Workpiece cleaning machine and method of use thereof

A technology for cleaning machines and workpieces, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low efficiency of manual cleaning and damage to the human body by chemical substances, and achieve the effects of avoiding direct contact, reducing injuries and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

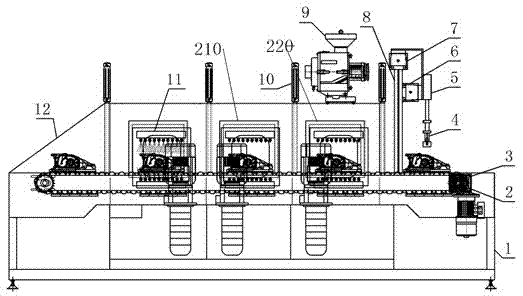

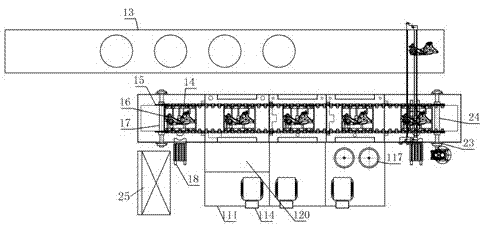

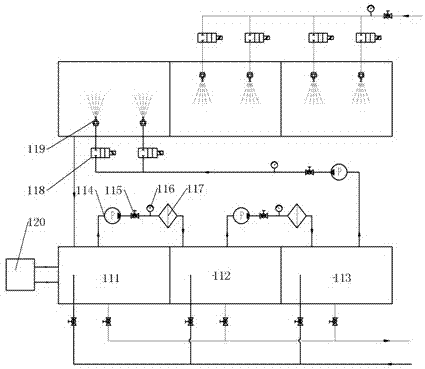

[0031] The specific structures and characteristics known in the following schemes will not be described here. Such as figure 1 and figure 2 As shown: the workpiece cleaning machine includes a frame 1, a cooling section 13 is installed beside the frame 1, a conveyor belt 2 is installed on the frame 1, and the drive motor 3 drives the conveyor belt 2 through the drive shaft 23 and the sprocket 15 from left to right Movement, the drive shaft 23 is sleeved with the bearing seat 23 and fixed on the frame 1, the other end of the conveyor belt 2 is provided with a driven shaft 17 and a sprocket 15, and the conveyor belt 2 is provided with a fixture 16 for fixing the workpiece 14, and the conveyor belt 2 on the frame Positioning cylinders 18 are provided at both ends to fix or loosen the workpiece 14 on the fixture 16 . The frame 1 is also provided with an electric control cabinet 25 for controlling electric devices such as solenoid valves.

[0032] The front end of the conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com