Patents

Literature

90results about How to "Balance stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

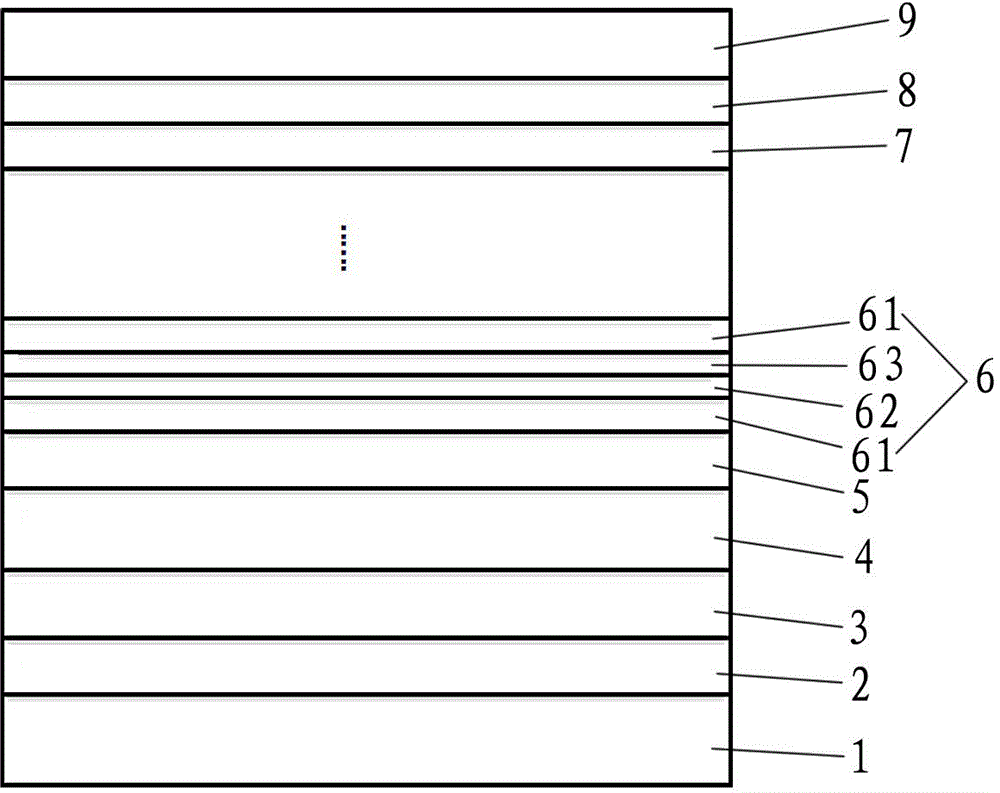

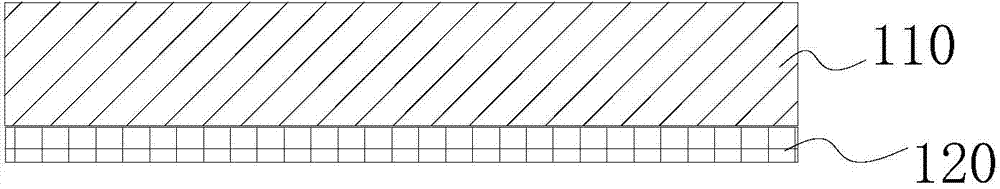

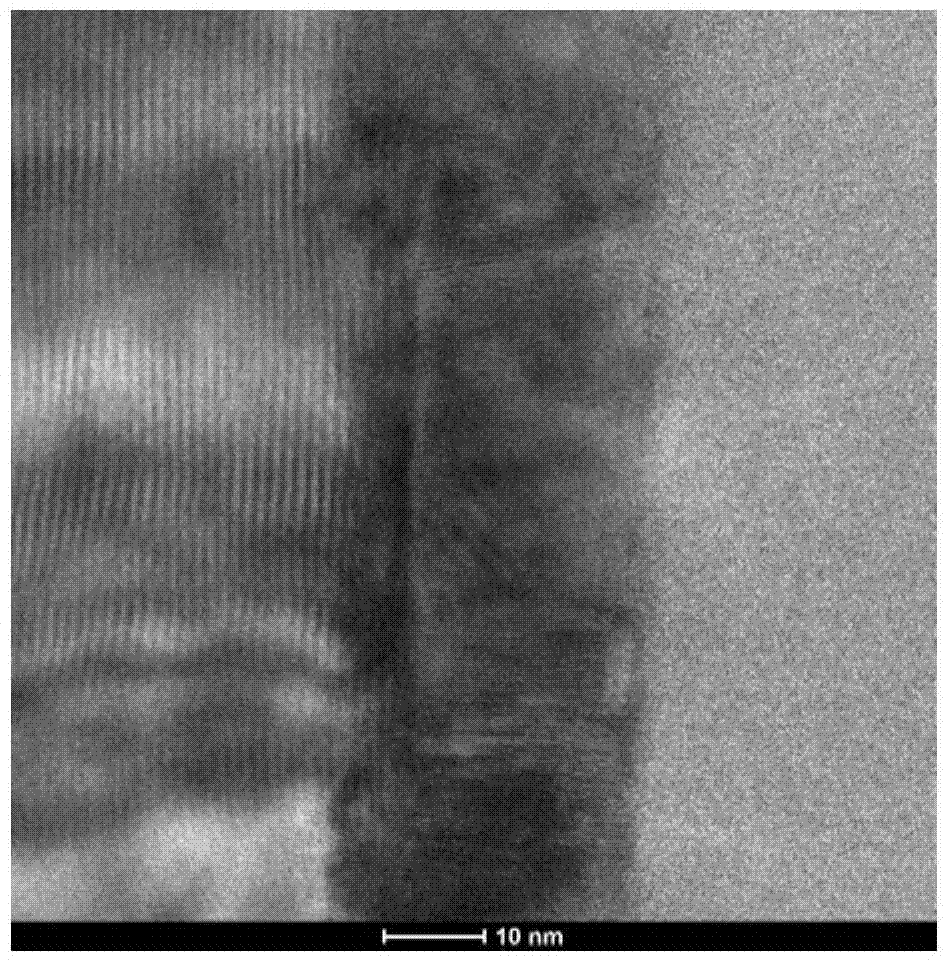

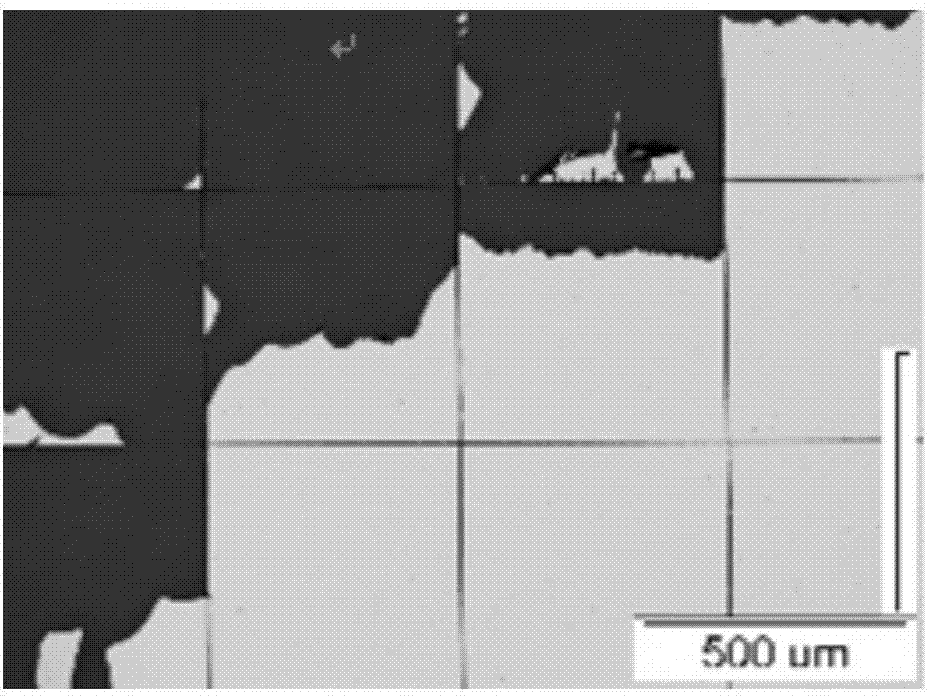

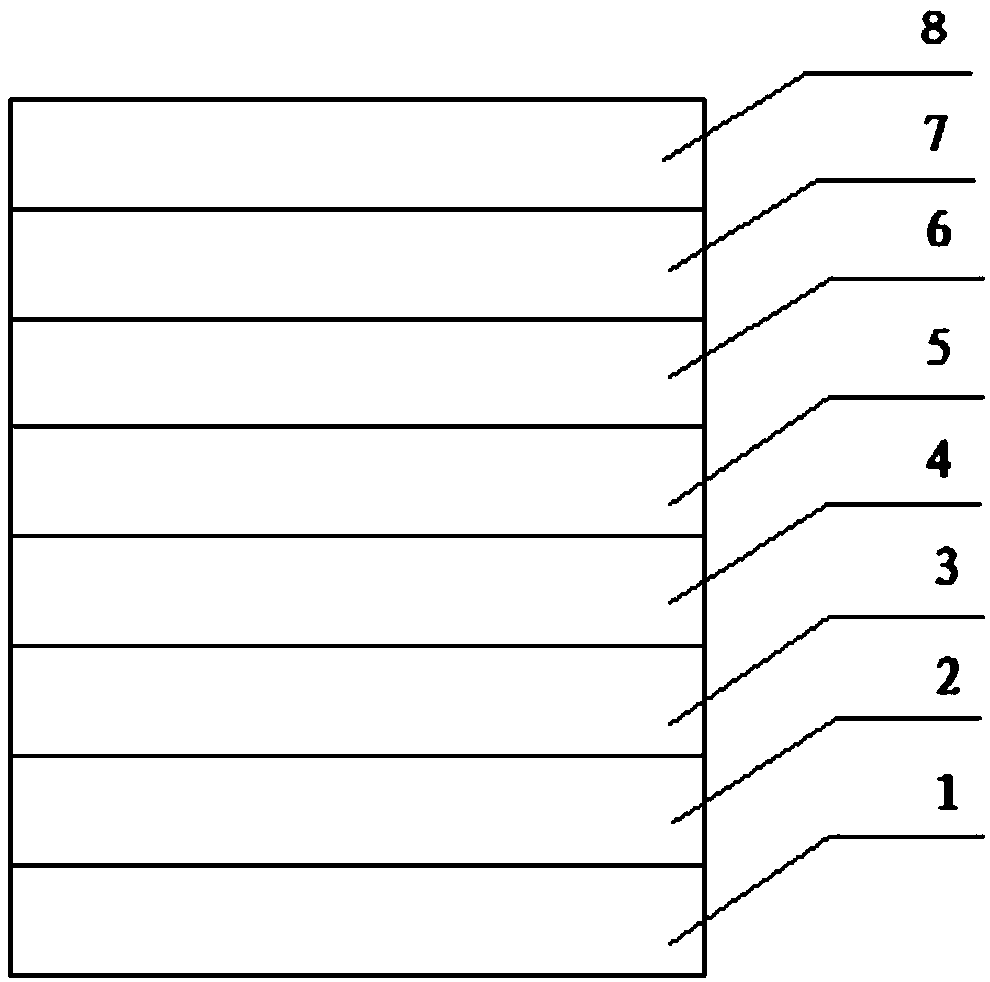

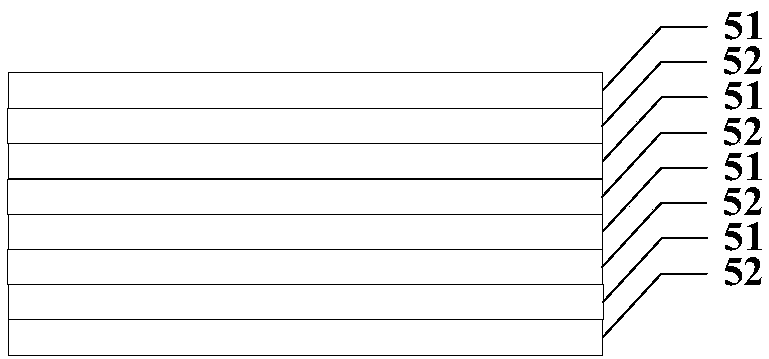

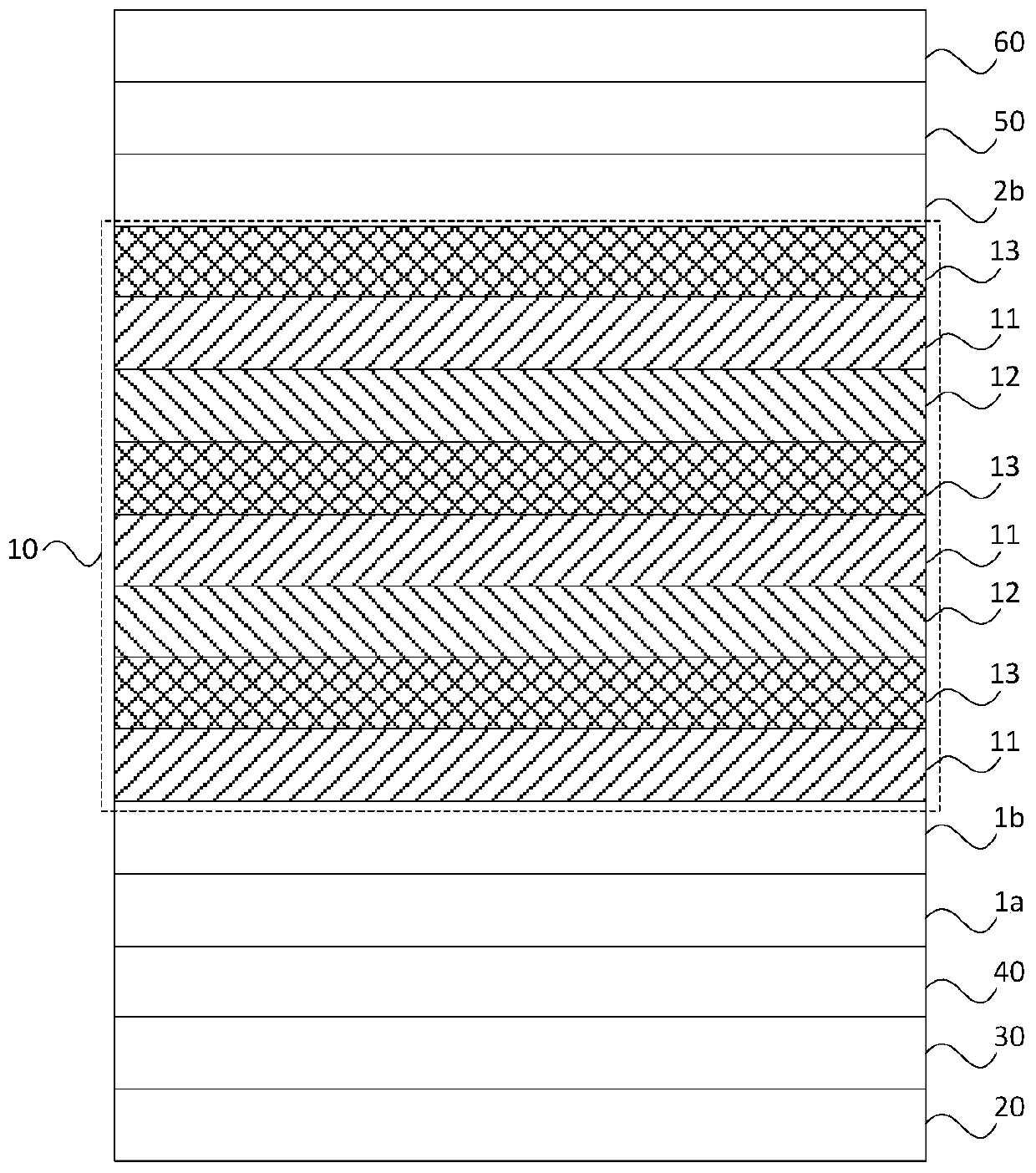

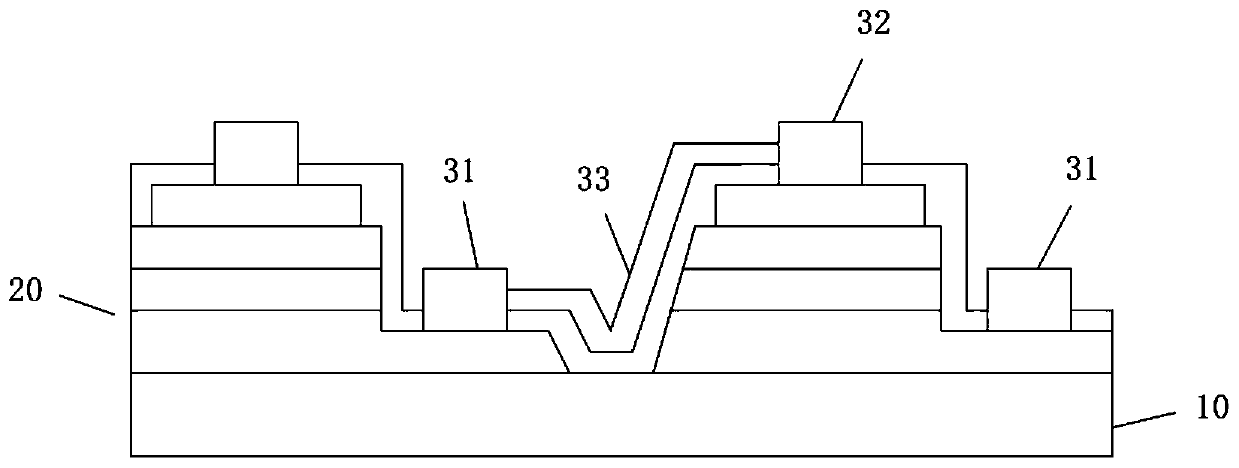

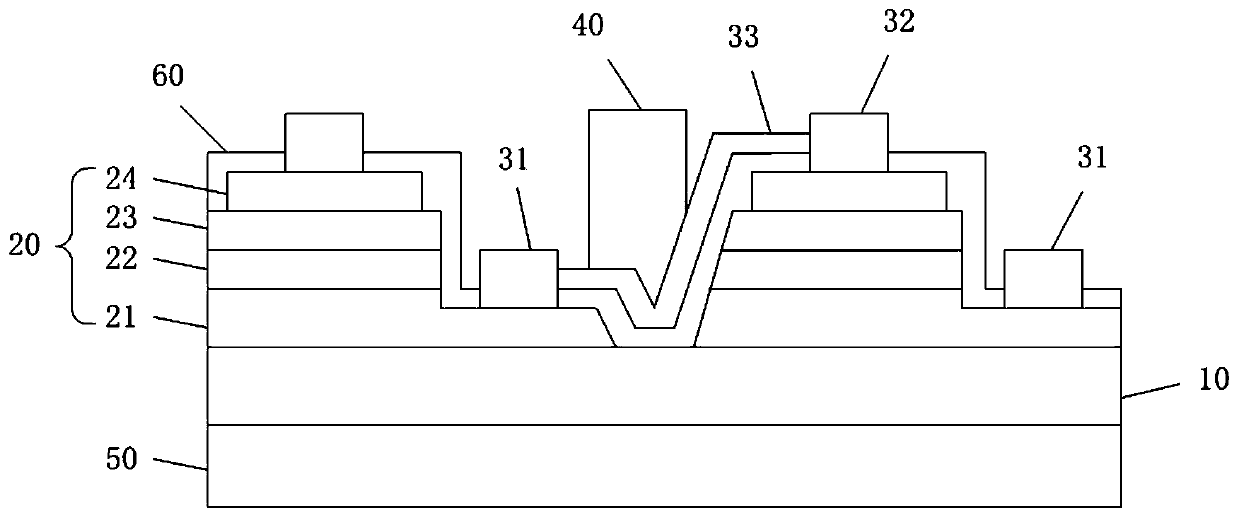

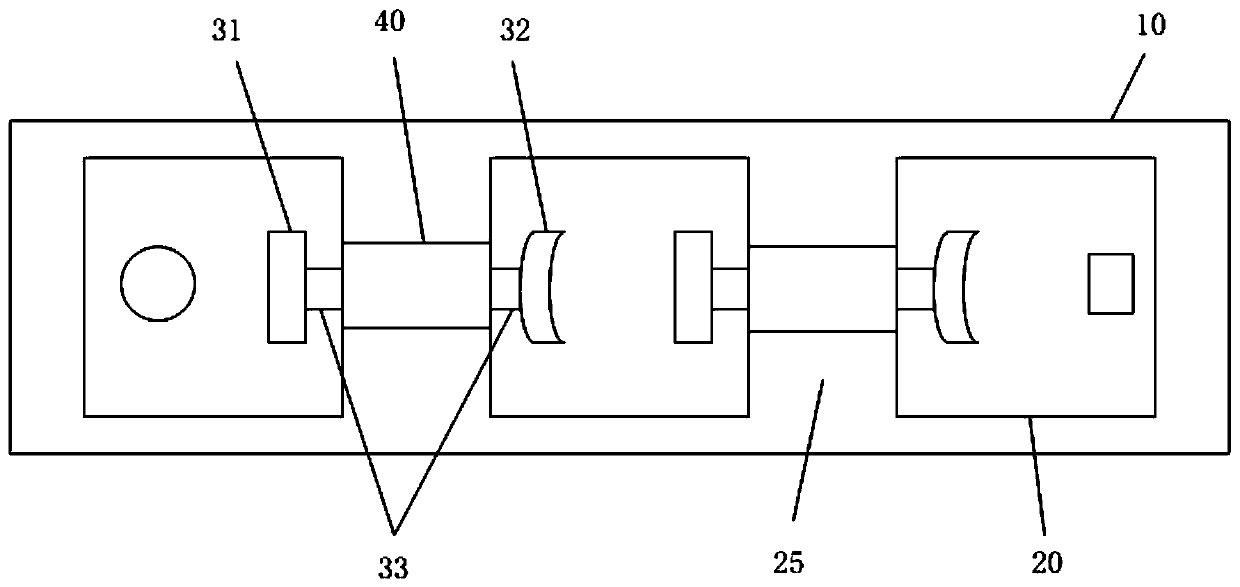

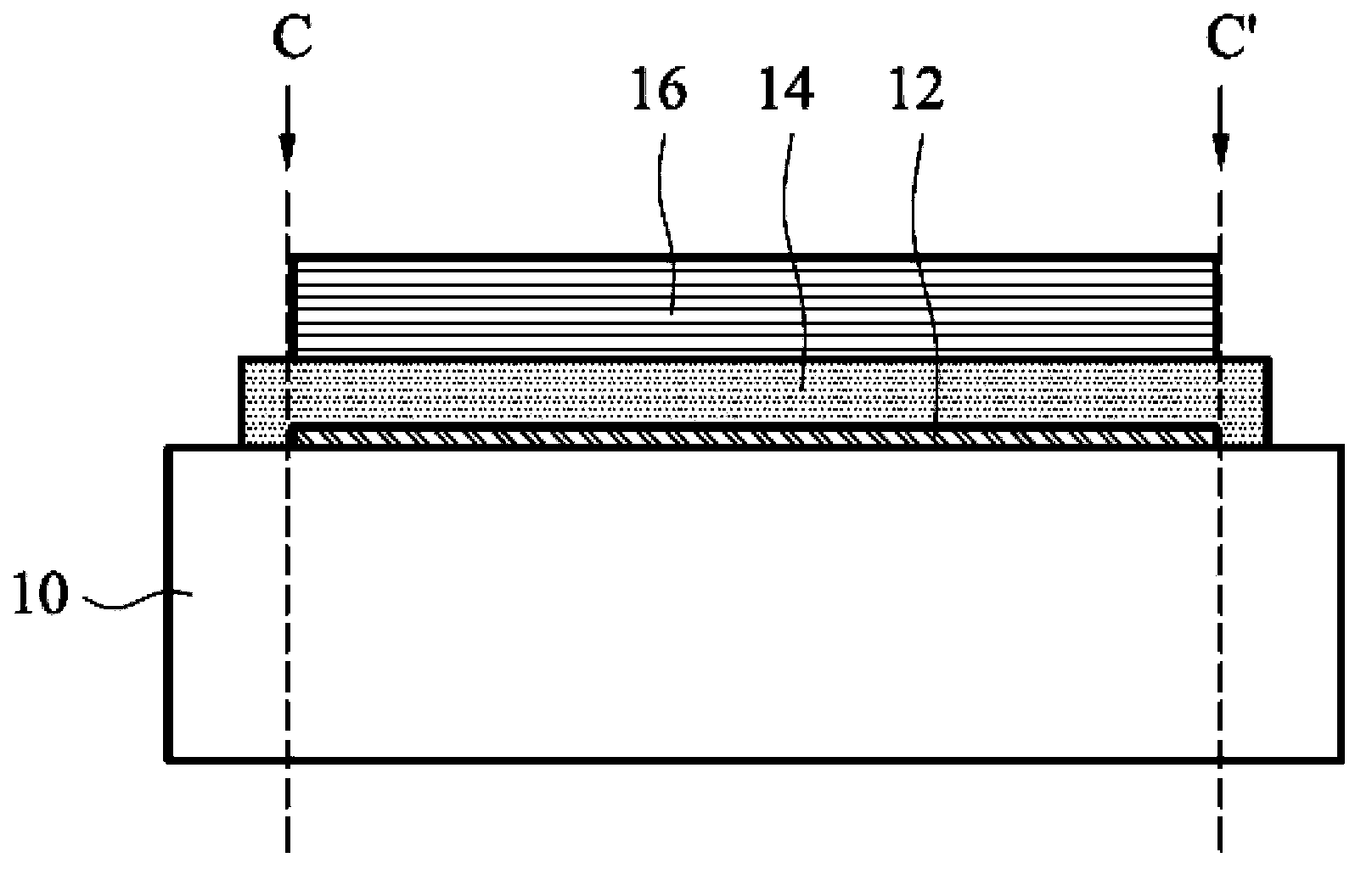

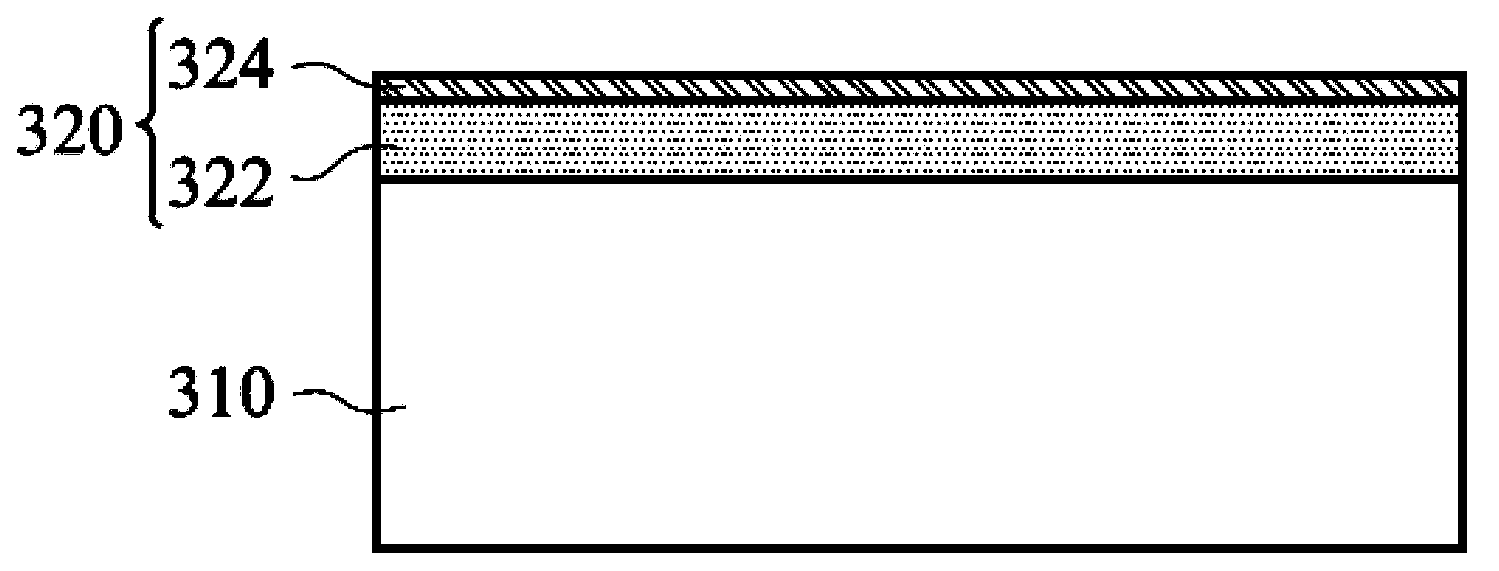

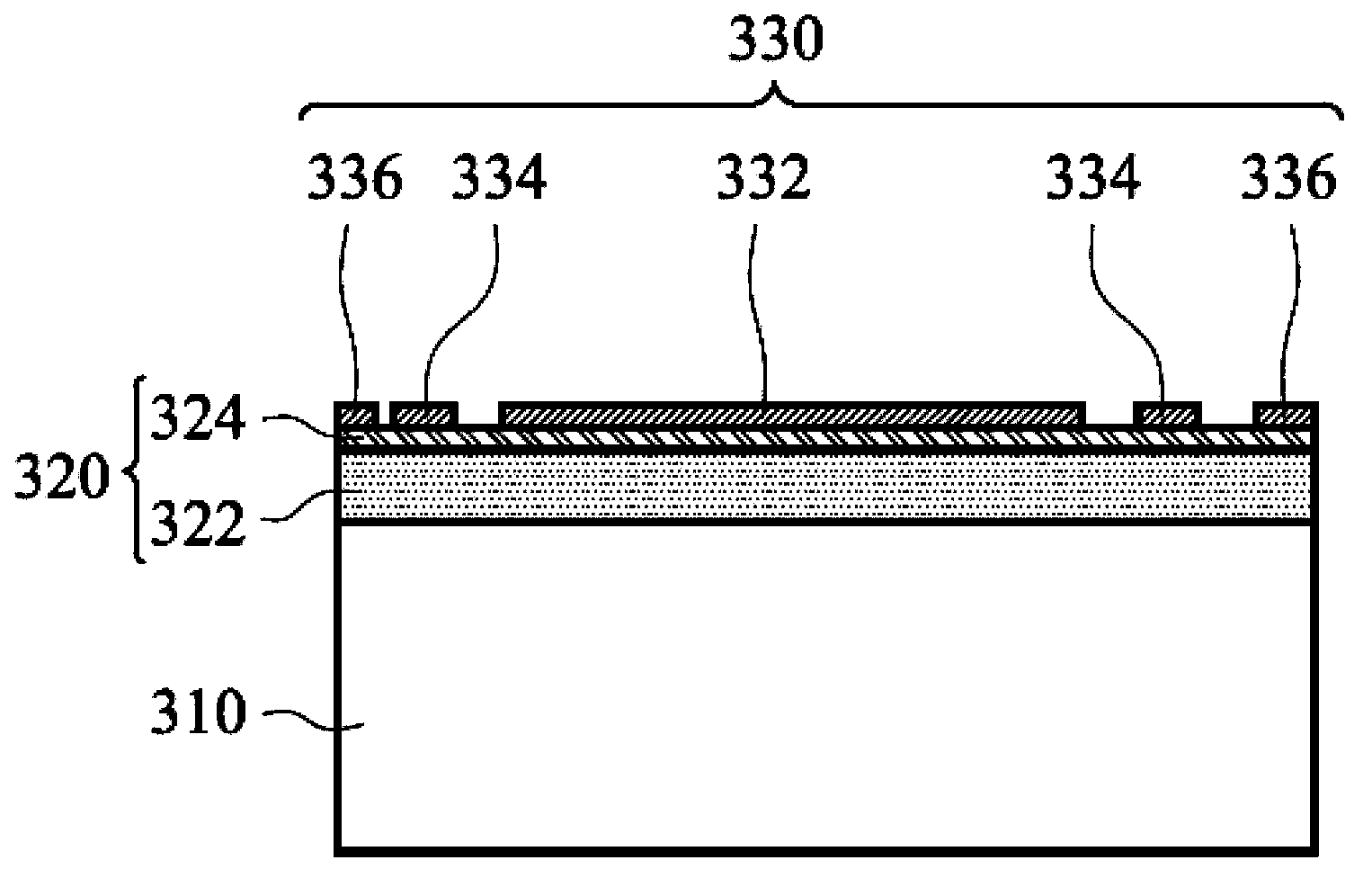

InAs/GaSb superlattice infrared photoelectric detector and manufacturing method thereof

ActiveCN103887360AImprove performanceSuppression-recombination dark currentFinal product manufactureSemiconductor devicesPhotovoltaic detectorsElectrode Contact

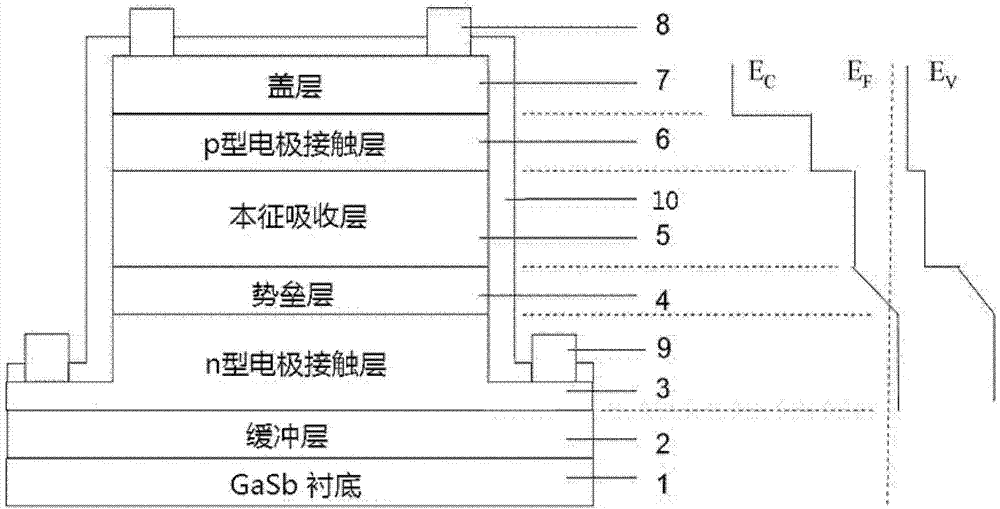

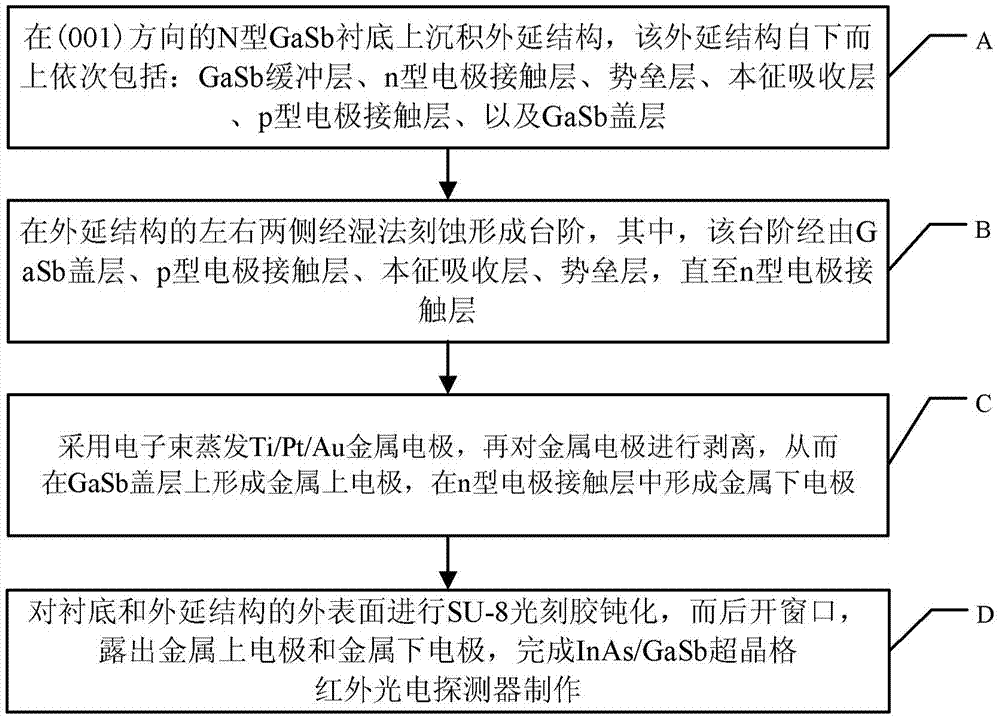

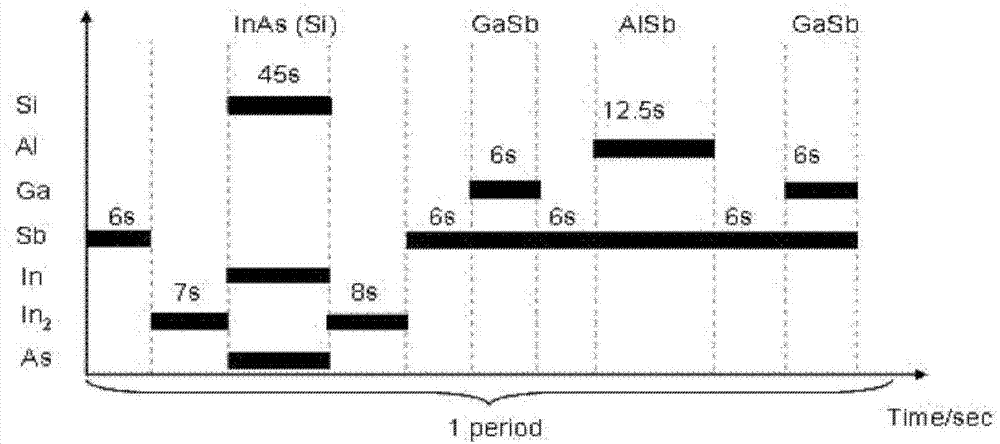

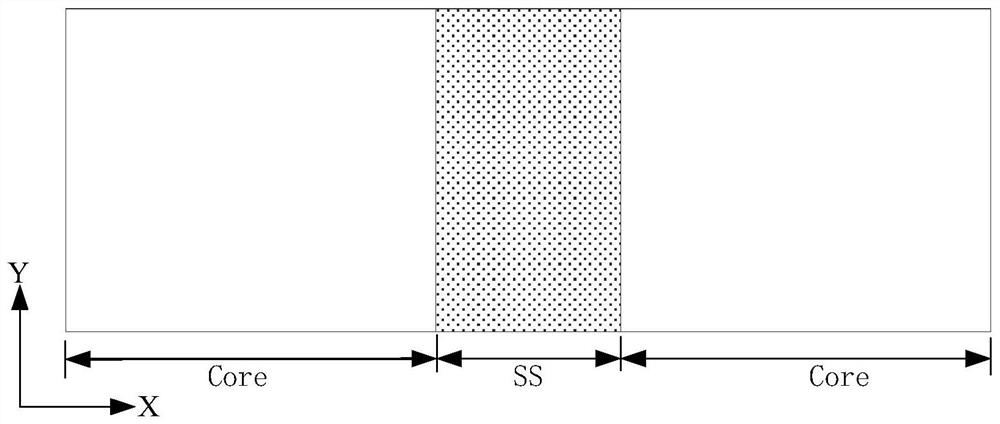

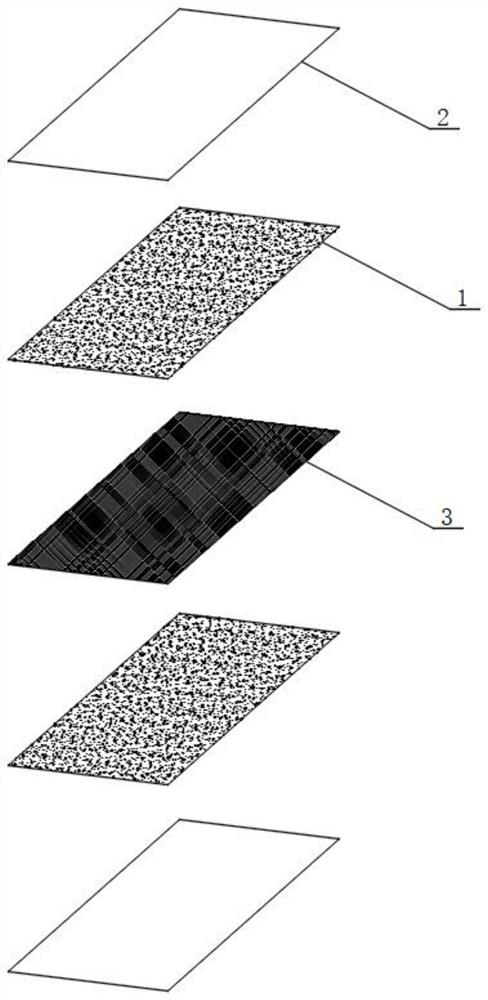

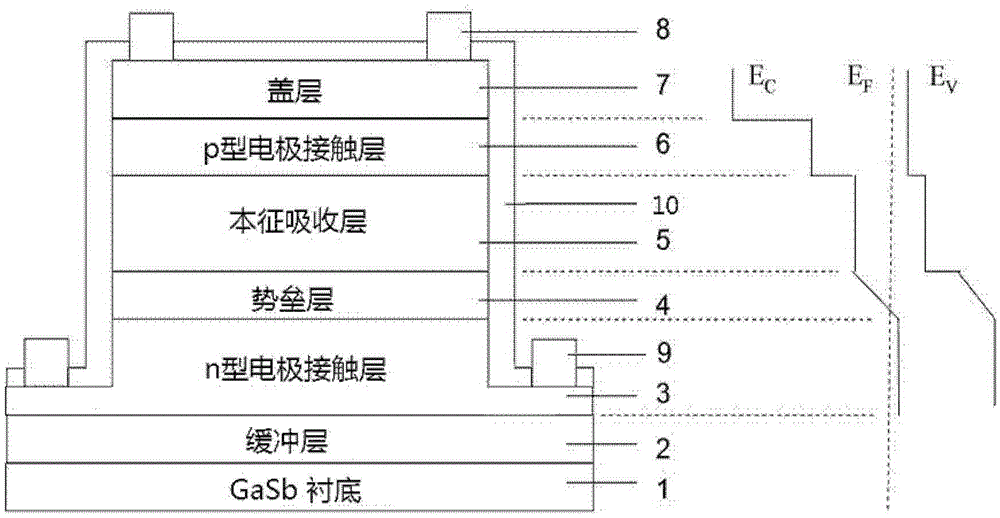

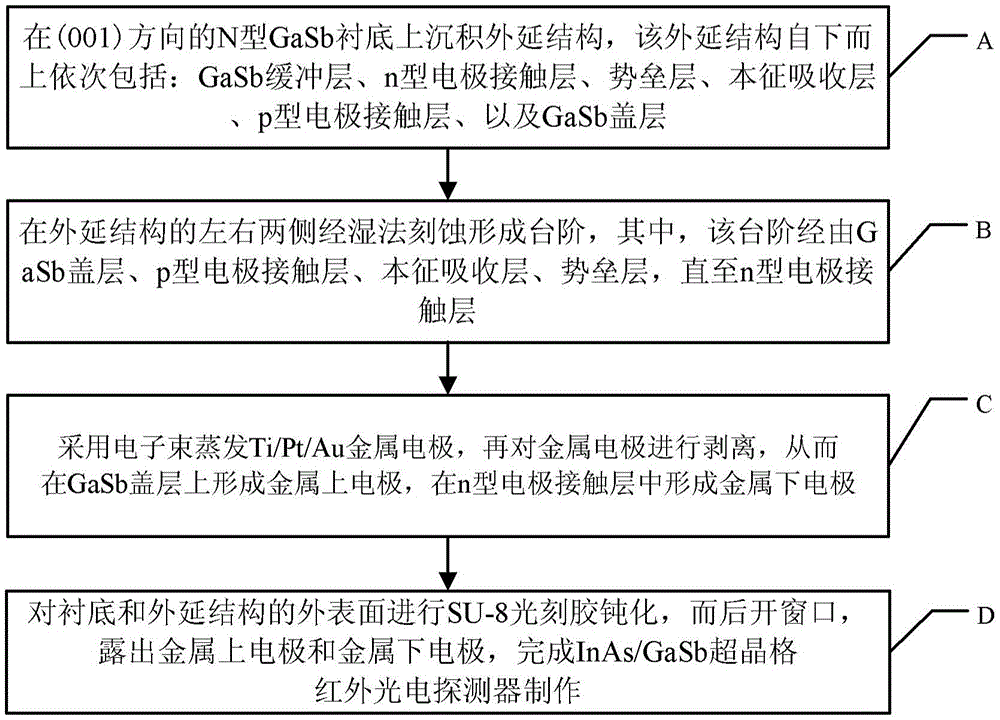

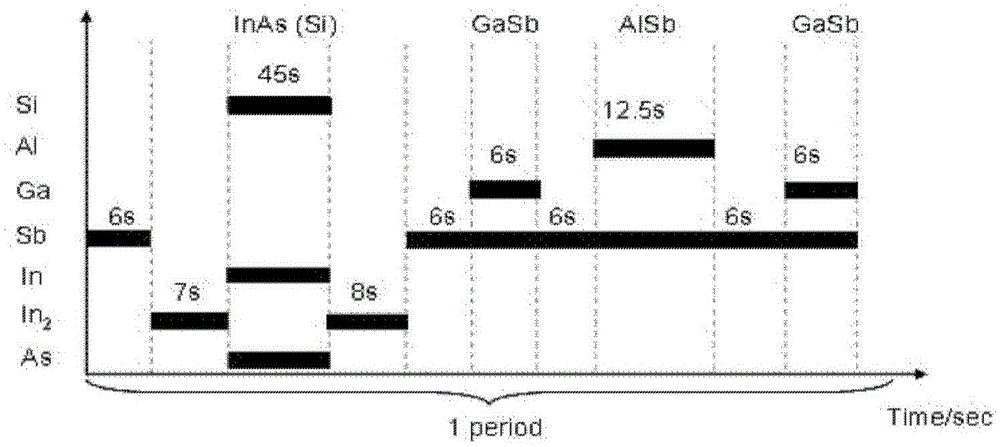

The invention provides an InAs / GaSb superlattice infrared photoelectric detector and a manufacturing method thereof. The InAs / GaSb superlattice infrared photoelectric detector comprises a substrate, an epitaxy structure deposited on the substrate, an upper metal electrode formed above steps, a lower metal electrode formed under the steps and a passivation layer, wherein the epitaxy structure comprises an n-type doping buffer layer, an n-type electrode contact layer, a barrier layer, an intrinsic absorption layer, a p-type electrode contact layer and a cover layer, the steps are formed on two sides of the epitaxy structure through etching, the intrinsic absorption layer is composed