Peripheral rewinding machine for producting rolls of wound web material and corresponding method of winding

A technology of rewinding machine and roll production, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc., and can solve problems such as web deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following description, it is illustrated that the present invention is applied to an automatic peripheral rewinding machine described in WO-A-9421545, but it is understood that the concept of the present invention can also be applied to automatic peripheral rewinding with other configurations machine.

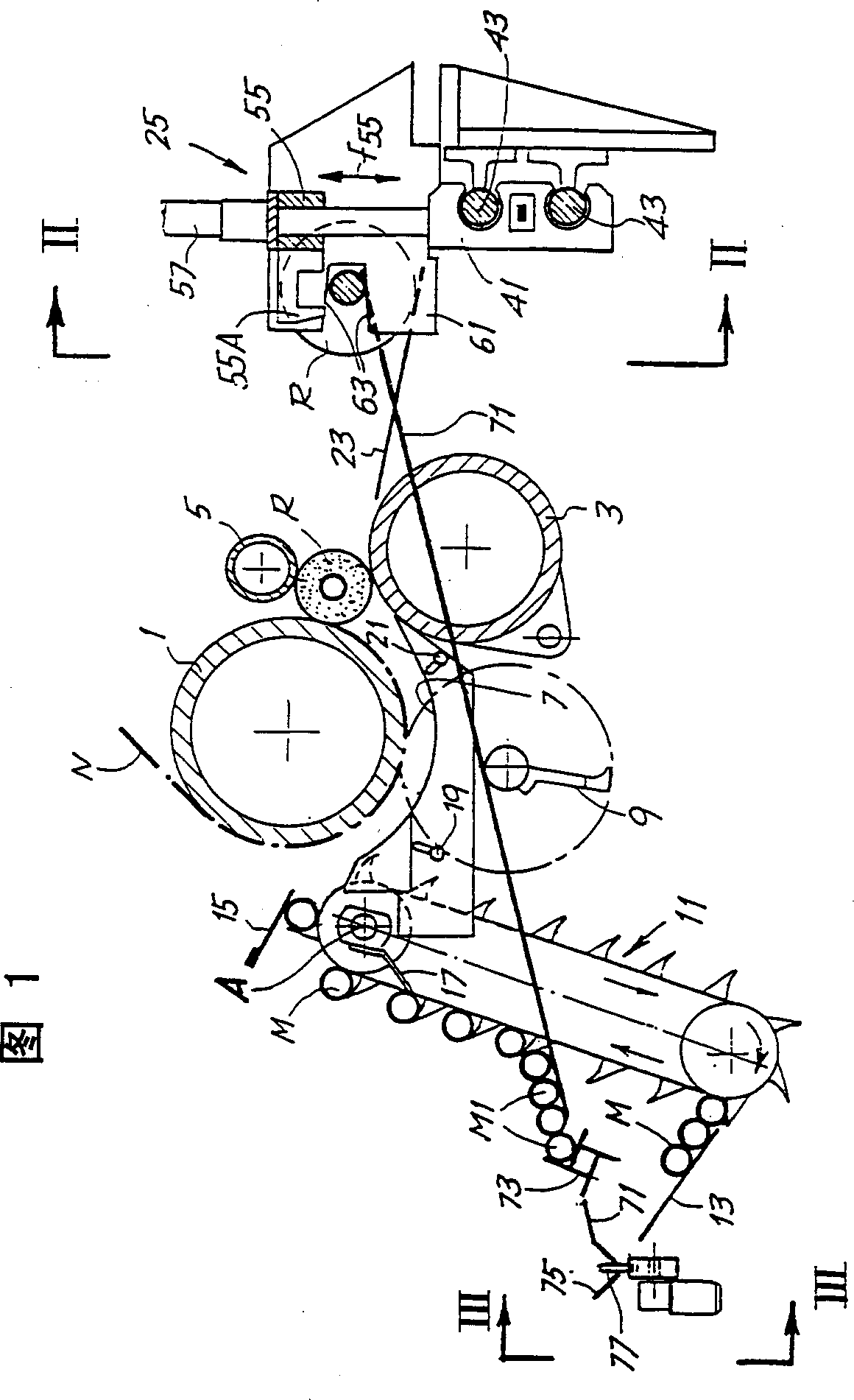

[0024] Figure 1 schematically shows the winding area of a peripheral winding machine. The letter N designates a web to be wound, such as a single or multiple sheets of paper to be wound into a roll, with transverse perforations, if required. Reference numerals 1, 3 and 5 denote 3 winding rollers which define a winding area forming the roll R. As shown in FIG. The web N runs around the upper winding roll 1 and the reel R is formed in the area between the rolls 1, 3 and 5 and is in contact with them.

[0025] An insertion channel for the winding mandrel M is formed by a curved surface 7 located below the winding roller 1 . A rotating system 9 , which is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com