Reaming process of polycrystalline black silicon

A polycrystalline silicon wafer and black silicon technology, which is applied in the directions of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems affecting the popularization and popularization of black silicon technology, the low pulling force of the front silver gate line, and the unsatisfactory effect. Good appearance, low reflectivity, the effect of retaining appearance advantage and current advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0028] The technical scheme of concrete implementation of the present invention is:

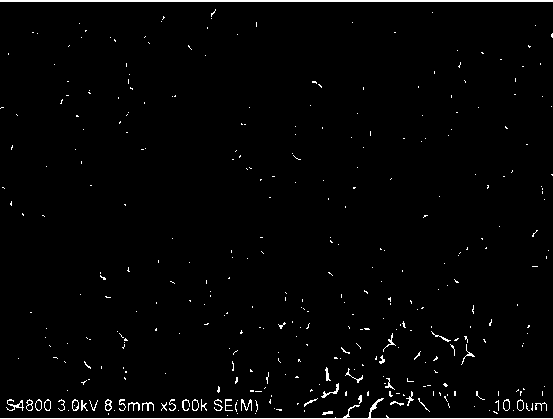

[0029] A hole-enlarging process for polycrystalline black silicon. First, metal-assisted wet chemical etching is used to prepare diamond wire-cut polycrystalline silicon wafers into polycrystalline black silicon with nano-holes; Black silicon carries out hole expansion process; Described hole expansion process comprises the steps:

[0030] 1) Put the above-mentioned polycrystalline black silicon with nano-holes into the first reaming tank for pre-expanding. The reaming liquid used for pre-expanding consists of 8% to 18% Nitric acid, 0.2% ~ 0.6% hole expansion auxiliary a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com