Back junction backcontact solar cell

A solar cell and back contact technology, applied in the field of solar cells, can solve problems such as increasing series resistance, increasing carrier recombination rate, and reducing battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

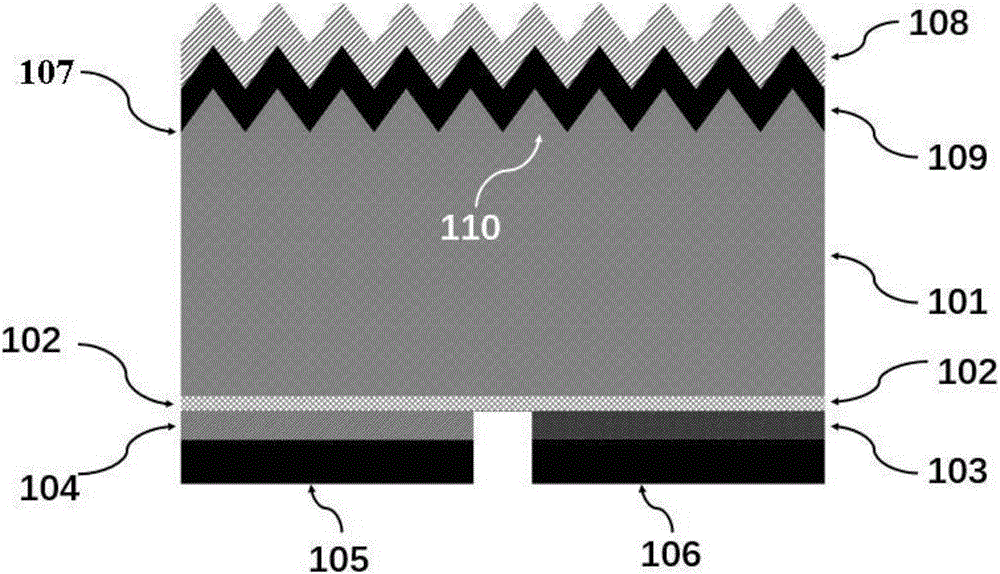

[0113] see figure 1 , figure 1 A schematic diagram of the structure of the back-junction and back-contact solar cell provided in Example 1 of the present invention. Among them, 101 is the substrate (substrate), 102 is the tunnel oxide layer, 103 is the N-type doped semiconductor layer, 104 is the P-type doped semiconductor layer, 105 is the positive electrode, 106 is the negative electrode, and 107 is the front electrode. In the field area, 108 is an anti-reflection layer, 109 is a passivation layer on the front surface, and 110 is an overall suede light-trapping structure.

[0114] Depend on figure 1 It can be seen that the P-type doped semiconductor layer and the N-type doped semiconductor layer are alternately distributed in the shape of interpolated fingers, and the P-type doped semiconductor layer and the N-type doped semiconductor layer are separated by a trench, and are insulated from each other. of. Wherein the P-type doped semiconductor layer as the emitter is wid...

