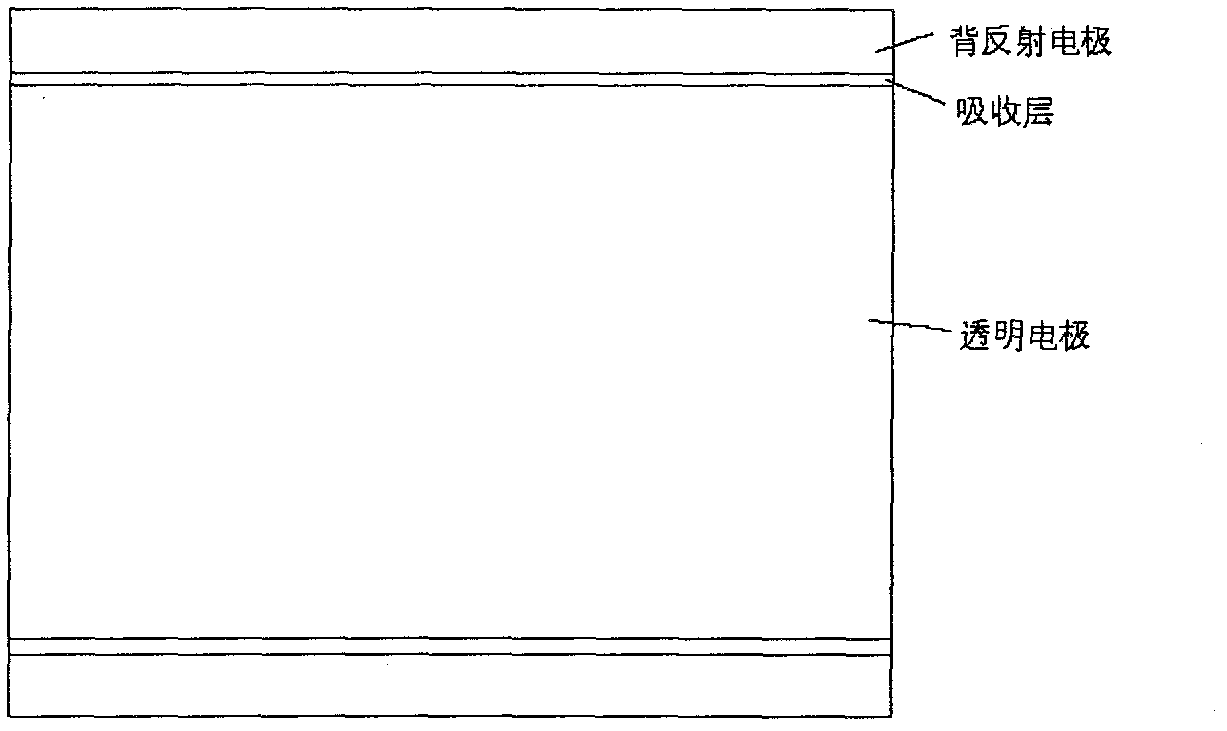

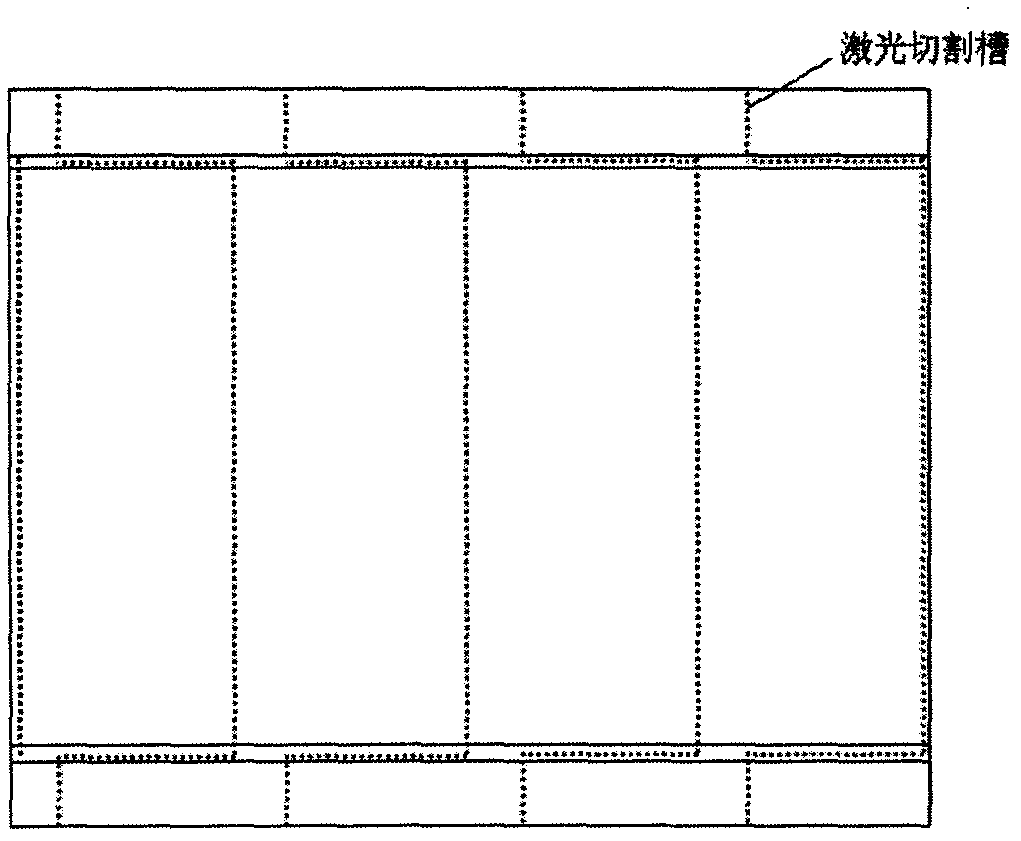

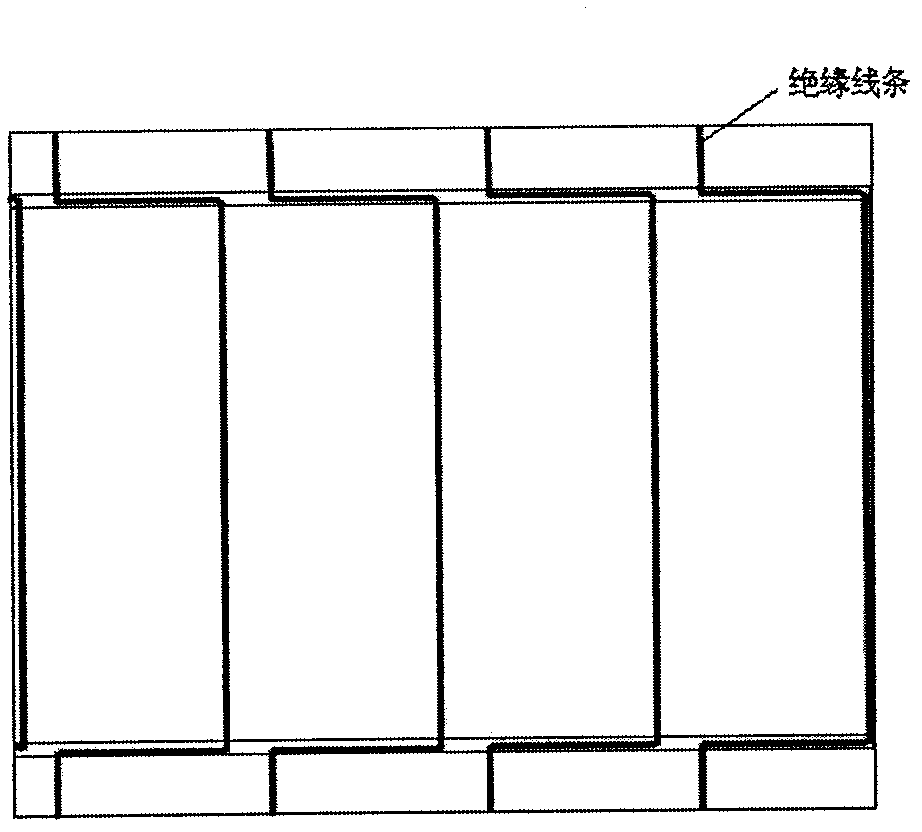

[0023] 1. A roll of flexible polyimide (thickness 125um) is sequentially passed through the vacuum chamber, and the Ag / ZnO back reflection layer is grown by magnetron sputtering, the Ag thickness is 300nm, and the ZnO thickness is 500nm; the amorphous silicon nip structure, the n layer is 30nm, i layer 300nm, p layer 15nm, ITO transparent conductive film, ITO thickness 80nm. The vacuum chamber adopts cover plate, baffle or other te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com