of a plurality of periodical InAs / InSb / GaSb / InSb superlattice structures. In the InAs / GaSb superlattice infrared photoelectric detector, InSb is respectively inserted into two interfaces of each superlattice period of the intrinsic absorption layer to form strained superlattices, the stress between the superlattices and the substrate is effectively balanced, the material growing quality is improved, and accordingly the photoelectric performance of the detector is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

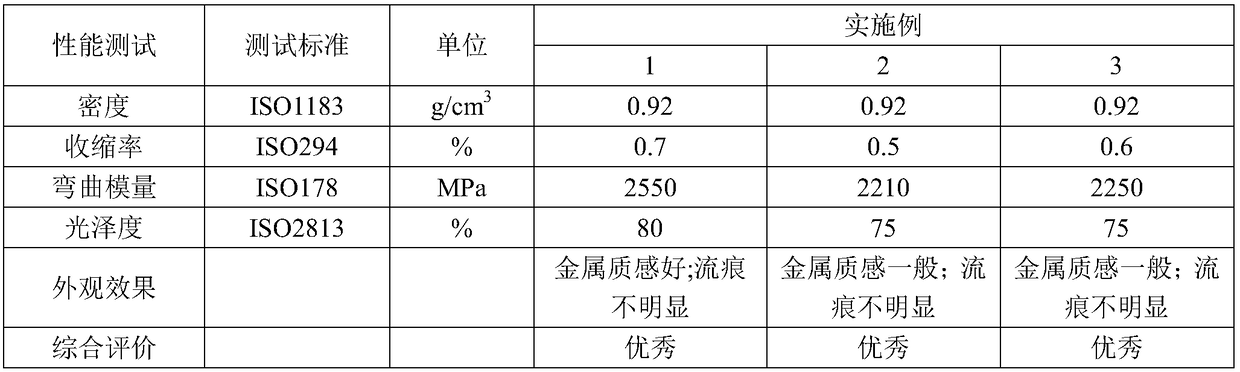

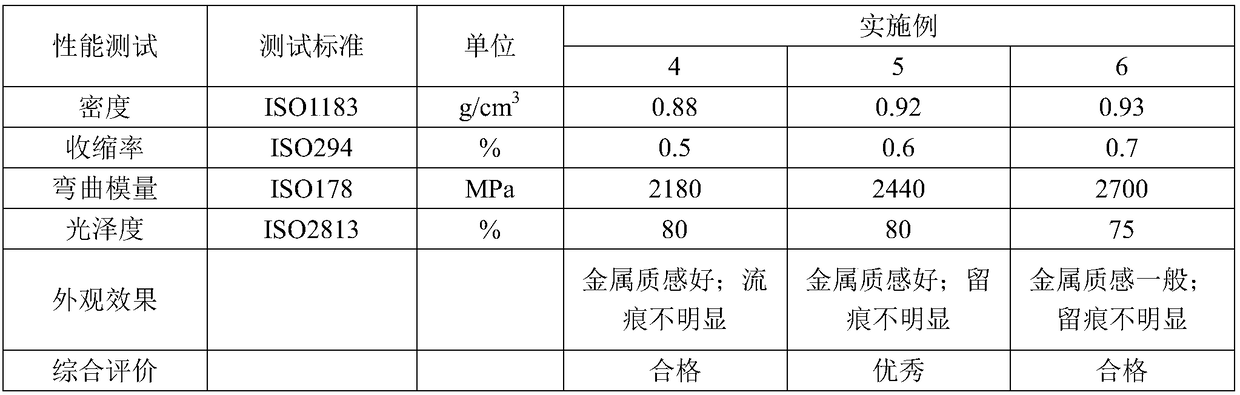

Low-density and low-shrinkage-rate silver metal texture polypropylene composite material and preparation method thereof

The invention discloses a low-density and low-shrinkage-rate silver metal texture polypropylene composite material and a preparation method thereof. The polypropylene composite material comprises high-crystallized polypropylene, high-melt-value polypropylene, low low-shrinkage-rate polypropylene, hollow glass beads, ultra-white and ultra-fine talcum powder, toughening fillers, metal pigments, nano-zinc sulfide, hyperbranched resin, antioxidants and scratch-resistant agents. In the injection molding process of the free-spraying polypropylene composite material, obvious welding marks on the surface of the material are omitted, the appearance of the material approaches to spraying effects, components can be directly used, later spraying treatment is omitted, cost is saved, the material is green and environmentally friendly, the density of the material is much lower than that of common modified polypropylene, lightweight requirements of clients are met, the shrinkage rate of the material is lower than 0.5, the material can directly replace ABS (acrylonitrile butadiene styrene) in the field such as household electric appliance shells, secondary mold opening is omitted, and cost is saved.

