N-type monocrystalline silicon HBC solar cell preparation method

A technology of solar cells and monocrystalline silicon, which is applied in the field of solar cells, can solve the problems of limiting the large-scale production of HBC cells, increasing the power generation per watt, and reducing LCOE, etc., and achieves the effects of low cost, simplified process, and simplified process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

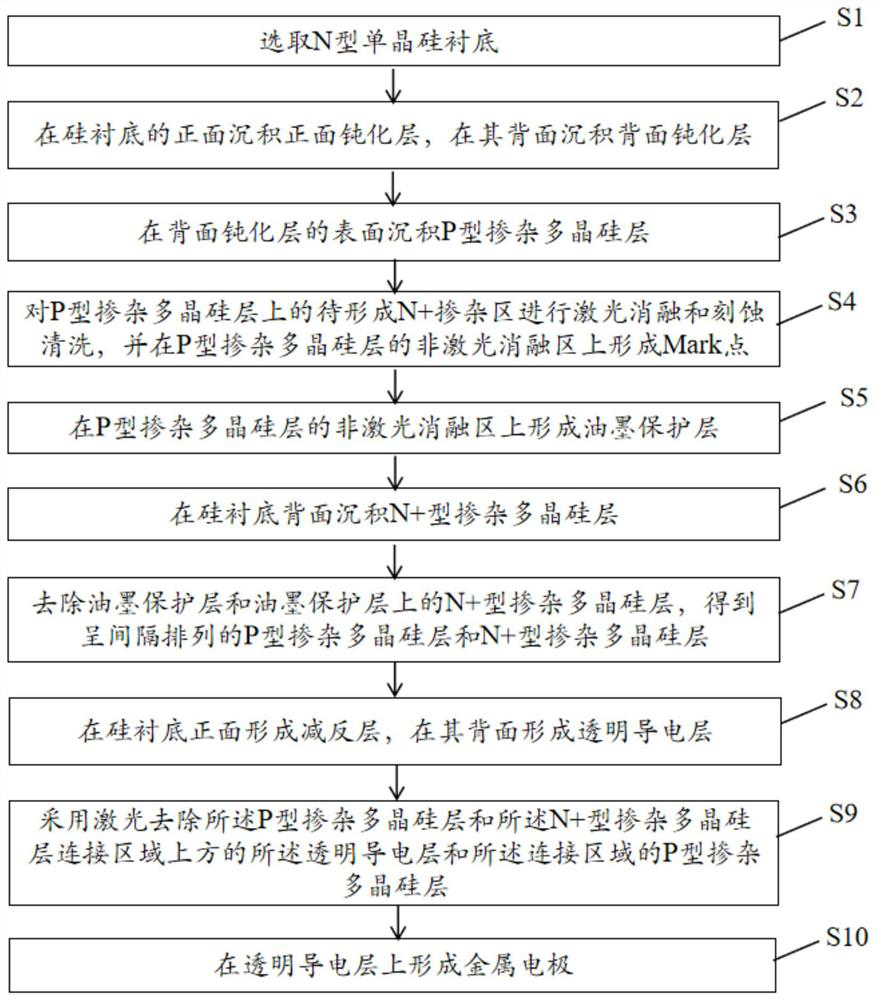

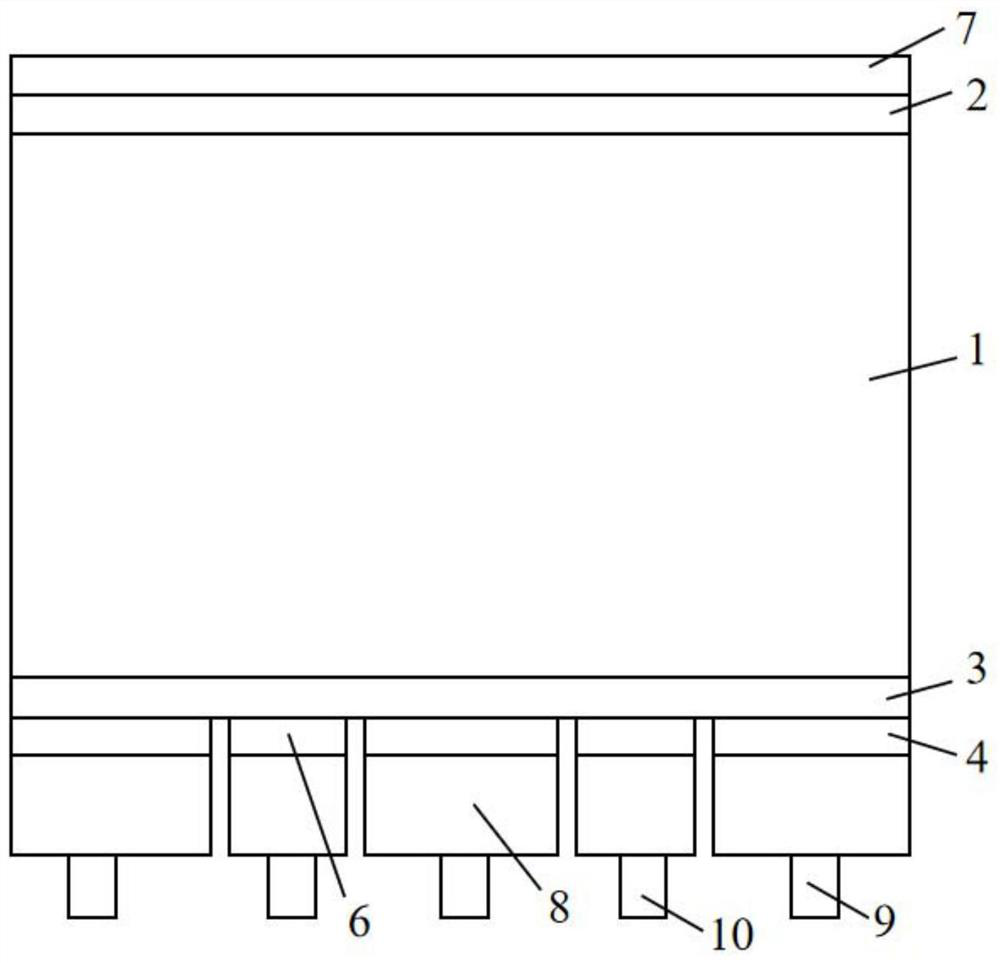

[0048] See figure 1 The present invention provides an N-type single crystal silicon HBC solar cell preparation method, including:

