Free cut fabric not prone to hemming

A fabric and hemming technology, which is applied in the field of knitted fabrics, can solve the problems of cutting angle and orientation restrictions, large fabric cutting loss, and poor comfort in use, so as to avoid curling and falling off, high comfort in use, and soft hand feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

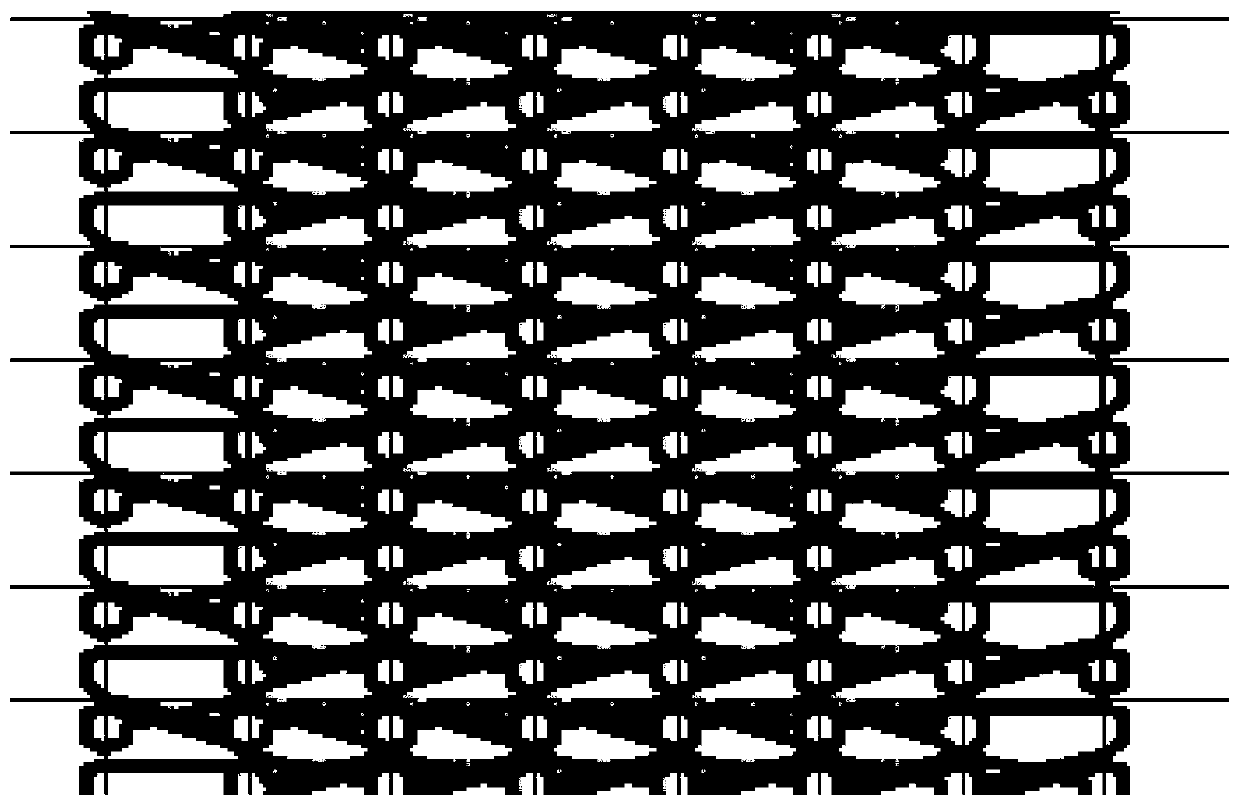

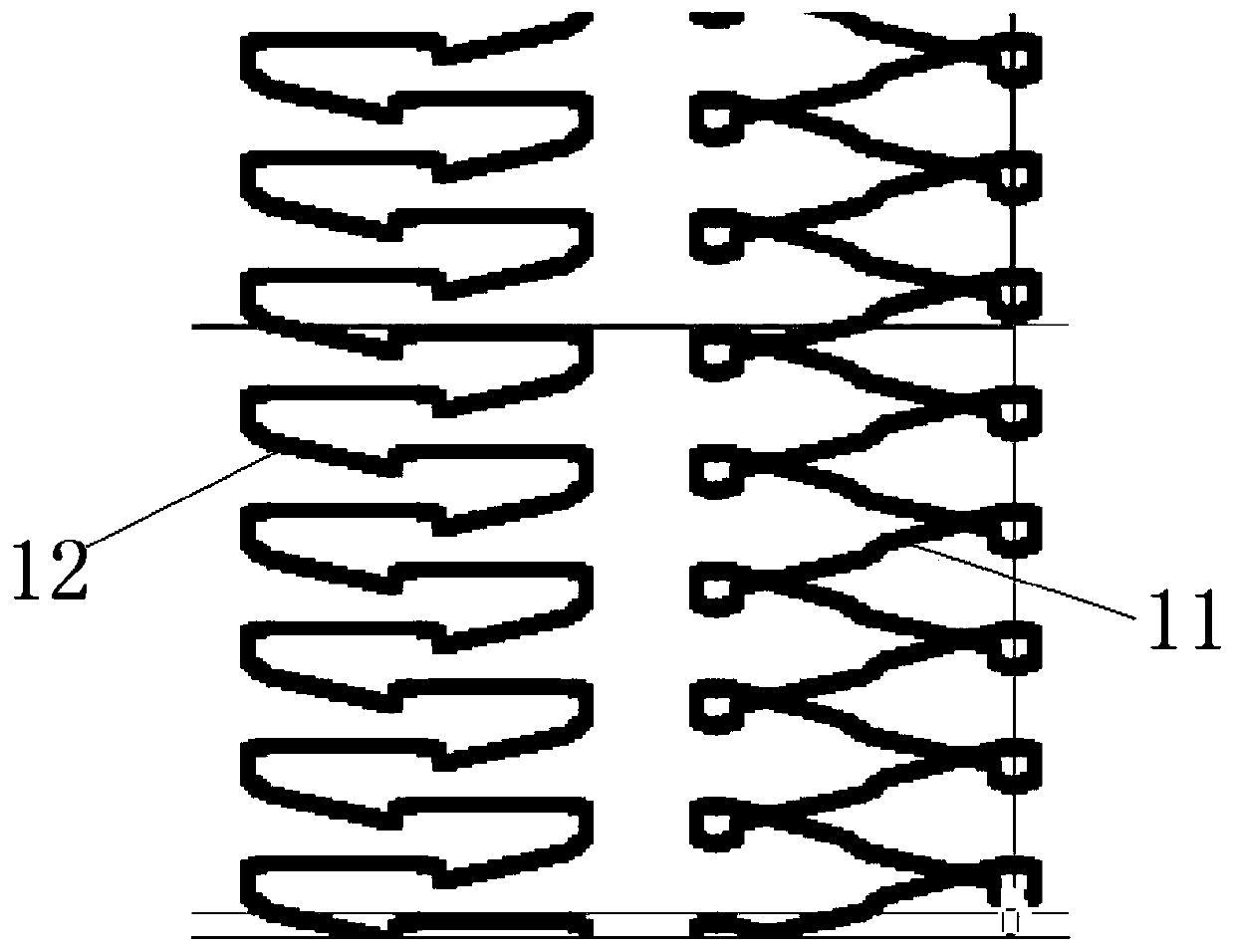

[0024] Please refer to figure 1 with figure 2 , Embodiment 1 of the present invention provides a kind of fabric that is not easy to curl and can be cut randomly, including a fabric body, and the fabric body includes a first yarn 11 (front comb GB1) and a second yarn that are interwoven by several warp knitting techniques. Thread 12 (back comb GB2), the first yarn 11 can preferably be set as nylon yarn, and the second yarn 12 can be preferably set as spandex yarn.

[0025] Nylon fiber (polyamide fiber) is commonly known as nylon (Nylon), and its most prominent advantage is that its wear resistance is higher than all other fibers, 10 times higher than cotton and 20 times higher than wool; when stretched to 3-6 %, the elastic recovery rate can reach 100%; it can withstand tens of thousands of times of bending without breaking, and its fatigue resistance ranks first among all kinds of fibers.

[0026] Polyurethane Fiber (Polyurethane Fiber) is the abbreviation of polyurethane e...