Owner:WANHUA CHEM GRP CO LTD +1

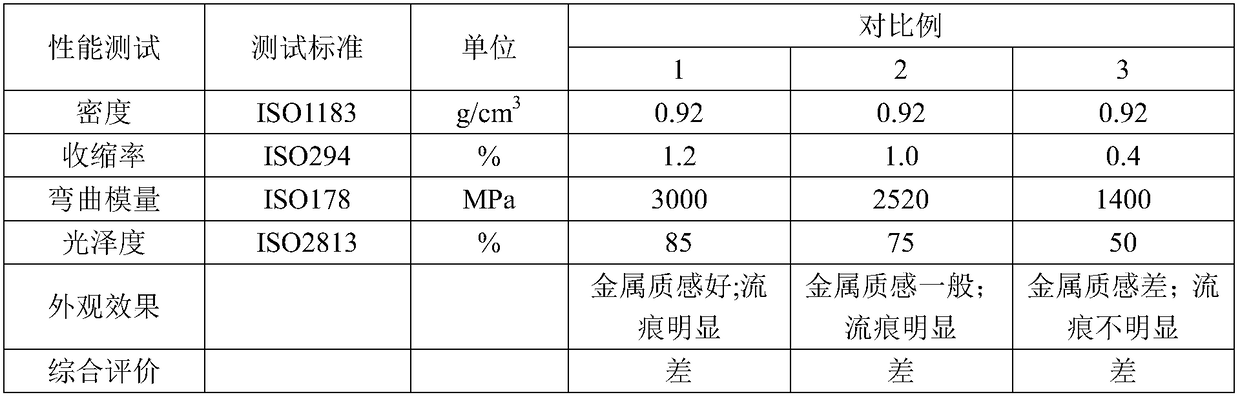

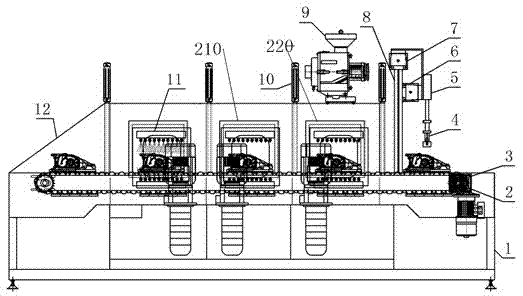

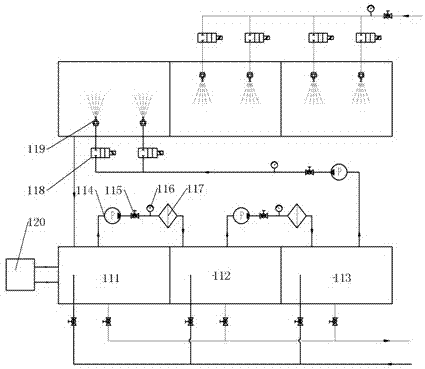

Workpiece cleaning machine and method of use thereof

InactiveCN102284452AImprove securityAvoid direct contactCleaning processes and apparatusSprinkler systemWind shear

The present invention relates to a cleaning device and its use method, and aims to provide a workpiece cleaning machine and its use method to solve the problems in the prior art that the manual cleaning efficiency is low and some chemical substances in the cleaning process are easy to cause damage to the human body . The workpiece cleaning machine includes a frame; a conveyor belt on the frame; a spray system on the frame; an air cutting system on the frame. In the cutting system, the workpiece is first washed by the liquid spray head in the spray system, and then cleaned by the air spray head in the wind cutting system, and finally sent to the rear end of the conveyor belt. The batch cleaning of the workpieces is carried out in an assembly line, which improves the work efficiency, avoids direct contact between personnel and chemical substances such as cleaning fluids, and reduces the damage to the human body.

Owner:CHONGQING KEBEN TECH

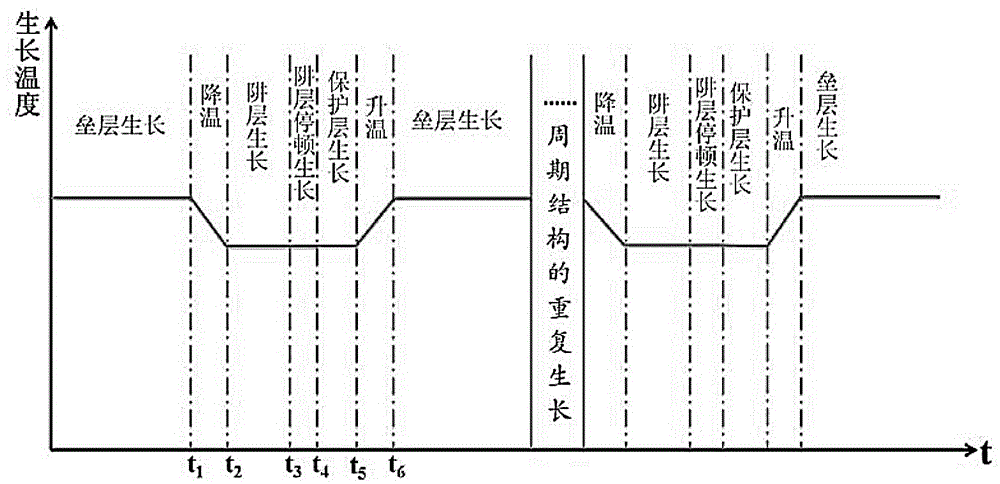

Method for growing LED epitaxial structure with high-quality InGaN/GaN active layer

ActiveCN104319330AQuality improvementImprove luminous efficiencySemiconductor devicesOptoelectronicsActive layer

The invention discloses a method for growing an LED epitaxial structure with a high-quality InGaN / GaN active layer. The InGaN / GaN active layer is grown by use of the steps of introducing a Ga source and NH3 to grow a GaN barrier layer of 8-5nm in the atmosphere of H2 serving as a main carrier gas, switching the main carrier gas to N2 and introducing the Ga source, an In source and the NH3 to grow an InxGa1-xN trap layer of 2-5nm, shutting down the Ga source and the In source while keeping normal introduction of the NH3 to stop the growth of the InxGa1-xN, turning on the Ga source to grow a GaN protective layer of 1-5nm, switching the main carrier gas to the H2 and introducing the Ga source and the NH3 to grow the GaN barrier layer of 8-5nm, and finally, repeating the second to fifth growth steps for 1-20 cycles. The method for growing the LED epitaxial structure with the high-quality InGaN / GaN active layer is capable of obtaining the high-quality InGaN / GaN active layer and improving the LED luminous efficiency.

Owner:XIAMEN CHANGELIGHT CO LTD

Source-drain electrode of thin film transistor and manufacturing method thereof and thin film transistor and manufacturing method thereof

ActiveCN104766891AReduce contact resistanceImprove conductivityTransistorSemiconductor/solid-state device manufacturingOxideBonding strength

The invention discloses a source-drain electrode of a thin film transistor. The source-drain electrode is composed of a molybdenum layer and a copper layer in a sequential overlaying mode, and the copper layer is arranged on the molybdenum layer. The molybdenum layer is arranged on an active layer of the thin film transistor; the growth direction of crystal lattices of the molybdenum layer and the growth direction of crystal lattices of the copper layer are perpendicular to each other; the thickness of the molybdenum layer is 20 nm-40 nm; the thickness of the copper layer is 150 nm-250 nm. The invention further discloses a manufacturing method of the source-drain electrode, the thin film transistor comprising the source-drain electrode and a manufacturing method of the thin film transistor. The defects that in the prior art, copper electrodes are prone to being oxidized, and copper atoms diffuse toward oxide after the copper electrodes deposit on the active layer of the metal oxide are overcome, the source-drain electrode has the advantage of high conductivity, stress balance between two layers of electrodes can be achieved, the disbanding ratio of the electrodes is lowered, and the bonding strength is improved.

Owner:SOUTH CHINA UNIV OF TECH

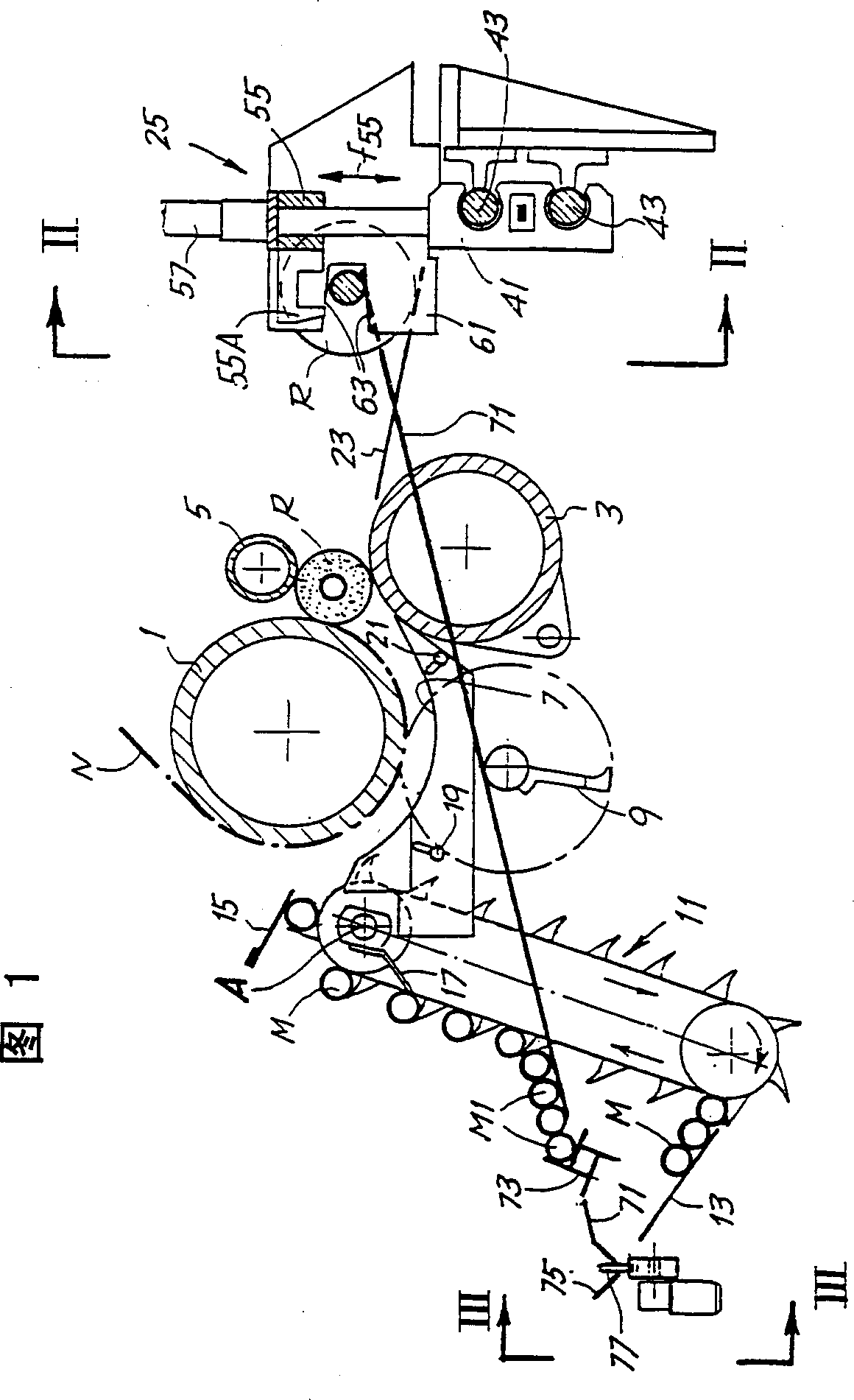

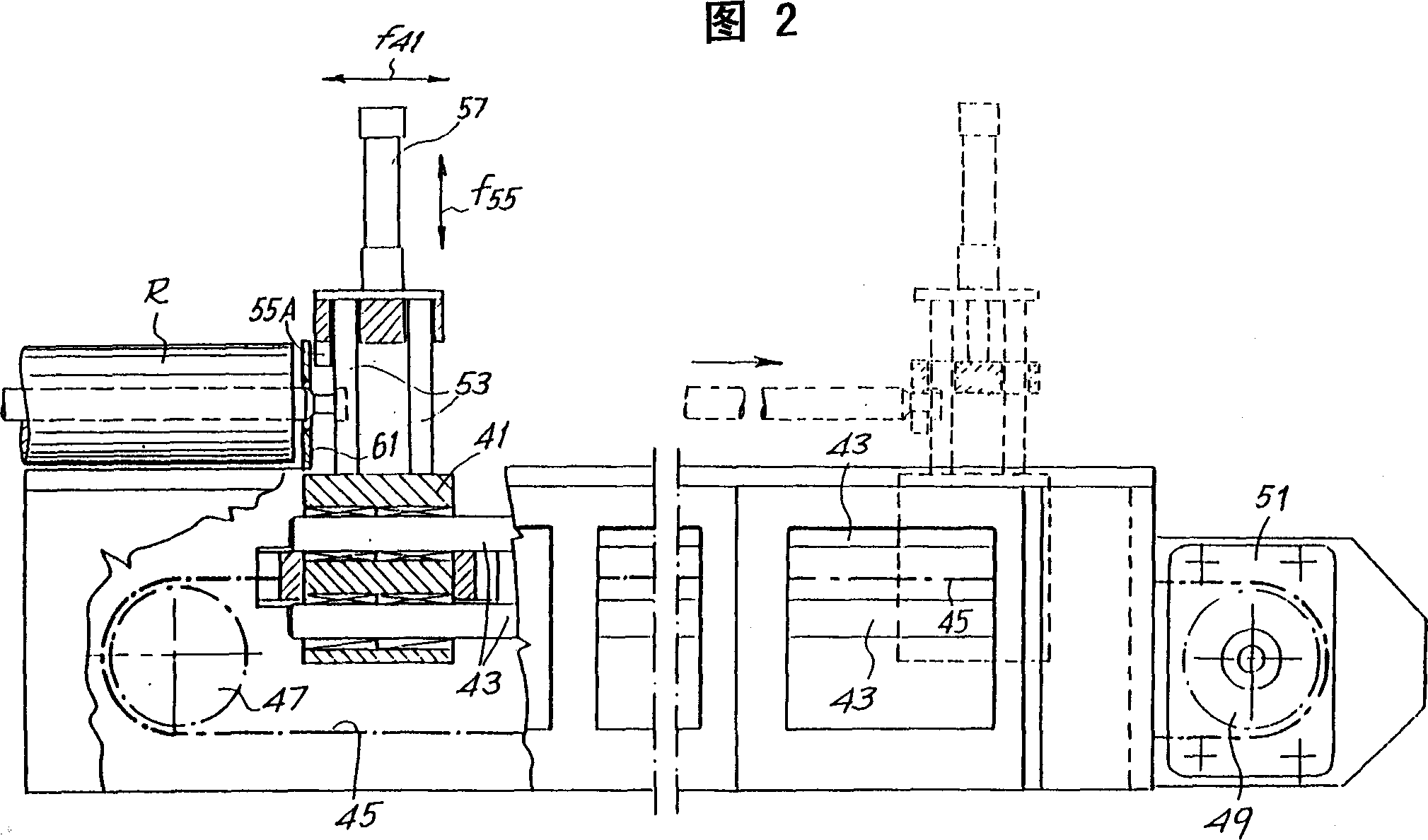

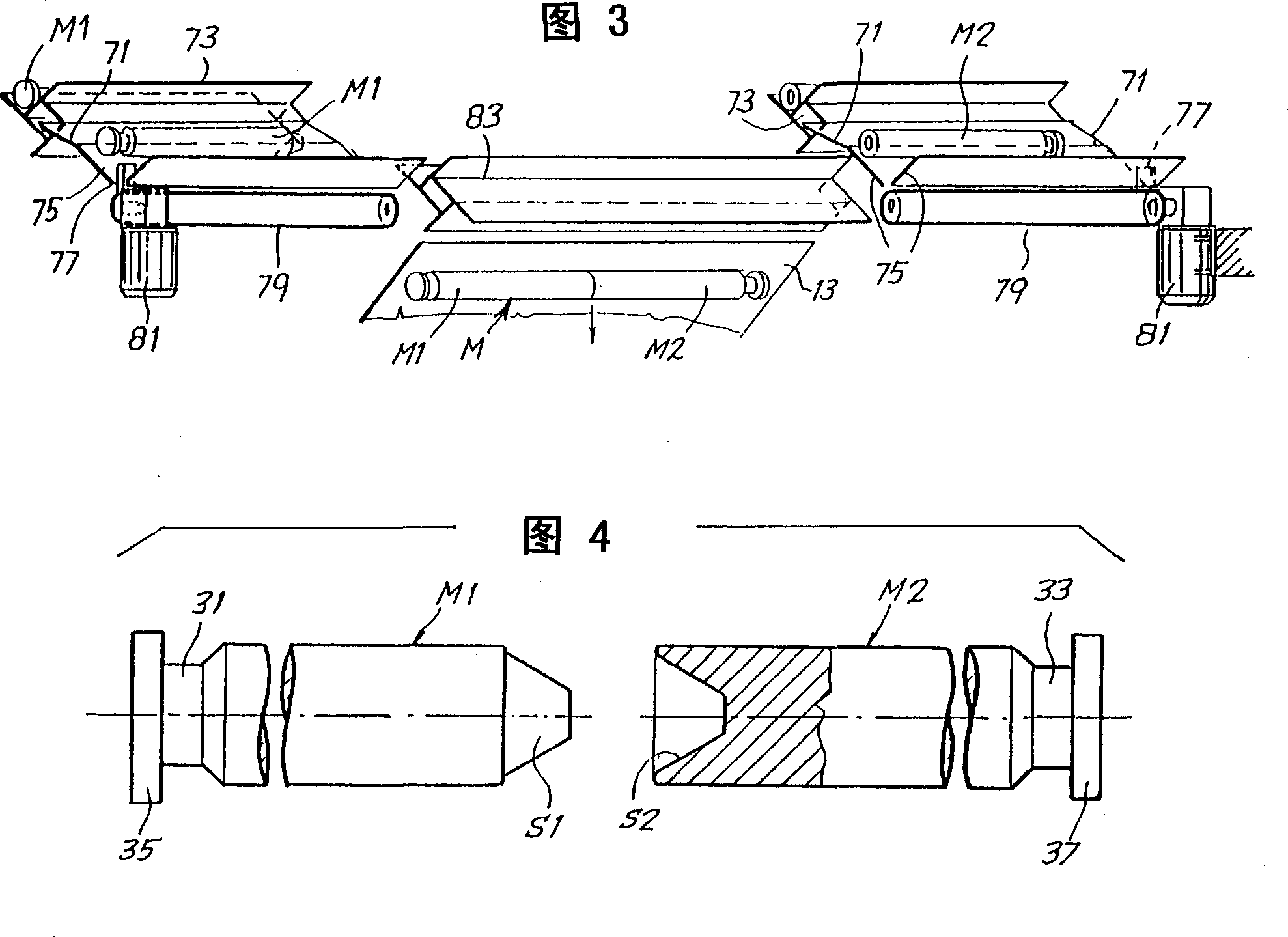

Peripheral rewinding machine for producting rolls of wound web material and corresponding method of winding

The rewinding machine comprises: an insertion device (11) for sequentially inserting winding spindles (M) into a winding area; winding means (1, 3, 5) in said winding area, which wind predetermined quantities of web material onto said spindles; an extractor (25) for extracting said spindles from the rolls of web material formed on them; and a recirculation path (71) for returning the spindles extra from said rolls toward said insertion device. The spindles are made in two portions which can be connected and disconnected; the extractor extracts each of said two portions from a corresponding end of the corresponding wound roll. Means are also provided for reconnecting said two portions to each other so that said spindles can be reinserted into said winding area.

