Wash solution for removing laser damage layers

A technology of laser damage and lotion, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., to achieve the effect of increasing opening voltage and reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

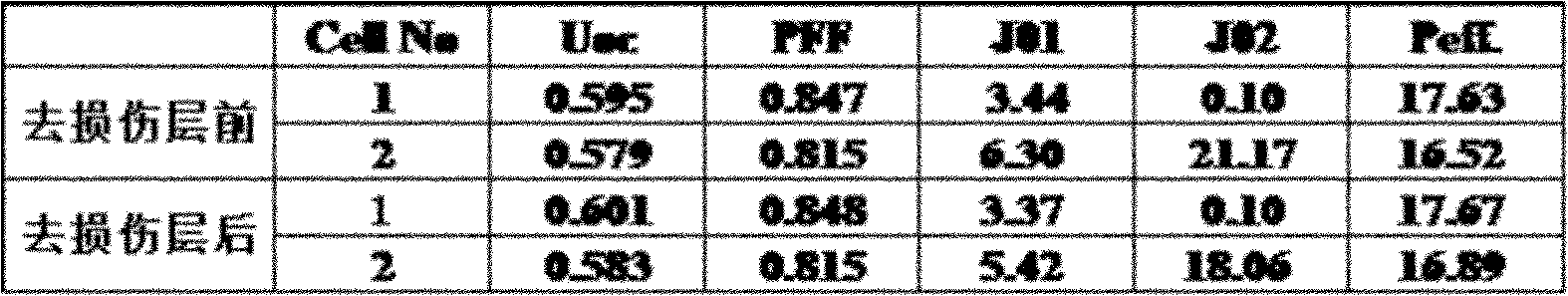

[0008] Add 80g of ammonium fluoride, 20ml of 49% hydrofluoric acid solution and 20ml of 65% nitric acid solution into 1L of water to make a washing solution for removing the laser damage layer, and use the washing solution to treat single crystal silicon wafers (type P, with a resistivity of 0.5- 3), after alkali texturing (pyramid), diffusion (SHR=70), post-cleaning (removing edge PN junction and backside etching), PECVD, front-side laser doping (ShR=5-10ohm), and removing the damaged layer , Suns-Voc test.

Embodiment 2

[0010] Add 60g of ammonium fluoride, 10ml of 49% hydrofluoric acid solution and 10ml of 68% nitric acid solution into 1L of water to make a washing solution for removing the laser damage layer, and use the washing solution to treat single crystal silicon wafers (type P, with a resistivity of 0.5- 3), after alkali texturing (pyramid), diffusion (SHR=70), post-cleaning (removing edge PN junction and backside etching), PECVD, front-side laser doping (ShR=5-10ohm), and removing the damaged layer , Suns-Voc test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com