Single crystal alkali polishing additive, polishing solution and polishing method

A single crystal alkali and additive technology, applied in the field of solar cells, can solve the problems of high liquid medicine cost and tail liquid treatment cost, poor control of the reaction process, high reflectivity of silicon wafers, etc., and achieve pollution-free and controllable polishing effect Good effect with broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

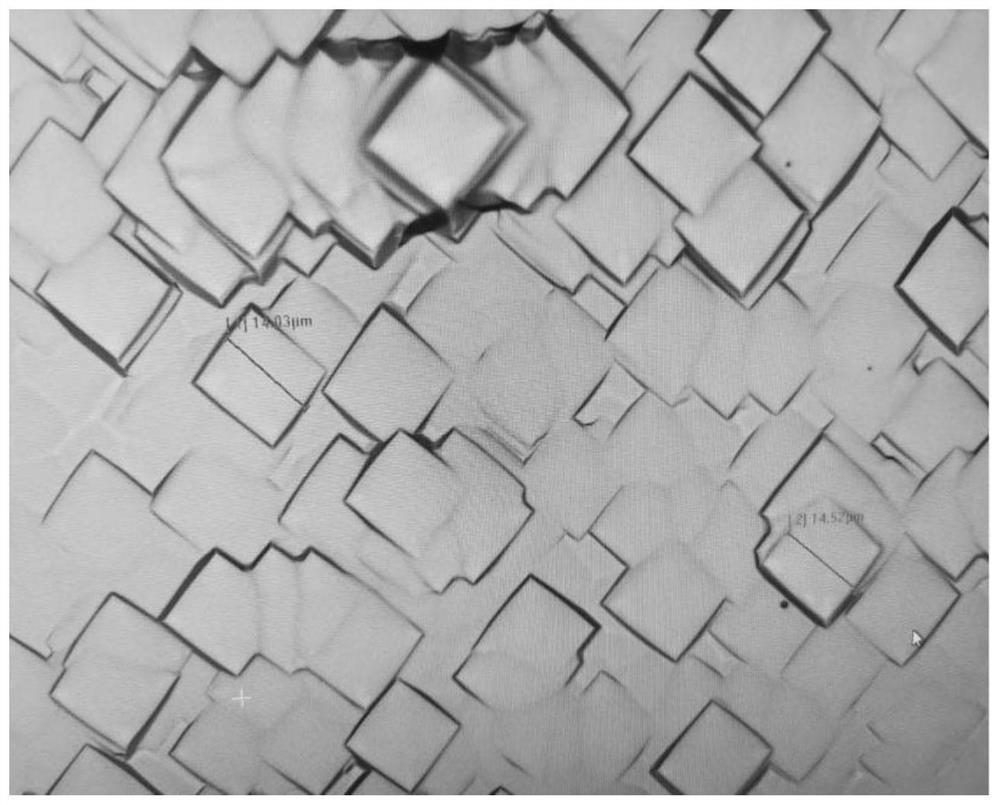

[0031] Apply the polishing process of single crystal alkali polishing additive of the present invention, take following process steps:

[0032] (1) Preparation of single-crystal alkali polishing additive: using ultrapure water as a solvent, 0.1 g of organic silicon, 0.1 g of brightener, and 0.05 g of fluorocarbon surfactant are dissolved in ultrapure water to obtain 100 g of texturing additive;

[0033] (2) configuration polishing liquid: the potassium hydroxide of 250g is dissolved in ultrapure water, obtains 10kg potassium hydroxide solution; Then in this potassium hydroxide solution, add the 100g single crystal alkali polishing additive that step 1) makes and obtain polishing liquid;

[0034] (3) Polishing process: immerse the monocrystalline silicon cells in the polishing solution for surface polishing, the texturing temperature is 75°C, and the texturing time is 180s.