Owner:FABIO PERINI SPA

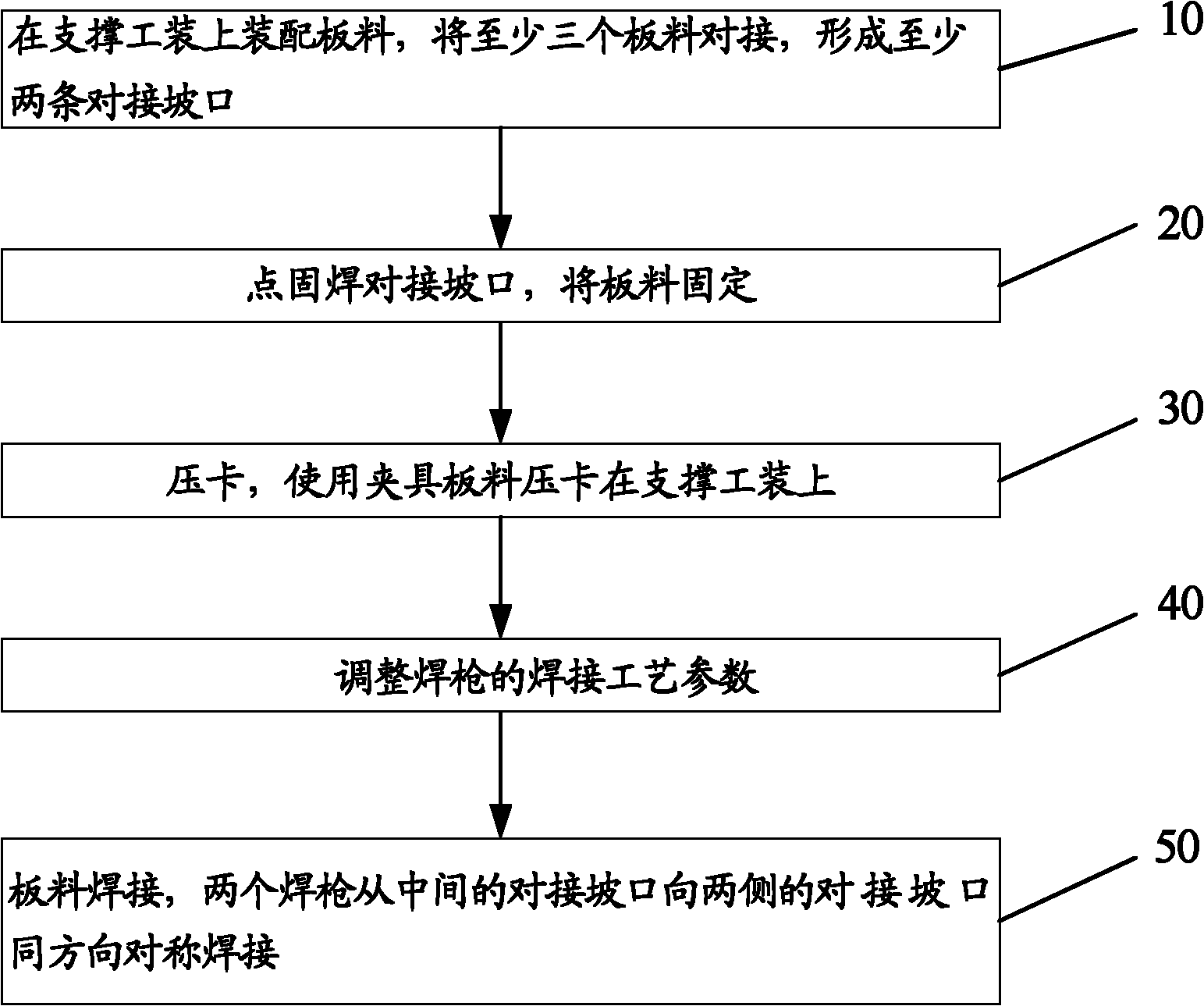

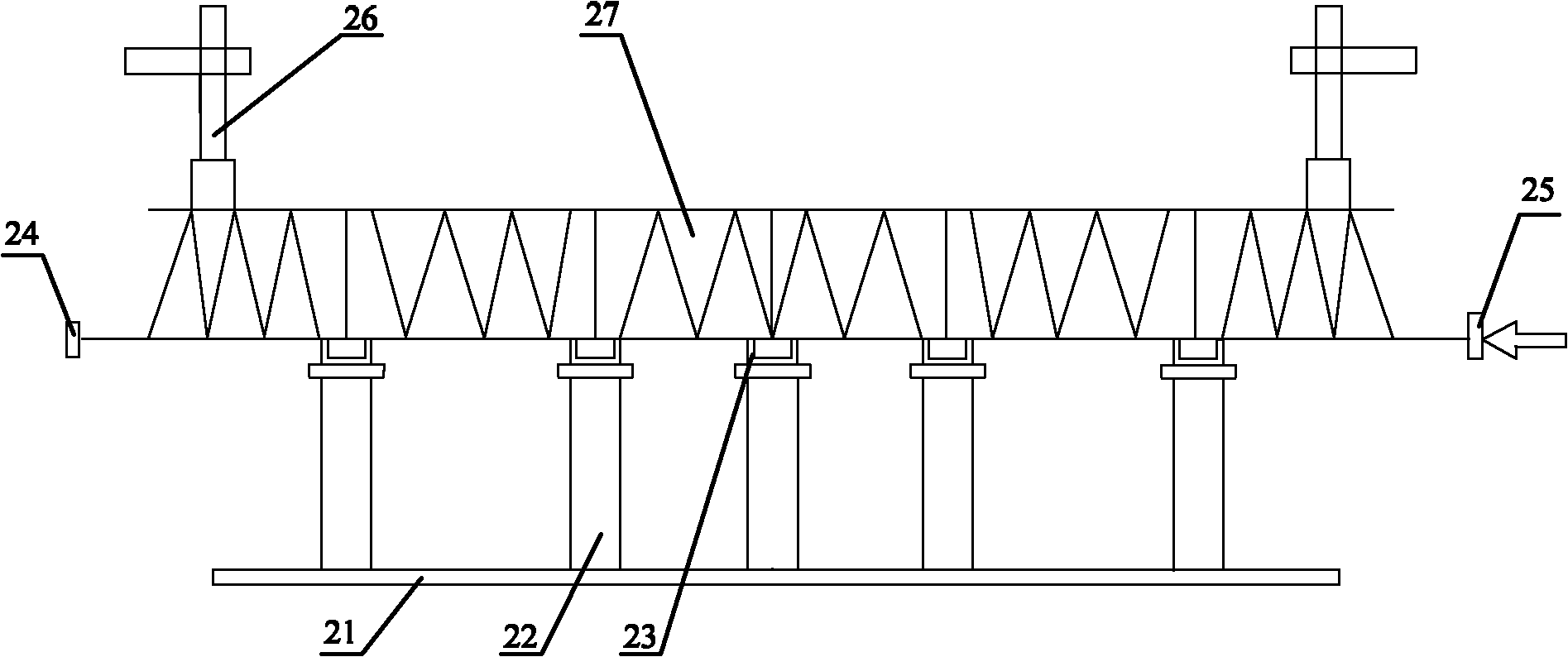

Sheet welding method

ActiveCN102350563ABalance stressUniform deformationWelding/cutting auxillary devicesArc welding apparatusButt jointEngineering

The invention discloses a sheet welding method which comprises the following steps of: assembling sheets on a support device, wherein at least three sheets are in butt joint to form at least two butt-joint grooves; tack-welding the butt-joint grooves, and fixing the sheets; pressing and clamping the sheets on the support device with a fixture; adjusting the welding technological parameters of a welding gun; and welding the sheets, wherein two welding guns perform equidirectional symmetric welding from the middle butt-joint groove towards the butt-joint grooves on the two sides. In the invention, two welding guns are adopted to perform equidirectional symmetric welding from the middle butt-joint groove towards the butt-joint grooves on the two sides. Through the invention, the stress produced by the sheets during the welding can be effectively balanced, and the heat can be quickly dispersed so that the deformation of the welded sheets is more uniform, the deformation generated by the welding of large-size sheets can be reduced, the regulation and maintenance workload after welding is reduced, and the production efficiency is improved.

Owner:CRRC TANGSHAN CO LTD

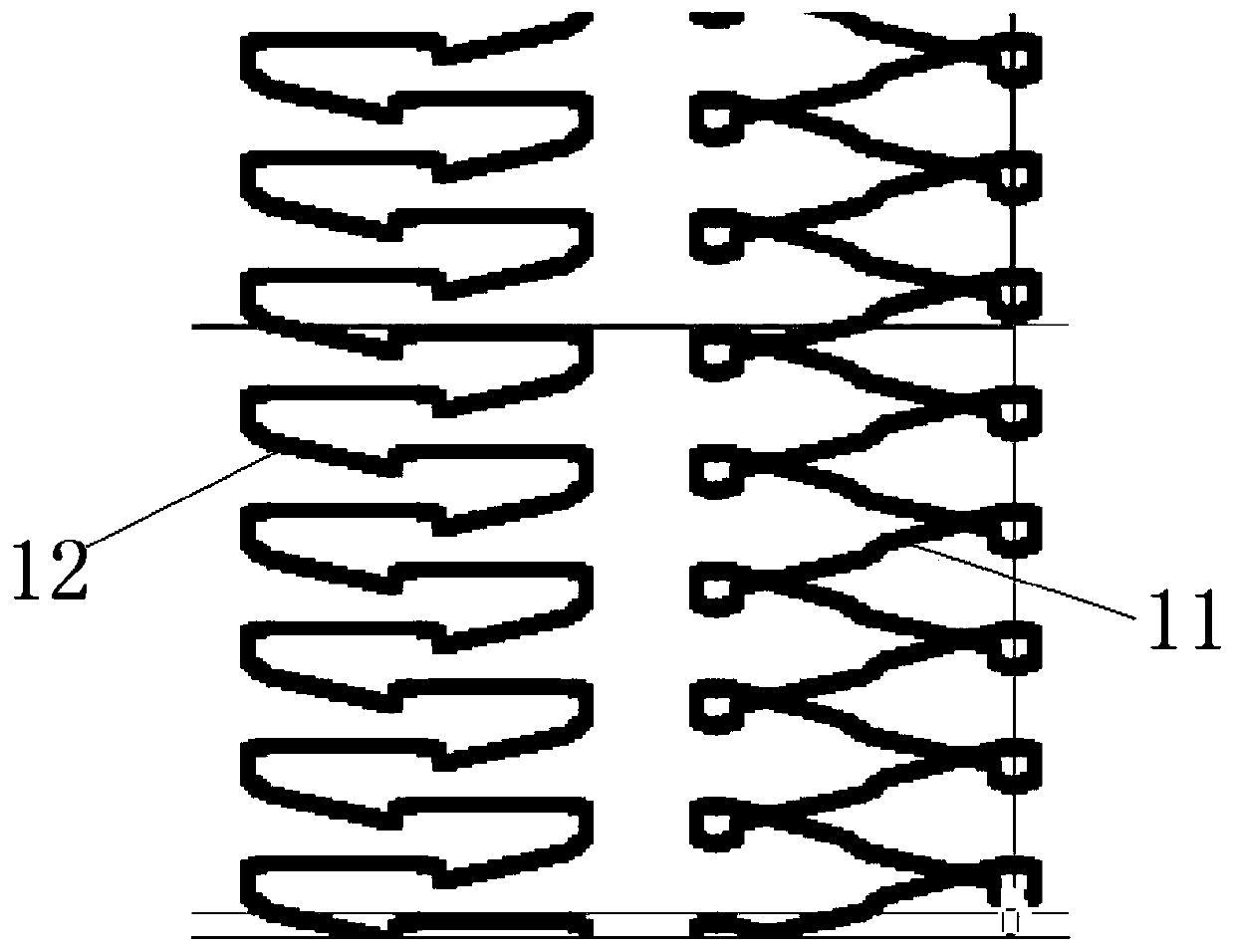

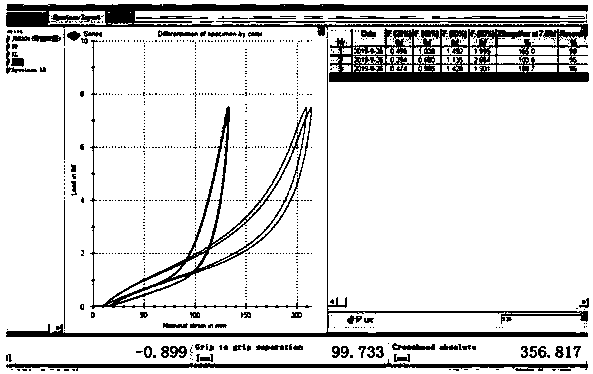

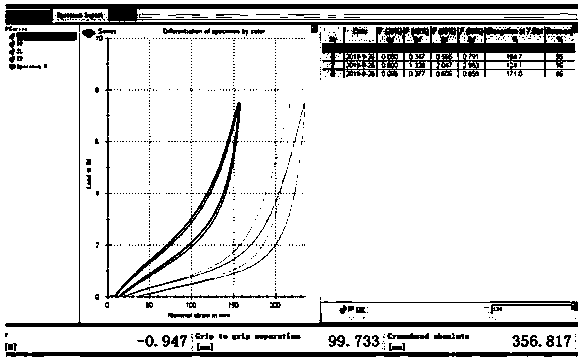

Free cut fabric not prone to hemming

PendingCN110042551AIncrease elasticityModerate elasticityWarp knittingResilient fabricsEngineeringSurface structure

Owner:梁源

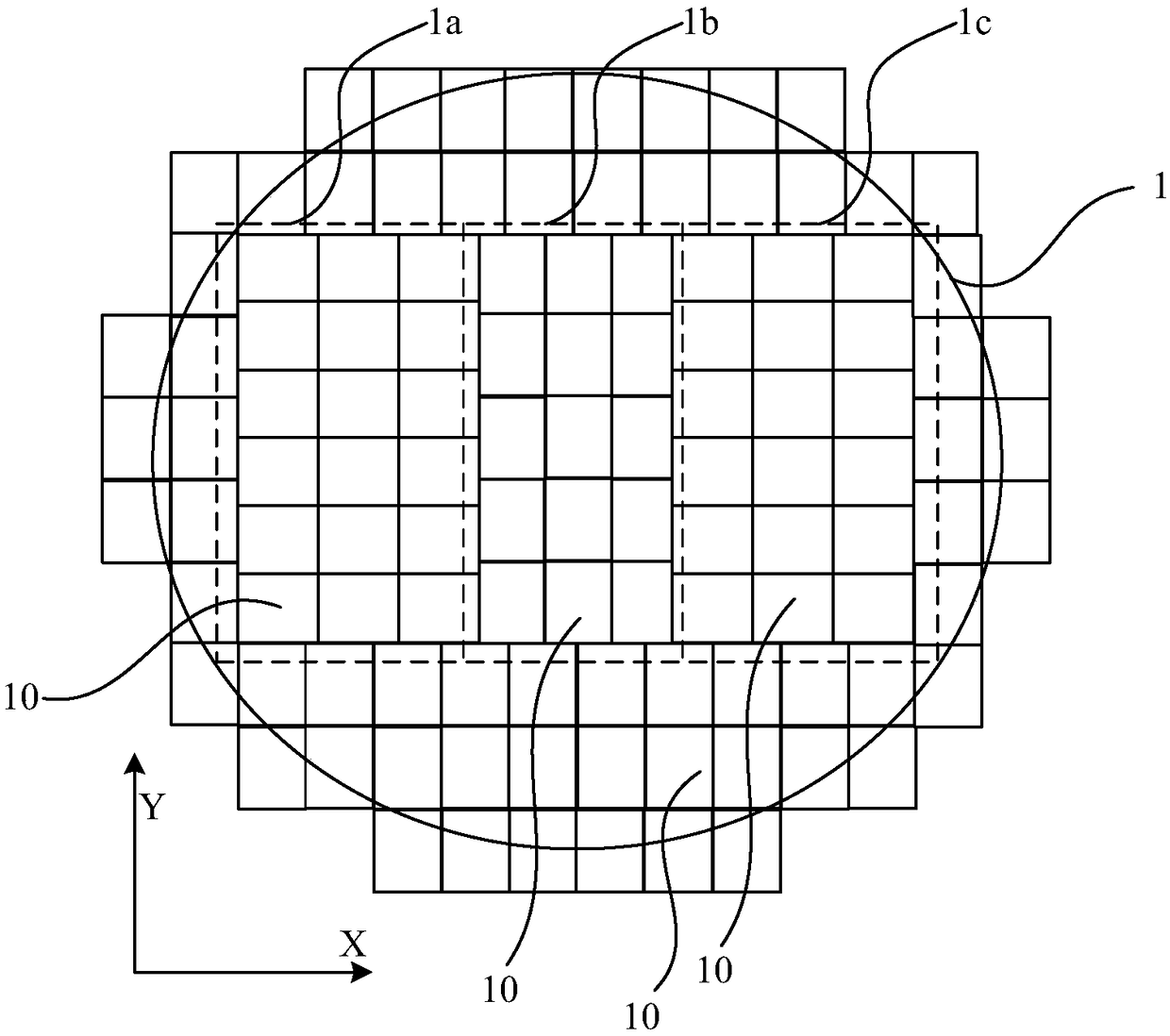

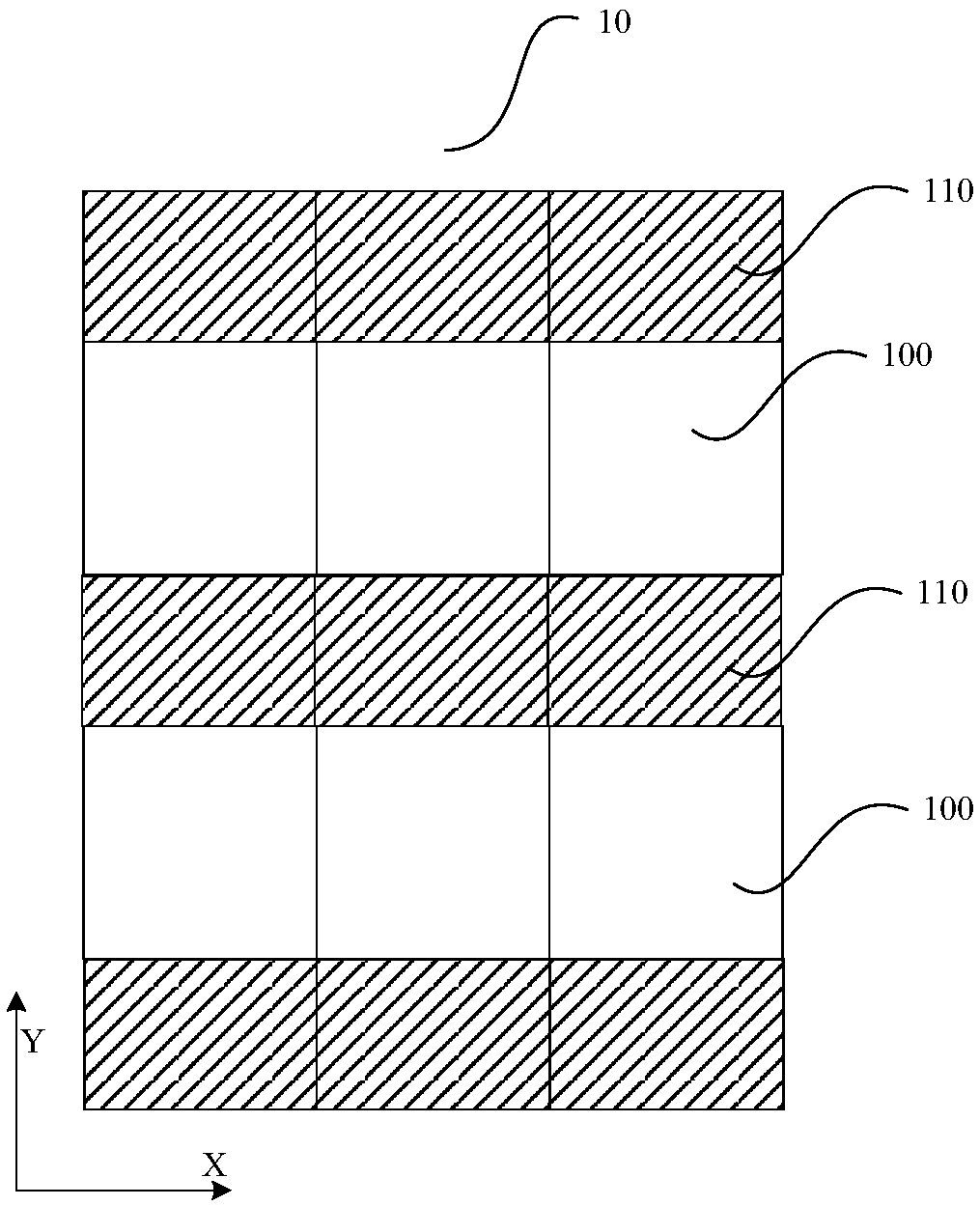

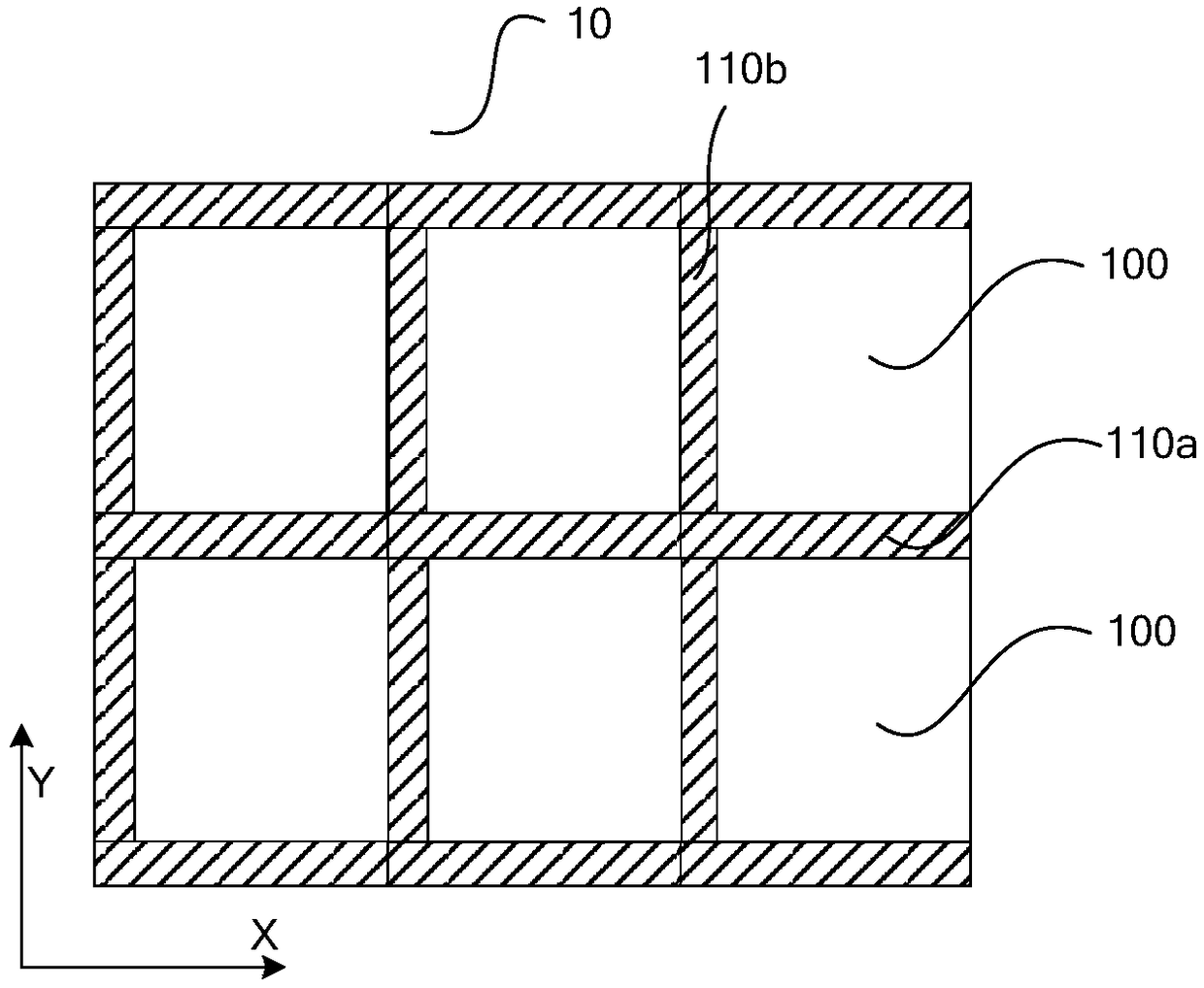

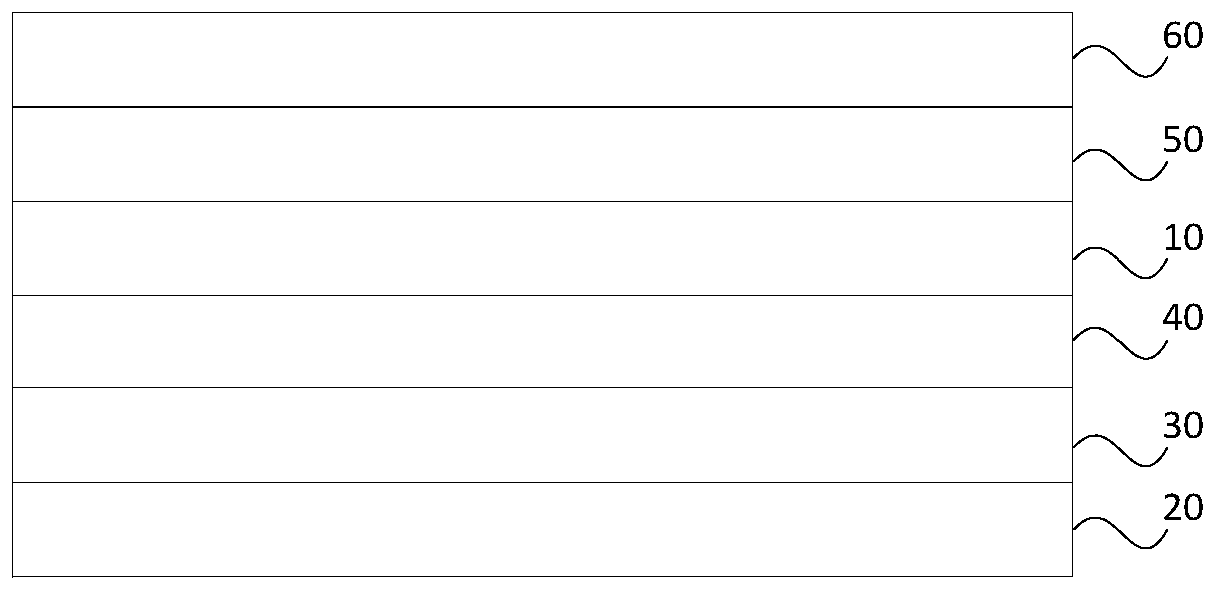

Wafer and chip

ActiveCN109065536AReduce warpage defectsImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingWafer fabricationEngineering

The invention provides a wafer and a chip, which realize stress balance by arranging gate line slots in different directions in a stack layer. As the gate line gap is formed in the stacked lay and formed in different directions, the stress in the stacked layer can be released in different directions, so that the stress of the wafer or the chip in different directions can be balanced, the defects of the wafer warping in the wafer manufacturing process can be reduced, and the wafer yield can be improved.