Embodiment 2

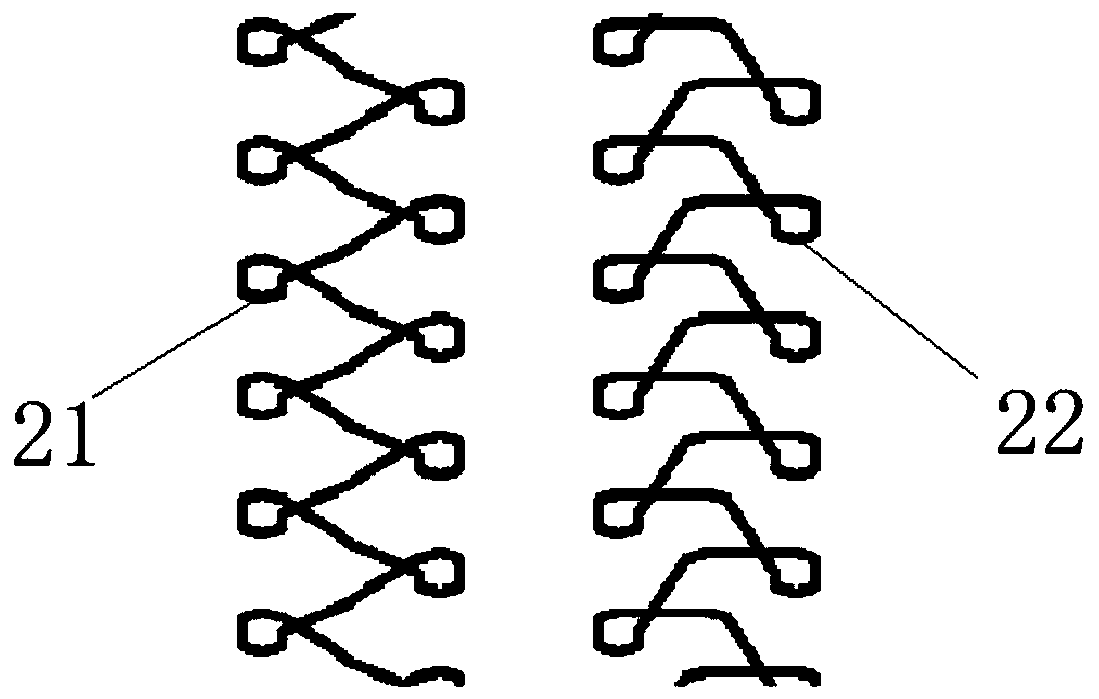

[0036] Please refer to image 3 , Embodiment 2 of the present invention provides a fabric that is not easy to curl and can be cut at will, including a fabric body, and the fabric body includes a number of first yarns 21 and second yarns 22 interwoven by a warp knitting process. The yarn 21 can preferably be set as nylon yarn, and the second yarn 22 can be preferably set as spandex yarn.

[0037] Such as image 3 As shown, each first yarn 21 takes turns laying yarn into a loop every other stitch, so that the warp knitting structure formed by knitting the first yarn 21 is a warp weave, and the extension line of the warp weave spans two gauges. The warp velvet tissue is a closed warp velvet tissue, and its coils are closed loops, that is, extension lines at the base of the coils intersect each other, and the closed warp velvet tissue is used as a surface weave. The lapping number of the closed warp velvet is 1-0 / 2-3 / / .

[0038] Such as image 3 As shown, each second yarn 22 i...

Embodiment 3

[0042] Please refer to Figure 4 , the third embodiment of the present invention provides a fabric that is not easy to curl and can be cut at will, including a fabric body. Yarn 33, the first yarn 31 can be preferably set to nylon yarn, the second yarn 32 can be preferably set to spandex yarn, the third yarn 33 can be preferably set to nylon yarn or spandex yarn, of course it can also be Use other elastic yarns or non-elastic yarns.

[0043] Such as Figure 4 As shown, each first yarn 31 takes turns laying the yarn into loops every other stitch, so that the warp knitting structure formed by knitting the first yarn 31 is a warp weave, and the extension line of the warp weave spans two gauges. The warp velvet tissue is a closed warp velvet tissue, and its coils are closed loops, that is, extension lines at the base of the coils intersect each other, and the closed warp velvet tissue is used as a surface weave. The lapping number of the closed warp velvet is 1-0 / 2-3 / / .

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com