Heterojunction solar cell of inclined metal contact structure based on N type silicon wafer

A metal contact, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of amorphous silicon thin film solar cell application limitations, many thin film defects, low conversion efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

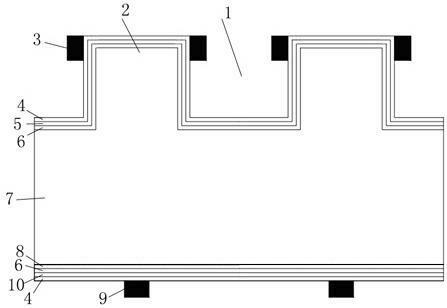

[0018] like figure 1 As shown, a heterojunction solar cell based on an N-type silicon wafer inclined metal contact structure, including an N-type single silicon wafer substrate 7. Battery positive electrode 3. Groove 1. Intrinsic hydrogenated nano-silicon Thin film 6, P-type heavily doped hydrogenated nano-silicon Thin film 5, N-type heavily doped hydrogenated nano-silicon Thin film 10, N formed by diffusing phosphorus source + Heavy doping layer 8, transparent conductive film TCO 4, battery negative electrode 9. The N-type monocrystalline silicon substrate 7 Set groove 1 on the front (main light-receiving surface), and deposit a layer of intrinsic hydrogenated nano-silicon sequentially on the front Thin film 6, P-type heavily doped hydrogenated nano-silicon Film 5, in P-type heavily doped hydrogenated nano-silicon A layer of transparent conductive film TCO 4 is prepared on the film 5; the N-type single crystal silicon substrate 7 Phosphorus source diffused on t...

Embodiment 2

[0023] like figure 1 As shown, a heterojunction solar cell based on an N-type silicon wafer inclined metal contact structure, including an N-type single silicon wafer substrate 7. Battery positive electrode 3. Groove 1. Intrinsic hydrogenated nano-silicon Thin film 6, P-type heavily doped hydrogenated nano-silicon Thin film 5, N-type heavily doped hydrogenated nano-silicon Thin film 10, N formed by diffusing phosphorus source + Heavy doping layer 8, transparent conductive film TCO 4, battery negative electrode 9. The N-type monocrystalline silicon substrate 7 Set groove 1 on the front (main light-receiving surface), and deposit a layer of intrinsic hydrogenated nano-silicon sequentially on the front Thin film 6, P-type heavily doped hydrogenated nano-silicon Film 5, in P-type heavily doped hydrogenated nano-silicon A layer of transparent conductive film TCO 4 is prepared on the film 5; the N-type single crystal silicon substrate 7 Phosphorus source diffused on...

Embodiment 3

[0028] The positive electrode 3 of the battery is made by plating Ag on the N-type monocrystalline silicon substrate by vacuum evaporation. 7 Both sides inside the front groove 1. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com