Single-glass touchpad and manufacturing method thereof

A technology of monolithic glass and manufacturing method, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc., and can solve the problem of easy curling, falling off or damage of touch structure, and affecting the quality of monolithic glass touch panels. Ratio and other issues, to achieve the balance of stress and reduce the effect of easy curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

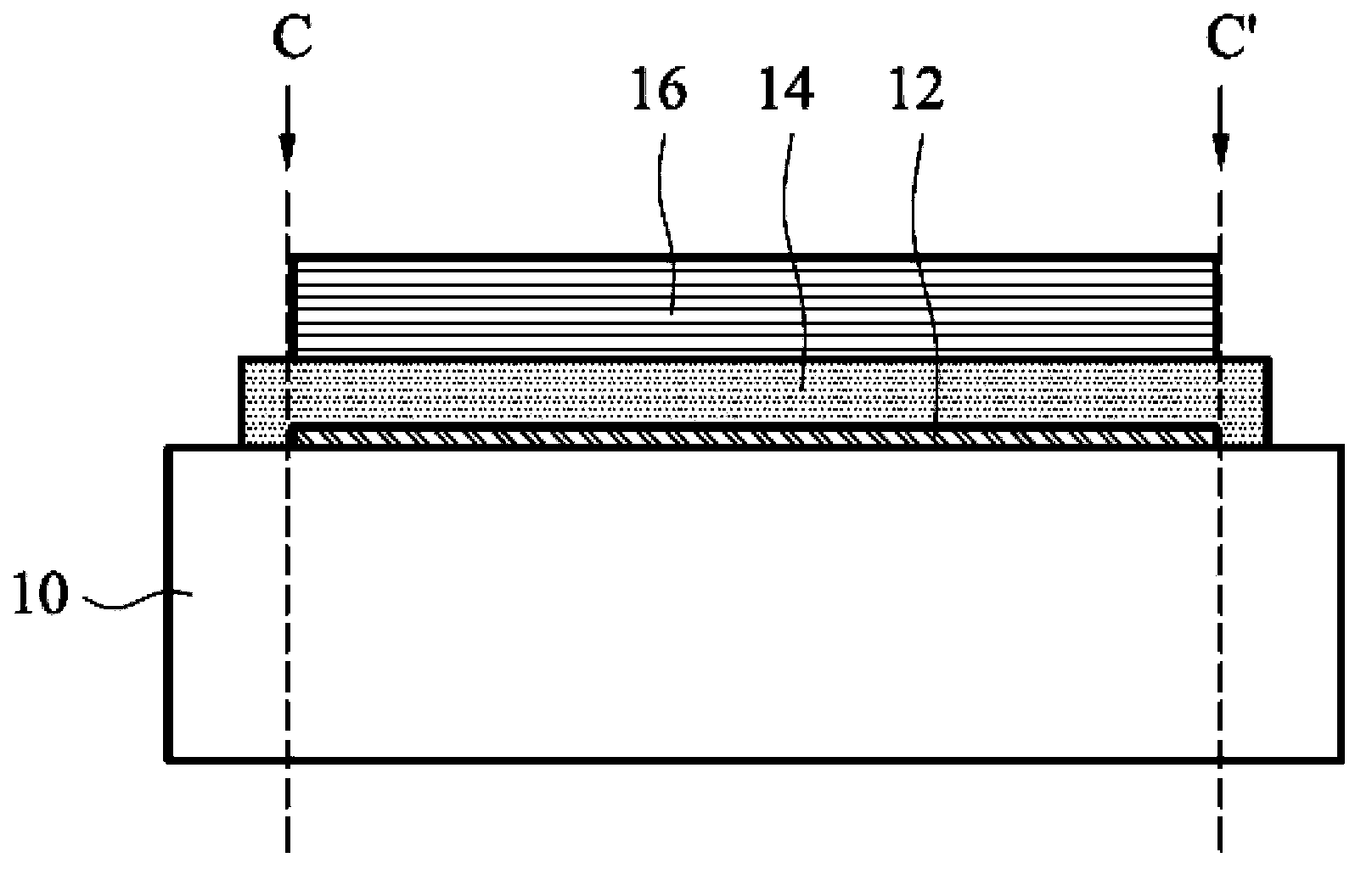

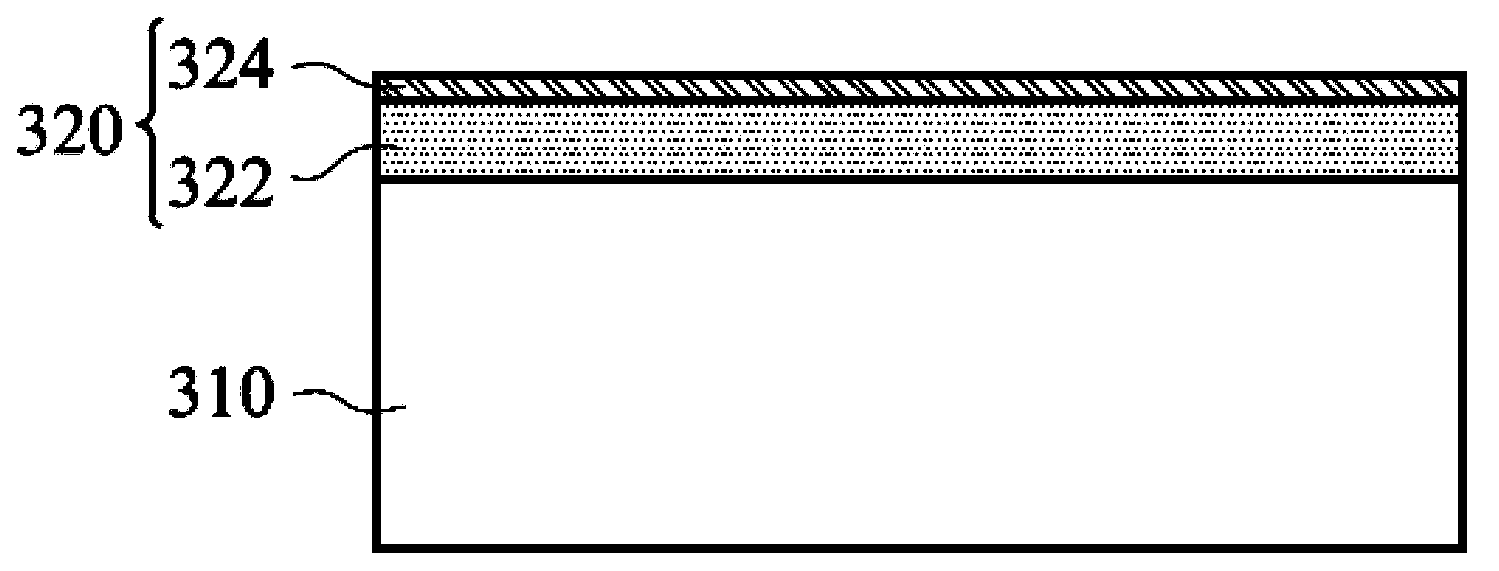

