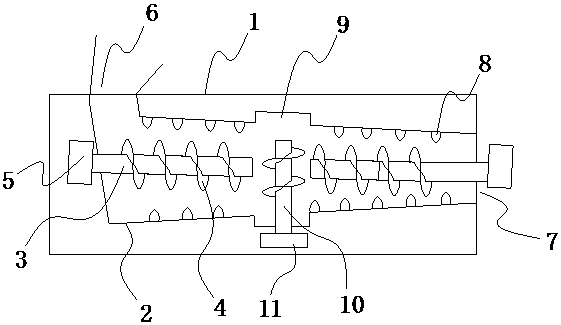

Two-stage sludge dewatering machine

A sludge dehydrator, two-stage technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems such as reducing compression dehydration effect, and achieve improved dehydration effect, balance the stress situation, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The two-stage sludge dewatering machine of this embodiment includes a horizontally arranged outer casing 1 with a closed side wall, and an inner pipe body 2 with a water-permeable side wall is horizontally arranged in the outer casing 1, and the inner pipe body 2 is arranged at intervals There are two augers formed by the agitating shaft 3 and the spirally rising agitating blades 4 arranged on the outer wall of the agitating shaft 3, the axes of the two augers are on the same straight line; the agitating shaft 3 is driven to rotate by a motor 5 connected thereto, There is a drain port on the outer shell 1, and one end of the inner pipe body 2 has a sludge feed port 6 that supplies sludge material to the stirring blade 4, and a sludge discharge that matches the top end of the stirring blade 4 is arranged on the outer shell 1 port 7; the inner diameter of the inner pipe body 2 gradually decreases from the side of the sludge feed port 6 to the side of the sludge discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com