[0049] S1, select the n-type single crystal silicon substrate 1;

[0050] As the preferred embodiment, including:

[0051] Select the back polishing, the front surface of the n-type single crystal silicon substrate 1 is provided; the resistivity of the N-type single crystal silicon substrate 1 is from 1 to 15 Ω · cm, and the thickness is 60-250 μm.

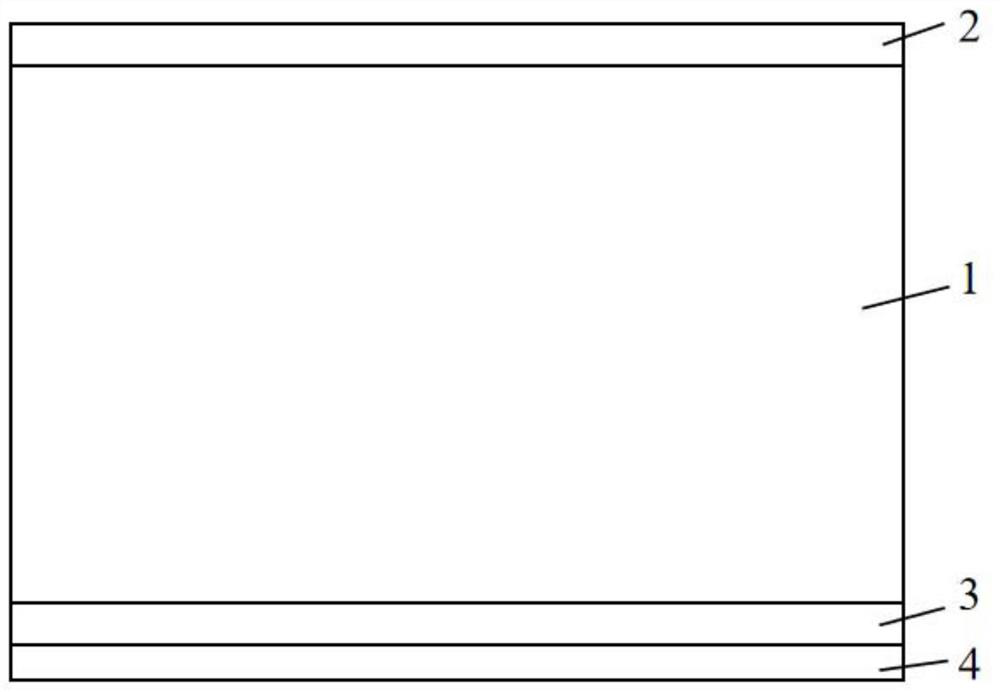

[0052] S2, the front passivation layer 2 is deposited on the front side of the silicon substrate 1, and the back surface passivation layer 3 is deposited thereof;

[0053] As a preferred embodiment, including:

[0054] The front pass passivation layer 2 and the back passivation layer 3 are deposited in the front and back surfaces of the n-type single crystal silicon substrate 1 by the LPCVD device.

[0055] The front passivation layer 2 and the back passivation layer 3 are made of one or more of silicon o...

Embodiment 1

[0107] Method for preparing n-type single crystal silicon HBC solar cell, including:

[0108] S1, select the back surface polishing, the front surface of the N-type single crystal silicon substrate, the N-type single crystal silicon substrate is 15 Ω · cm, and the thickness is 250 μm;

[0109] S2, the front pass passivation layer and the back surface passivation layer are deposited on the surface of the silicon substrate using the LPCVD device; the thickness of the front passivation layer and the back passivation layer is 20 nm;

[0110] S3, using the LPCVD device to deposit the P-type doped polysilicon layer on the surface of the back passivation layer; the P-type doped polysilicon layer is a composite film of 5 layers, each layer thickness of 30 nm, and the total thickness is 150 nm; the P-type The doping concentration of the doped polysilicon layer is incremented by the intrinsic layer interface to the conductive layer interface, and the boron doped concentration ranges from 1 ...

Embodiment 2

[0119] Method for preparing n-type single crystal silicon HBC solar cell, including:

[0120] S1, select the back polishing, the front of the N-type single crystal silicon substrate is provided, the resistivity of the n-type single crystal silicon substrate is 5 Ω · cm, and the thickness is 60 μm;

[0121] S2, using the LPCVD device to deposit a front passivation layer and a back passivation layer on the surface of the silicon substrate; the thickness of the front passivation layer and the back passivation layer is 5 nm;

[0122] S3, using the LPCVD device to deposit the P-type doped polysilicon layer on the surface of the back passivation layer; the P-type doped polysilicon layer is a two-layer composite film having a thickness of 50 nm, a total thickness of 100 nm; the P-type The doping concentration of the doped polysilicon layer is sequentially incremented by the intrinsic layer interface to the conductive layer interface, and the boron doped concentration ranges from 1 to 10%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com