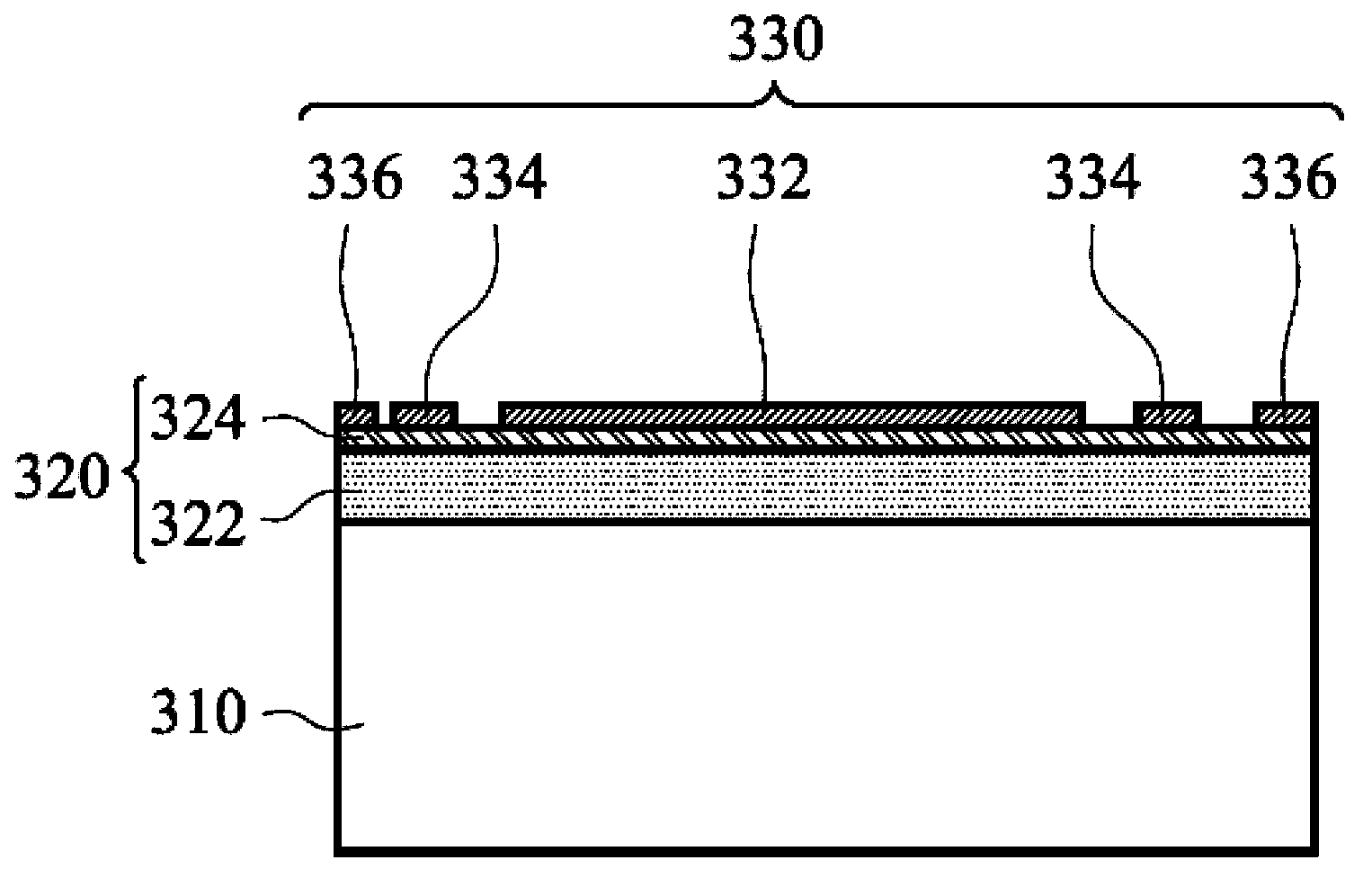

[0013] The present invention provides several embodiments to illustrate the technical features of the present invention, and the contents and drawings of the embodiments are only for illustrative purposes, and are not intended to limit the protection scope of the present invention. Non-essential elements may be omitted from the drawings, and various features may not be drawn to scale and are used for illustration purposes only. The disclosure of the present invention may use repeated element symbols in different embodiments, which does not mean that there is a relationship between different embodiments or drawings. In addition, an element formed "above", "on", "under" or "under" another element may include an embodiment in which the two elements are in direct contact, or may include other additional elements interposed between the two elements. the embodiment. Various elements may be shown in arbitrarily different scales for clarity and simplicity of illustration.

[0014] P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com