Owner:YANGTZE MEMORY TECH CO LTD

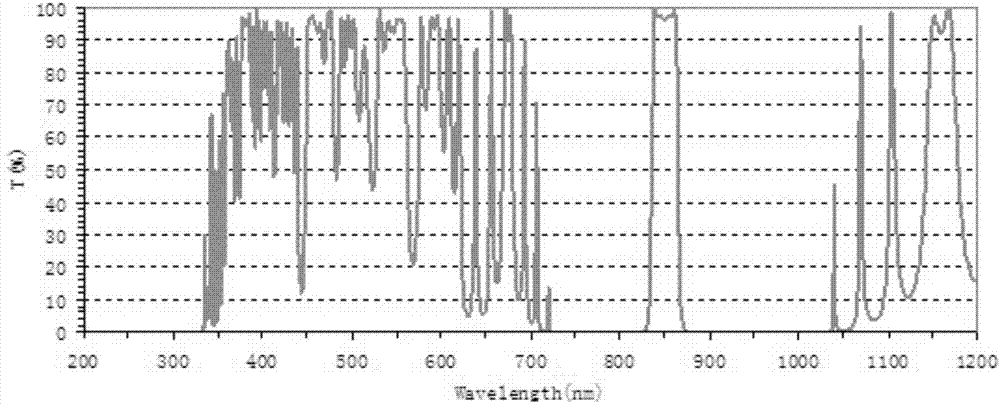

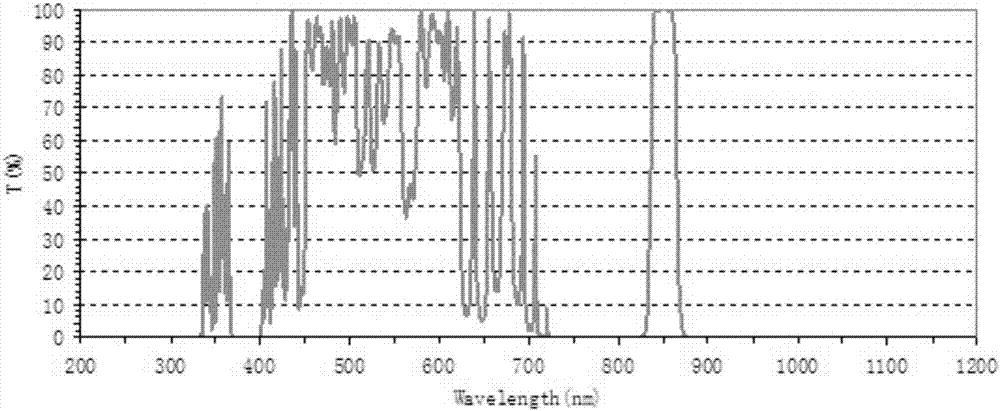

Narrowband optical filter and film plating method thereof

InactiveCN107193071AGuaranteed image qualityReduce distortionOptical elementsRefractive indexLength wave

The invention discloses a coating process for a narrow-band filter, which comprises the following steps: coating a main membrane stack on one side of a blank glass substrate, so that the main membrane stack and the blank glass substrate form an equivalent base. The equivalent refractive index of the equivalent substrate at the center wavelength is equal to the refractive index of the blank glass substrate; the first sub-film stack is coated on one side of the equivalent substrate, and the second sub-film stack is coated on the other side of the equivalent substrate. Two membrane stacks. The invention can prevent the thickness of the secondary film layer from being too thick compared with that of the main film layer, so that the stress on both sides of the substrate is basically balanced, the deformation of the substrate is reduced, and the imaging quality is guaranteed.

Owner:上海兆九光电技术有限公司

Production process of vacuum glass

InactiveCN101391859AAvoid stickingAvoid pollutionGlass reforming apparatusGlass productionInorganic saltsPhosphate

The invention relates to a production technique of vacuum glass. The production technique is characterized by comprising the following steps: a glass liquid point of water-soluble inorganic salt is placed on one of glass so as to form glass liquid stacking matters, a closed water-soluble inorganic salt glass liquid strip is coated along the periphery of the glass surface pointed with the glass liquid stacking matters, then a plurality of adhesion protective supports are arranged between an upper piece of glass and a lower piece of glass, after closed, the two pieces of glass are arranged in an exhaust furnace for curing, the glass liquid stacking matters are also cured to form a glass support while curing and sealing the edges, the glass support is vacuumized, temperature-reduced, sealed and finished and then the vacuum glass can be obtained; the glass liquid of the water-soluble inorganic salt belongs to inorganic compound salts which are dissolved in water or other liquid solvents, comprising silicates, phosphates or sulfates, and also comprises water-soluble silicate glass liquid. The technique can improve the quality of the produced vacuum glass, improves the production efficiency, greatly reduces the production cost, does not have environmental pollution and is beneficial to the promotion and use of the vacuum glass.

Owner:刘元生

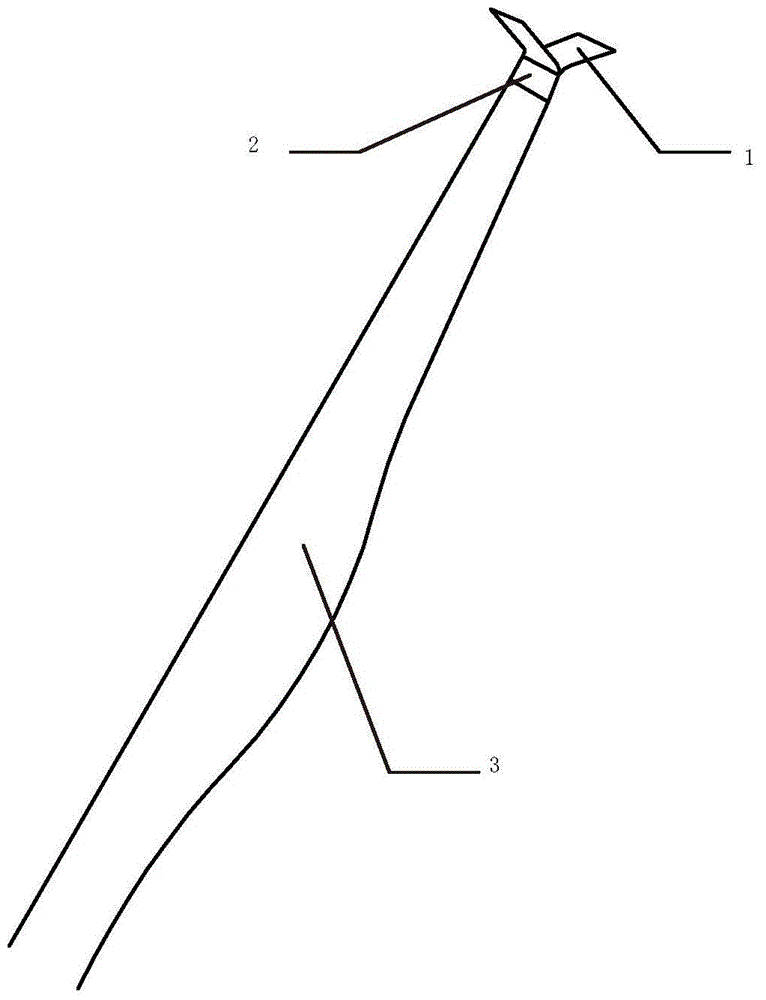

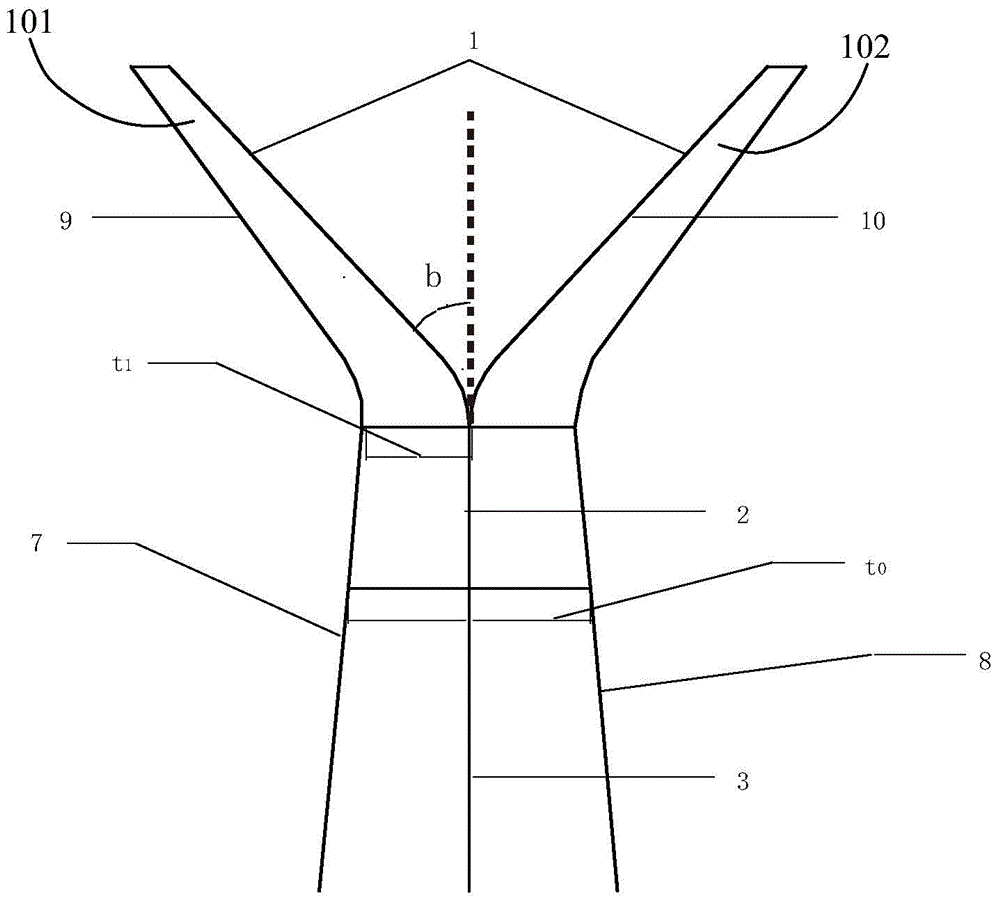

Novel wind turbine blade

InactiveCN104863791AImproved aerodynamic layoutReduce intensityMachines/enginesEngine componentsTurbine bladeUltimate tensile strength

The invention provides a novel wind turbine blade which comprises a main blade body, a blade tip extension segment and symmetrical little wings. The blade tip extension segment is connected with the main blade body and the symmetrical little wings respectively. The chord length of the blade tip extension segment is in smooth transition from the blade tip chord length to the little wing root chord length. The symmetrical little wings comprise the first little wing and the second little wing. The first little wing and the second little wing are symmetrical to each other. Both the first little wing and the second little wing are provided with lifting airfoils. Both the suction surface of the first little wing and the suction surface of the second little wing face a wind turbine body. The novel wind turbine blade has the advantages that the blade tip vortex is reduced, the blade stress is balanced, the pneumatic efficiency of the wind turbine is improved, the blade root waving moment is lowered, the requirement for the strength level of all components of the wind turbine is lowered, the reliability degree of the components of the wind turbine is increased, and the power generation cost of the wind turbine is reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

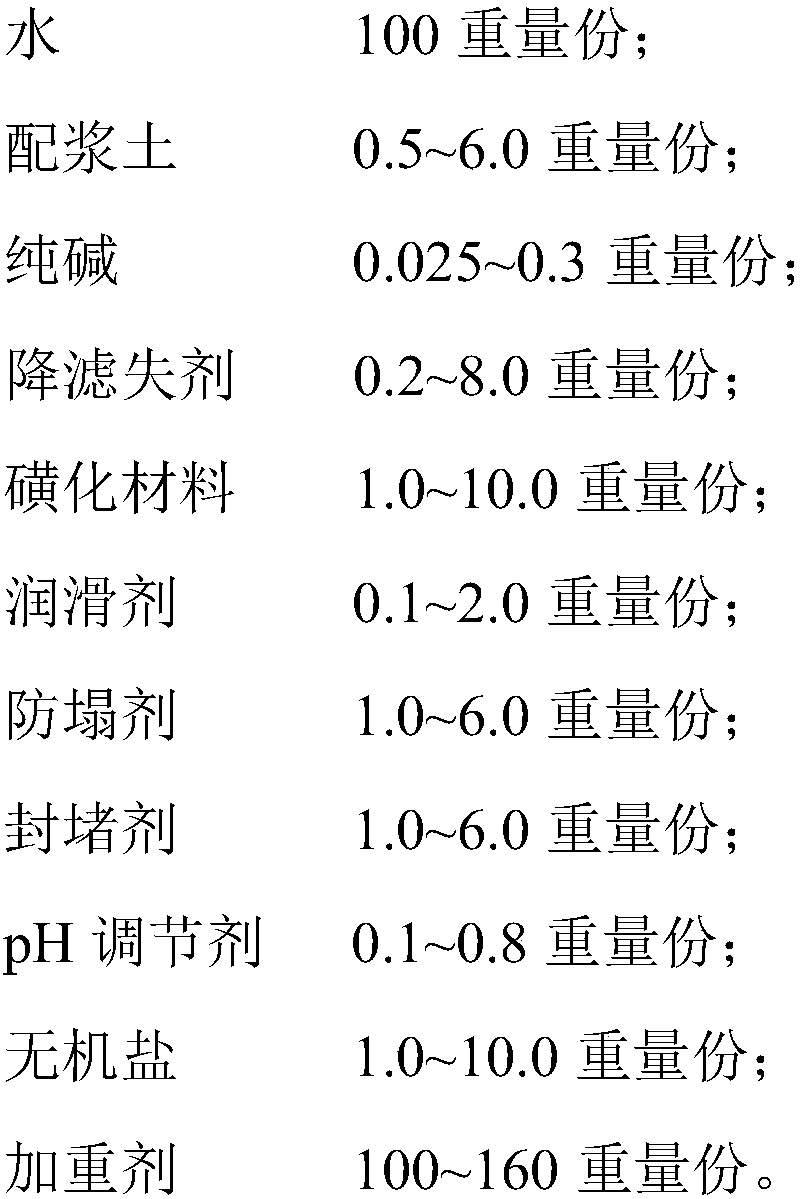

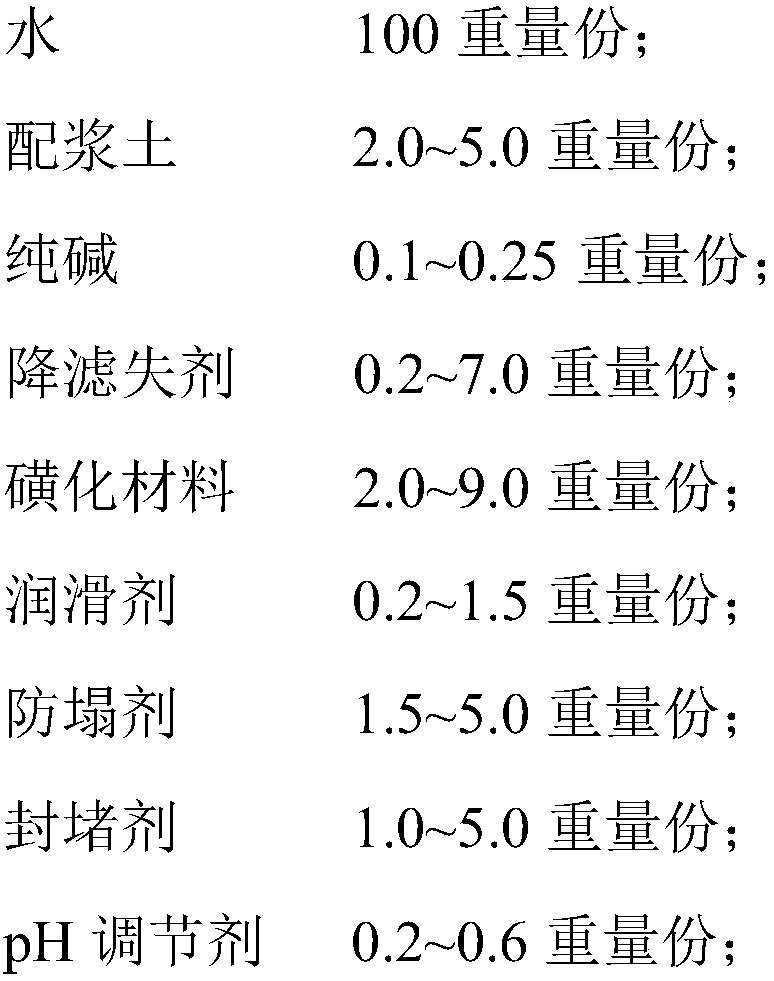

High-density water-based drilling fluid and preparation method thereof

InactiveCN109868122AMeet the requirements of safe drillingGood settlement stabilityDrilling compositionWater basedInorganic salts

The invention relates to the technical field of drilling fluids, and provides a high-density water-based drilling fluid system for safely drilling through a diabase formation. The drilling fluid comprises the following components, in parts by weight: 100 parts by weight of water, 0.5-6.0 parts by weight of slurry mixing soil, 0.025-0.3 part by weight of sodium carbonate, 0.2-8.0 parts by weight ofa fluid loss reducing agent, 1.0-10.0 parts by weight of a sulfonated material, 0.1-2.0 parts by weight of a lubricant, 1.0-6.0 parts by weight of an anti-collapse agent, 1.0-6.0 parts by weight of ablocking agent, 0.1-0.8 part by weight of a pH adjusting agent, 1.0-10.0 parts by weight of an inorganic salt and 100-160 parts by weight of a weighting agent. The high-density drilling fluid systemprovided by the invention can not only ensure that the diabase formation is safely drilled, but also can carry diabase fallen blocks caused by release of ground stress in the initial stage of drillingthrough the diabase formation out of the ground in time, effectively avoid an occurrence of complex situations such as stuck drilling, and improve drilling efficiency on the basis of ensuring safe drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

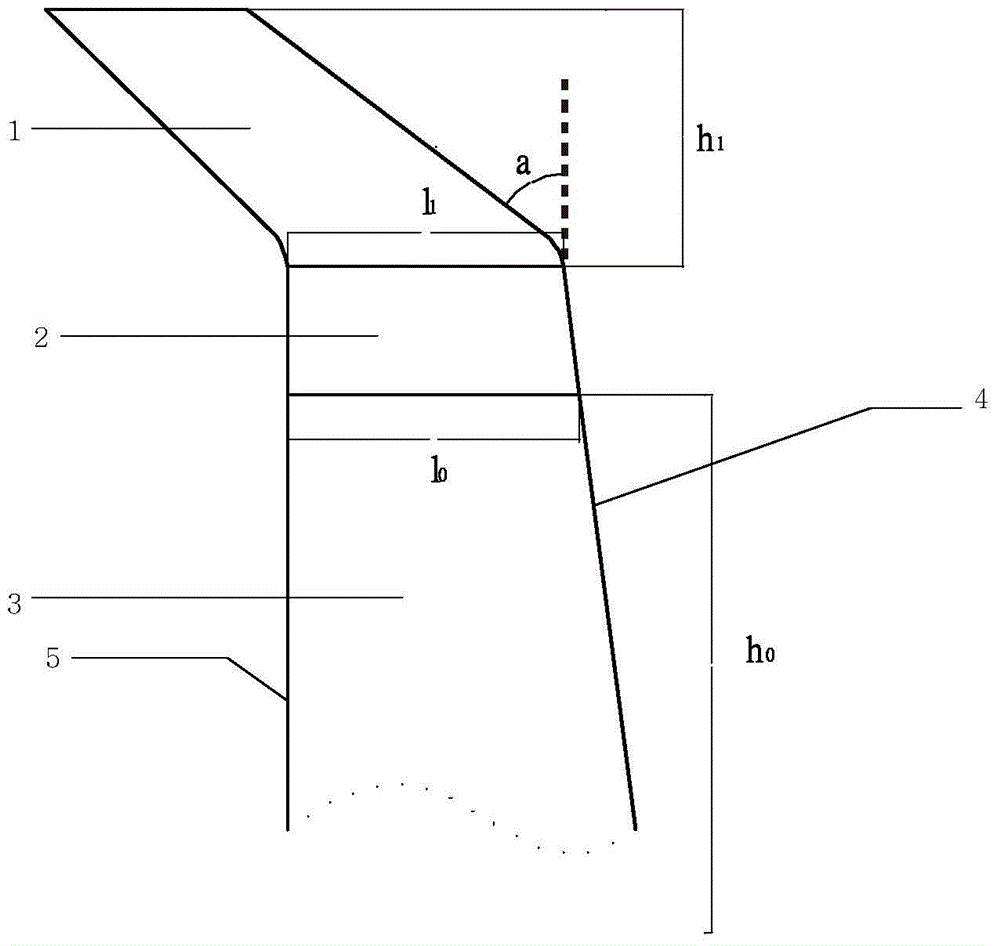

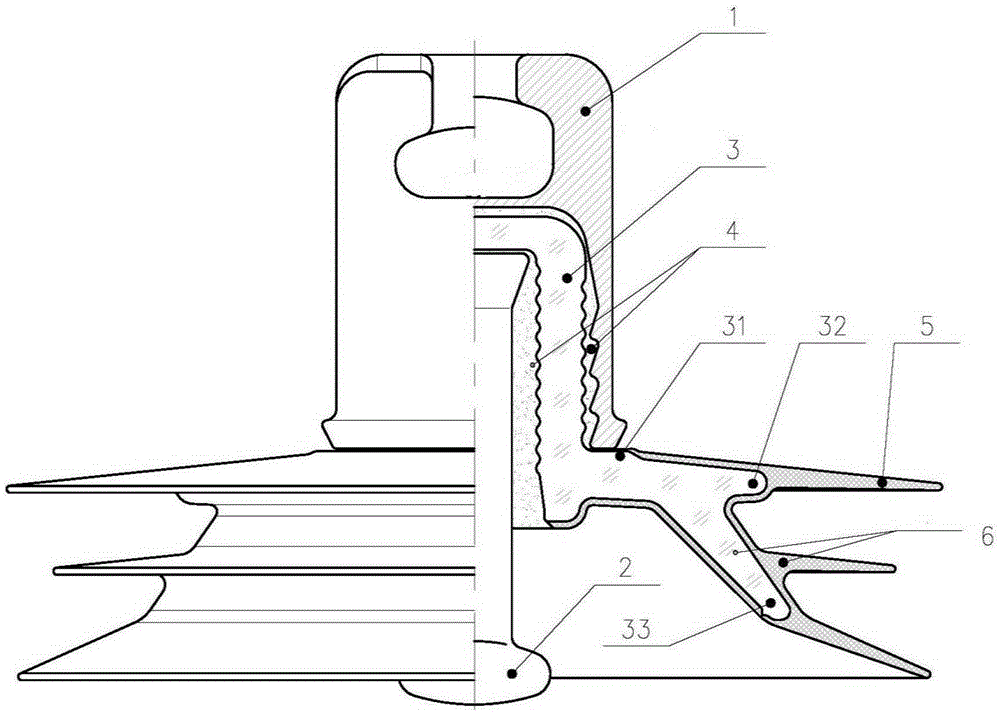

Glass composite insulator and manufacturing method therefor

ActiveCN105355340AStrong antifoulingBalance stressSuspension/strain insulatorsSupporting insulatorsRubber materialGlass composites

A manufacturing method for a glass composite insulator is disclosed. The manufacturing method comprises the following steps: a skeleton umbrella edge structured glass part is moulded; a silicone rubber umbrella cover is covered and wrapped with the glass part; an assembling mold integral injection mode is adopted; due to the use of the assembling mold, the silicone rubber umbrella cover (with multiple umbrella skirts) is integrally molded, so that the molded silicone rubber umbrella cover is attractive in appearance, high in efficiency, and less in interfaces, the electrical performance of the product is improved; a multi-point symmetrical type adjustable glue injection technology is adopted to be matched with a mold cavity pressure control scheme in the molding process in order to balance the stress conditions of each point on the glass part to prevent the glass part from being crushed; the mold cavity is integrally subjected to vacuumizing processing to reduce the generation of rubber material bubbles; iron caps and steel caps are cemented with insulating parts through cement adhesive, so that the influence on the cement adhesive performance caused by the high temperature of the molds is avoided, and the mechanical property dispersion of the product is greatly reduced; the cement adhesive is not covered with the silicone rubber, so that the product completely follows the zero self-destruction characteristic of the glass insulator; and the influence on the umbrella cover molding caused by the central straightness of caps generated by cement adhesive fittings is avoided.