Embodiment 2

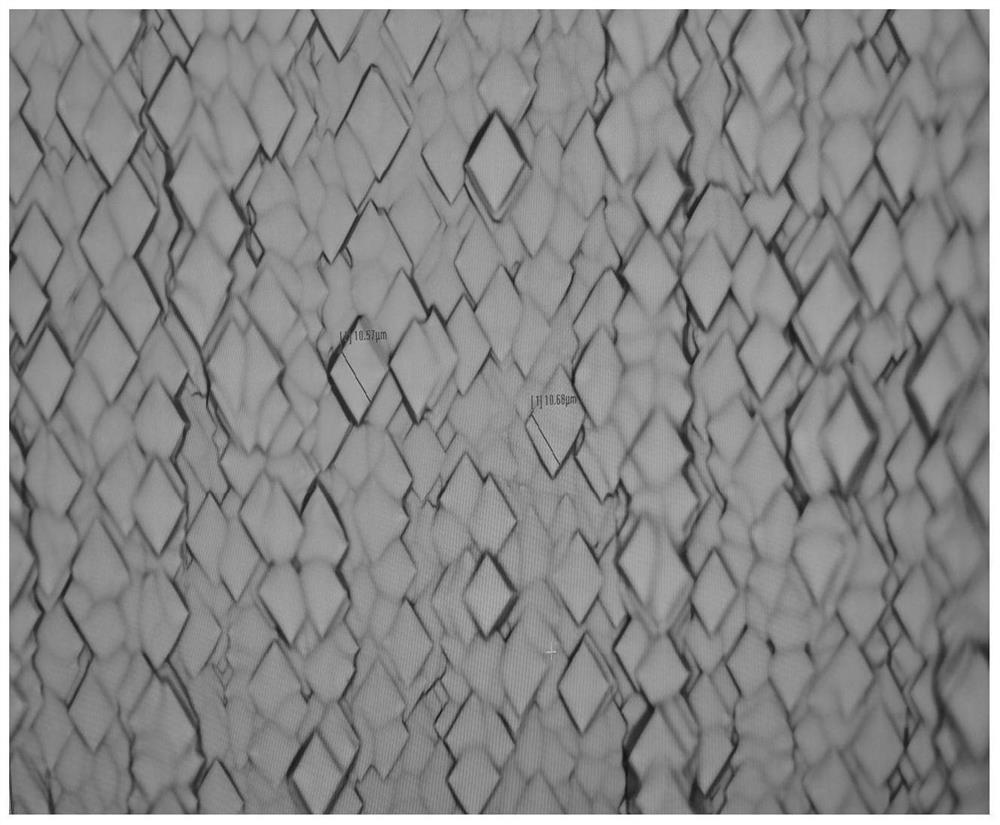

[0036] Apply the polishing process of single crystal alkali polishing additive of the present invention, take following process steps:

[0037] (1) Preparation of single crystal alkali polishing additive: with ultrapure water as a solvent, 2g of organic silicon, 2g of brightener, and 0.32g of fluorocarbon surfactant are dissolved in ultrapure water to obtain 400g of texturing additive;

[0038] (2) Configure the velvet making solution: dissolve the aqueous potassium hydroxide solution of 300g in ultrapure water to obtain a 10kg potassium hydroxide solution; then add the 400g single crystal alkali polishing additive made by step 1) in the potassium hydroxide solution get polishing solution;

[0039] (3) Polishing: immerse the monocrystalline silicon cells in the polishing solution for surface polishing, the texturing temperature is 65° C., and the texturing time is 240 s.

Embodiment 3

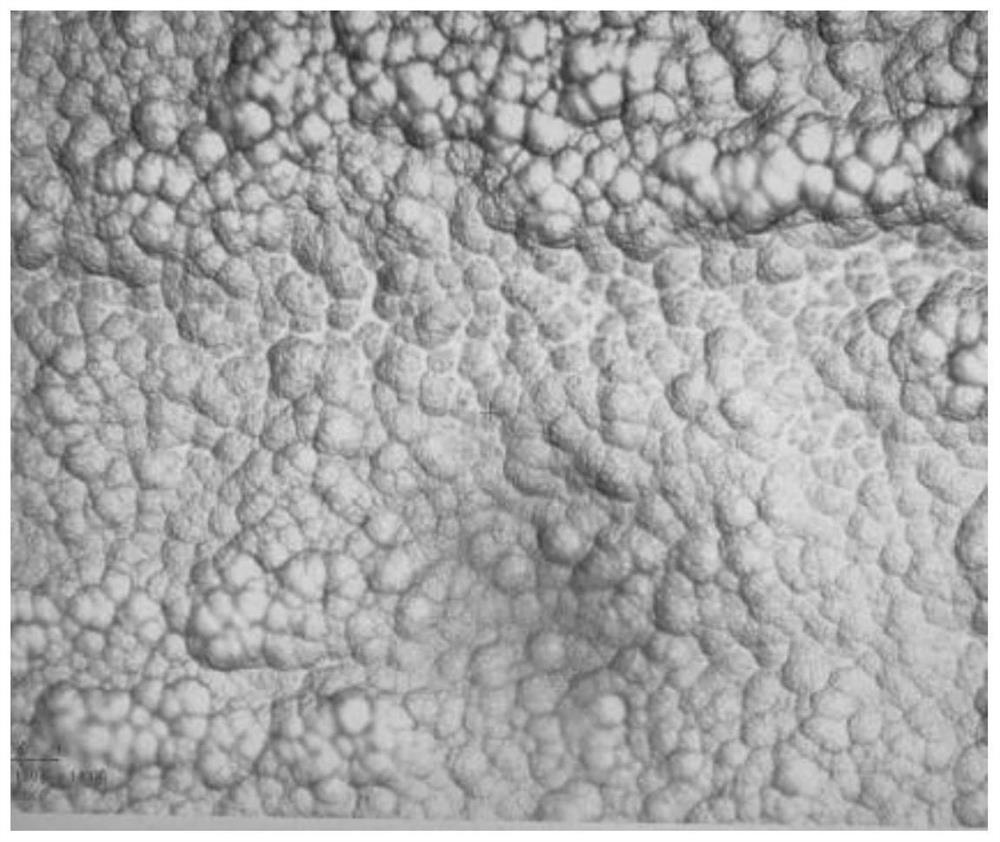

[0041] Apply the polishing process of single crystal alkali polishing additive of the present invention, take following process steps:

[0042] (1) Organic silicon, brightener, fluorocarbon surfactant are added into water, mix uniformly and be made into single crystal alkali polishing additive; In terms of mass percentage, additive contains organic silicon 2%, brightener 2.5%, fluorocarbon surfactant 0.1% and the balance of water.

[0043] (2) adding the prepared single crystal alkali polishing additive to the potassium hydroxide aqueous solution with a mass fraction of 4%, and mixing uniformly to make a polishing liquid; wherein, the mass ratio of the single crystal alkali polishing additive to the potassium hydroxide aqueous solution is 1 : 50.

[0044](3) Polishing: immerse the monocrystalline silicon cells in the polishing solution for surface polishing, the texturing temperature is 80°C, and the texturing time is 360s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com