Electric hoist used for hot-dip galvanizing production line

A hot-dip galvanized, electric hoist technology, applied in portable lifting devices, hoisting devices, etc., can solve the problems of easy volatilization to the atmosphere, not meeting environmental protection requirements, affecting the sealing performance of collection hoods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific embodiment:

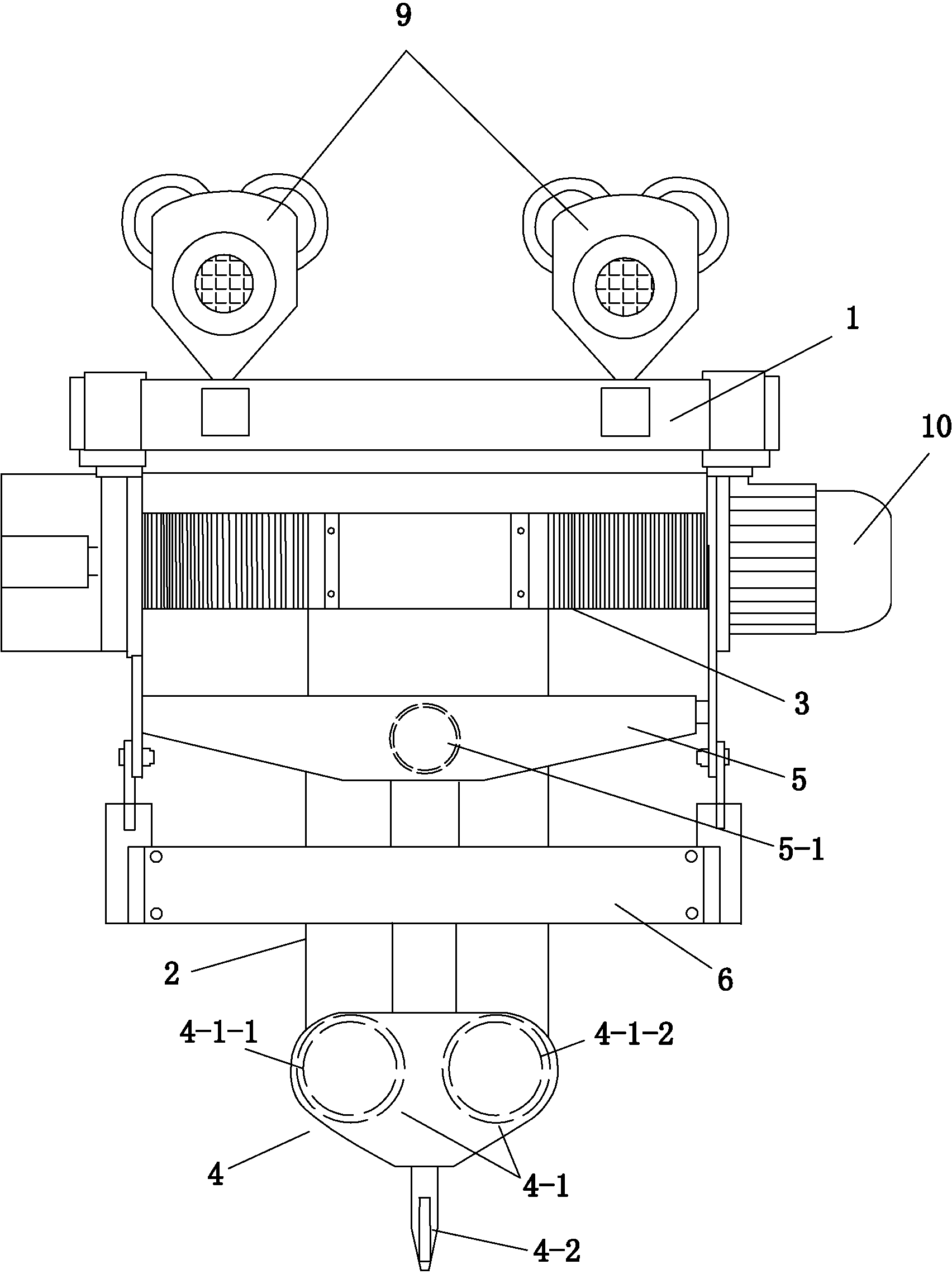

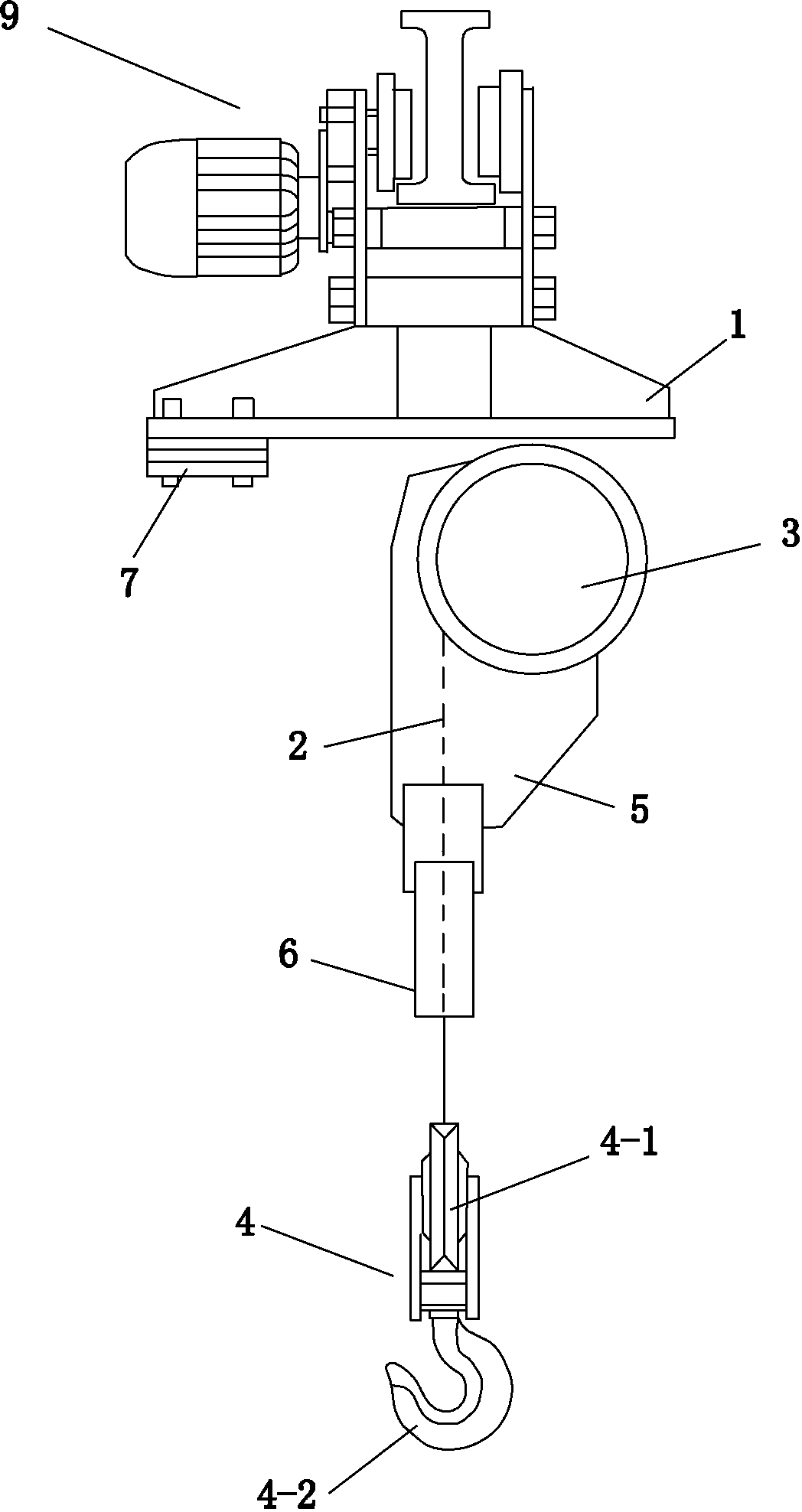

[0012] See attached figure 1 to attach figure 2 As shown, the electric hoist used in the hot-dip galvanizing production line described in this embodiment includes a load-bearing frame 1, a suspension rope 2, a reel 3, a hook device 4, a fixed frame 5, a guide plate 6 and a counterweight Block 7, wherein the hook device 4 is built with a movable pulley block 4-1, the movable pulley block 4-1 is composed of the first movable pulley 4-1-1 and the second movable pulley 4-1-2, and the fixed frame 5 has a built-in fixed pulley 5-1, the reel 3 is fixed under the load frame 1 and on one side in the width direction of the load frame 1, and the counterweight 7 is fixed under the load frame 1 and on the side opposite to the reel 3 in the width direction of the load frame 1, The fixed frame 5 is located downstream of the reel 3, the guide plate 6 is located downstream of the fixed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com