Owner:南京电气绝缘子有限公司

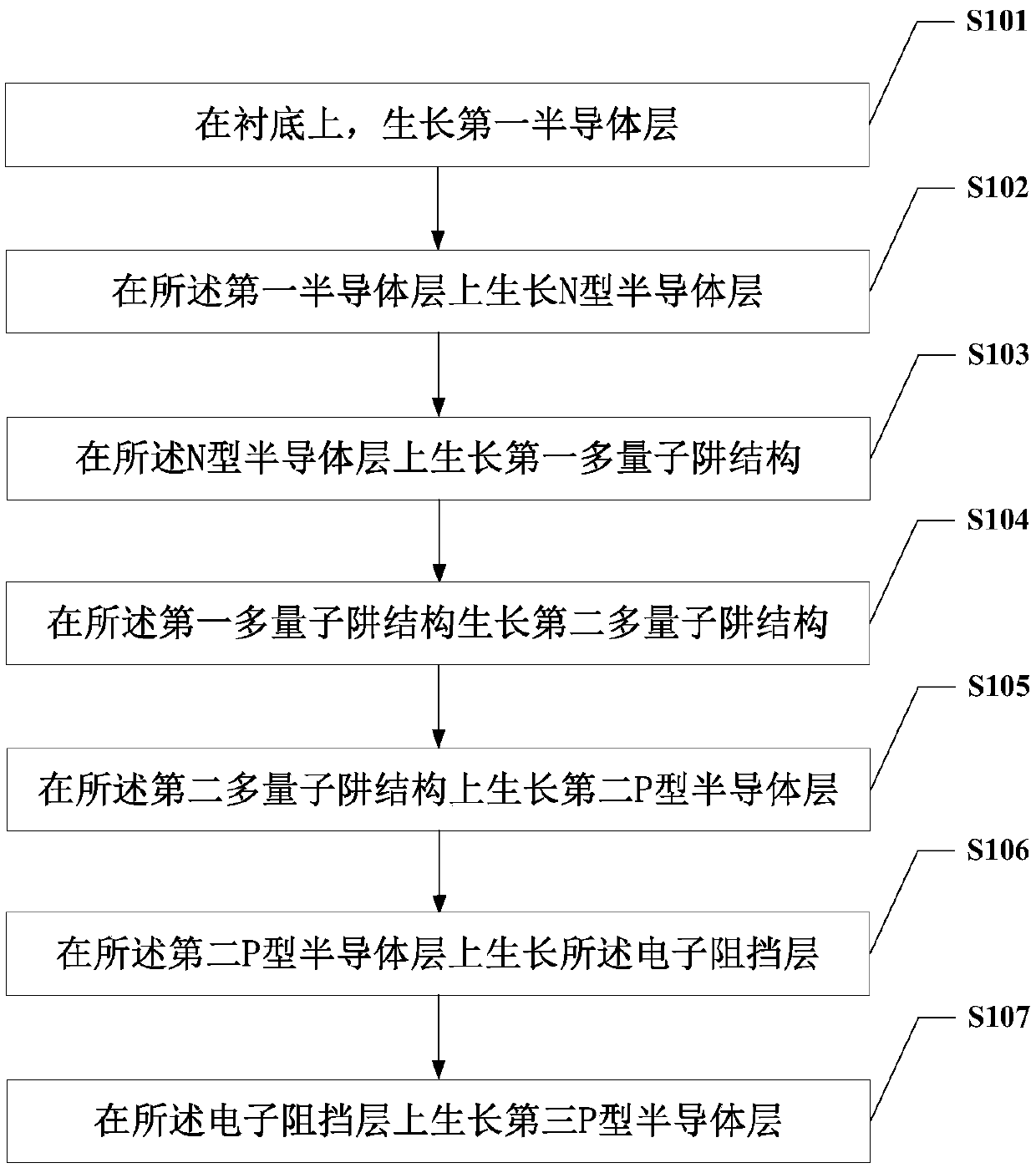

Light-emitting diode epitaxial structure growth method

ActiveCN110911529APrevent overflowImprove compound efficiencySemiconductor devicesElectron blocking layerNitride

The invention provides a light-emitting diode epitaxial structure growth method, which comprises the following steps of: growing a first semiconductor layer on a substrate; growing an N-type semiconductor layer on the first semiconductor layer; growing a first multi-quantum well structure on the N-type semiconductor layer; growing a second multi-quantum well structure on the first multi-quantum well structure, wherein the second multi-quantum well structure at least comprises at least two multi-quantum wells and a multi-quantum potential barrier, the multi-quantum potential barrier comprises afirst nitride containing aluminum and gallium and a second nitride containing aluminum, and the first nitride and the second nitride grow alternately; growing a second P-type semiconductor layer on the second multi-quantum well structure; growing the electron blocking layer on the second P-type semiconductor layer; and growing a third P-type semiconductor layer on the electron blocking layer.

Owner:宁波安芯美半导体有限公司

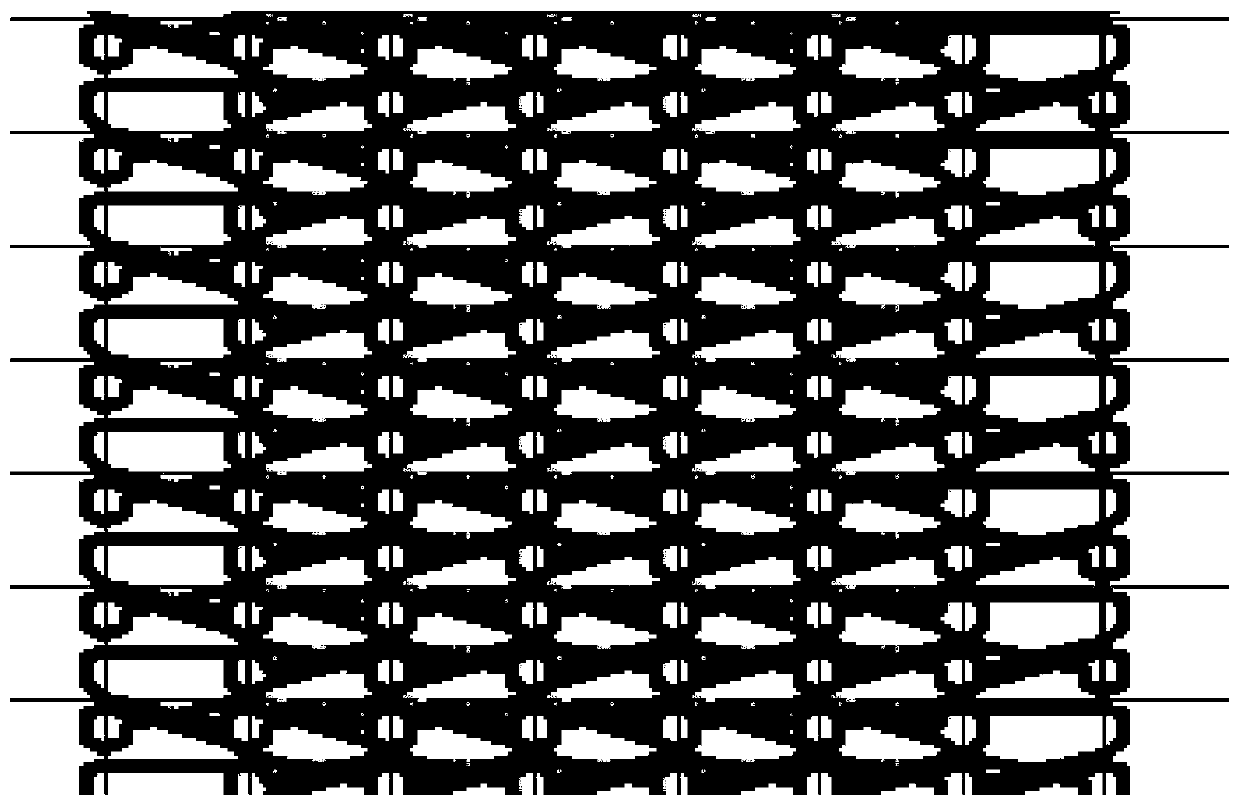

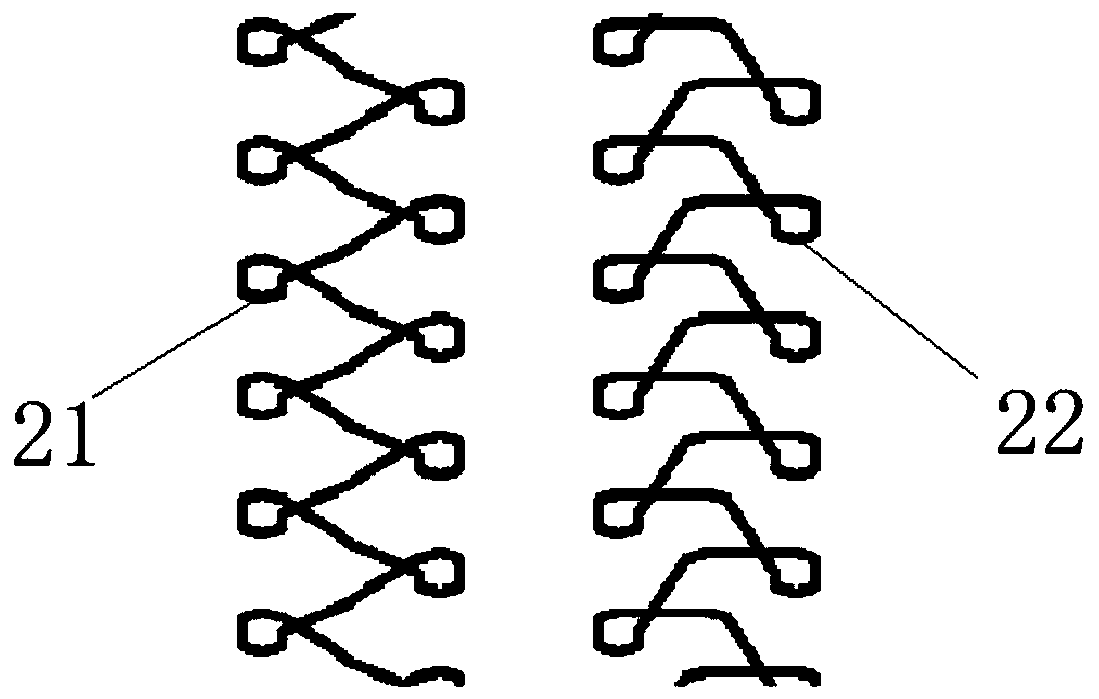

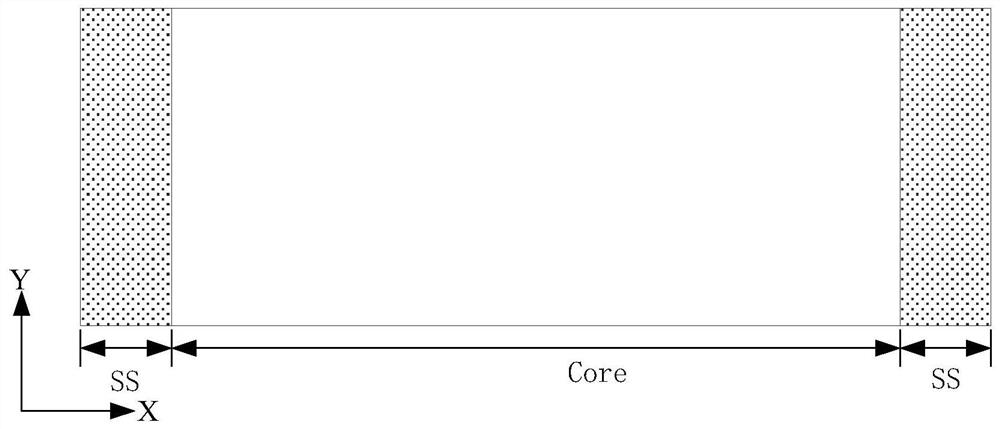

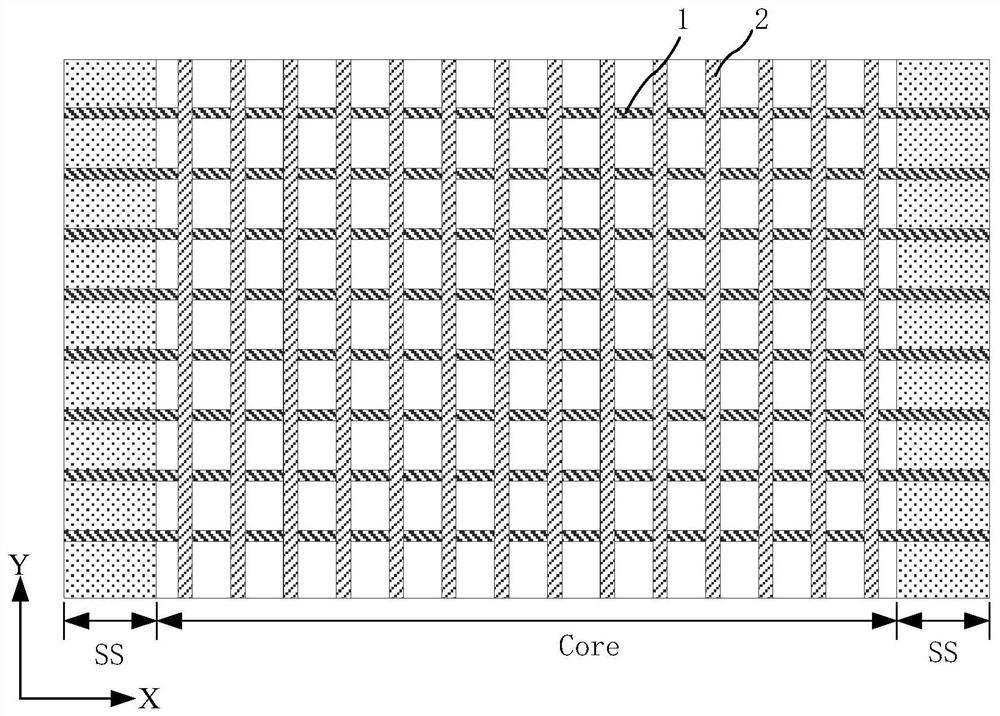

Novel warp knitting fabric

PendingCN111020858ATo achieve the effect of not curlingIncrease elasticityWarp knittingBraidManufacturing engineering

The invention provides a novel warp knitting fabric. The novel warp knitting fabric comprises a fabric body formed by knitting of at least three guide bars of a warp knitting machine, the fabric bodycomprises a surface layer and a bottom layer, the surface layer is formed in the mode that a group of yarns Y1 composed of a plurality of yarns is knitted and formed on the front face of the fabric body by means of a warp satin weave structure through the first guide bar, a group of yarns Y2 composed of a plurality of yarns are knitted by using a variable double-loop-stitch structure through the second guide bar and a group of yarns Y3 composed of a plurality of yarns is knitted by using a pad-lacking weft insertion weave structure through the third guide bar, and then the bottom layer is formed through co-forming of the yarns 2 and the yarns 3 on the bottom surface of the fabric body, wherein the yarns Y1, the yarns Y2 and the yarns Y3 are connected with each other in a penetrating and sleeving manner, and any two or three groups of the yarns Y1, the yarns Y2 and the yarns Y3 are elastic yarns. The fabric has the advantages of being not prone to edge curling and loosening and having elasticity in the warp and weft directions larger than or equal to 80%, the utilization rate of the fabric is increased, the garment manufacturing cost is reduced, and the garment wearing comfort and attractiveness of consumers are improved.

Owner:BEST PACIFIC TEXTILE

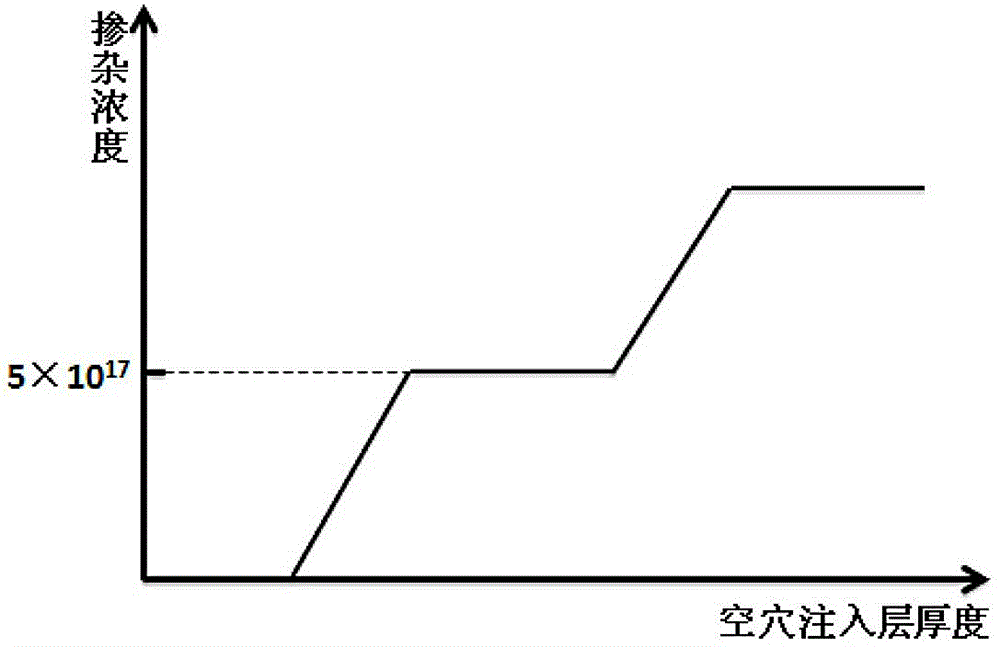

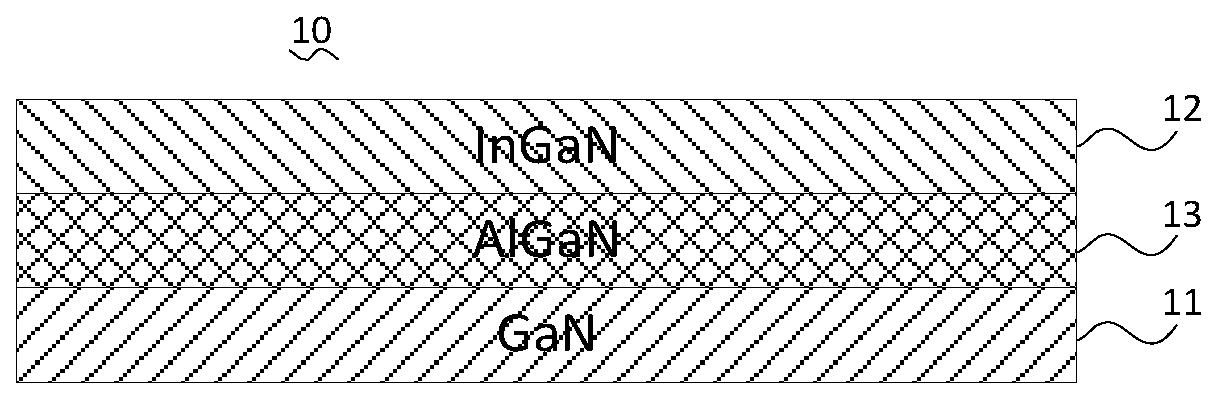

GaN-based semiconductor light emitting device having AlGaN interposer and manufacturing method thereof

InactiveCN110401106AReduce leakageReduce dislocationLaser detailsSemiconductor lasersStrain energyDevice leakage

The invention discloses a GaN-based semiconductor light emitting device having an AlGaN interposer and a manufacturing method thereof. The semiconductor light emitting device includes a quantum well structure, wherein the quantum well structure includes at least one set of gallium nitride quantum barriers and indium gallium nitride quantum wells, and each set of gallium nitride quantum barriers and indium gallium nitride quantum wells includes at least a layer of aluminum gallium nitride insertion layer. The semiconductor light emitting device is advantaged in that the aluminum gallium nitrideinsertion layer is utilized between the gallium nitride quantum barriers and the indium gallium nitride quantum wells of the quantum well structure, obtaining atomic level flat surfaces on the gallium nitride quantum barriers, improving interface steepness and eliminating V-shaped defects are not only facilitated, device leakage is reduced, light emitting uniformity is improved, but also balancing the stress accumulated during growth of the indium gallium nitride quantum wells is further facilitated, dislocation of quantum well materials due to accumulation of strain energy is reduced, and thereby improvement of the quality of material forming is facilitated.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

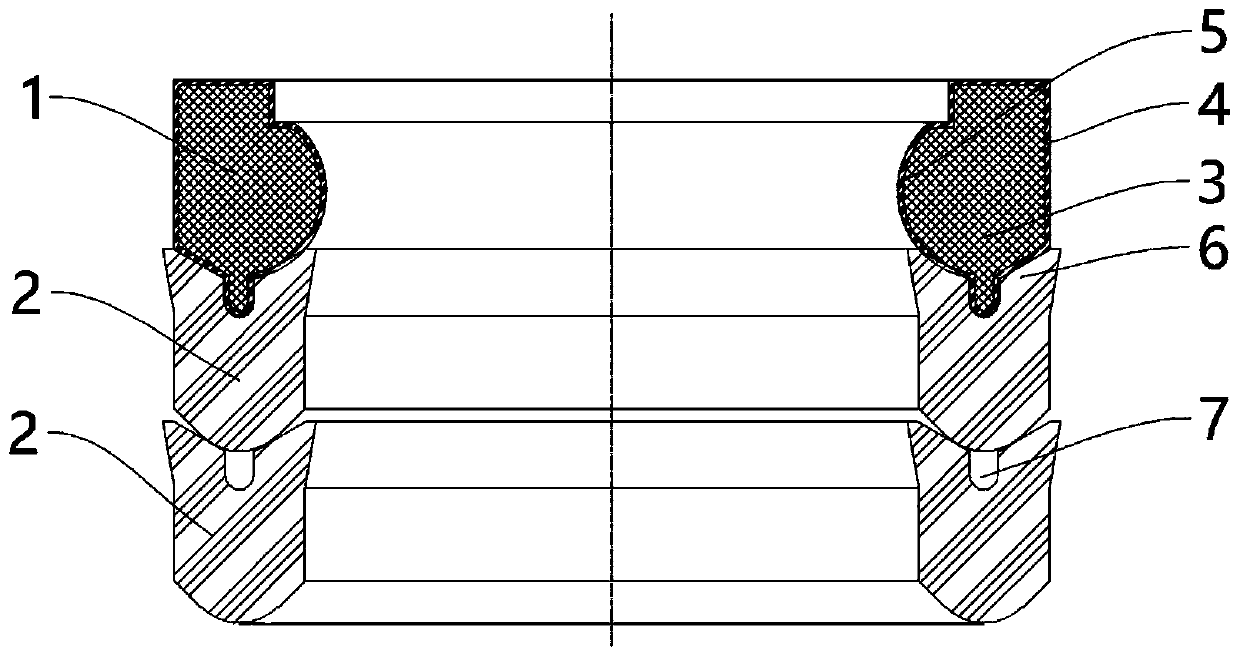

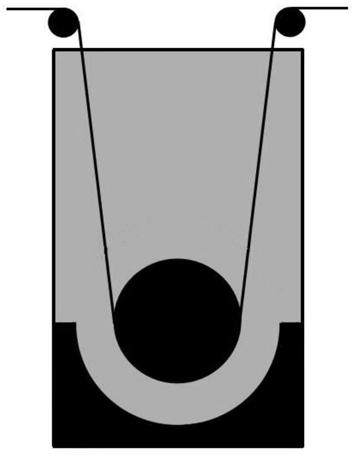

Sealing ring of plunger fracturing pump

InactiveCN110671500AExtended service lifeHigh strengthEngine sealsPositive displacement pump componentsCompressive resistanceEngineering

The invention relates to the technical field of sealing rings, and discloses a sealing ring of a plunger fracturing pump. The sealing ring of the plunger fracturing pump comprises a pressure-bearing ring and sealing rings distributed in a stacked manner; the pressure-bearing ring and the sealing rings are coaxially arranged; the sealing rings are arranged by at least two; the pressure-bearing ringincludes a substrate layer located inside and a protective layer wrapping the substrate layer; the substrate layer is made of an elastic material; and the protective layer is made of a wear-resistantmaterial. The exterior of the substrate layer of the pressure-bearing ring is further provided with the protective layer, the protective layer is made of the wear-resistant material, and the wear-resistant material is high in wear resistance and strength, so that the pressure-bearing ring has higher wear resistance and compressive strength, and the service life of the sealing ring is prolonged.

