Perovskite solar cell and preparation method of modified layer of perovskite solar cell

A solar cell, perovskite-type technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of ineffective charge transfer and low NiO conductivity, achieve easy control, avoid reverse recombination, speed up separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of cobalt acetylacetonate modified perovskite solar cells

[0044] 1) Preparation of NiO hole transport layer and cobalt acetylacetonate modification layer

[0045] The specific steps are: dissolving 125 mg of nickel acetate in 5 ml of ethanol, and adding 30 ul of ethanolamine. After the dissolution is complete, filter. With 1mg / ml ethanol solution of cobalt acetylacetonate.

[0046]Spin-coat the prepared ethanol solution of nickel acetate onto the FTO glass, and anneal at a high temperature of 400°C. The thickness of the NiO thin film is about 50 nm.

[0047] Then take 90 ul of the prepared ethanol solution of cobalt acetylacetonate and spin-coat it on the NiO film, and spin the film for 30 seconds at a rotation speed of 5000 rpm. After finishing, the film is annealed at 300°C.

[0048] 2) Preparation of perovskite layer

[0049] Precursor PbI 2 , FAI (85%) and CsI (15%) are dissolved in gamma butyrolactone according to the concentration of...

Embodiment 2

[0059] Embodiment 2, prepare the molybdenum acetylacetonate modified perovskite solar cell

[0060] According to the steps of Example 1, only the ethanol solution of cobalt acetylacetonate used in step 1) was replaced with molybdenum acetylacetonate. The concentration of the modifying material was likewise 1 mg / ml.

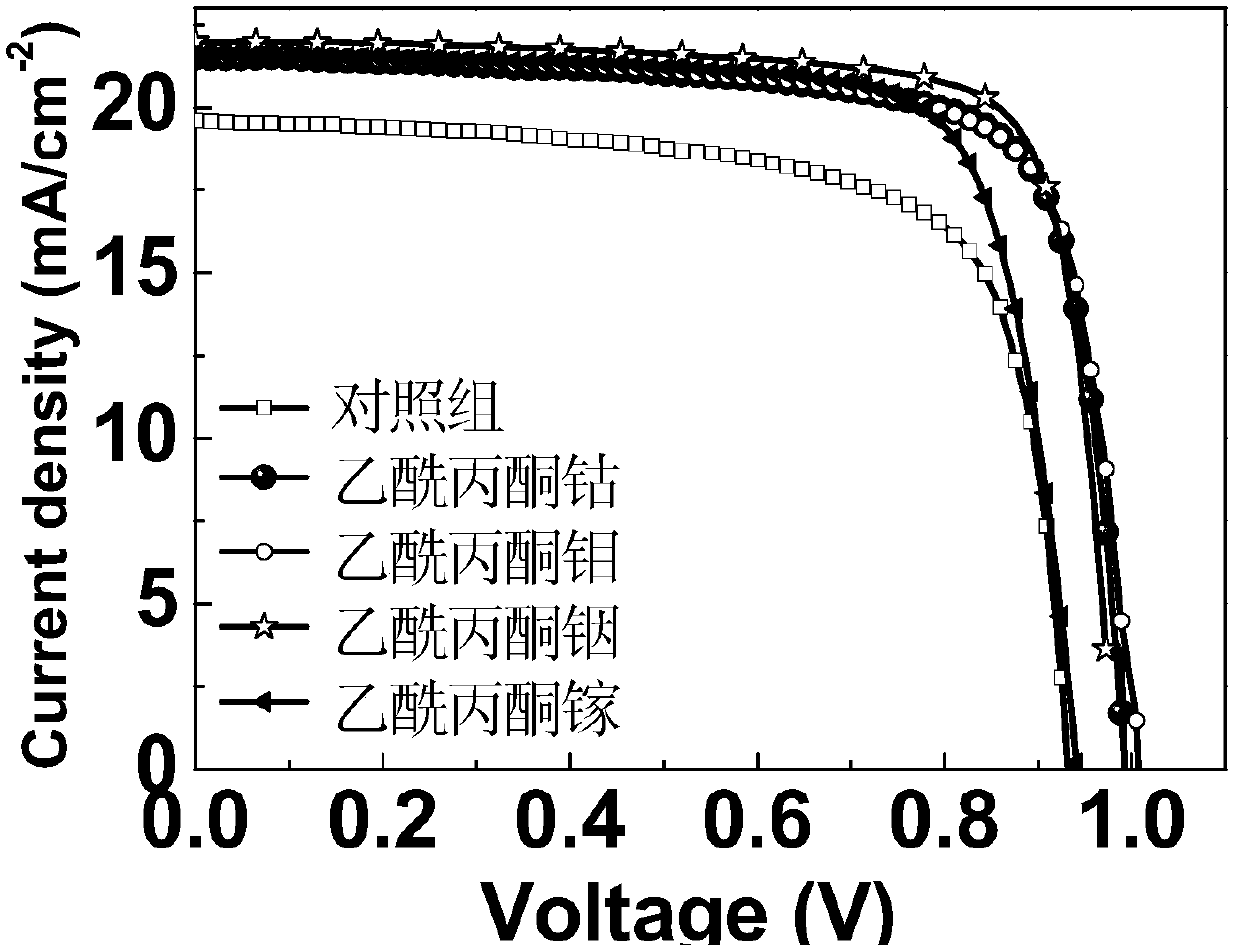

[0061] In AM1.5, 100mW / cm 2 Test the J-V performance curve of the battery with KEITHLEY 4200 under light, such as figure 2 As shown in , the short-circuit current density of the battery is 22.16mA / cm 2 , the open circuit voltage is 0.95V, the fill factor is 0.75, and the photoelectric conversion efficiency is 15.92%.

Embodiment 3

[0062] Example 3, preparation of indium acetylacetonate modified perovskite solar cells

[0063] According to the steps of Example 1, only the ethanol solution of cobalt acetylacetonate used in step 1) was replaced with indium acetylacetonate. The concentration of the modifying material was likewise 2 mg / ml.

[0064] Test the J-V performance curve of the battery with KEITHLEY 4200 under AM1.5, 100mW / cm2 light, as shown in figure 2 As shown in , the short-circuit current density of the battery is 21.16mA / cm 2 , the open circuit voltage is 0.95V, the fill factor is 0.79, and the photoelectric conversion efficiency is 16.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com