Glass material with low melting point and silver paste prepared from same

A glass frit, low melting point technology, used in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, photovoltaic power generation, etc. Resistance to silicon wafer electrical performance requirements and other issues, to achieve the effect of excellent electrical performance and welding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

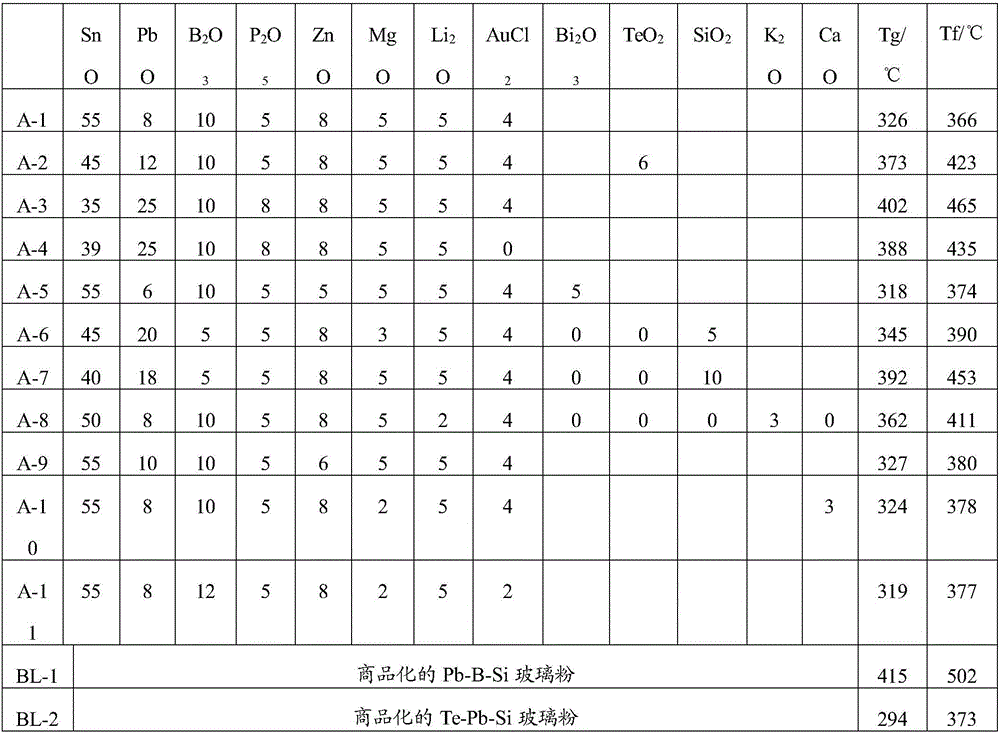

Examples

preparation example Construction

[0018] The preparation method of the above-mentioned glass frit provided by the present invention can be prepared by conventional high-temperature melting and quenching method, or by sol-gel and other preparation methods.

[0019] For example, the high-temperature melting and quenching method is as follows: Weigh the raw materials according to the formula, and the raw materials can be oxides or carbonates; after mixing and homogenizing with a double-roller or a three-dimensional mixer, transfer them to an alumina crucible for melting, and the melting temperature range is 1100~1300℃, the melting time is 30~80min, stir during the melting process, and further homogenize; after the melting is completed, directly quench the glass melt, which can be quenched with deionized water or iron plate; The obtained glass frit is ball-milled with a planetary ball mill, and dried after the powder particle size D50 is less than 10um, more preferably less than 5um.

[0020] Herein, a range indic...

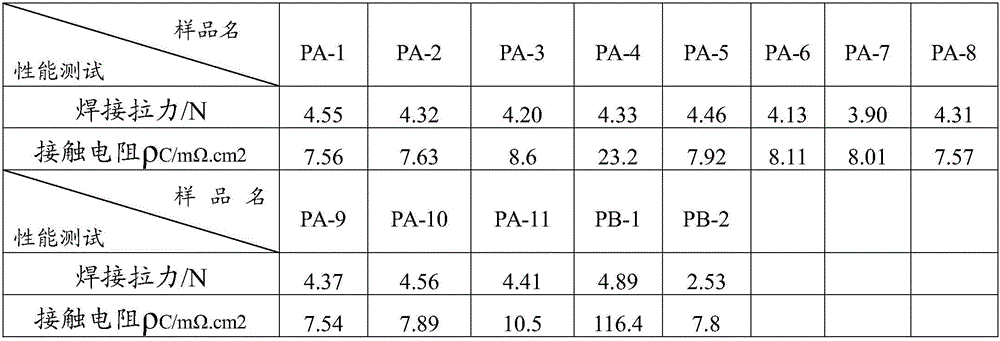

Embodiment 1

[0029] Fully mix 87wt% conductive silver powder, 2wt% A-1 glass frit, and 11wt% organic medium, use a three-roll mill to grind the slurry, use a scraper fineness agent to test the grinding fineness, and grind the slurry The fineness is below 10μm. The prepared slurry was named PA-1.

Embodiment 2

[0031] Fully mix 87wt% conductive silver powder, 2wt% A-2 glass frit, and 11wt% organic medium, use a three-roll mill to grind the slurry, use a scraper fineness agent to test the grinding fineness, and grind the slurry The fineness is below 10μm. The prepared slurry was named PA-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com