Novel warp knitting fabric

A warp knitted fabric and a new type of technology, applied in the field of warp knitted fabrics, can solve the problems of difficulty in arbitrarily cutting fabrics, large cracking risks, and easy cracking of fabrics, so as to increase elasticity and tear resistance, and improve comfort and aesthetics. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

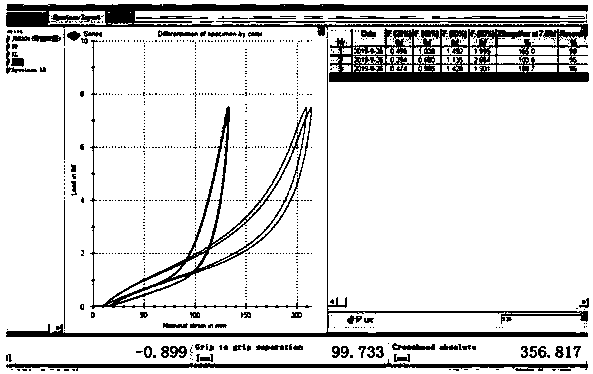

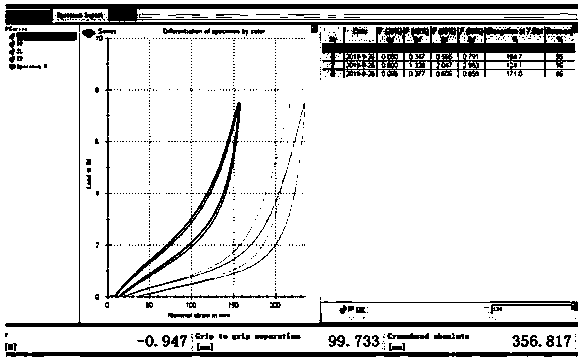

[0119] Compared with Example 1, this example only changed the GB4 spandex elastic yarn to be 105 deniers, and other conditions and production processes were the same as Example 1, and the hemming and dedispersing properties of the fabric were the same as Example 1, and the opening Sampling position and test condition are identical with embodiment 1 during test, and test result is as follows: two test sample openings of fabric radial direction are 123.3%, 124.1%, two test sample openings of weft direction are 184.7%, 171.0%, such as Figure 13 , it can be seen that the warp and weft elasticity of the fabric is greater than 80%.

[0120] To sum up, the novel warp-knitted fabric provided by the present invention has the advantages of not easy curling, no unraveling, and warp and weft elasticity ≥ 80%. Compared with the existing random-cut fabrics, this fabric only needs to use ordinary yarns, and through the production equipment and technology commonly used in the industry, it ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com