Alkali polishing preparation method of PERC solar cell

A solar cell and laser technology, applied in the field of solar cells, can solve the problems of low cell conversion efficiency and low reflectivity of the backside of silicon wafers, and achieve the effects of improving passivation effect, increasing open voltage, and improving conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

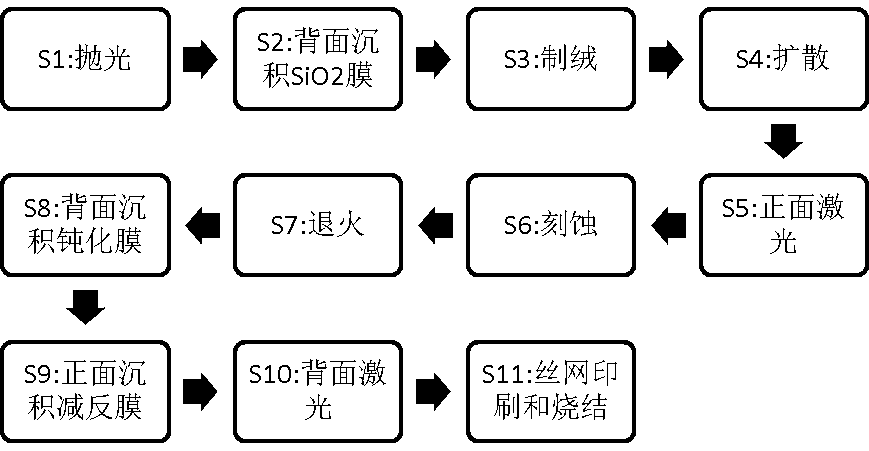

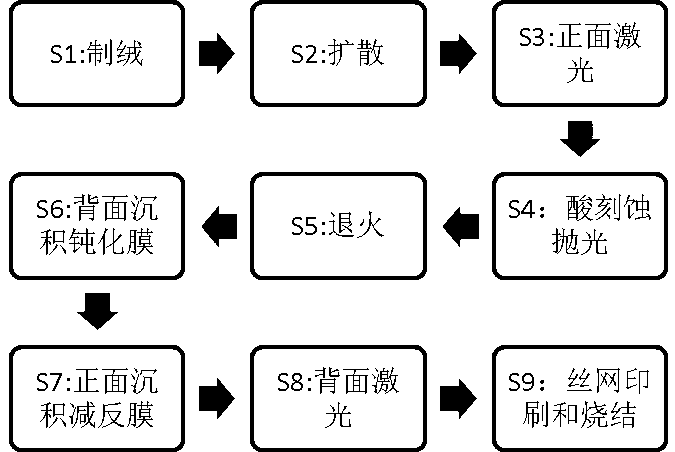

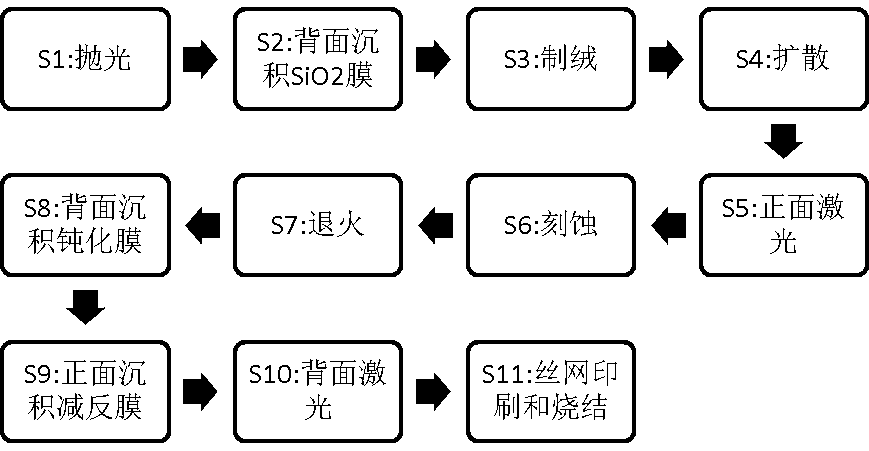

[0024] Such as figure 1 Shown, a kind of PERC solar cell alkali polishing preparation method, comprises the steps:

[0025] S1: Polishing, using P-type silicon as the base material, putting the silicon wafer in a polishing solution with a KOH mass ratio of 2%-10% and a temperature of 65-85°C for 120-200s to polish, and the reflectance of the alkali-polished surface obtained is controlled At 40-50%, the weight loss after polishing is controlled between 0.2-0.6g;

[0026] S2: Deposit SiO2 film on the back, use PERC technology to deposit a dense SiO2 mask on the back of the silicon wafer, and control the thickness at 80-200nm;

[0027] S3: Texturing. Place the silicon waf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com