Embodiment 2

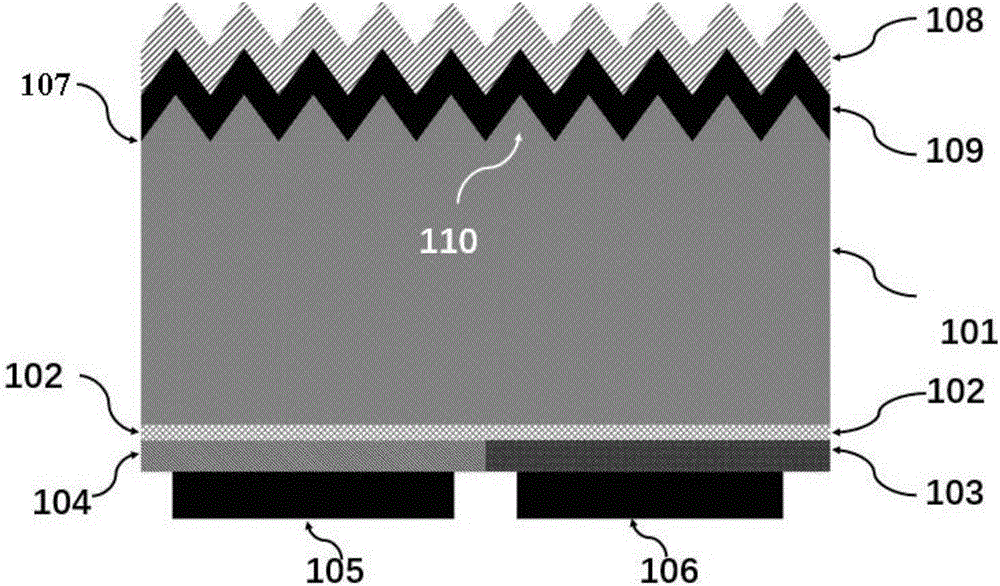

[0120] see figure 2 , figure 2 A schematic diagram of the structure of the back-junction and back-contact solar cell provided by Example 2 of the present invention. Among them, 101 is the substrate (substrate), 102 is the tunnel oxide layer, 103 is the N-type doped semiconductor layer, 104 is the P-type doped semiconductor layer, 105 is the positive electrode, 106 is the negative electrode, and 107 is the front electrode. In the field area, 108 is an anti-reflection layer, 109 is a passivation layer on the front surface, and 110 is an overall suede light-trapping structure.

[0121] Depend on figure 2 It can be seen that the P-type doped semiconductor layer and the N-type doped semiconductor layer can also be as figure 2 It is shown that they are connected together. Although they are connected together, the P-type doped semiconductor layer and the N-type doped semiconductor layer will form a PN junction. When the battery is working normally, the PN junction is in a reve...

Embodiment 3

[0128] The preparation method of the solar cell is as follows:

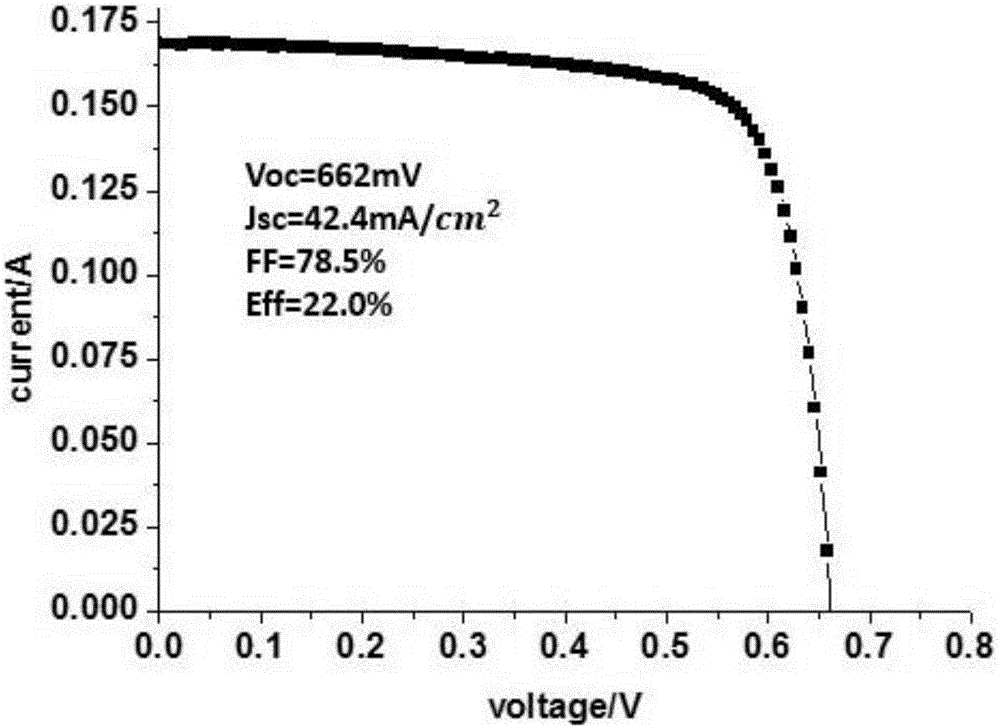

[0129] A pyramid-shaped suede structure is prepared by corroding the front surface of an N-type single crystal silicon wafer with a thickness of 100 microns with a sodium hydroxide solution. The concentration of sodium hydroxide is 1%, the etching time is 5 minutes, and the temperature is 60 ℃. On the textured surface, arsenic atoms were implanted by ion implantation to form an N-type doped region on the front surface with a doping concentration of 10 17 cm -3 , the doping depth is 2 microns. After forming the N-type doped region on the front surface, a layer of silicon oxide with a thickness of 20 nanometers is deposited on the front surface as a passivation layer by plasma-enhanced chemical vapor deposition, and then placed on the passivation layer by sputtering A layer of 200nm ITO was deposited as an anti-reflection layer by the way. Then use thermal oxygen oxidation method to form a tunnel oxide layer wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com