A source-drain electrode of a thin film transistor and its preparation method, a thin film transistor and its preparation method

A technology of thin-film transistors and source-drain electrodes, applied in the field of preparation of thin-film transistors, can solve problems such as easy oxidation of copper, high contact resistance, and peeling, and achieve the effects of reduced electrode peeling rate, improved transmission performance, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

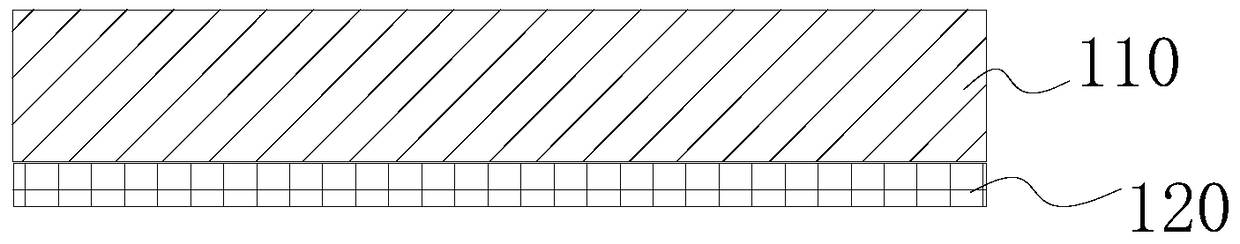

[0045] The source and drain electrodes of the thin film transistor of this embodiment are as figure 1 As shown, it is composed of a molybdenum layer 120 and a copper layer 110 stacked in sequence, the copper layer 110 is located above the molybdenum layer 120, and the molybdenum layer 120 is disposed above the active layer of the thin film transistor.

[0046] Wherein, the thickness of the molybdenum layer is set to be 20-40 nm. The thickness of the copper layer is set to 150-250 nm. In this embodiment, the thickness of the copper layer is preferably set to 200 nm, and the thickness of the molybdenum layer is set to 30 nm.

[0047] The preparation method of the source and drain electrodes of the thin film transistor of this embodiment is as follows:

[0048] (1) Under the Ar gas environment of 10sccm, the air pressure is 1mTorr, with 50 watts of power, the molybdenum film is prepared as the molybdenum layer in the sputtering of the active layer of the thin film transistor;

...

Embodiment 2

[0059] Such as Figure 4 As shown, the thin film transistor of this embodiment includes a substrate 200, a bottom gate 300, a gate insulating layer 400, an active layer 500, and a source-drain electrode 100 from bottom to top; layers and copper layers.

[0060] The preparation process of the thin film transistor of this embodiment is as follows:

[0061] a. First, a 300nm aluminum alloy film is deposited on the glass substrate by DC sputtering and wet etching as the bottom gate;

[0062] b. Then prepare a layer of 200nm Al on the bottom gate by chemical anodic oxidation 2 o 3 gate insulating layer;

[0063] c. A 50nm a-IGZO thin film is used as the active layer by radio frequency magnetron sputtering at room temperature, and the a-IGZO thin film is patterned by wet etching, and then annealed in an air atmosphere at 300 ° C for 30 min;

[0064] d. Under the Ar gas environment of 10sccm, the air pressure is 1mTorr, sputtering a molybdenum 30nm film with a power of 50 watts ...

Embodiment 3

[0067] The preparation process of the thin film transistor of this embodiment is as follows:

[0068] a. First, a 300nm aluminum alloy film is deposited on the glass substrate by DC sputtering and wet etching as the bottom gate;

[0069] b. Then prepare a layer of 200nm Al on the bottom gate by chemical anodic oxidation 2 o 3 gate insulating layer;

[0070] c. A 50nm a-IGZO thin film is used as the active layer by radio frequency magnetron sputtering at room temperature, and the a-IGZO thin film is patterned by wet etching, and then annealed in an air atmosphere at 300 ° C for 30 min;

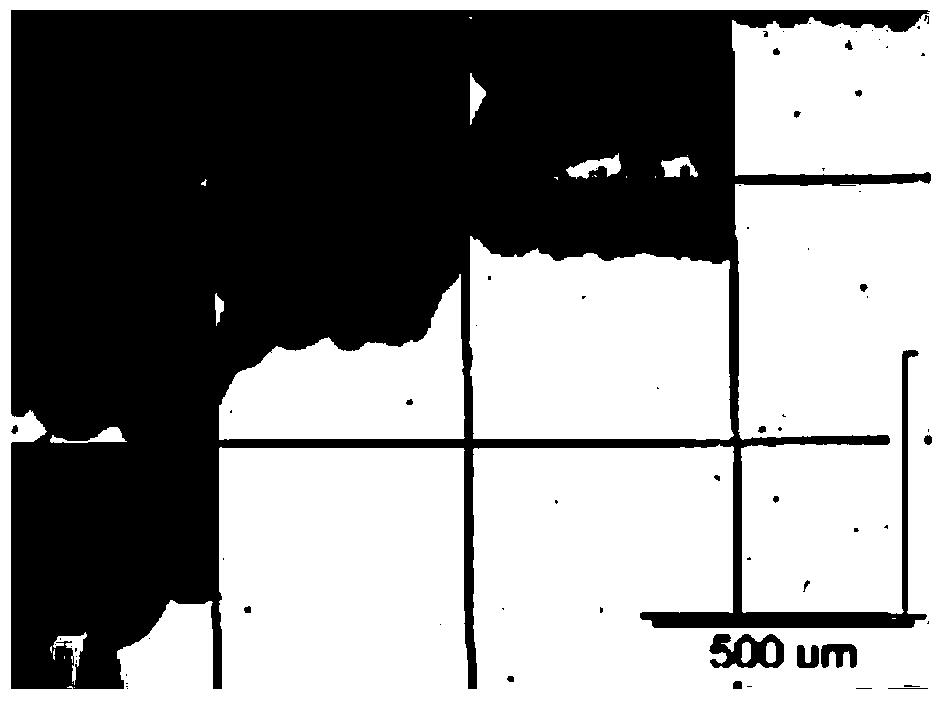

[0071] d. Under the Ar gas environment of 25sccm, the air pressure is 7mTorr, sputtering molybdenum 30nm thin film with 200 watts of power as the molybdenum layer, then under the Ar gas environment of 10sccm, the air pressure is 7mTorr, sputtering 100nm copper thin film with 100 watts of power as the molybdenum layer Copper layer; then, the prepared molybdenum layer and copper layer are patt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com