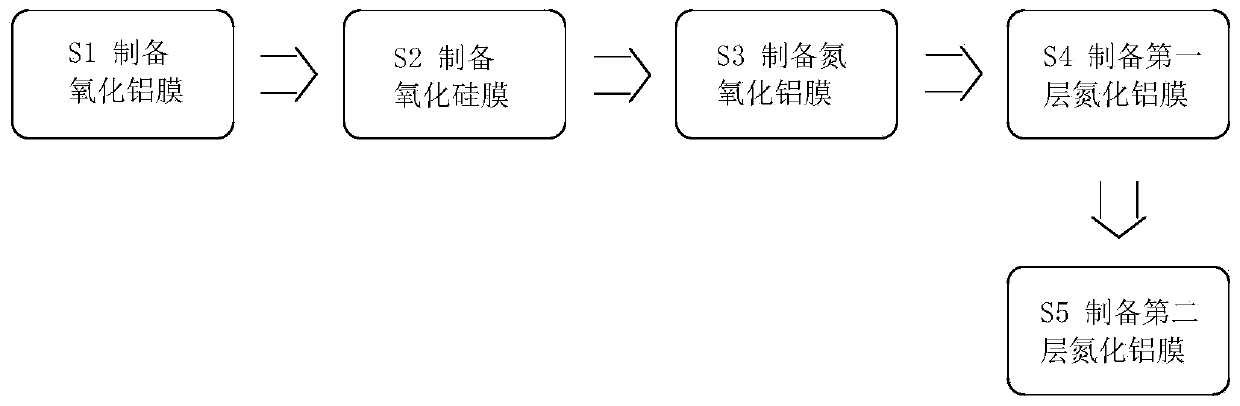

Preparation method of back membrane capable of improving conversion efficiency of single-faced PERC cell

A technology of battery conversion efficiency and back film, applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems of reduced silicon wafer thickness and reduced light absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

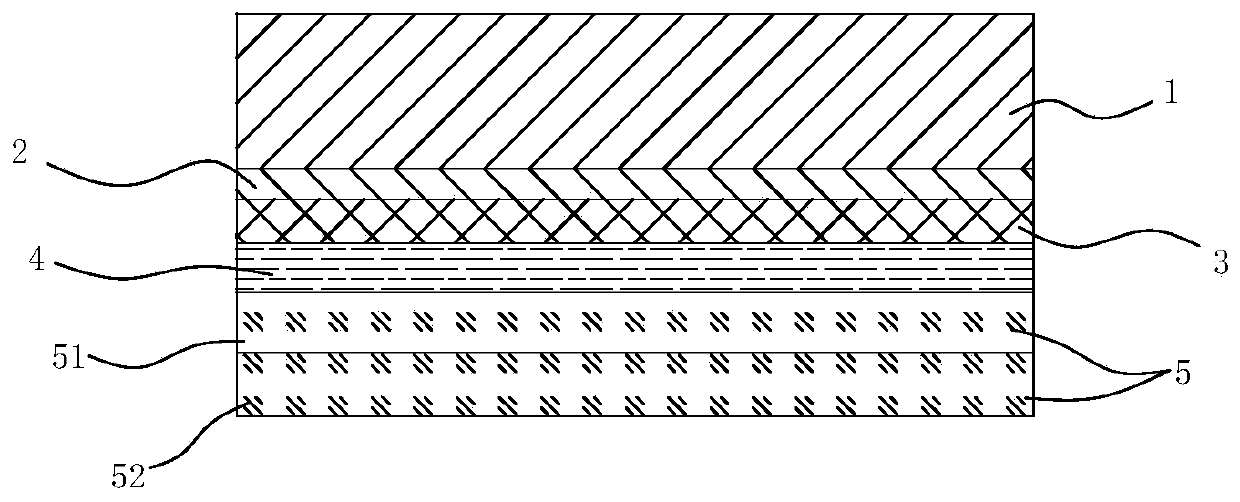

[0019] Example 1: The first step: prepare the back side alumina film 2, put the cell 1 into a graphite boat, and send it into the deposition furnace tube, and deposit the alumina film on the back side of the cell in the deposition furnace tube at a deposition temperature of 250°C —350℃, the thickness of the aluminum oxide film is 10nm;

[0020] The second step: prepare a silicon oxide film 3 on the back side, raise the temperature to 450°C after the first step, and introduce the reaction gas SiH 4 And N2O, where the gas flow rate is SiH 4 150sccm, N 2 O is 4500sccm, RF power is 9kw, duty ratio is 1:30, furnace tube pressure is 1000mtorr, silicon oxide film deposition time is 220s, silicon oxide thickness is 4nm, refractive index is 1.5;

[0021] The third step: prepare a silicon oxynitride film 4 on the back side, and pass the reaction gas SiH after the second step is completed 4 , NH 3 And N 2 O, where the gas flow rate is SiH 4 1000sccm, NH 3 2500sccm, N 2 O is 500sccm, RF power i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com