Owner:GUANGZHOU JST SEALS TECH

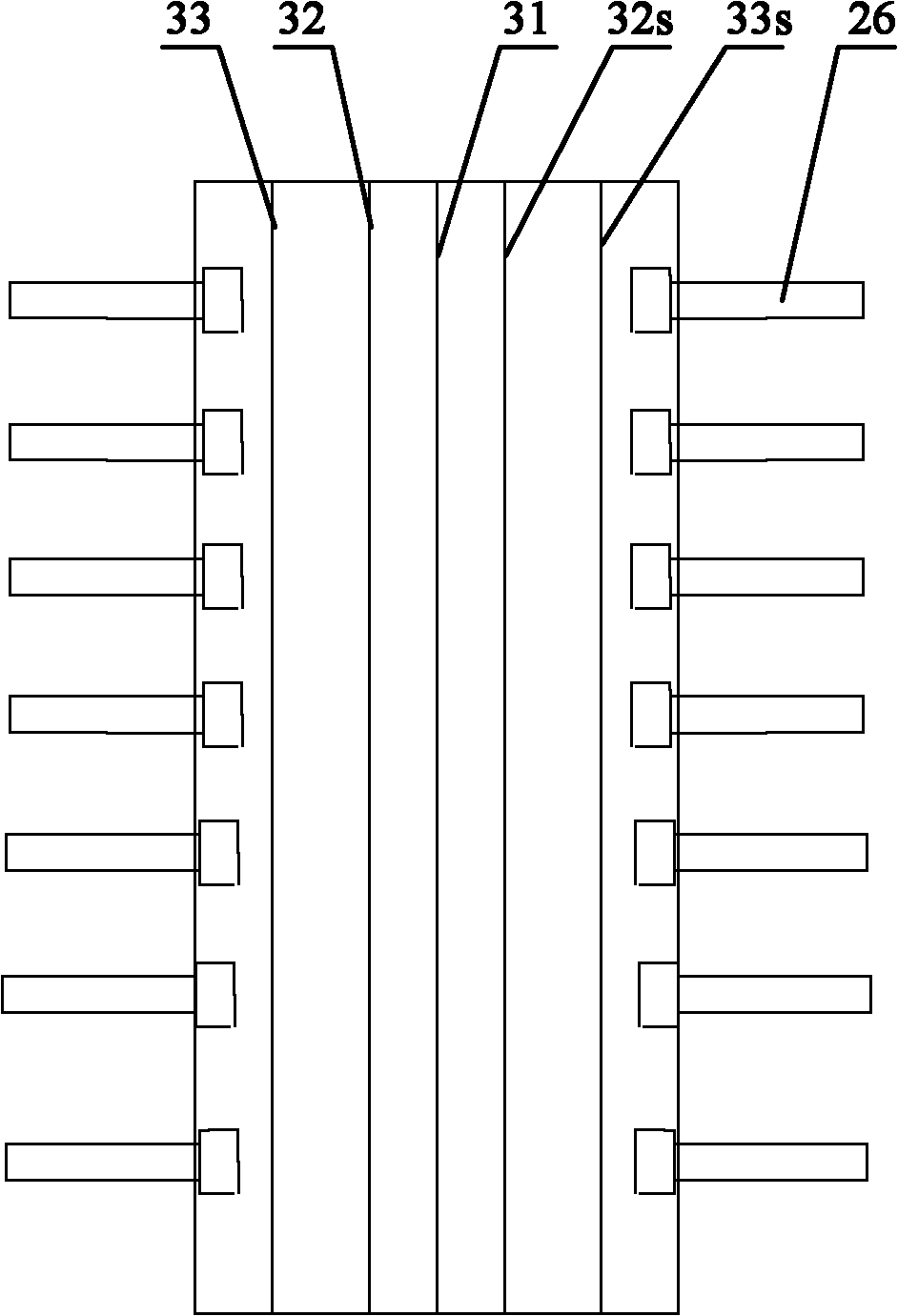

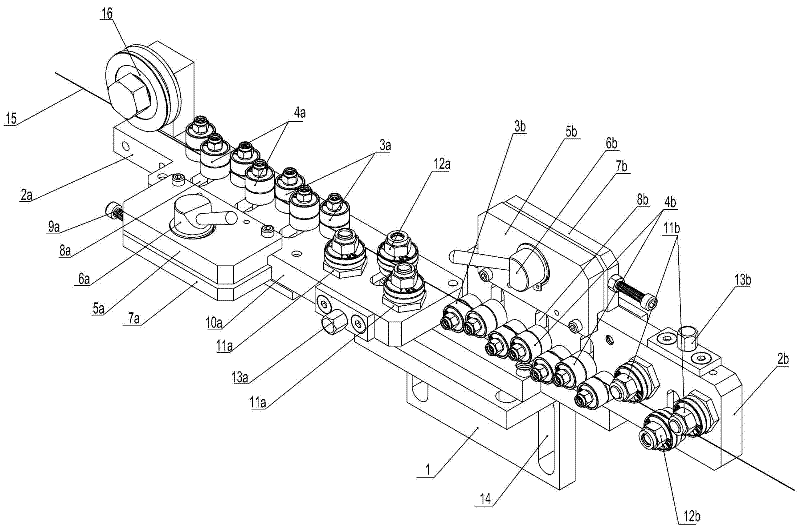

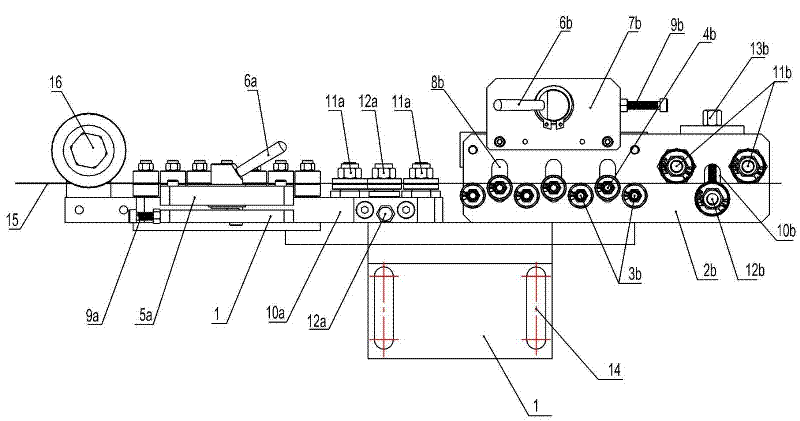

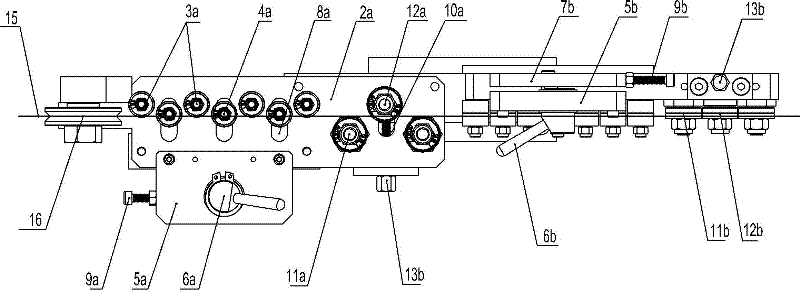

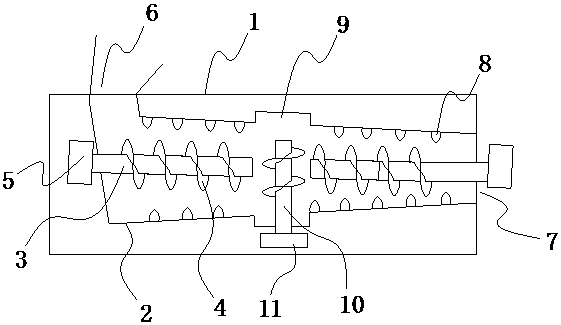

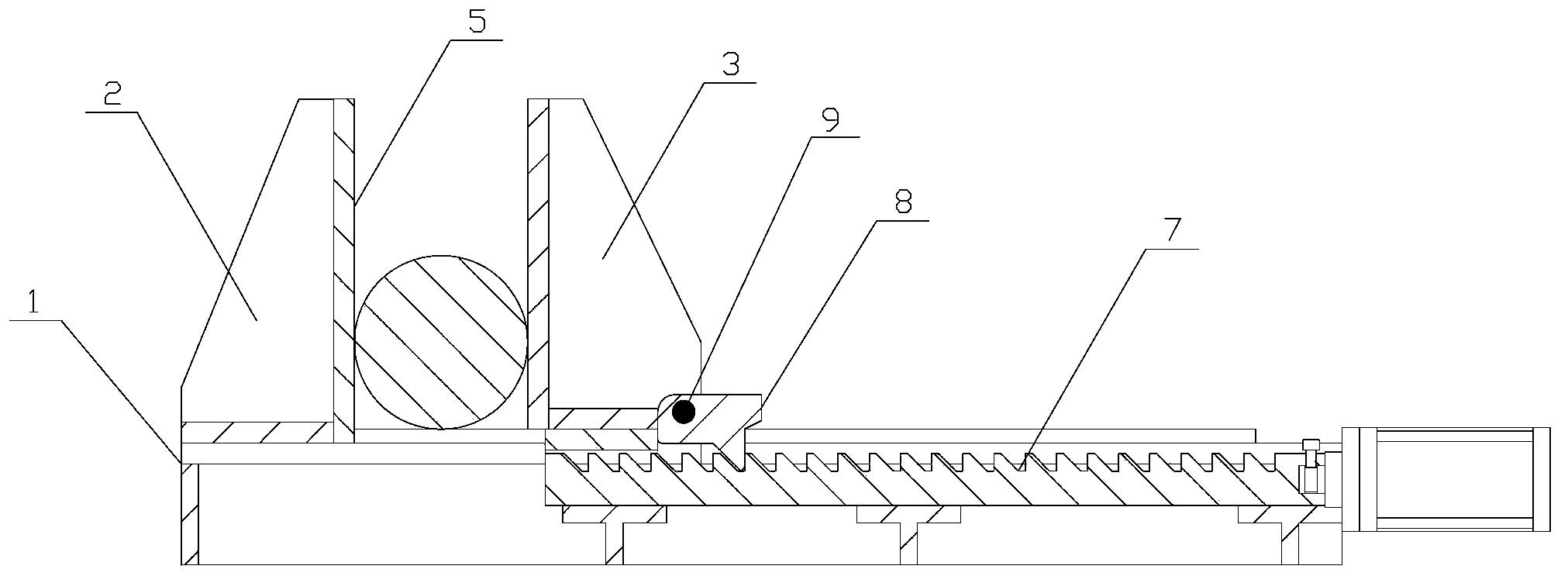

Multilayer strand cord twisting process and core wire straightener

The invention relates to a multilayer strand cord twisting process and a core wire straightener. The process comprises three steps of core strand twisting, outer layer strand twisting and external winding, wherein the pitch in core strand twisting is controlled to be 11.1-12.3mm; the straightener is additionally arranged between core strand twisting and outer layer strand twisting, and comprises a bracket and an inlet end guide wheel; a transverse adjustable rolling mechanism and a vertical adjustable rolling mechanism are simultaneously arranged on the bracket; a core strand sequentially penetrates through each pulley block of the transverse adjustable rolling mechanism and the vertical adjustable rolling mechanism of the straightener; and during outer layer strand twisting, the ratio of the core strand rotating speed to a top wire rotating speed is controlled to be any value of (0.91:1)-(0.93:1), and the over-twist speed ratio in twisting is controlled to be 97%-99%. The invention can eliminate residual stress of the core wire, so that the inner layer stress and the outer layer stress of the cord are in balance more easily, the finished product of the cord after aging is more stable in twisting, residual twisting of the cord is easier to control and adjust in the production process, the overall stress is smaller when the cord is used in a tire factory, and the cord can not generate edge lifting and unevenness easily.

Owner:HENAN HENGXING SCIENCE & TECHNOLOGY CO LTD

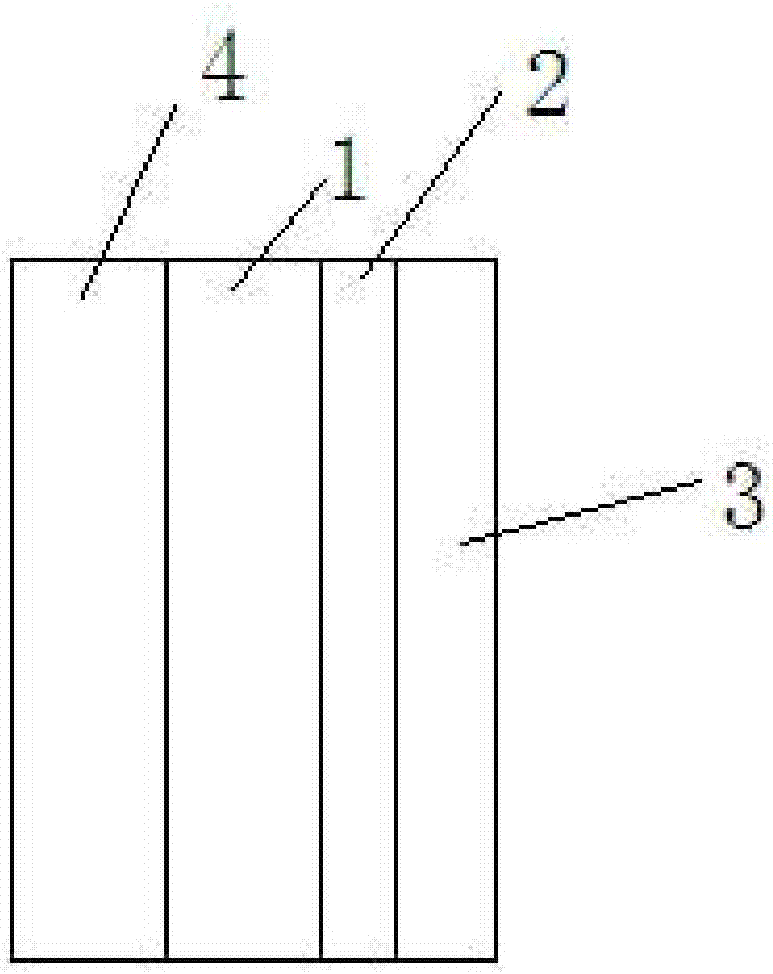

Three-dimensional memory structure, manufacturing method thereof and three-dimensional memory device

PendingCN112054028AImprove stabilityUniform stress distributionSolid-state devicesSemiconductor devicesEtchingEngineering

The invention provides a three-dimensional memory structure. The three-dimensional memory structure comprises a substrate; and a stacking structure which is formed on the substrate, and the stacking structure is provided with a first subarea and a second subarea which are sequentially arranged in the first direction; wherein the first subarea comprises a first core array area and a first step areawhich are sequentially arranged in the second direction, the first step area is located on the edge of the first subarea, and the second subarea comprises a second core array area and a second step area which are sequentially arranged in the first direction; the second step area is located at the edge of the second subarea, and the first direction intersects with the second direction. By utilizing the method, the stress after the etching of gate isolation grooves in the three-dimensional memory can be balanced, and the stress after increasing of the number of layers of the gate laminated structure of the three-dimensional memory can be balanced, so that the stress distribution is more uniform, and the stability of the structure of the three-dimensional memory is improved.

Owner:YANGTZE MEMORY TECH CO LTD

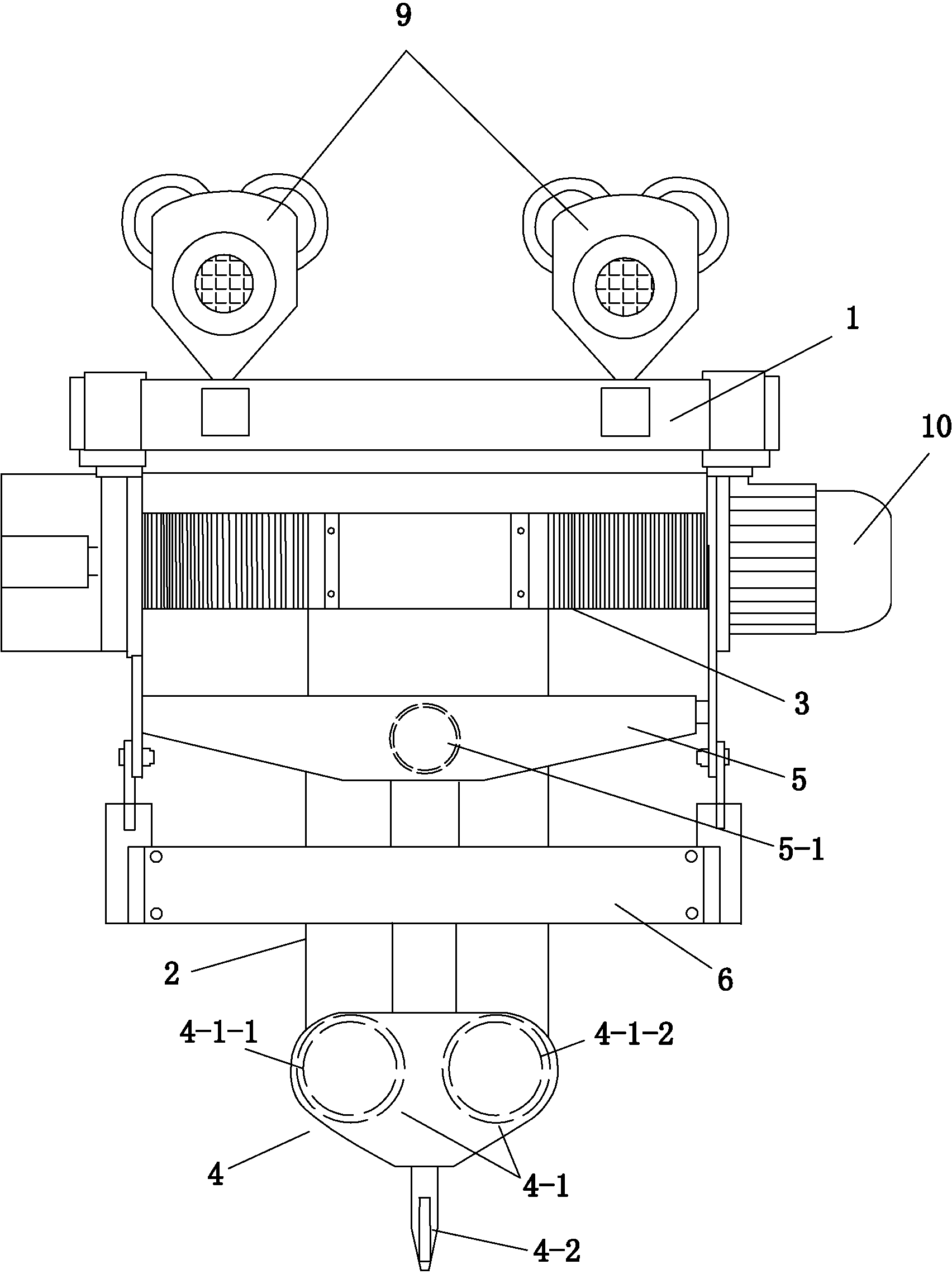

Two-stage sludge dewatering machine

InactiveCN105776813BBalance stressExtended service lifeSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesPulp and paper industryExpansion chamber

Owner:SUNNY ENVIRONMENTAL PROTECTION JIANGSU CO LTD

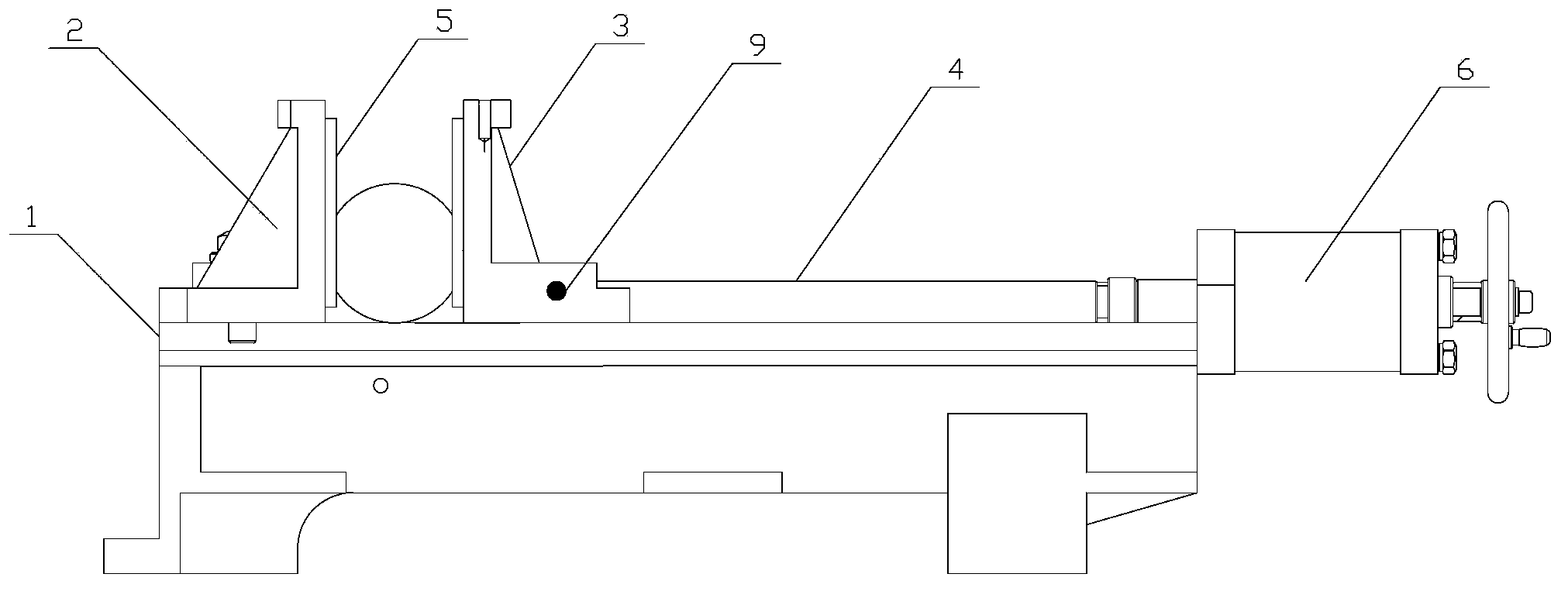

High-thrust-point bench clamp

InactiveCN103395012AImprove working precisionExtend working lifeVicesControl theoryMechanical engineering

The invention provides a high-thrust-point bench clamp which comprises a bench clamp track, a fixed clamp port and a moving clamp port. The fixed clamp port is fixed on the bench clamp track, the moving clamp port is arranged in the bench clamp track in a sleeved mode, a clamp port thrust device is connected to the moving clamp port, the moving clamp port can slide on the bench clamp track under the thrust of the clamp port thrust device, and the force bearing point, thrust by the clamp port thrust device, of the moving clamp port is higher than the matching surfaces of the moving clamp port and the bench clamp track. Through the above manner, the problem that the sliding working surface of the moving clamp port is stressed unevenly is solved according to the force analysis of the moving clamp port in the actual using process, the force situation of the moving clamp port is balanced, the working precision of the bench clamp is improved, and the service life of the bench clamp is prolonged.

