Crystal silicon cell back field back pole and printing technology thereof

A technology of crystalline silicon battery and back field, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of inability to passivate, block aluminum paste coverage, gettering, etc., and increase the passivation area , improve battery electrical performance, reduce the effect of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

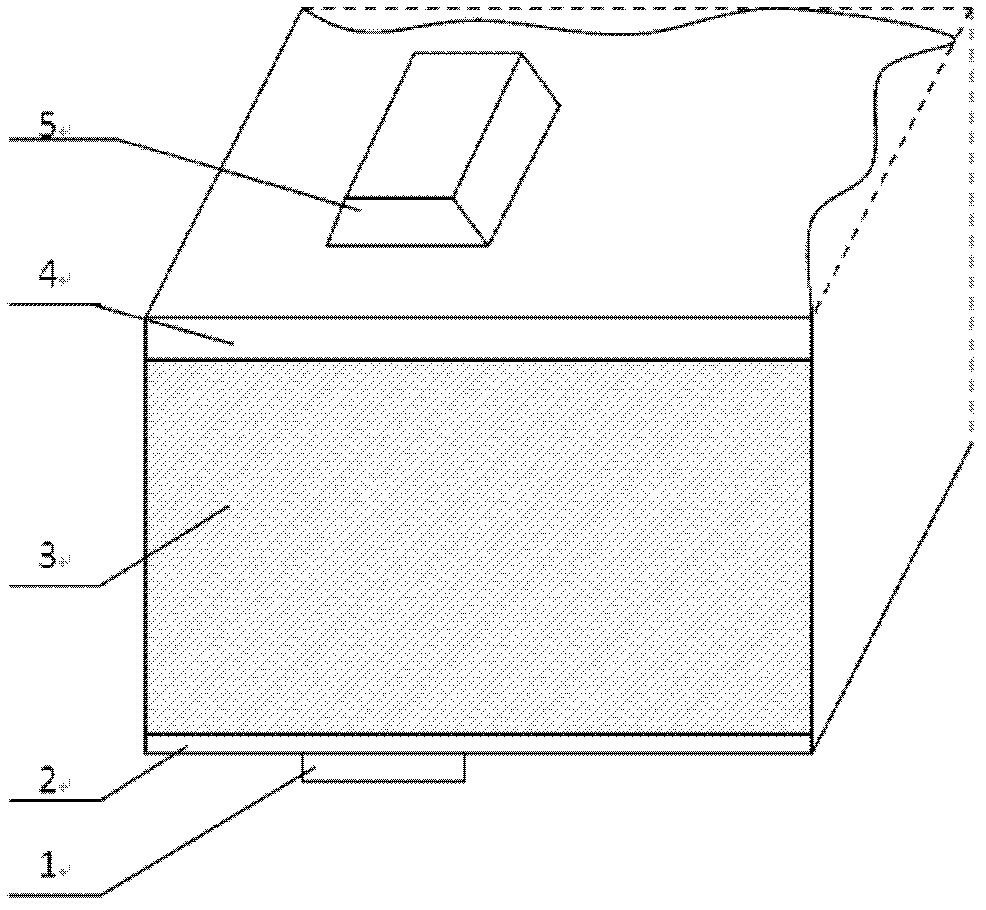

Image

Examples

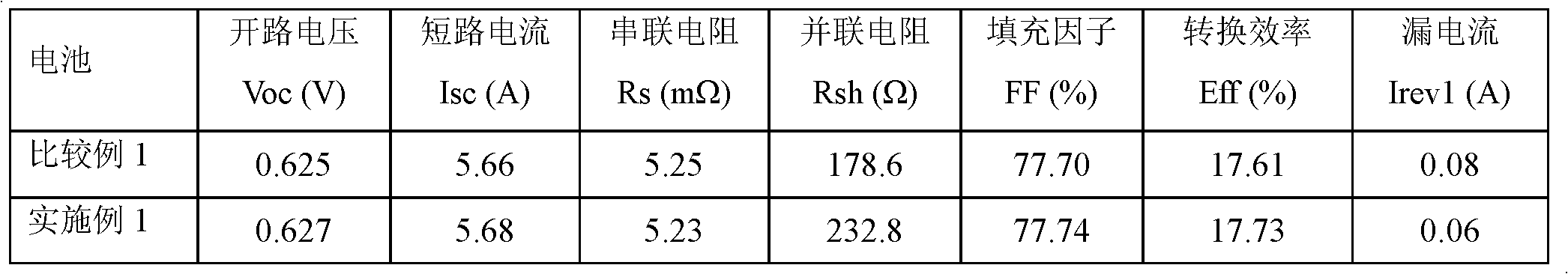

Embodiment 1

[0021] After the monocrystalline silicon wafer is diffused and coated on the light-receiving surface, the existing screen printing technology is used to print aluminum paste on its back surface. The aluminum paste is produced by Ruxing Company. The thickness of the printed aluminum paste is 30μm. After drying the aluminum paste at about 150°C, a continuous back electrode silver-aluminum paste is printed on the surface of the aluminum paste. The model of the back-electrode silver-aluminum paste is Flow 33462. The back electrode has a width of 2mm and a thickness of 15μm. Finally, follow-up production processes such as printing and sintering are carried out.

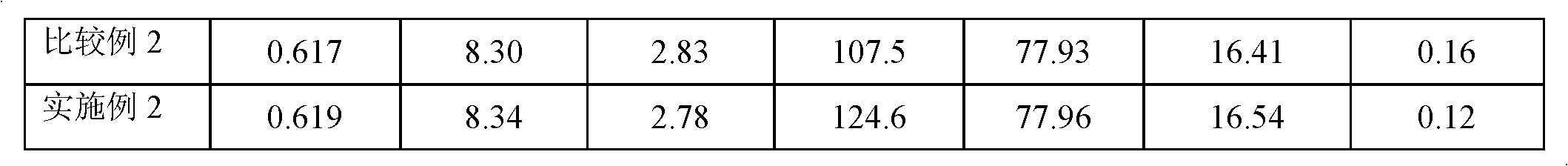

Embodiment 2

[0023] After the polycrystalline silicon wafer is diffused and coated on the light-receiving surface, the aluminum paste is printed on the back surface of the polysilicon wafer by screen printing technology. The aluminum paste is produced by Ruxing Company. The thickness of the printed aluminum paste is 40μm. After drying the aluminum paste at 200°C, a segmented back electrode silver paste is printed on its surface. The back electrode silver paste model is DuPont PV505, and the back electrode has a single width of 3mm and a thickness of 30μm. Finally, follow-up production processes such as printing and sintering are carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com