Owner:苏州赛特尔集团机械有限公司

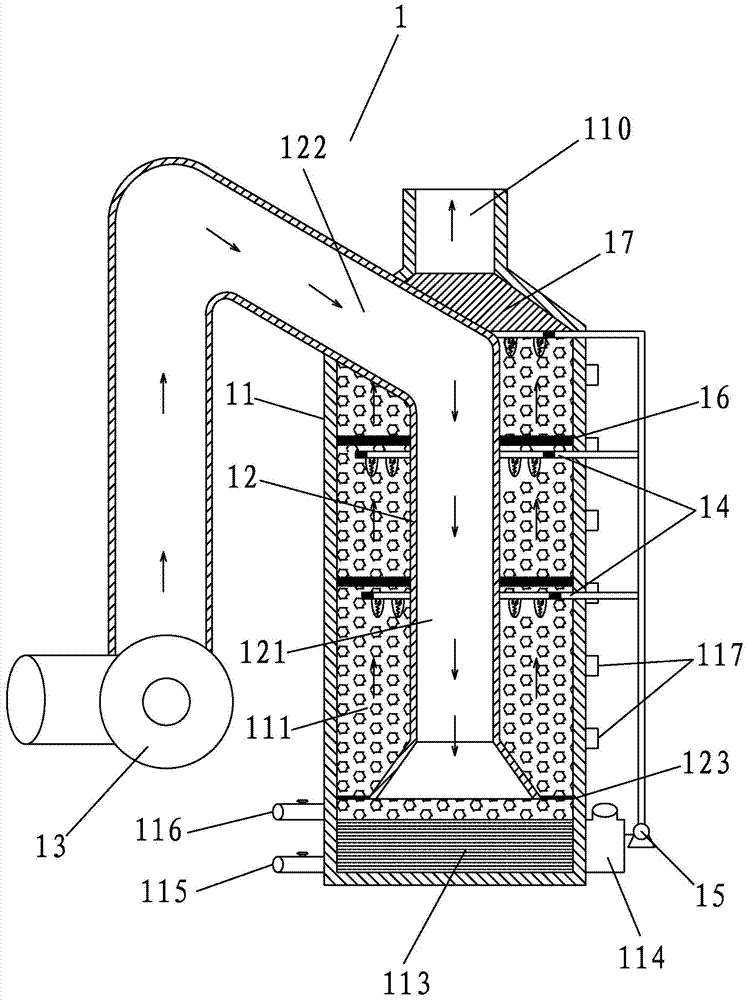

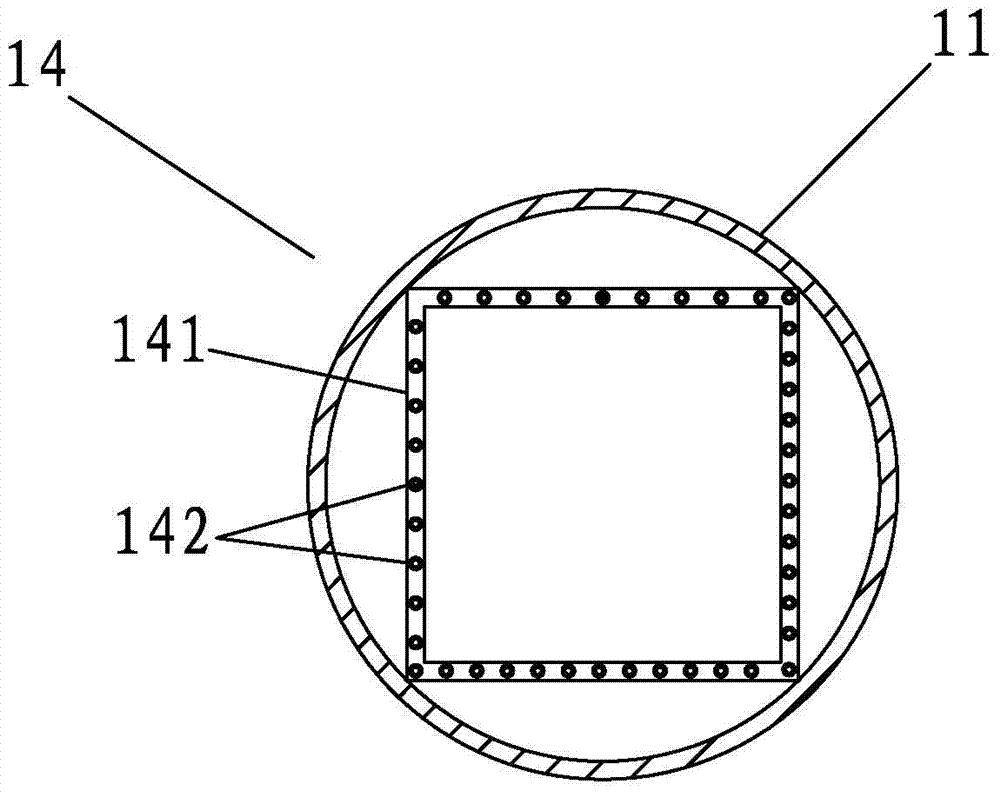

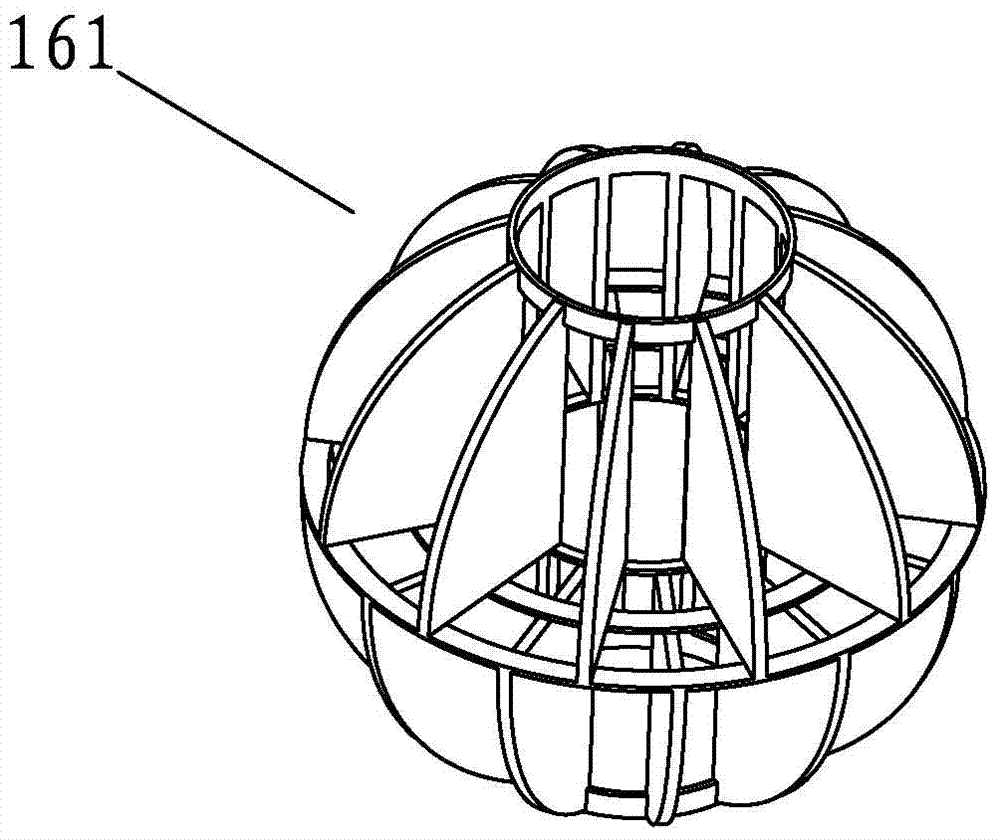

Waste gas purification tower

ActiveCN103566677ABalance stressAchieving a full tank effectUsing liquid separation agentTowerWaste management

The invention discloses a waste gas purification tower. The waste gas purification tower comprises a first tower body, wherein the top of the first tower body is provided with a first exhaust port; a first inner tower tube is sleeved inside the first tower body; the bottom of the first inner tower tube is close to the bottom of the first tower body; a first inner air chamber and a first outer air chamber are respectively arranged inside and outside the first inner tower tube; a first air inlet communicated with the first inner air chamber is formed in the side wall, close to the top end, of the first tower body; foam spray heads are distributed inside the first outer air chamber. The waste gas purification tower has the advantages of being simple in structure, high in purification rate, low in cost, free of cleaning and maintenance and the like, and can be widely applied to providing an excellent way for promoting the quality of social environment in industry, commercial business and life.

Owner:SHISHI XINGHUO ALUMINUM PROD CO LTD

High-voltage LED chip and manufacturing method thereof

PendingCN110957404AReduce shockImprove the ability to resist pulse current impactSolid-state devicesSemiconductor devicesEngineeringElectric current flow

The invention discloses a high-voltage LED chip and a manufacturing method thereof. The chip comprises a substrate, a plurality of light-emitting structures arranged on the front surface of the substrate, N electrodes, P electrodes, a connecting electrode and a bridging reinforcing layer, wherein the N electrodes and the P electrodes are arranged on the light-emitting structures; the bridging strengthening layer comprises a Cr layer, a Ti layer, a Pt layer and an Au layer, the Cr layer is arranged between the connecting electrode and the Ti layer, and the Pt layer is arranged between the Ti layer and the Au layer; the N electrodes and the P electrodes of every two adjacent light-emitting structures are conductively connected through the connecting electrode, and the bridging strengtheninglayer is arranged on the connecting electrode so as to strengthen the connecting electrode and shunt a current passing through the connecting electrode. According to the invention, the bridging strengthening layer is arranged on the connecting electrode, so that only the current flowing through the connecting electrode can be shunted to the bridging strengthening layer, the impact of pulse currenton the bridging part of the connecting electrode is reduced, and the pulse current impact resistance of the chip is improved.

Owner:FOSHAN NATIONSTAR SEMICON

A treatment method for reducing warping of electrolytic copper foil

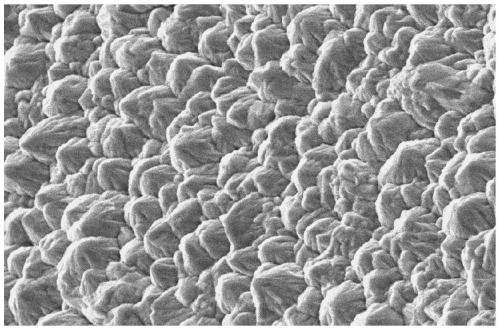

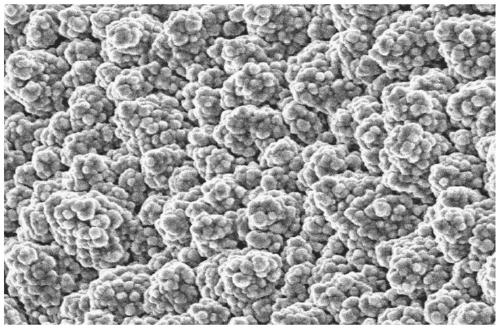

ActiveCN108677225BReduce residual stressReduce warpageMetallic material coating processesElectroforming processesRough surfaceElectrolysis

The invention belongs to the technical field of copper foil treatment, and particularly relates to a treatment method for reducing warpage of an electrolytic copper foil. The method comprises acid washing, special coarsening, special curing, coarsening, curing, zinc-plated nickel alloy, anti-oxidation treatment, silane coupling agent treatment and drying. According to the treatment method for reducing warpage of the electrolytic copper foil, by special treatment on a rough surface of the copper foil, the surface pressure stress is increased, the stress on the two surfaces of the copper foil isfurther balanced, the residual stress of the copper foil is further reduced, and the warping degree of the copper foil is reduced; the electrolytic copper foil obtained by the treatment method, the rough surface is relatively large than the surface area, and the anti-stripping strength can be improved while the surface roughness is reduced; the electrolytic copper foil has excellent oxidation resistance, chemical resistance and etching resistance; and the treatment process is easy to control, and the product quality is stable.

Owner:SHANDONG JINBAO ELECTRONICS

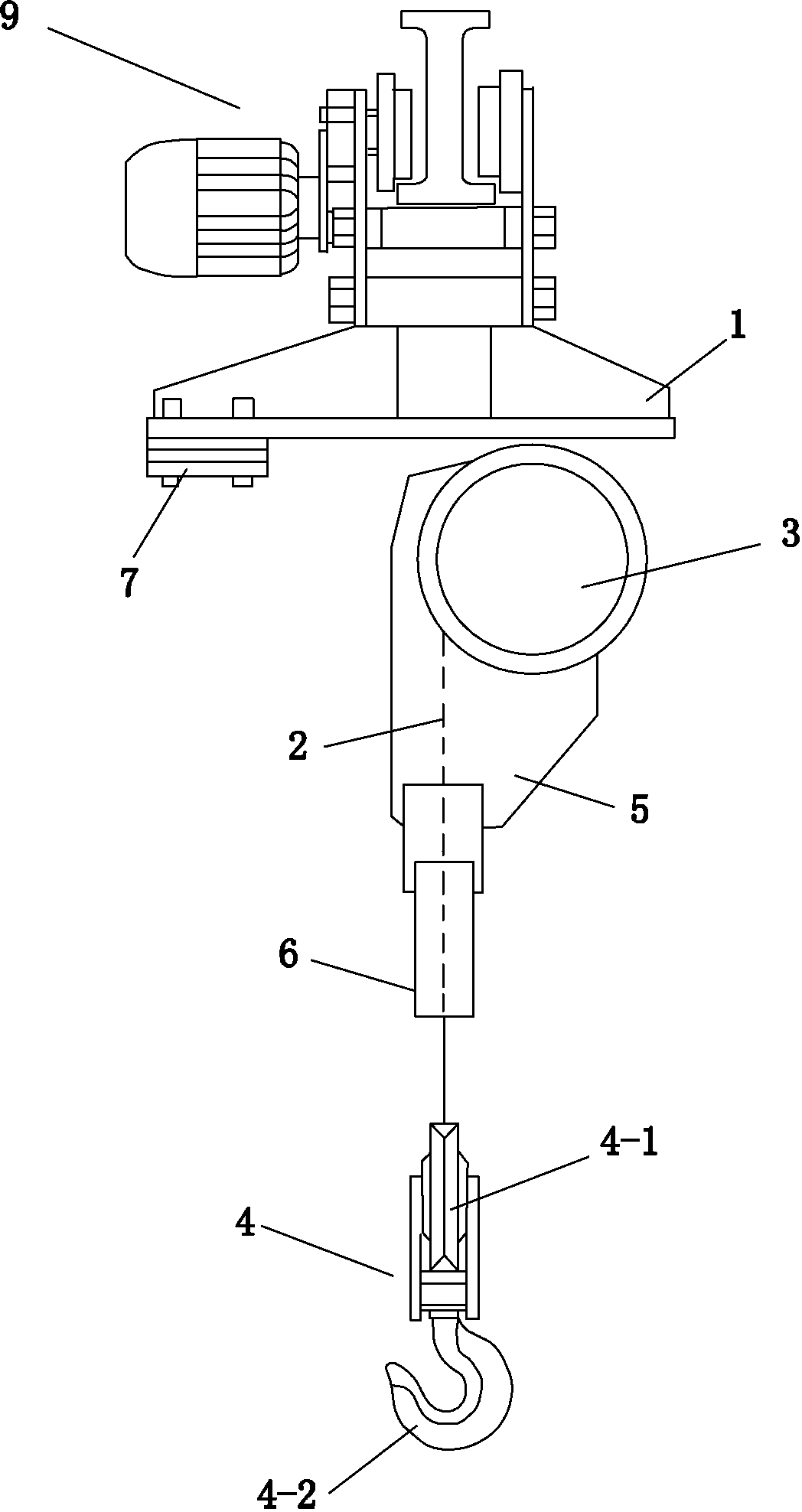

Electric hoist used for hot-dip galvanizing production line

The invention provides an electric hoist used for a hot-dip galvanizing production line. The electric hoist comprises a bearing frame, a winding drum, a lifting hook device and a lifting rope and is characterized by further comprising a fixed frame with a fixed pulley built in, the winding drum is fixed below the bearing frame and on the side, in the width direction, of the bearing frame, the fixed frame is located at the downstream position of the winding drum, the lifting hook device is located at the downstream position of the fixed frame, the axial direction of the fixed pulley is perpendicular to the axial direction of the winding drum, and a movable pulley set is built in the lifting hook device and consistent with the fixed pulley in the axial direction; after the lifting rope strides the fixed pulley, the two ends of the lifting rope are wound downwards around the movable pulley set, then evenly wound upwards on the left side and the right side of the winding drum and finally fixed to the two outer ends of the winding drum. Due to the electric hoist, reset of air guide battens is more stable and reliable, the problem that the reset is not in place due to resilience force and abrasion of a mold are solved well, customer complaints are reduced, and the satisfaction degree of customers is improved.

Owner:GUANGDONG DISHENG ELECTRIC POWER STEEL EQUIP

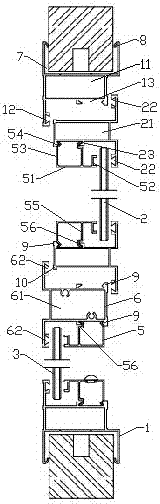

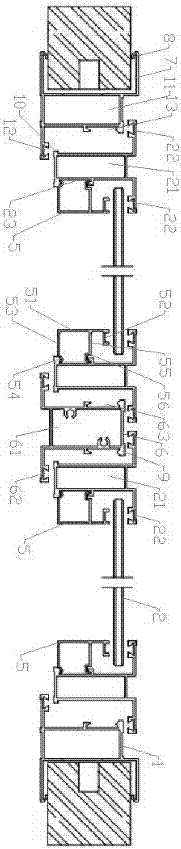

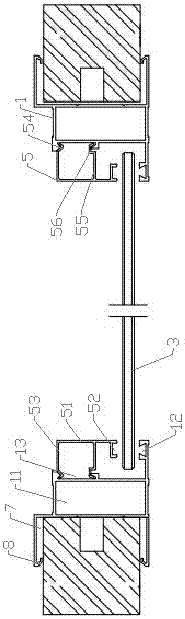

Externally-wrapped type door and window and installation method thereof

InactiveCN107100488AAchieve reuseImprove complex structuresFrame fasteningWindow/door framesAbdominal cavitySash window

The invention discloses an externally-wrapped type door and window and an installation method thereof. The externally-wrapped type door and window comprises a window frame, an upper window sash and a lower window sash, the window frame comprises upper, lower, left and right window frame section bars which are connected through corner connectors, the upper window sash comprises a left window sash and a right window sash, and the left window sash and the right window sash each comprise upper, lower, left and right window sash section bars, window-sash press wire rods and glass; the lower window sash is arranged below the left window sash and the right window sash, the window frame is connected with the upper window sash and the lower window sash through sealing rubber strips, and each window-sash press wire rod comprises a base plate, a second seal groove formed in the right end of the base plate and a baffle arranged at the left end of the base plate; a hook groove is formed in the lower end of each baffle, the glass is arranged between the first seal grooves and the second seal grooves, and the hook grooves are connected with protrusions on second abdominal cavities; and adjoining positions of the left window sash, the right window sash and the lower window sash are connected with transition section bars.

Owner:湖州国奥门窗有限公司

Single-glass touchpad and manufacturing method thereof

ActiveCN103838408ABalance stressLighten frizzInput/output processes for data processingTouchpadEngineering

The invention provides a manufacturing method of a single-glass touchpad. The manufacturing method of the single-glass touchpad comprises the steps that firstly, a substrate is provided; secondly, a bearing layer is formed on the substrate; thirdly, a patterned conductive layer is formed on the bearing layer, and the patterned conductive layer comprises a sensing electrode and an auxiliary electrode located at the outer side of the sensing electrode; fourthly, a signal conductor is formed and electrically connected with the sensing electrode, the signal conductor is gathered in least one bonding region, the bonding region or bonding regions are located in at least one outer side edge of the sensing electrode; fifthly, a covering plate is attached to the patterned conductive layer, and the substrate is removed from the bearing layer. By means of the manufacturing method of the single-glass touchpad, the problems that an edge area of the bearing layer curls easily and components at the edge area fall off or are damaged easily when the substrate is removed are relieved.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

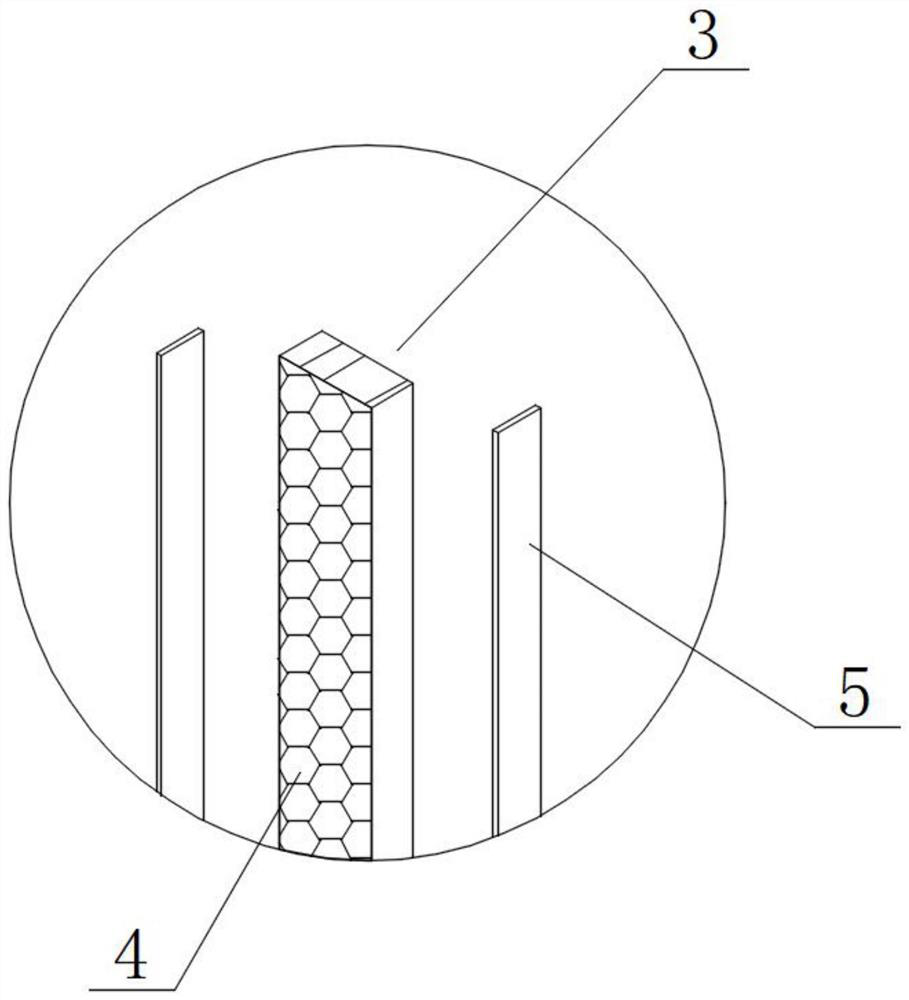

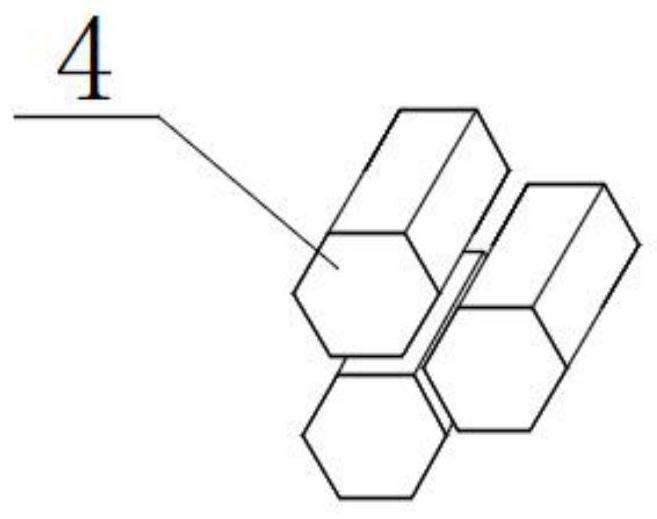

Hexagonal solid wood splicing structure and processing method thereof

InactiveCN113478592ABalance stressAvoid shrinkage and swellingDomestic upholsteryLaminationSolid woodEngineering

The invention relates to a hexagonal solid wood splicing structure and a processing method of the hexagonal solid wood splicing structure. The hexagonal solid wood splicing structure comprises density boards which are symmetrically arranged; solid wood veneers attach to light-seeing surfaces of the density boards, and a pressure-resistant board is arranged between the two density boards; the pressure-resistant board is formed by splicing a plurality of polygonal profiles; force rib plates are arranged on the periphery of the pressure-resistant board in a surrounding manner; and a veneer, a fireproof plate or a multi-layer board is arranged on the surface of each solid wood veneer. The technical scheme has the following beneficial effects that eucalyptus boards are rotationally cut into slices with the thickness of 1.5 mm through a rotary cutter, the remaining eucalyptus core sticks are fully utilized, therefore, the waste material core boards of the multi-layer board are recycled, meanwhile, stress release control through temperature and humidity and moisture absorption analysis of the wood are realized in the whole process through the rigorous and scientific processing technology, and thus the stability of the product is ensured; and all regular hexahedral rhombic materials (eucalyptus cores) are hexagons with the same size, and the same splicing area adopts the density boards made of the same material, so that balance stress can be released, and the defects that wood shrinks after being dried and expands after being wetted, cracks and the like are effectively overcome.

Owner:广东玛格家居有限公司

inas/gasb superlattice infrared photodetector and preparation method thereof

ActiveCN103887360BBalance stressImprove growth qualityFinal product manufactureSemiconductor devicesPhotovoltaic detectorsPhotodetector

The invention provides an InAs / GaSb superlattice infrared photoelectric detector and a manufacturing method thereof. The InAs / GaSb superlattice infrared photoelectric detector comprises a substrate, an epitaxy structure deposited on the substrate, an upper metal electrode formed above steps, a lower metal electrode formed under the steps and a passivation layer, wherein the epitaxy structure comprises an n-type doping buffer layer, an n-type electrode contact layer, a barrier layer, an intrinsic absorption layer, a p-type electrode contact layer and a cover layer, the steps are formed on two sides of the epitaxy structure through etching, the intrinsic absorption layer is composed of a plurality of periodical InAs / InSb / GaSb / InSb superlattice structures. In the InAs / GaSb superlattice infrared photoelectric detector, InSb is respectively inserted into two interfaces of each superlattice period of the intrinsic absorption layer to form strained superlattices, the stress between the superlattices and the substrate is effectively balanced, the material growing quality is improved, and accordingly the photoelectric performance of the detector is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com